Transformers Solution For Oil and Gas Plant

Transformers play a vital role in oil and gas plants by ensuring a stable and reliable power supply—essential for safe and efficient operations. However, these transformers often encounter challenges due to harsh environments and high power demands, which can lead to performance degradation and reduced lifespan.

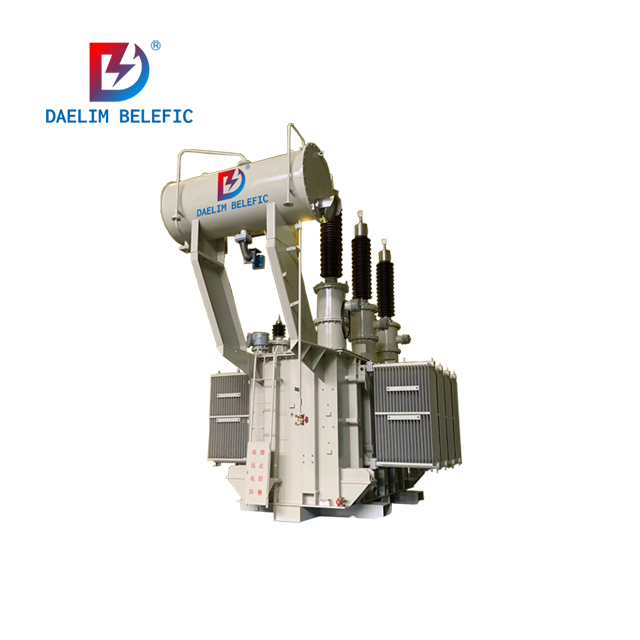

At DAELIM Solutions, we deliver advanced and innovative transformer solutions specifically designed to overcome these obstacles. We also provide mobile and scalable equipment solutions tailored to the unique needs of the oil and gas industry.

Contact Daelim TransformerDaelim’s state-of-the-art transformer technology is specifically designed for oil and gas plants providing reliable performance and improved efficiency. Daelim’s transformers are designed to withstand harsh environments and high temperatures commonly found in oil and gas plants. Daelim Transformers use advanced insulation materials such as high-temperature insulation systems, which greatly improve the transformer's insulation and reduce the risk of electrical faults. Additionally, Daelim transformers feature advanced cooling technology solutions like liquid cooling that offer better heat dissipation compared to traditional air-cooled transformers, resulting in superior performance. Daelim transformers are constructed using durable materials such as diamond-coated materials, which provide high resistance to oxidation and wear and tear, ensuring longevity and reducing the need for frequent maintenance.

Daelim Solutions For Oil and Gas

At Daelim Transfromer, the goal is to provide sustainable and secure work environments that meet the growing demand. To achieve this, we innovate electrical transformer solutions that are customized to meet specific requirements such as voltage, power rating, climate, network topography, and noise level, among others. Each transformer is uniquely designed to adhere to the strictest standards. Our solutions include high efficiency, environmental sustainability, maximum short-circuit strength, overload capability, high-temperature operation, reliable start-up after power outages, and low maintenance costs.

Transformer Solution For Oil Project In USA

Site: Houston, Texas, USA

Specification:

Standard: IEEE C57.12.00

Rated voltage: 24.96/4.16kV

Winding;Copper

Vector Group: YNd11

ONAF cooling

Frequency 60 Hz

High-rated voltage 24.96 kV

Low-rated voltage 4.16kV

Full neutral insulation (not reduced)

DispoYestion of the neutral in the high voltage network To ground

DispoYestion of neutral in the network of low ground

Installation type Outdoor

Maximum ambient temperature 45º C

Minimum ambient temperature -20º C

Maximum average ambient temperature (24 hours) 26º C

Altitude above sea level ≤1500m

Exposure to solar radiation

Local push button control

Free terminals for current control circuit blocking

Interlock switch for the motor when the crank is placed

Automatic passage of central steps of the same voltage

Step-by-step maneuver

No. of potential-free contact tracks

Limit switches 1st and last adjustment take

Potential-free signaling contact “Crank inserted

Transformer Solution for Oil and Gas Project in the USA

In February 2025, Daelim Belefic completed the production of a batch of transformers for an oil and gas project located in Texas, USA. A total of nine units were manufactured for this project. These transformers feature a specialized design that allows them to be mounted on mobile trailers, enabling flexible and efficient on-site operations.

The transformers are built with a core-type construction and comply with the IEEE C57.12.00 manufacturer standard. They are also UL Listed. With a temperature rise rating of 55°C, they are well-suited for the high-temperature conditions commonly found in oil and gas extraction environments.

Send Inquiry NowThese units are equipped with a two-stage forced air cooling system. Their capacities are rated at 12 MVA under natural air cooling (ONAN), 16 MVA with stage-one forced air cooling (ONAF-1), and up to 20 MVA with stage-two forced air cooling (ONAF-2), offering adjustable performance depending on field requirements.

The high-voltage side of each transformer features five tap positions—23 kV, 25 kV, 27 kV, 33 kV, and 35 kV—to accommodate different power grid requirements. The low-voltage side is rated at 13.8 kV. The winding configuration is YNd1.

Daelim Belefic’s experienced engineering team delivered precise calculations and a carefully optimized design to meet strict dimensional constraints, especially in terms of the width and height of the transformers, ensuring seamless integration with mobile trailer platforms.

Transformer Solution For Gas Project In Australia

The 2000 kVA 11 kV transformer is based on the IEC 60076 and AS/NZS 60076 standards, which are international and Australian/New Zealand standards for power transformers, respectively. It is designed and produced by Daelim Transformer, a company specializing in transformer manufacturing.

This particular transformer is commonly used in gas projects in Australia. It has a high voltage rating of 11 kV and a low voltage rating of 1 kV. The capacity of the transformer is 2000 kVA, which indicates its ability to handle a power load of up to 2000 kilovolt-amperes.

Send Inquiry NowOne notable feature of this transformer is the use of environmentally friendly vegetable oil as the cooling medium. Vegetable oil has become an alternative to mineral oil, which is traditionally used in transformers. Vegetable oil offers improved fire resistance and is considered more environmentally friendly due to its biodegradability and lower toxicity.

Additionally, this transformer is designed with several characteristics that enhance its safety and reliability. It is fireproof, meaning it is resistant to catching fire or sustaining damage from flames. It is also explosion-proof, which means it can withstand internal or external explosions without rupturing or causing significant damage. Moreover, it is corrosion-resistant, making it suitable for various environments, including those with high humidity or corrosive substances.

You may enjoy: Skid Mounted Transformer

The Role of Transformers in Oil and Gas Plants

Transformers are essential in oil and gas plants as they provide stable power to critical equipment. They are responsible for adjusting incoming voltage levels to meet the specific requirements of various devices, such as motors, pumps, compressors, and control systems. Without transformers, it would be challenging to operate electrically-driven equipment in the plant safely and efficiently.

In the oil and gas industry, transformers are classified into two types:

HV Power transformer

Step-Up and Step-Down Voltage: HV power transformers are responsible for stepping up or stepping down the voltage levels of electrical power to match the requirements of different equipment and processes in the oil and gas production facilities. They efficiently convert the electrical energy to the desired voltage levels for transmission or distribution purposes.

Connection to Electrical Grid: Oil and gas production sites are often situated in remote locations, far from the main electrical grid. HV power transformers are used to connect these sites to the grid, enabling them to receive power from the central utility network. These transformers help regulate the voltage levels and facilitate the efficient transfer of electrical energy to the production facility.

Get PriceVoltage Regulation and Power Quality: HV power transformers play a vital role in regulating voltage levels and ensuring power quality within the oil and gas production facility. They stabilize voltage fluctuations, maintain a constant supply voltage, and mitigate power-related issues like harmonics, voltage distortions, and reactive power. By improving power quality, these transformers enhance the performance and efficiency of electrical equipment and systems.

Backup Power Supply: HV power transformers can be utilized in conjunction with backup power sources, such as diesel generators or battery banks, to provide uninterrupted power supply during grid outages or emergencies. They help transfer power from the backup source to critical loads, ensuring the continuous operation of essential equipment and maintaining safety systems.

Distribution transformer

Oil and gas production facilities require a stable and reliable power supply to operate various equipment and processes. Power transformers step up or step down the voltage levels of electrical power to match the requirements of different equipment, ensuring efficient power distribution throughout the facility.

You may enjoy: Pad Mounted Transformer

Challenges and Optimizing Transformers in Oil and Gas Plants

Challenges Transformers in Oil and Gas Plants

Oil and gas plants present unique challenges for transformers due to the harsh operating conditions and the high electricity demand. The harsh environments of oil and gas plants can cause damage to electrical equipment, including transformers

In addition, the demand for electricity in these facilities can fluctuate significantly, which can put additional stress on transformers.

Another challenge that transformers face in oil and gas plants is the potential for power surges and voltage spikes. These events can occur due to lightning strikes, switching operations, or other causes. Transformers that are not designed to handle such events may fail, leading to costly downtime and repairs.

Key strategies for optimizing transformers

1. Proper Sizing

To handle the expected load and voltage variations, transformers need to be sized correctly. This involves detailed planning and analysis of the electrical

systems in the plant to ensure that the transformers are the appropriate size.

2. Robust Design

When it comes to transformers used in oil and gas plants, they need to be built tough enough to endure extreme temperatures and moisture. This means that only the best materials and coatings can be used for protection.

3. Advanced Monitoring

Monitoring systems for transformers can give advance notice of potential problems, enabling maintenance and repairs to be done proactively. Such systems might incorporate sensors that can detect temperature, vibration, and other signals of a transformer's condition.

4. Redundancy

To avoid any interruptions caused by transformer failure, it is recommended to incorporate redundancy into the electrical system. This could entail the installation of backup transformers or other systems to guarantee an uninterrupted power supply.

5. Smart Grid Integration

The energy industry is seeing a rise in smart grid technology, which has the potential to enhance the dependability and effectiveness of electrical systems. When transformers are combined with smart grid technologies, oil and gas plants can oversee and regulate power usage more efficiently, resulting in improved energy management.

Recent Advancements in Transformer Technology

Dry-Type Transformers

In the past, transformers were commonly cooled using oil as a coolant. However, dry-type transformers have become increasingly popular due to their many benefits. Dry-type transformers use air or synthetic resin to cool the transformer windings instead of oil. These types of transformers have several advantages, including a lower risk of fire compared to traditional oil-cooled transformers. Additionally, dry-type transformers are more environmentally sustainable since they do not use toxic oil and are easier to dispose of. Finally, maintenance requirements for dry-type transformers are lower because they do not have oil leaks or require oil changes.

Superconductive Transformers

Transformers have seen recent development in the use of superconductive materials, which are materials that can conduct electricity without resistance. This allows them to operate more efficiently and with less energy loss than traditional transformers. As a result, users can save on costs and reduce their carbon emissions.

Superconductive transformers are made with coils of superconducting materials, which are cooled with liquid nitrogen to achieve superconductivity. Since there is no resistance, these transformers operate at higher efficiency levels while using less energy. This translates to significant cost savings over time.

In addition, superconductive transformers are advantageous for power plants with limited space, as they have a smaller footprint. They also have a longer lifespan than traditional transformers, reducing the need for frequent replacements.

Future Trends in Transformer Technology

Looking to the future, advancements in transformer technology will have an impact on oil and gas plants. The ongoing development of smart grid technologies will enable more precise control and monitoring of electrical systems. Additionally, the increasing use of renewable energy sources such as wind and solar power will necessitate the use of different types of transformers, requiring new designs and technologies to be developed.

Transformers are crucial components in the electrical infrastructure of oil and gas plants, responsible for converting power from one voltage level to another. As the energy landscape continues to evolve, transformers must also evolve to keep up with new technologies and requirements.

Smart grids

Smart grids are designed to enable more precise control and monitoring of electrical systems, which can help improve efficiency, reliability, and safety. For example, transformers equipped with sensors can provide real-time data on their operating conditions and allow maintenance teams to identify potential problems before they occur. Furthermore, smart grid technologies can enable the integration of renewable energy sources into the power grid, by dynamically adjusting power flows and voltage levels as needed.

Use of renewable energy sources

Transformers used in renewable energy sources like wind and solar power require a specialized design to handle varying voltage and current levels. For instance, solar panels generate DC power which needs to be converted to AC power before being fed into the grid. This requires a unique transformer design. Similarly, wind turbines require step-up transformers to increase voltage levels for long-distance transmission. To ensure efficiency and reliability, transformers used in renewable energy must be optimized using new materials and advanced cooling systems. Hybrid materials that combine magnetic and non-magnetic materials are an example of a material that can increase efficiency. Effective heat dissipation is another factor that can be improved through advanced cooling systems.

Complex facilities like oil and gas plants require reliable and stable electrical systems to ensure safe and efficient operations. Transformers are critical components of these electrical systems, and they are used to adjust voltage levels as needed for different equipment and devices.

Daelim Transformer provides transformer solutions that effectively tackle the distinctive obstacles encountered by oil and gas plants. Daelim’s state-of-the-art technology guarantees dependable performance, improved efficiency, and prolonged lifespan. By utilizing advanced-of-the-line technology and regular preventative maintenance, our transformer solutions offer a secure power supply and ensure the safe and efficient functioning of oil and gas plants.

Contact Daelim Transformer