Measures to Prevent Transformer Short-Circuit Accidents

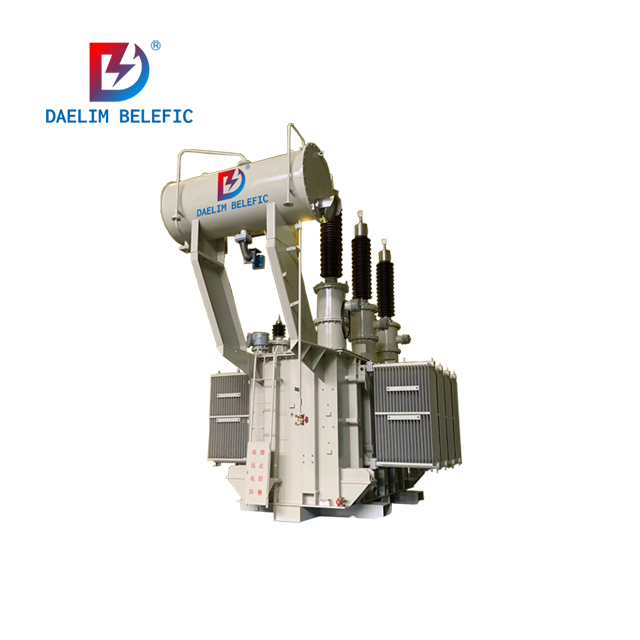

The modern power grid's increased capacity and complexity have amplified short-circuit risks for transformers due to high loads and system capacities. Manufacturers must enhance transformer designs to withstand outlet short-circuits, a prevalent cause of recent damages.

During a short-circuit, excessive currents cause overheating and strong electric forces, leading to winding deformations and insulation damage. Swift on-site assessment is crucial to promptly repair or replace damaged coils, minimizing downtime and shipping costs. Moisture prevention measures must align with specific site conditions.

Effective preventive measures include optimizing winding designs to balance ampere-turns, reinforcing low-voltage coils with self-adhesive wires and robust insulation, and enhancing structural components like iron yoke clamps and pressure rings. Improved insulation processes and robust relay protection systems further mitigate risks.

Post-short-circuit, immediate assessment is essential to detect winding deformations and insulation damage. Oil chromatography and comprehensive electrical tests, including DC resistance measurement and frequency response analysis, guide decisions on transformer operability. Detailed inspection and analysis integrate gas chromatography data, electrical tests, and device operation, ensuring accurate fault diagnosis.

To minimize low-voltage outlet short-circuit failures, ensure robust insulation through closed busbars and upgraded insulation on transformer lead-out lines. Enhance phase insulation ratios using appropriate insulators, adjust switch cabinet sizes for optimal air insulation, and improve cable outlet structures.

Additional measures include installing arc suppression coil devices for ungrounded systems, disabling reclosing devices for permanent faults, enhancing pollution flashover protection, and verifying short-circuit resistance in aging transformers. Consider installing external series reactors for transformers prone to frequent short-circuit shocks.

Comprehensive prevention strategies entail strengthening distribution line maintenance, protecting against animal damage, and optimizing relay protection operation. Evaluate grid operation modes for layered zoning to reduce overall short-circuit capacities. Enhance lightning protection measures to prevent instantaneous faults caused by strikes.

These measures collectively enhance transformer resilience and operational safety against short-circuit accidents, ensuring reliable power supply in complex grid environments.

Related Products

Related Article

Causes and Measures for Abnormal Transformer Temperature

Abnormal transformer temperature can result from internal faults, unopened radiator doors, blocked or leaking respirators, poor transformer structure, and cooling device malfunctions. Measures include identifying faults, opening doors, clearing respirators, installing magnetic isolation, and ensuring cooling device functionality.

Transforming Global Energy Infrastructure with Large Transformers

Large transformers crucial for global electricity transmission. China leads in eco-friendly, advanced tech. Daelim Transformer excels globally with high-performance units, expanding in North America, meeting rising demand.

Requirements for Transformer Core Grounding Points

Transformer cores must have a single grounding point to prevent floating potentials, short-circuit currents, and overheating. Improper grounding can cause insulation damage, increased iron loss, gas generation, and power interruptions, compromising transformer and grid safety.

Manifestation Characteristics of Transformer Core Grounding Fault

Transformer core grounding faults cause overheating, gas production, and insulation damage. Symptoms include increased hydrocarbons in oil analysis, high grounding current, and visible core burns or discharge marks. Accurate diagnosis requires comprehensive testing, electrical measurements, and visual inspections.

Prevention and Treatment Measures for Transformer Core Grounding Faults

Prevent transformer core grounding faults by ensuring proper insulation, regular current measurements, and chromatographic analysis. Address faults with temporary measures, inspections, and targeted repairs. Emphasize design and manufacturing standards to prevent faults and ensure safe operation.

The Harm of Outlet Short-Circuit Faults to Power Transformers

Outlet short-circuit faults in power transformers cause winding deformation, insulation damage, and overheating, affecting dynamic and thermal stability. Analysis via oil chromatography and electrical testing guides timely repair planning.