Substation Transformer(Skid Mounted Transformer)

Daelim Transformer

Substation Transformer(Skid Mounted Transformer)

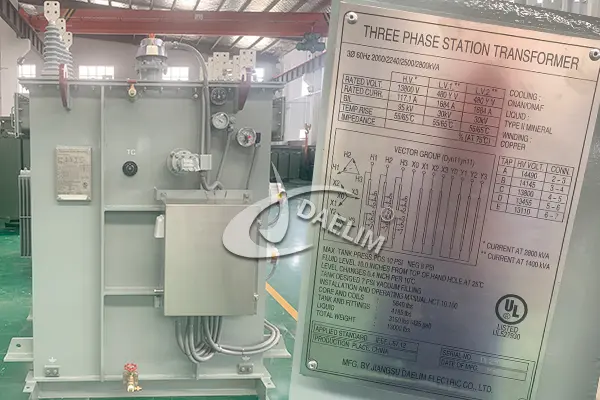

Certificate: UL/cUL, CSA; Capacity: 750kVA -20,000kVA; Bushings: Top-mounted / Side-mounted; Standards: ANSI, IEEE, CSA, AS/NS, IEC, etc; Primary Voltage: 2400 V to 44,000 V, or others; Secondary Voltage: 120 V to 24,940 Vor others; Enclosure Material: Carbon steel, stainless steel(304L)

Daelim substaion transformer

Daelim's substation transformers(skid-mounted transformers) feature a sealed tank construction, making them suitable for challenging environments. These transformers can be customized to meet your specific requirements, including special environments, altitudes, efficiency values, and more.

Furthermore, Daelim's skid-mounted transformers adhere to a wide range of international standards, including CSA, ANSI, IEEE, AS, NZS, IEC, and EN. This ensures that our transformers meet the necessary quality and safety regulations for various regions.

Send Inquiry NowStation Transformer Customization

Daelim Transformer, supported by a highly skilled technical team, offers extensive customization options to meet your specific requirements. Some of the customizable features include:

- Standards and Rules:

- K-Factor.

- Audible Sound

- Efficiency Value

- Bushing Layout

- Accessories Brand

- Impedance Value

- Standard Testing

- Special Environments

If you have other special requirements, please contact Daelim Transformer or send information to pingruidan@daelim-electric.com

Contac Daelim Transformer

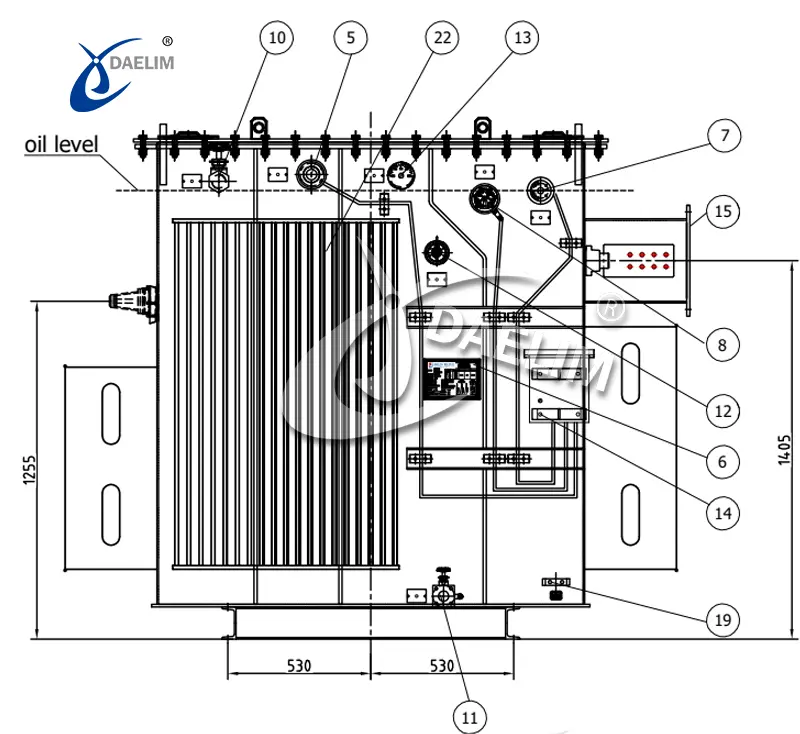

Substation Transformer Drawing

The Daelim Transformer's substation transformer outline drawings mainly contain the following information:

- Transformer Dimensions: length * width * height;

- Transformer Part Location and Identification

- Transformer Accessories

- LV & HV Cable Entry Points

- HV and LV Terminal Spacing

- LV Cable Outlet Box Size

- HV Cable Outlet Box Dimensions

- Technical Data

- Transformer Weight(oil, tank & accessories)

The substation transformer designed and produced by Daelim Transformer ensures that it fully meets your requirements, ensuring that the transformer can be installed and used accurately after you receive it.

Contact Daelim TransformerStandard Features & Available Options

| Standard Features | Available Options |

|

|

Small Substation Transformer Catalog

Contact Daelim Transformer

Substation Transformer Warranty

Daelim substation transformers offer a minimum warranty period of 24 months, providing you with peace of mind. Daelim Transformer's dedicated after-sales team is committed to promptly addressing any non-human faults that may arise during the warranty period.

- Offline Factory Inspection

- Online Video Factory Inspection

- Online Video Supervision of Substation Transformer Tests

Small Substation Transformer Manual

Get PriceDaelim Transformer Services

Daelim Transformer's comprehensive services encompass pre-sales, sales, and after-sales support.

Pre-sales: Daelim Transformer's knowledgeable sales team possesses expertise in transformer technology, enabling them to quickly understand your needs, answer technical queries, and provide swift quotations. Efficient communication ensures valuable time and energy savings for you.

Sales: Once you place an order with Daelim Transformer, its after-sales team keeps you informed about the production progress of your substation transformer. You can conveniently track the status of your order through Daelim's system, anytime and anywhere.

After-sales: With a widespread presence across the American market, Daelim Transformer's after-sales team is always ready to assist you. Should any issues occur with your transformer, our local team will promptly visit your site to troubleshoot and resolve the problem, ensuring minimal disruption.

Contact Daelim Transformer

Substation Transformer Testing

At Daelim Transformer, we prioritize the strict testing of every transformer we produce. Our testing procedures adhere to the regulations of different countries and cater to specific customer requirements, ensuring compliance with various standards. The extensive range of tests we conduct includes:

- Dielectric Tests: Safeguarding Insulation Integrity

- Voltage Ratio and Vector Group Measurement: Ensuring Precision

- Winding Resistance Measurement: Validating Electrical Conductivity

- Power-Frequency Voltage Withstand Test: Assessing Endurance

- Induced Voltage Withstand Test: Ensuring Robustness

- Measurement of No-load Losses and No-load Current: Optimizing Efficiency

- Measurement of Impedance Voltage and Load Losses: Evaluating Performance

- Sealed Test: Verifying Protection

- Sound Level Measurement: Ensuring Quiet Operation

- Lighting Impulse Voltage Withstand Test: Enhancing Resilience

- Temperature Rise Test: Validating Heat Dissipation

- Oil Test: Assessing Insulation Properties

Rest assured that Daelim Transformer employs stringent testing procedures to deliver transformers that meet the highest quality standards, comply with regulations, and surpass customer expectations. Choose Daelim Transformer for reliable, thoroughly tested transformers that power your electrical systems with confidence.

Get PriceCSA IEEE Standard For North America

•IEEE C57.12.00™—Standard General Requirements for Liquid-Immersed Distribution, Power, and Regulating Transformers

• IEEE C57.12.10™—IEEE Standard Requirements for Liquid-Immersed Power Transformers

• IEEE C57.12.36™—IEEE Standard Requirements for Liquid-Immersed Distribution Substation Transformers

• IEEE C57.12.40™—IEEE Standard for Network, Three-Phase Transformers, 2500 kVA, and Smller;High Voltage, 34 500 V and Below; Low Voltage, 600 V and Below

• IEEE C57.12.70™—Terminal Markings and Connections for Distribution and Power Transformers

• IEEE C57.12.28™—Switchgear and Transformers, Pad-Mounted Equipment—Enclosure Integrity

• IEEE C57.12.80™— Standard Terminology for Power and Distribution Transformers

• IEEE C57.12.90™—IEEE Standard Test Code for Liquid-Immersed DistributionPower, and Regulating Transformers

Send Inquiry Now

CSA IEEE Standards For North America

• IEEE C57.12.91™—IEEE Guide for Loading Mineral-Oil-Immersed Transformers andStep-Voltage Regulators

• IEEE C57.105™—Guide for Application of Transformer Connections in Three-Phase Distribution Systems

• IEEE C57.109™—Guide for Liquid-Immersed Transformer Through-Fault-Current Duration

• IEEE C57.111™—Guide for Acceptance of Silicone Insulating Fluid and Its Maintenance in Transformers

• IEEE C57.121™—Guide for Acceptance and Maintenance of Less Flammable Hydrocarbon Fluid in Transformers

• CSA-C88—Power Transformers and Reactors

• CSA-C802.3—Maximum Losses For Power Transformers

• DOE 2016 Energy Efficient (225–2500 kVA)

Substation Transformer Specification

| kVA | HV | LV | Width(mm) | Length(mm) | Height(mm) |

| 315kVA | 11000V | 400V | 800 | 696 | 1336 |

| 500kVA | 27600V | 480GrdY/277V | 1730 | 2300 | 1510 |

| 500kVA | 11000V Delta | 415V Star | 1700 | 1700 | 1650 |

| 750kVA | 11000V | 433V | 1850 | 1845 | 1465 |

| 1000kVA | 14400V | 415/240V | 1085 | 1860 | 1570 |

| 1200kVA | 13800V | 240V | 2450 | 1850 | 1820 |

| 1500kVA | 24940V | 600V | 1800 | 1880 | 1895 |

| 2000kVA | 7200V | 600GrdY/346 | 1766 | 2680 | 1982 |

| 2000kVA | 44000V | 600V | 1260 | 2090 | 1700 |

| 2500kVA | 24940V | 480GrdY/277V | 2400 | 2200 | 2060 |

| 3000kVA | 11000V | 415V | 1600 | 2330 | 1920 |

| 3000kVA | 22800V | 415/240V | 2130 | 3500 | 1910 |

| 3750kVA | 44000V | 600V | 2240 | 2650 | 2700 |

| 4000kVA | 33kV×13.2kV | 600Y/347 | 2150 | 3250 | 2290 |

| 5000kVA | 34500V | 7200V | 3780 | 1850 | 3450 |

| 5000kVA | 34500V | 4160V Star | 2799 | 2400 | 2938 |

| 6300kVA | 35000V | 400V | 3520 | 2820 | 3470 |

| 6800kVA | 34500V | 800V | 3400 | 2670 | 3400 |

| 7500kVA | 27600Y | 4160DELTA | 3350 | 3290 | 2270 |

| 12000kVA | 34500V | 800V | 3690 | 3200 | 3650 |

Substation Transformer Specification

| Power rating | HV | LV | Width(mm) | Length(mm) | Height(mm) |

| 1500/2000kVA | 13800V | 480GrdY/277V | 1960 | 1750 | 2165 |

| 2500/3000kVA | 34500V | 480GrdY/277V | 2199 | 2651 | 2159 |

| 2500/3000kVA | 34500V | 480V | 2044 | 2672 | 2062 |

| 2500/3125kVA | 16500V | 600V Star | 2247 | 1981 | 2286 |

| 3000/4000kVA | 25000V | 600V | 2250 | 2850 | 1980 |

| 4000/5333kVA | 25000V | 600V | 2260 | 2950 | 2200 |

| 1.5MVA | 11000/6600V | 1000V Star | 1800 | 2200 | 1960 |

| 2.5MVA | 22000V | 11000V Star | 2850 | 2200 | 2100 |

| 3/4MVA | 4160V | 480/277V Star | 2800 | 2100 | 2080 |

| 4/5MVA | 13800V | 4160V Delta | 3302 | 2700 | 2103 |

| 5/6.667MVA | 44000V | 124700V | 2230 | 2235 | 3450 |

| 7.5/9.375MVA | 34500V | 4160V | 2800 | 3800 | 3000 |

| 10/12.5MVA | 249400V | 4160V | 2900 | 3800 | 3200 |

| 18/24MVA | 13.8kV | 6900V Star | 3770 | 4900 | 3200 |

| 20/26.6MVA | 249400V | 4160V | 4270 | 3180 | 3245 |

| 2000/2240-2500/2800kVA | 13800V | 2*480/277V | 1950 | 2125 | 2414 |

IEC AS Standard For Skid Mounted Transformer

Features

• Simple tank and terminal configurations for optimum cost efficiency

• Accessories for Transformer Protection and Monitoring

• Cable Boxes, Kiosks, or open bushing arrangements

• Hermetically sealed for long life

• 100 to 20000kVA

• Zinc spray Paint system available for highly corrosive environments

• Standard Transformer oil or biodegradable fluid options available.

Get Price

IEC AS Standard For Skid Mounted Transformer

| Electrical Steel Type Cold rolled, grain oriented, silicon steel sheets Tank Sealing Hermetically sealed Oil Type Oil filled to AS1767 and BS148 HV Volts 6600, 11000, 22000, 33000 (others available) LV Volts 433 - 250V Dyn11 As standard (others available) | HV Tappings +5% to -7.5% up to 300kVA + 2.5 to -10% in 2.5% steps 500kVA and above (others available) Oil / Winding Rises 60 / 65˚C As standard (others available) BIL / Power Frequency Levels 95kVpeak / 28kVrms 150kVpeak / 50kVrms 200kVpeak / 70kVrms Maximum Operating Pressure 35kPA |

AS Specification For Skid Mounted Transformer

| kVA | Width(mm) | Length(mm) | Height(mm) | Oil(Litre) | Total Mass(kg) |

| 100 | 1300 | 1200 | 1000 | 300 | 900 |

| 200 | 1360 | 1200 | 1100 | 350 | 1200 |

| 300 | 1400 | 1300 | 1150 | 400 | 1480 |

| 500 | 1500 | 1400 | 1300 | 600 | 2200 |

| 750 | 1500 | 1700 | 1550 | 800 | 2780 |

| 1000 | 1500 | 1700 | 1550 | 780 | 3000 |

| 1250 | 1600 | 1800 | 1600 | 1000 | 3780 |

| 1500 | 1650 | 2000 | 1650 | 1200 | 4500 |

Substation Transformer Package

Due to the substantial weight of substation transformers, sea transportation is the preferred method for delivery. At Daelim Transformer, we employ two different packaging methods based on container types to ensure safe transit:

1. Wooden Box Packaging: Ultimate Protection

To safeguard the transformer from any potential impact or bumps during transportation, we utilize robust wooden box packaging. Firstly, the transformer is securely fastened onto a sturdy wooden support. Next, the entire unit is enveloped with fumigated logs, providing comprehensive protection, including the top. This packaging method guarantees that the transformer arrives at its destination undamaged.

2. Bare Installation: Ensuring Safety and Security

In cases where a naked installation is feasible, we employ an alternative packaging approach. The transformer is firmly secured on sleepers, ensuring stability during transportation. Additionally, to protect the terminal box (control box), we encase it within a wooden box. This method offers an additional layer of safeguarding while maintaining the overall integrity of the transformer.

At Daelim Transformer, we prioritize the secure packaging of substation transformers for sea transportation. Our packaging methods are designed to prevent any potential damage and ensure that your transformer arrives in pristine condition, ready for installation. Trust Daelim Transformer to handle your transformer transportation needs with utmost care and professionalism.

Daelim Transformer Factory

Finished transformer area

Material processing area

Substation Transformer assembly area

Substation transformer with UL

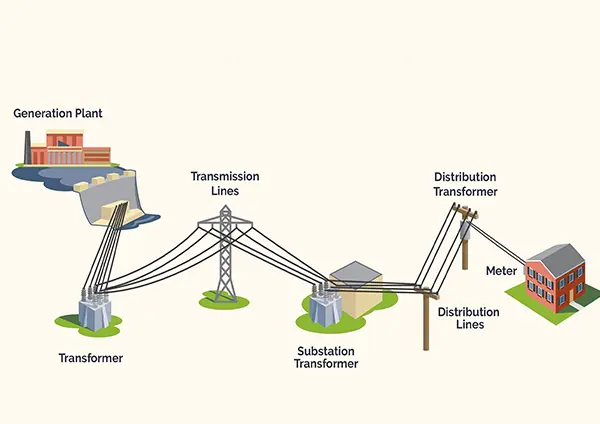

Substation Transformer Application

For Renewable Energy

Substation transformers are commonly utilized in solar and wind power plants to integrate with the grid, stabilize its operation, and enable direct interconnection of energy.

For Energy Storage

Substation transformers are crucial components in energy storage systems, facilitating voltage transformation, grid connection, power dispatch, grid stability, power quality, and frequency regulation.

For Portable Substation

The Daelim Transformer'substation transformer, purchased by an Australian customer, is designed for portable substations. It enables temporary power infrastructure deployment in remote or temporary locations for industrial, construction, or emergency power applications.

For Data Center & Mining

Daelim Transformer's substation transformers are employed in a small bitcoin mining facility in Texas. Four transformers are utilized to support the power needs of the facility, ensuring efficient and reliable operations.

For Utility

Substation transformers are vital components in utility power systems. They enable the efficient transmission and distribution of electrical energy, ensuring reliable power supply to end-users. These transformers facilitate voltage transformation, regulate power flow, and maintain grid stability, contributing to the smooth operation and resilience of the utility grid infrastructure.

For Oil & Gas Exploitation

Substation transformers provide electrical support to the oil and gas industry, providing electrical support to offshore and onshore facilities. They facilitate power distribution, ensure power quality and stability, and enhance efficiency, safety, and productivity in oil and gas exploration and production operations.