Pad Mounted Transformer

Pad Mounted Transformer Manufacturer With UL/cUL

Daelim has been serving the American market for almost 20 years with custom-designed transformers that meet multiple standards. Daelim has partnered with well-known companies like Eton, Solomon, and Amazon.

-

UL certification for all Pad Mounted transformer series

-

Pad-Mounted Transformer Use Cases in the Americas Market

-

4-8 weeks lead time

-

Local after-sales service

Professional Pad Mounted Transformer Supplier

Daelim is a reputable manufacturer and supplier of pad mounted transformers, offering UL/cUL and CSA listed products. Daelim offers both three phase and single phase pad mounted transformer.

3 phase pad mounted transformers have a maximum voltage of 44kV and come in power ranging from 75kVA to 10,000kVA.

Trust Daelim for high-quality pad mounted transformers that meet your specific needs.

Lightning Production Time

UL/CUL Certified

Top 3 Chinese Manufacturers Exporting Transformers to the USA and Canada

Annual Export of Over 2000 Units to North America

Over 10,000 Units Installed and Operating in North America

Pad Mounted Transformer

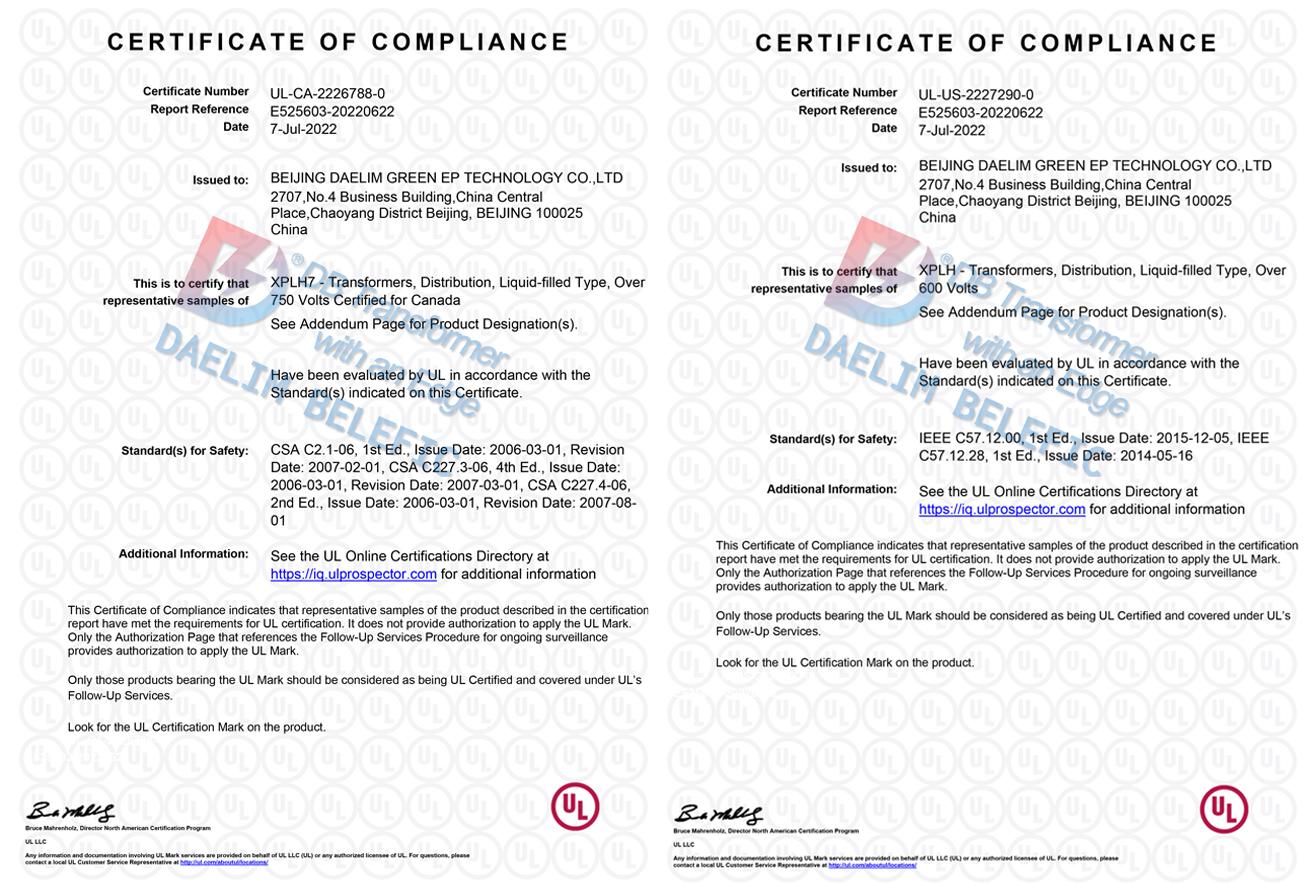

Pad Mounted Transformer Certificates

Daelim is a leading global supplier of high-quality pad-mounted transformers that are designed and manufactured to the highest standards. Daeim pad mounted transformer is not only reliable and safe but also environmentally friendly, helping to reduce your carbon footprint.

Daelim has earned authoritative third-party certification certificates in North America, such as UL/cUL, CSA, SGS, CESI, and more. These certifications are a testament to the quality and safety of the Daelim transformer and its commitment to meeting the highest industry standards.

Contact Daelim Transformer3 Phase Pad Mounted Transformer

Here are some different types of 3 Phase Pad Mounted Transformers offered by Daeim

- Live Front Type: Three Phase Pad Mounted Transformer with Exposed High Voltage Porcelain Bushing.

- Dead Front Type: Three Phase Pad Mounted Transformer with load break bushing insert, bushing well, and dead break elbow connector.

- Loop Feed Configuration: A Three Phase Pad Mounted Transformer designed for looped power distribution systems, with multiple power sources and paths.

- Radial Feed Configuration: A Three Phase Pad Mounted Transformer designed for radial power distribution systems, with a single power source and one path of distribution.

Single Phase Pad Mounted Transformer

Daelim produces various types of single-phase pad-mounted transformers that can be customized to meet specific requirements. These transformers are designed to be placed outdoors inside a cabinet with doors and locks. They are oil-insulated, self-cooled, and have ratings ranging from 15-250 kVA.

There are two main configurations available: radial and loop feed, depending on the circuit type. Daelim transformers use aluminum or copper winding and are optimized for efficiency and size. They adhere to the latest standards such as ANSI, IEEE, DOE, CSA, and NEMA. The transformers are tailored to meet customer specifications and are known for their high quality, high voltage capability, stable neutral point, low loss, compact size, cost-effectiveness, safety, environmental friendliness, and appealing appearance.

More DetailPad Mounted Transformer Inventory

Daelim Transformer offers a series of stock of pad-mounted transformers to pressing market demands. The extensive stock of these transformers is fully aligned with the exacting standards set forth by ANSI, IEEE, CSA, and DOE, ensuring high quality.

Within the inventory, you will find both 3 phase and single-phase pad-mounted transformers, embodying excellence in engineering and performance. There are a large number of pad mounted transformers in Daelim Transformer's factory and the Texas warehouse in the United States, we are equipped to swiftly respond to your needs.

Benefit from our expedited delivery services, characterized by lightning-fast efficiency, enabling you to meet project timelines with ease. Furthermore, our range boasts a complete UL listing, underscoring our commitment to upholding the highest safety and reliability benchmarks.

Transformer Inventory Detial

Pad Mounted Transformer Accessories

Daelim's pad-mounted transformers have a variety of accessories, including well-known international brands like ABB, Eaton, Qualitrol, and others. We also offer affordable options from domestic brands. This gives customers the flexibility to select accessories that meet their specific needs and budget.

- Oil Two-Position Load Breaker Switch

- Oil Four-Position Load Breaker Switch

- Two & Three Phase Magnex Interrupter

- ELSP Fuse, Bay-O-Net Fuse

- Bay-O-Net Fuse Assembly

- Off-circuit Tap Changer

- Dual-Voltage Switch

- Bushing Well, Surge Arrester

- Deadbreak Elbow Connector

- Load Break Bushing Insert

- Kirk key interlock

- Mineral and vegetable oil(FR3, RAPO)

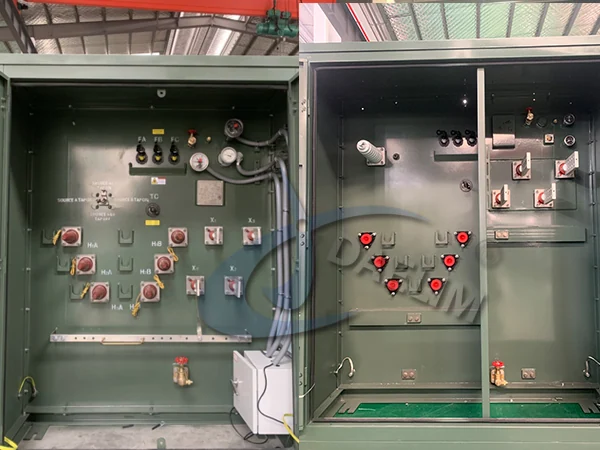

Pad Mounted Transformer Custom

Daelim specializes in providing tailored services for pad-mounted transformers. Daelim's team of experienced engineers has successfully designed numerous custom pad-mounted transformers for customers in the United States, Canada, and other countries. When it comes to customization, Daelim offers a wide range of options to choose from, including ratings, voltage, configurations, colors, features, and more.

Rest assured that Daelim's pad-mounted transformers fully comply with internationally recognized standards such as IEC60076, ANSI/IEEE C57.12.00, C57.12.20, C57.12.38, C57.12.34, CSA C227.4, C227.5, C227.3, DOE, NEMA, and others. By adhering to these stringent standards, Daelim ensures that pad mount transformers meet the highest quality and safety requirements in the industry.

Send Inquiry NowPad Mounted Compartmental Type Transformer

Standard Features:

Pad Mounted Compartmental Connections and Neutral Configurations:

- Delta - Wye: The low voltage neutral point is grounded with X0 bushing;

- Grounded Wye-Wye: The high and low voltage neutral point grounding with H0 bushing and X0 bushing;

- Delta-Delta: Transformer provided without a neutral bushing.

- Wye-Wye: The high voltage neutral is connected to the H0 bushing in the primary compartment, and the low voltage neutral is connected to the X0- bushing in the secondary compartment.

- Wye-Delta: The primary compartment functions as the high-voltage neutral point for the H0 bushing output. If a wire-to-wire rated fuse is present, a ground strap is unnecessary; however, if such a fuse is absent, a ground strap should be provided.

Pad Mounted Compartmental High and Low Voltage Bushings:

- 200 A bushing wells (15, 25, and 35 kV)

- 200 A, 35 kV Large Interface

- 600 A (15, 25, and 35 kV) Integral bushings (dead-front)

- Electrical-grade wet-process porcelain bushings (live-front)

Pad Mounted Compartmental Tank/Cabinet Features:

- Welded cover with hand hole

- Three-point latching door for security

- Removable sill for easy installation

- Lifting lugs (4)

- Stainless steel cabinet hinges and mounting studs

- Steel divider between HV and LV compartment

- Pentahead captive bolt

- Stainless steel 2-hole ground pads

- Parking Stands (dead-front)

Pad Mounted Compartmental Valves/Plugs:

- One-inch upper filling plug

- One-inch drain plug (45-500 kVA)

- One-inch combination drain valve with sampling device in low voltage compartment (750-10,000 kVA)

- Automatic pressure relief valve

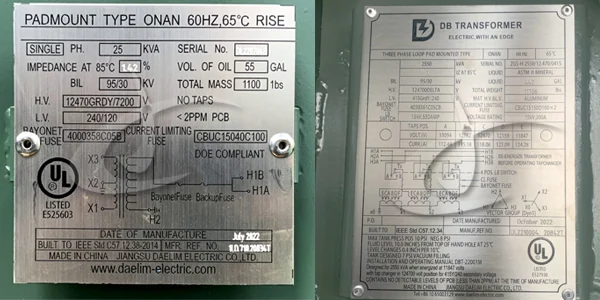

Pad Mounted Compartmental Type Transformer Nameplate:

Laser-scribed anodized aluminum nameplate

Pad Mounted Compartmental Type Transformer Optional Features:

Pad Mounted Compartmental Type Transformer High and Low Voltage Bushings:

- 200 A (15, 25 kV) bushing inserts

- 200 A (15, 25 kV) feed-thru inserts

- 200 A (15, 25 kV) (HTN) bushing wells with removable studs

- High-voltage 600 A (15, 25, 35 kV) dead break one-piece bushings

- Low voltage 6-, 8-hole spade

- Low voltage 12-, 16-, 20-holes spade

- Low-voltage bushing supports

Pad Mounted Compartmental Type Transformer Tank/Cabinet Features:

- Stainless steel tank base and cabinet

- Stainless steel tank base, cabinet sides, and sill

- 100% stainless steel unit

- Service entrance (2 inch) in sill or cabinet side

- Touch-up paint

- Copper ground bus bar

- Kirk-Key

- Nitrogen blanket

- Bus duct cutout

Pad Mounted Compartmental Type Transformer Special Designs:

- UL Listed

- High altitude

- K-Factors

- Critical application

- Seismic applications (including OSHPD)

- External Gauges

Pad Mounted Compartmental Type Transformer Switches:

- 2-position load break switches

- 4-position load break V-blade switch or T-blade switch

- Dual voltage switch

Pad Mounted Compartmental Type Transformer Gauges and Devices:

- Liquid level gauge (optional contacts)

- Pressure vacuum gauge (optional contacts and bleeder)

- Dial-type thermometer (optional alarm contacts)

- Cover-mounted pressure relief device (optional alarm contacts)

- Ground connectors

- Hexhead captive bolt

- Molded case circuit breaker mounting provisions

- External gauges in pad-lockable box

Pad Mounted Compartmental Type Transformer Overcurrent Protection:

- Bay-O-Net fusing (Current sensing, dual-sensing, dual element, high amperage overload)

- Bay-O-Net expulsion fuse in series with a partial range under-oil ELSP current limiting fuse (below 23 kV)

- Cartridge fusing in series with a partial range under-oil ELSP current-limiting fuse (above 23 kV)

- MagneX™ interrupter with ELSP current-limiting fuse

- Vacuum Fault Interrupter (VFI)

- Visible break window

- Fuse/switch interlock

Pad Mounted Compartmental Type Transformer Valves/Plugs:

- Drain/sampling valve in high-voltage compartment

- Globe-type upper fill valve

Pad Mounted Compartmental Type Transformer Overvoltage Protection:

- Distribution-, intermediate-, or station-class surge arresters

- Elbow arresters (for dead-front connections)

Pad Mounted Compartmental Type Transformer Metering/Fan/Control:

- Full metering package

- Current Transformers (CTs)

- Metering Socket

- NEMA® 4 control box (optional stainless steel)

- NEMA® 7 control box (explosion-proof)

- Fan Packages

Pad Mounted Compartmental Type Transformer Testing:

- Customer test witness

- Customer final inspection

- Zero Sequence Impedance Test

- Heat Run Test

- ANSI® Impulse Test

- Audible Sound Level Test

- RIV (Corona) Test

- Dissolved Gas Analysis (DGA) Test

- 8- or 24-Hour Leak Test

Pad Mounted Compartmental Type Transformer Finish (Paint):

- ANSI® Bell Green

- ANSI® #60 Light Gray

- ANSI® #70 Sky Gray

- Seafoam Green

- Munsell Green

- Special paint available per request

Pad Mounted Compartmental Type Transformer Nameplate:

Stainless steel nameplate

Pad Mounted Compartmental Type Transformer Decals and Labels:

- High voltage warning signs

- Mr. Ouch

- Warning

- DOE compliant

- Stock code number

- Shock and arc flash warning decal

- Non-PCB sticker

Pad Mounted Transformer Application Cases

Block Chain Case

Daelim Transformer's state-of-the-art solutions have forged pioneering pathways within North America's Block chain landscape. Our pad-mounted transformers, meticulously crafted to meet rigorous industry benchmarks, empower mining facilities with dependable and optimized power distribution. Seamlessly integrating into mining infrastructures, the three-phase pad-mounted transformers elevate operational resilience. As the demand for b continues its ascent, Daelim Transformer's swift delivery and UL-listed products stand as cornerstones in sustaining power-demanding operations. Illustrated above are 50 units of 2000kVA pad-mounted transformers. Daelim Transformer has provided pad transformers for multiple block chain farms in North America and South America.

Reading more about Data Centers and Block Chain Solution

Solar Energy Project: Nevada, USA

Daelim Transformer received an inquiry on Thursday evening for a solar project. The customer intends to establish a solar power plant in Nevada, USA. Daelim Transformer has selected the most suitable transformer type, capacity, and quantity for the customer based on the total power generation capacity and equipment load.

For this project, four sets of transformers are required. These transformers are specifically designed for solar energy projects and necessitate certain special features. Examples of these special designs include low-voltage side outlets, electrostatic shielding between high and low voltages, Primary Surge Arresters, and NEMA 4x Control Box.

BESS(Battery Energy Storage System): USA, California

Upon receiving an inquiry for an energy storage project, Daelim Transformer promptly engaged with the client to understand the project's specifics. After thoroughly confirming the customer's requirements, Daelim Transformer selected the appropriate transformers in terms of power rating, efficiency level, and configuration.

The solution entailed designing and producing two units of 500 kVA pad-mounted transformers and one unit of 2000 kVA pad-mounted transformers. These transformers adhere to the IEEE C57.12.20 standard and meet the efficiency criteria set by DOE 2016 standards.

Reading more about Daelim Transformers Solutions For Energy Storage

Oil and Gas Project: Texas, USA

Daelim Transformer received a request for twelve units of 2550 kVA pad-mounted transformers. These transformers are designated for a sizable oil field in Texas, where they will replace the existing older transformers.

More detail about Transformers Solution For Oil and Gas Plant

Utility Project: Canada, Edmonton

For the Edmonton utility's power distribution system in Canada, Daelim Transformer has provided eight sets of three phase pad-mounted transformers. These transformers feature high voltage ratings of 24.94 kV and low voltage ratings of 480Y/277 V. The power ratings include 150 kVA, 225 kVA, 300 kVA, and 750 kVA, with two units each.

Due to the urgency of the customer's project, Daelim Transformer efficiently communicated and confirmed the technical transformer requirements through video conferences in the initial stages. Within one week of receiving the order, transformer drawings were designed and presented to the customer for confirmation.

Throughout the order execution, continuous communication with the customers was maintained. Customers were able to monitor the real-time production progress of transformers through the website's order entry. The entire production process of these transformers was completed in 8 weeks, and the customers received and smoothly installed them ahead of schedule. Daelim Transformer's efficiency and professionalism garnered praise and recognition from the customers.

Daelim Transformer's pad-mounted transformers find versatile applications within public utilities. The accompanying image showcases both three-phase and single-phase pad-mounted transformers acquired by a prominent utility company in the United States from Daelim Transformer. Additionally, the customer also purchased single phase overhead pole mounted transformers.

The picture below is the application of Daelim transformer’s pad mounted transformer in oil and gas plant. Daelim Transformer's reach extends to diverse sectors such as data centers, energy storage facilities, renewable power plants, oil and gas plants, as well as industrial and commercial construction projects. Our steadfast presence underscores our commitment to powering a wide spectrum of vital industries.

Pad Mounted Transformer Paints And Varnishes

Daelim's pad-mounted transformer utilizes paints and varnishes that adhere to the ISO 12944-1 international standard. The steel structure of the transformer oil tank is protected against corrosion through coating systems and coatings. The selection of the coating system is determined based on environmental conditions and the desired durability. According to ISO 12944-1, durability is categorized as low (L), medium (M), high (H), and very high (VH). This particular coating system falls under the medium category, offering a lifespan of 7-15 years.

The paint protection level of the pad-mounted transformer can be customized according to specific requirements. Daelim Transformer can adjust the coating system and its durability based on the needs and environmental conditions of the transformer installation site. By considering factors such as climate, exposure to corrosive elements, and expected lifespan, Daelim can tailor the paint protection to ensure optimal performance and longevity of the transformer. This customization allows for the selection of a coating system that best meets the specific needs and requirements of the transformer and its operating environment.

Why Choose Daelim Pad Mounted Transformer

High Quality

Daelim pad-mounted transformer with ul/cul, CSA certificate, and inspection reports from international third-party authoritative organizations, such as SGS, CESI, IEEE, etc.

Daelim pad-mounted transformer use cases

Many Daelim pad-mounted transformers in the Americas are used in factories, buildings, hotels, residential commercial areas, renewable energy, and energy storage industries.

Daelim also has established successful partnerships with renowned Fortune 500 companies in the Americas, including Eaton, Amazon, Exxon Mobil, and DOW. These collaborations demonstrate the trust and confidence that major industry players place in Daelim's products and services

Fast delivery and Inventory

The lead time of the Pad-mounted transformer is 8-10 weeks, there are some standard pad-mounted transformers in inventory.

Daelim factory benefits from a well-established and comprehensive supply chain, eliminating any concerns of raw material shortages. Moreover, the availability of skilled workers, technical experts, and other essential labor forces in the surrounding area further guarantees the fast delivery time of Daelim's pad-mounted transformers.

Local after-sales service

Daelim's pad-mounted transformers offer local after-sales installation and maintenance services in both North America and South America. Daelim's dedicated team ensures prompt response and support, available 24/7, to provide you with fast and efficient service. Daelim prioritizes your satisfaction and strives to address any installation or maintenance needs promptly and effectively, ensuring the optimal performance and longevity of pad mounted transformers.

Production Capacity

Daelim production capacity for 3 phase pad mounted transformer is 300 units per month. For single-phase pad-mounted transformers, Daelim can produce between 600 and 800 units per month.

Daelim Pad Mounted Transformer Factory

Radial Feed Pad Mounted Transformer

Daelim specializes in the production of radial feed pad-mounted transformers, capable of handling voltages up to 44 kV and power ratings ranging from 45 kVA to 10,000 kVA. These transformers feature three high voltage bushings, ensuring efficient power transmission and distribution.

Daelim can provide custom design and production of Radial Feed Pad Mounted Transformers according to your specific needs.

Loop Feed Pad Mounted Transformer

The loop feed transformer pad-mounted transformer with six high-voltage bushings. And can be equipped with lightning arresters on the high-voltage side. This provides extra protection against lightning-induced electrical surges, keeping the transformer and the connected system safe.

If a circuit fails, the loop feed transformer can connect three high voltages to an alternative circuit, ensuring uninterrupted power supply to the terminals.

Pad Mounted Transformer Nameplates

Both the 3-phase pad-mounted transformers and single-phase pad-mounted transformers produced by Daelim bear the UL or cUL logo on their nameplates, ensuring compliance with recognized safety standards.

Liquid Oil With UL

Daelim's pad-mounted transformers offer a choice of liquid options. One is RF3, a type of oil with UL certification, known for its exceptional performance and safety. Daelim also offers the RAPO vegetable oil the same features as FR3 but cheaper.

Live Front Pad Mounted Transformer

The high-voltage bushing configuration of the Live Front Pad Mounted Transformer typically involves a porcelain bottle-style bushing with exposed metal terminal strips at the end. While this design allows for convenient access to the live parts without disconnecting the transformer, it may not offer the same level of security as a dead front pad-mounted transformer.

Dead Front Pad Mounted Transformer

The high voltage bushings of dead-front pad-mounted transformers are pluggable and fully insulated, providing enhanced safety features by completely enclosing live parts and isolating them from external access. This design significantly reduces the risk of accidental contact and provides a higher level of safety, especially in environments where electrical safety is a greater concern.

Core Leg Structurers

Daelim offers pad-mounted transformers with two distinct core structures to cater to different requirements. One option is the 3-leg core connected with Dyn1, while the other is the 5-leg core connected wth YNyn0.

Pad Mounted Transformer Testing

Evey unit pad mounted transformer of Daelim must pass strict performance tests before leaving the factory, and the electrical and mechanical properties of all aspects comply with IEEE, ANSI, DOE, CSA, NEMA, and other standards.

Daelim Pad Mounted Transformer Applications

Block Chain

Pad-mounted transformers are pivotal for Block Chain. Their paramount advantage lies in providing a versatile power supply to cater to diverse mining machines, ensuring unwavering stability across dispersed mining sites. The unique adaptability of pad-mounted transformers is a standout feature in the multifaceted landscape of Block Chain. They adeptly accommodate high-efficiency ASIC miners and traditional GPU miners, ensuring optimal power conversion for peak performance. Especially crucial in remote or dispersed mining setups, these transformers skillfully convert high-voltage transmission lines into suitable low-voltage, effectively meeting the intricate power demands of the mining equipment. In doing so, they not only fulfill power requirements but also significantly contribute to the reliability and stability of the entire Block Chain system, fortifying its operational robustness.

EV Charging Station

Pad-mounted transformers are essential for electric vehicle (EV) charging, ensuring power system stability and efficient charging equipment operation. They play a crucial role in power distribution by converting grid power into the necessary voltage and current for charging piles. Additionally, these transformers adjust voltage levels, promoting stable power supply for enhanced charging efficiency and equipment durability. Their adaptability is a key advantage, accommodating various charging equipment types and power levels, allowing flexibility in serving diverse EV charging needs. Designed for outdoor resilience, pad-mounted transformers offer robust durability and protection, ensuring reliable performance in different weather conditions, vital for the safety and reliability of charging infrastructure, especially in outdoor and public deployment scenarios.

Energy Storage

Daelim's pad-mounted transformers have been successfully applied in the field of energy storage. These transformers play a crucial role in connecting and integrating energy storage systems, such as battery energy storage or other advanced storage technologies, with the electrical grid. They ensure efficient power conversion, distribution, and control, facilitating the seamless transfer of energy between the storage system and the grid. By employing Daelim's pad-mounted transformers in energy storage applications, customers can achieve enhanced performance, reliability, and overall efficiency in their energy storage installations.

Renewable Power Plant

Daelim's pad-mounted transformers have been effectively utilized in renewable power plants. These transformers play a critical role in renewable energy systems, such as solar farms and wind farms, by stepping up or stepping down the voltage levels to facilitate efficient power transmission and distribution. They ensure a smooth integration of renewable power into the grid, enhancing the overall performance and reliability of the power plant. Daelim's pad-mounted transformers are designed to meet the specific requirements of renewable power generation, contributing to the growth and sustainability of clean energy initiatives.

Utilities

Daelim's pad-mounted transformers have been successfully applied in utilities infrastructure. These transformers play a critical role in power distribution and transmission networks, ensuring the efficient and reliable supply of electricity to homes, businesses, and industries. They are designed to meet the rigorous requirements of utility applications, delivering consistent performance, high reliability, and optimal power distribution. Daelim's pad-mounted transformers contribute to the stability and resilience of utility systems, supporting the smooth operation of electrical grids and meeting the energy needs of communities.

Data Center

Daelim's pad mounted transformers have found successful applications in data centers, such as block chain. Pad mounted transformers play a vital role in ensuring reliable and efficient power distribution within data center facilities. They are designed to meet the specific needs of data centers, providing stable and uninterrupted power supply to critical equipment such as servers, networking devices, and cooling systems. Daelim's pad-mounted transformers contribute to the overall performance and resilience of data centers, supporting their mission-critical operations.

Oil And Gas Plant

Daelim's pad mounted transformers have been successfully utilized in oil and gas plants. Pad mounted transformer play a crucial role in supplying reliable and efficient electrical power to various operations within the plant. They are designed to withstand the demanding and often harsh conditions present in oil and gas facilities. Daelim's pad mounted transformers contribute to the overall safety and productivity of these plants, ensuring the smooth functioning of essential equipment and systems involved in the extraction, refining, and processing of oil and gas resources.

Industrial and Commercial Building

Daelim's pad mounted transformers have been successfully used in industrial, commercial, and residential buildings. These transformers ensure a reliable and stable power supply to support various operations and equipment. Whether manufacturing plants, warehouses, office buildings, shopping malls, or residences, Daelim's pad mounted transformers are designed to meet the specific needs of the applications. They help deliver power efficiently and safely, supporting the smooth operation of critical systems and processes in these buildings.

Pad Mounted Transformer Sales Records & Customer Comments

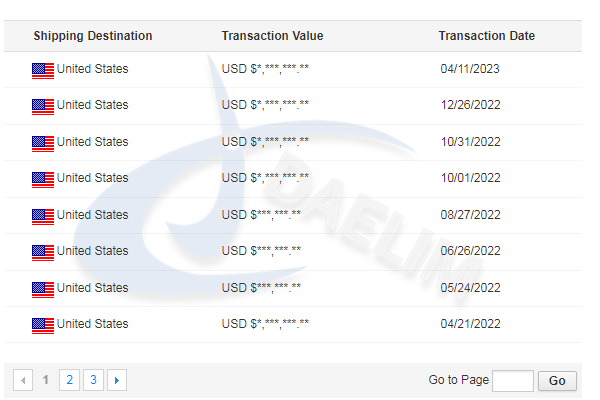

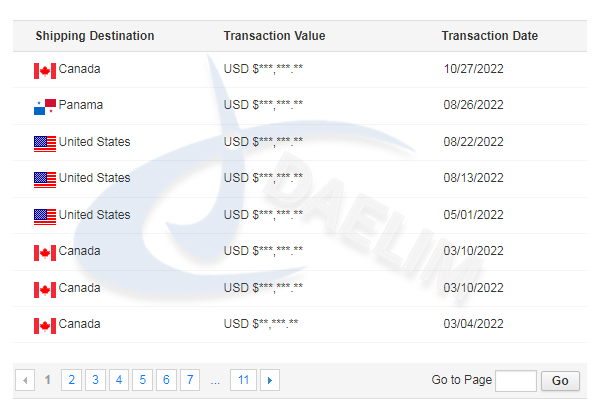

Sales Record In USA

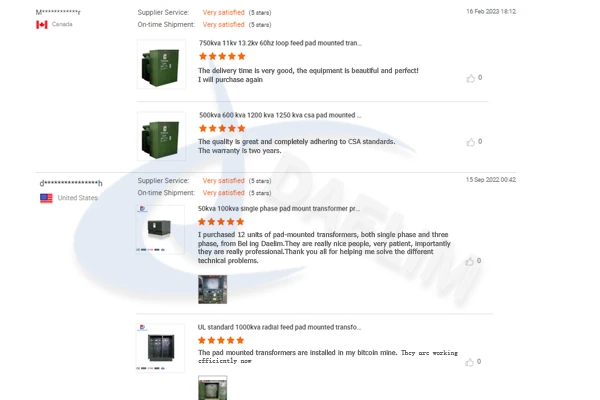

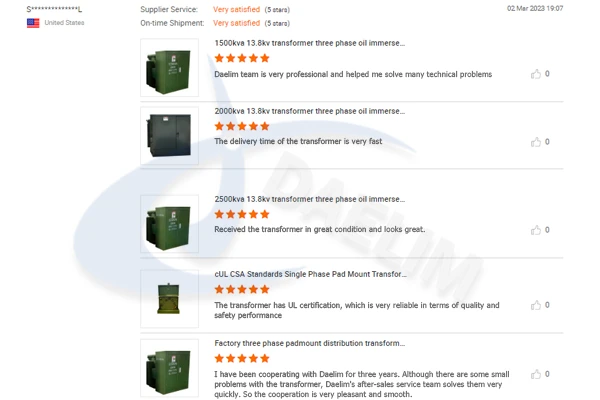

Daelim's pad-mounted transformer has gained significant traction in the US market and has garnered widespread recognition from satisfied customers. It has become a preferred choice for numerous projects, establishing Daelim as a trusted supplier in the industry.

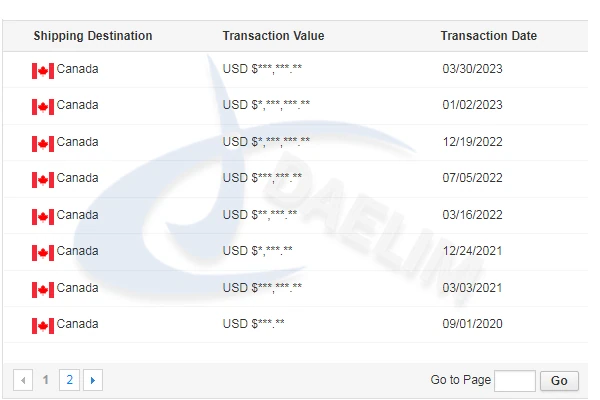

Sales Record In Canada

Daelim's pad-mounted transformer holds prestigious CSA and cUL certificates, affirming its compliance with rigorous standards. Its exceptional quality has led to the export of hundreds of units to Canada annually, where it has received consistent acclaim and praise from customers.

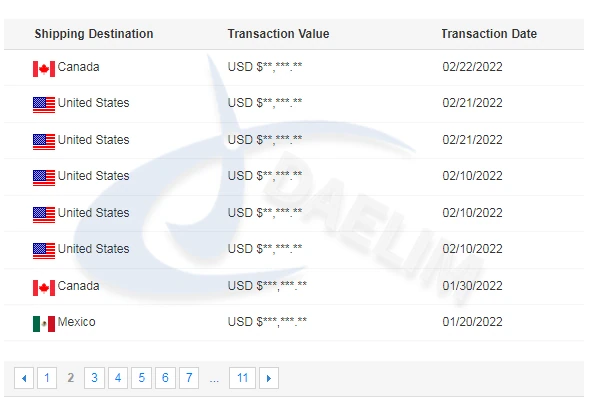

Pad mounted transformer sales

Pad mount transformer sales record

North American customers

Daelim's pad-mounted transformer has earned unanimous recognition from North American customers for its unwavering quality and prompt delivery. And is designated by many projects as a supplier directory list.

American Customer

American customers have consistently praised Daelim's pad-mounted transformer for its exceptional performance and reliability. It has garnered a strong reputation in the market and has become a trusted choice for a wide range of projects.

Pad Mounted Transformer Technical DATA

| Three Phase Pad Mounted Transformer Technical Data | Single Phase Pad Mounted Transformer Technical Data | |||||||||||

| Rating(kVA) | No Load Loss(W) | On Load Loss(W) | W(mm) | D(mm) | H(mm) | Rating(kVA) | No Load Loss(W) | On Load Loss(W) | W(mm) | D(mm) | H(mm) | |

| 75 | 180 | 1250 | 1280 | 990 | 1270 | 15 | 50 | 195 | 610 | 740 | 840 | |

| 150 | 280 | 2200 | 1480 | 1245 | 1270 | 25 | 80 | 290 | 610 | 740 | 840 | |

| 225 | 400 | 3050 | 1480 | 1295 | 1270 | 37.5 | 106 | 360 | 610 | 760 | 840 | |

| 300 | 480 | 3650 | 1480 | 1295 | 1270 | 50 | 135 | 500 | 610 | 810 | 840 | |

| 500 | 680 | 5100 | 1480 | 1345 | 1270 | 75 | 190 | 650 | 610 | 860 | 840 | |

| 750 | 980 | 7500 | 1730 | 1445 | 1625 | 100 | 280 | 1010 | 965 | 1200 | 910 | |

| 1000 | 1150 | 10300 | 1730 | 1500 | 1625 | 150 | 330 | 1260 | 965 | 1200 | 910 | |

| 1500 | 1640 | 14500 | 1730 | 2190 | 1854 | 167 | 435 | 1530 | 965 | 1200 | 1000 | |

| 2000 | 2160 | 20645 | 1730 | 2210 | 1854 | 200 | 490 | 2010 | 985 | 1200 | 1000 | |

| 2500 | 2680 | 27786 | 1730 | 2515 | 1854 | 250 | 550 | 2230 | 1430 | 1300 | 1250 | |

If the above pad-mounted transformer technical data cannot meet your needs, please send your requirements to the email address: [email protected]

FAQ

Daelim is a professional manufacturer of pad-mounted transformers. We have the expertise to design and produce a variety of pad-mounted transformers that comply with various international standards, including ANSI, IEEE, DOE, CSA, and IEC.

Daelim's pad-mounted transformers have obtained UL, cUL, and CSA certifications, ensuring their compliance with rigorous safety and performance standards. Our product line includes a comprehensive range of UL listed transformers, providing you with a wide selection of trusted and reliable options.

Daelim's pad-mounted transformers have earned recognition from customers in various American regions, including the United States, Canada, Mexico, Honduras, Panama, and more. We have established successful partnerships with Fortune 500 companies such as Eaton, Amazon, Exxon Mobil, DOW, and others. These collaborations reflect the trust and confidence that major industry players place in Daelim pad mounted transformers.

Daelim offers a minimum 2-year quality guarantee period for their pad-mounted transformers. This means that you can have confidence in the performance and reliability of Daelim pad mounted transformers, backed by Daelim commitment to quality assurance.

Daelim's pad-mounted transformers have been successfully applied in a wide range of industries, including:

- Data Center

- Oil and Gas Facilities

- Chemical Energy Storage

- Utilities and Power Distribution

- Renewable Energy: solar and wind farm

- Manufacturing and Industrial Facilities

- Commercial and Residential Developments

- Commercial and Residential Developments

Pad Mounted Transformer Installation & Routine Maintenance Guidelines

Pad Mounted Transformer Installation

- Place on sturdy concrete pads.

- Install below 1000 meters altitude with a 30-40 degree average ambient temperature.

- Thoroughly inspect for insulating oil leaks, appearance, seals, and instrument oil tanks before installation.

- Check and ensure normal oil level.

- If visible damage is found, consult professionals for internal inspection.

- Detect fuel tank grounding.

- Follow the transformer nameplate and electrical connection diagram for high-voltage connections.

- For Livefront transformers, use porcelain bushings with tin-plate eyebolt terminals; cables enter vertically from below.

- Deadfront transformers use compatible casing wells and inserts for cable connections.

- Spade terminals are standard for low voltage connections; externally clamp low voltage bushings to the transformer tank wall.

For detailed steps, refer to the Daelim Pad Mounted Transformer Operation Manual.

Learn More About Transfromer Installation

Transformer Routine Maintenance

Pad Mounted Transformer Routine Maintenance Guidelines

- Appearance Inspection: Regularly examine the transformer's appearance for damage, dents, deformation, scratches, aging, or peeling. Keep the surrounding area clean to prevent debris accumulation.

- In-Cabinet Maintenance: Periodically check internal components, including instruments and controllers, for proper functioning. Address any loose connections or unusual noises promptly.

- Maintenance Inside the Box: Access the transformer's interior through the manhole/handhole to inspect components and ensure normalcy. Clear away dust or foreign objects that may impact the transformer's operation.

- Comprehensive Inspections: Conduct regular comprehensive inspections of the exterior, interior, and surroundings. Thoroughly check insulation materials to prevent aging and oil leakage. Promptly repair damage and replace accessories to maintain system integrity.

- Oil Level Check: Regularly inspect the insulating oil level to ensure it falls within the normal range. Replenish or replace insulating oil as needed to sustain the transformer's insulation performance.

Adhering to these maintenance steps promotes the stable operation of pad-mounted transformers, extends their lifespan, and enhances overall reliability.

Contact Daelim Transformer

Related Products

In addition to pad-mounted transformers, Daelim also manufactures a diverse range of another exceptional transformers. These include small substation transformer, single-phase pole-mounted transformer, high-voltage transformer, and dry-type transformer, each designed to meet specific industry needs.