Three Phase Pad Mounted Transformer

Three Phase Pad Mounted Transformer

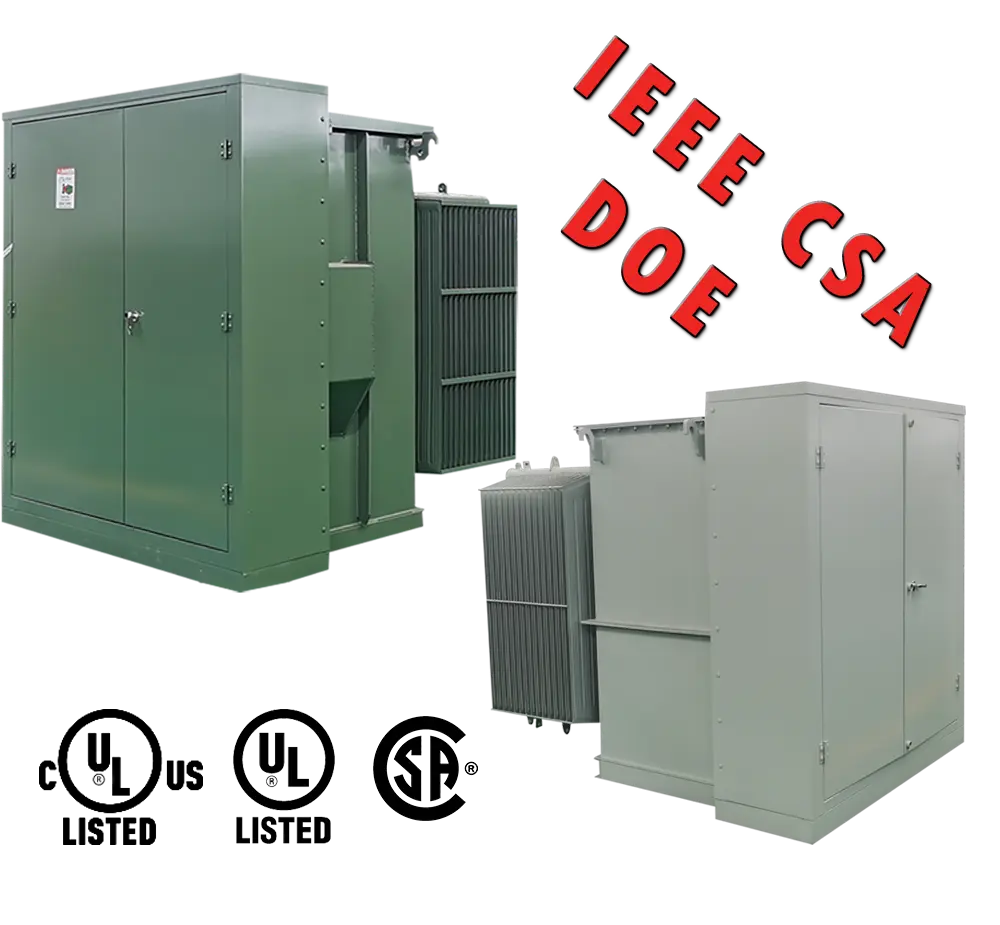

Daelim Transformer stands as a professional manufacturer of pad-mounted transformers, offering units with high voltages of up to 44kV and ratings of up to 10MVA. The pad-mounted transformers are fully certified by UL, ensuring adherence to stringent quality standards. With extensive experience in North American projects, we are proficient in ANSI/IEEE, CSA, DOE, NEMA, and other standards, as well as local laws and regulations. Thousands of pad-mounted transformers are exported to the United States and Canada every year, providing robust support for hundreds of projects. Additionally, we specialize in providing customized pad-mounted transformer solutions tailored to meet the unique requirements of your project.

Pad Mounted Transformer

The pad mounted transformer serves as a grounded power distribution system utilized outdoors or underground. Enclosed within pad-mounted units, these distribution systems eliminate exposed wires or cables, making them ideal for deployment in high-traffic and communal areas. This design feature not only obviates the need for fencing but also reduces wiring needs, resulting in cost savings and more dependable power connections. With a service life of 25-30 years, these transformers offer long-lasting reliability.

The pad-mounted transformers engineered and manufactured by Daelim Transformer adhere to stringent standards such as IEEE C57.12.4 and CSA C227.4, while also meeting efficiency requirements set by DOE and CSA. Customizable according to project specifications, our transformers can withstand harsh environments, including corrosion protection, low-temperature rise, and other demanding conditions, along with accommodating special design requirements.

Contact Daelim TransformerCertificates

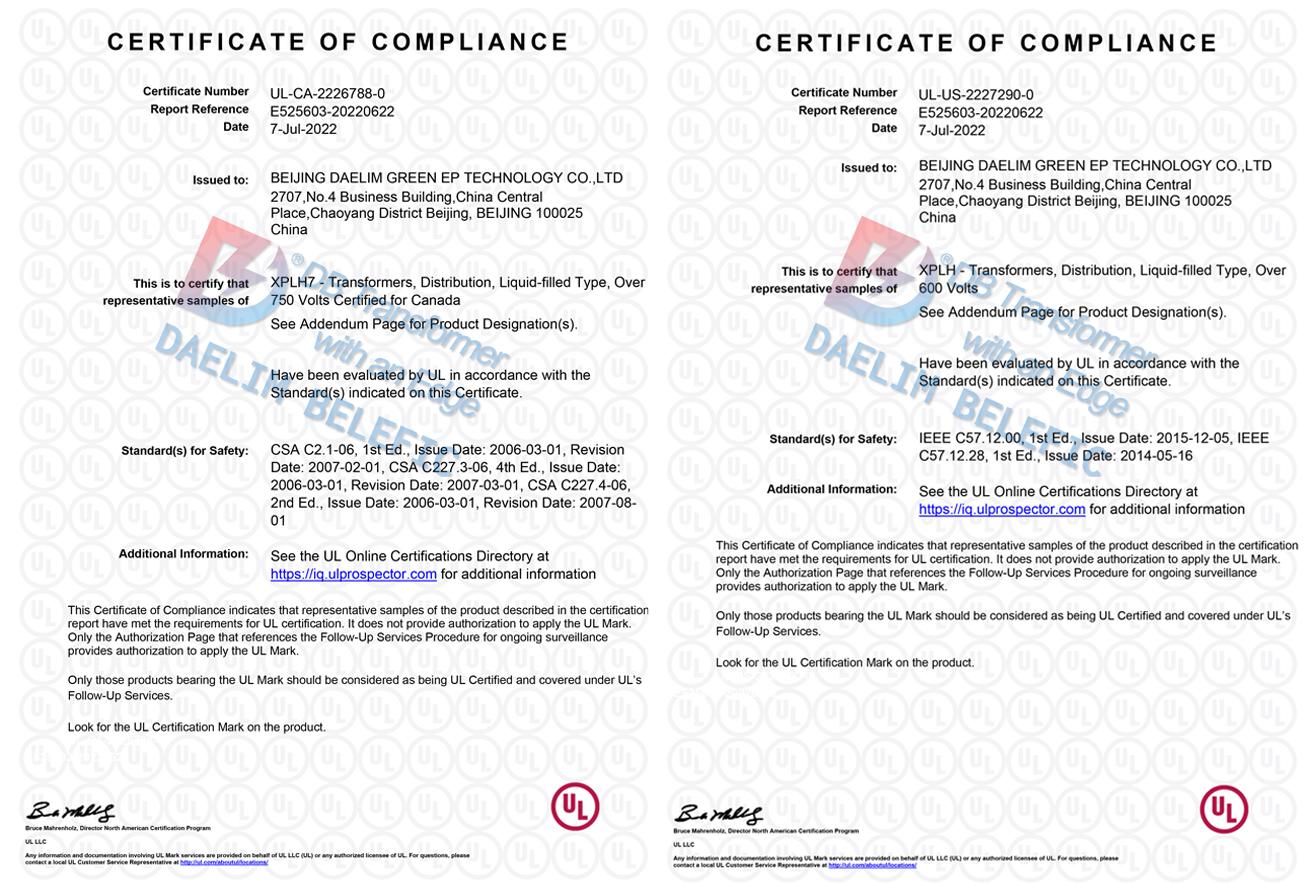

The 3-phase pad-mounted transformers manufactured by Daelim have successfully undergone testing and certification by authoritative organizations such as UL, CSA, CESI, SGS, and others.

Daelim's UL cUL Certificate 3-phase pad-mounted transformer series includes the following power ratings:

- 15kV with a power rating of up to 4000kVA

- 25kV with a power rating of up to 20MVA

- 35kV with a power rating of up to 10MVA

- 44kV with a power rating of up to 20MVA

Daelim three phase pad mounted transformers fully meet or exceed ANSI/IEEE, CSA, IEC, DOE, and other standards, these certifications ensure compliance with safety and performance standards, assuring customers worldwide.

Send Inquiry Now

3-Phase Pad mounted transformer Specification

| kVA | HV | LV | Total weigh | oil weight |

| 75 kVA | 25000Delta | 480GrdY/277 | 1,400Kg | 540KG |

| 100 kVA | 24900GrdY/14400 | 600V | 729KG | 138KG |

| 150 kVA | 14400V | 600GrdY/347 | 2400kg | 750L |

| 200 kVA | 13800V | 380GrdY/220 | 2000kg | 250kg |

| 225 kVA | 4160Delta | 347GrdY/600V | 2500KG | 850L |

| 300 kVA | 34500V | 208GrdY/120 | 2300kg | 1025L |

| 500 kVA | 24940DELTA×12470DELTA | 208GrdY/120 | 3050kg | 1170L |

| 625 kVA | 13,800Delta | 480GrdY/277V | 2000KG | 520KG |

| 750 kVA | 24940GrdY/14400 | 800GrdY/462 | 3100Kg | 920L |

| 1,000 kVA | 13,200DELTA | 480GrdY/277 | 8,360lbs | 310GAL |

| 1,250 kVA | 25000V | 416V | 4000kg | 1250L |

| 1,500 kVA | 4160GRDY/2400 | 600GrdY/347 | 4300kg | 1400L |

Three Phase Pad mounted transformer Specification

| kVA | HV | LV | Total weigh | oil weight |

| 1,700 kVA | 13,800Delta | 480GrdY/277V | 4600Kg | 1050L |

| 2,000 kVA | 4160DELTA | 415GrdY/240 | 4600Kg | 1280L |

| 2,500 kVA | 25000DELTA | 600GrdY/347 | 5850Kg | 1680L |

| 2,550 kVA | 12470DELTA | 415GrdY/240 | 5800Kg | 1750L |

| 2600 kVA | 34500DELTA | 416GrdY/240 | 6350Kg | 1940L |

| 2800 kVA | 21000V | 480V | 13669lb | 489gal |

| 3000 kVA | 13800V | 415V | 6700Kg | 1885L |

| 4000 kVA | 34,500DELTA | 12,470DELTA | 9,500Kg | 3560L |

| 5000 kVA | 22860GrdY/13200 | 4160GrdY/2400 | 9100Kg | 2435L |

| 7000 kVA | 27,600DELTA | 13,800DELTA | 11600kg | 2820L |

| 7500 kVA | 249400DELTA | 4.16kv Wye | 12000 Kg | 3000KG |

| 10000 kVA | 24900GrdY/14400 | 600V | 15000Kg | 3000L |

Pad Mounted Transformer Tests & QC

After each unit of Daelim Transformer's pad-mounted transformer is produced, routine tests/FAT will be conducted following the requirements of ANSI/IEEEC57.12.90 and C57.12.00. The test report complying with IEEE/CSA standards will then be issued.

We offer both online and offline test supervision options for our customers. You can choose to have a third party, such as SGS, CSA, or UL, visit the Daelim Transformer factory during the testing phase to witness the tests being conducted and receive a report that fully complies with standard requirements. Alternatively, you can opt for online video monitoring to observe the testing process in real-time. Ensuring transparency and confidence in the testing procedures.

Our production and testing equipment undergo professional calibration every year. The UL agency also supervises and inspects our factory every three months. These measures ensure that Daelim Transformer produces high-quality, safe, and reliable transformers.

Contact Daelim TransformerFactory Production Photos

Shipping Photos

Why Choose Daelim 3 Phase Pad Mounted Transformers

1. Daelim offers a comprehensive range of UL-listed pad-mounted transformers with a capacity range of 15-35kV and up to 20MVA.

2. Customized service, 24-month warranty

3. Experience fast turnaround times with Daelim's 3-phase pad mounted transformer drawings, typically provided within 1-2 weeks.

4. Daelim's local after-sales service teams are available in the United States, Canada, Mexico, Ecuador, and other countries.

5. Fast delivery of three-phase pad mounted transformer(6-8weeks)

Daelim Pad Mounted Transformer Projects

Live front & Dead front transformer

Daelim Transformer offers the flexibility to design and produce both live front and dead front pad-mounted transformers to suit your specific requirements.

Dead Front Transformer: In a dead front transformer, the high-voltage bushing is separate, comprising a bushing well and a load break bushing insert, both insulated. High-voltage cables connect to the transformer using a dead break elbow connector, ensuring no exposed electrical components in the energized high-voltage section. This design significantly reduces the risk of accidental contact or electric shock.

Live Front Transformer: In a live front transformer, the high-voltage bushing typically consists of a one-piece spade type made of materials like porcelain or epoxy, often with 2-4 holes at the end. High voltage cables connect to these holes using a mechanical lug or a crim plug. Unlike dead front transformers, the high-voltage bushing in live front transformers is fully exposed, potentially leading to safety concerns if moisture, oil, or dust is present, increasing the risk of arc generation.

Based on our extensive experience, most customers opt for the dead front pad-mounted transformer due to its superior safety features. However, the choice ultimately depends on your specific needs and preferences. Rest assured, Daelim Transformer can tailor our solutions to meet your project requirements.

Send Inquiry Now