Pole Mounted Transformer

Pole Mounted Transformer Manufacturer

Daelim Transformer is a professional manufacturer of pole mounted transformers, trusted by utility companies throughout North America. Their transformers carry endorsements from UL and test reports from internationally recognized organizations such as CESI and CSA. With a wide range of advantages, Daelim Transformer stands out in the market:

- Extensive experience in supplying utilities across North America.

- Swift delivery, ensuring transformers are delivered within 6-10 weeks.

- Dedicated aftermarket installation service in Texas and Houston.

- Full range of UL and CSA listed transformers.

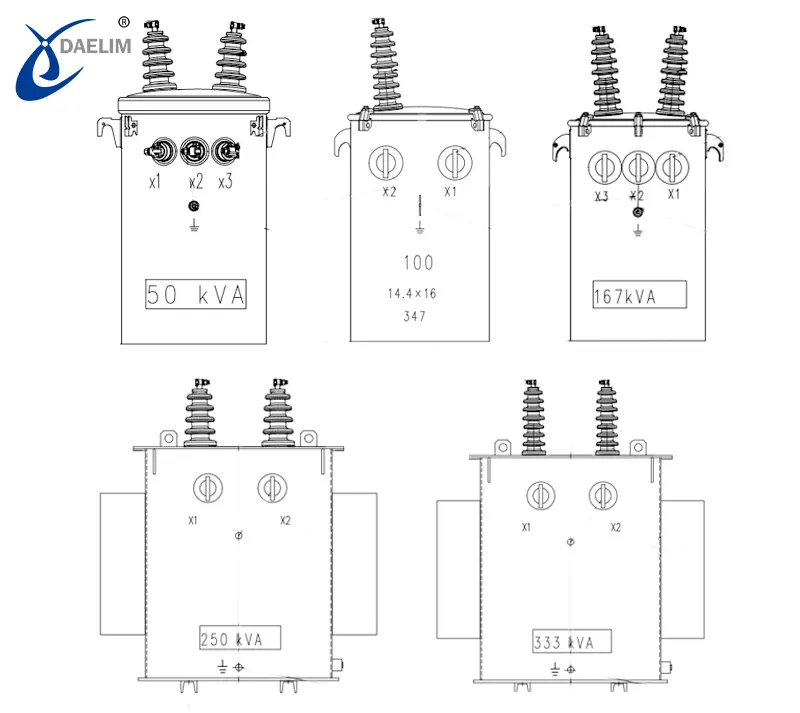

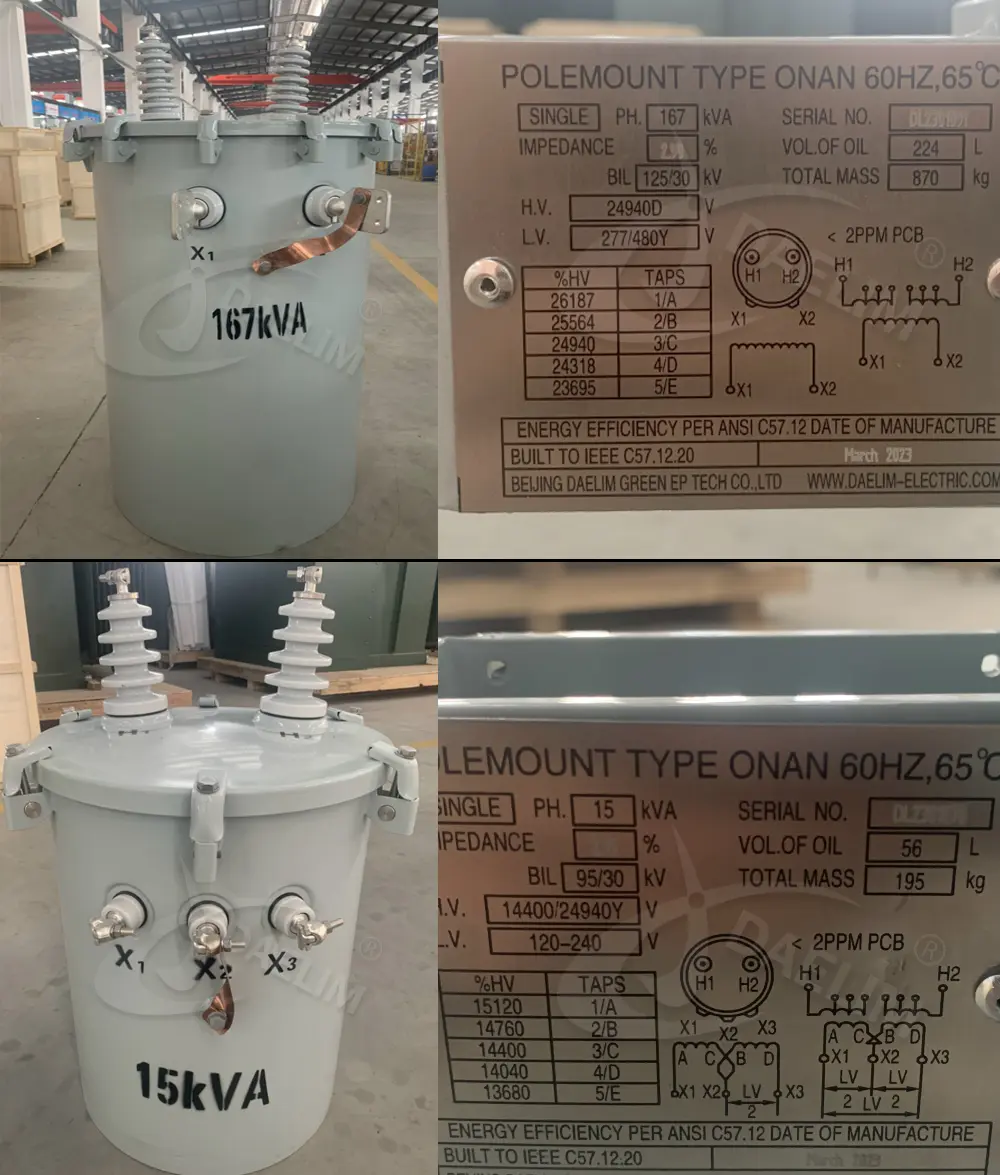

- Single phase pole mounted transformers ranging from 15 kVA to 333 kVA.

- Three phase pole mounted transformers ranging from 15 kVA to 500 kVA.

Pole Mounted Transformer

Single Phase Transformer

Pole Mounted Transformer Standards

With a robust technical team and extensive international project experience, Daelim Transformer excels in producing pole mounted transformers that meet global standards such as ANSI/IEEE C57, CSA C2.1, CSA C2.2, IEC 60076, AS 60076, ENA TS 35-1, and more. The pole mounted transformer not only comply with but also exceed the efficiency value requirements set by DOE and CSA. Trust Daelim Transformer's expertise to deliver reliable and efficient solutions, ensuring high performance and energy conservation.

Send Inquiry NowSinlge Phase Pole Mounted Transformer Types

Daelim Transformer offers a comprehensive production line dedicated to single-phase pole-mounted transformers, commonly known as overhead transformers. They specialize in designing and manufacturing both conventional and completely self-protected (CSP) variants.

The CSP overhead transformer, a standout product from Daelim Transformer, incorporates essential protective features. It integrates a surge arrester on the high voltage side, a circuit breaker on the low voltage side, and includes a built-in protective fuse. This all-in-one design eliminates the need for additional protective devices, resulting in significant cost savings during installation.

By providing the CSP overhead transformer, Daelim Transformer ensures enhanced safety and convenience for customers. Their innovative approach streamlines the installation process while maintaining essential protective measures, offering a reliable and cost-effective solution for overhead transformer applications.

Send Inquiry Now

Pole Mounted Transformer Specifications

| Power Rating | Width(mm) | Depth(mm) | High(mm) | Total Weight(kg) |

| 10 kVA | 500 | 525 | 885 | 150 |

| 15 kVA | 520 | 565 | 905 | 210 |

| 25 kVA | 560 | 590 | 935 | 258 |

| 37.5 kVA | 610 | 625 | 935 | 340 |

| 50 kVA | 635 | 675 | 1035 | 395 |

| 75 kVA | 745 | 840 | 1035 | 480 |

| 100 kVA | 770 | 965 | 1135 | 530 |

| 167 kVA | 795 | 890 | 1335 | 680 |

| 250 kVA | 1080 | 1030 | 1390 | 1280 |

| 333 kVA | 1140 | 1060 | 1450 | 1550 |

Pole Mounted Transformer Ratings

Pole-mounted transformer ratings vary based on the number of phases and the power requirements of the electrical distribution system. Below are optimized and unique power and voltage ratings for both single-phase and three-phase pole-mounted transformers:

Single-phase pole-mounted transformer power ratings:

10 kVA,25 kVA,37.5 kVA, 50 kVA, 100 kVA, 167 kVA, 250 kVA, 333 kVA

Single-phase pole-mounted transformer voltage ratings:

2400V, 7200V, 124 70V , 7620V, 13200V, 7957V, 13800V, 19920V, 34500V, 27600V (unique to Ontario, Canada).

Three-phase pole-mounted transformer power ratings:

25kVA, 45kVA, 63kVA, 100kVA, 200kVA,315kVA,400kVA and 500kVA.

Three-phase pole-mounted transformer primary nominal voltage ratings:

Primary nominal voltage rating from 11kV to 33kV.

Contact Daelim Transformer

Pole Mounted Transformer Features

Cost-effective design

High efficiency and low noise levels

Dual voltage capability

Customization based on specific requirements

Coating meets or exceeds IEEE C57 standard

CSA-compliant lifting lugs

Excellent sealing for protection against environmental factors

Polymer-type low voltage bushings

Porcelain-type high voltage bushings

Convenient cover or sidemounted voltage bushings

Spade or clamp type terminals

High and low voltage terminals

Compatible with both mineral oil and biodegradable vegetable oil as insulating oil

Provision for surge arrester bracket, with brackets available if needed

Get PriceSinlge Phase Pole Mounted Transformer Structural Features

1. The tank lids have high-voltage porcelain bushings that come with ring terminals, which can accommodate either aluminum or copper cables.

2. The circular sewing structure of the tank cover ensures even stress distribution and reliable sealing.

3. The ring bolts on the tank wall serve as the low-voltage bushing and terminal and are tin-plated.

4. This item comes with a pressure relief valve that is capable of self-sealing.

5. According to ANSI standards, the transformer's suspension hooks at the top and bottom comply.

6. The ground terminal on the tank is a ring bolt ground terminal.

Contact Daelim Transformer

Single Phase Pole Mounted Transformer Testing

Before the single phase pole mounted transformer is delivered, we will arrange a series of tests which help the customers to verify the quality and ensure the safety. Generally we will perform routine tests which include Ratio test, Winding resistance test, No load loss and no load current test, Applied voltage and induction voltage tests, Leakage test and so on. We will forward the test report by specifying all these tests result with the signature of a professional engineer on the test document. Beside the routine tests, there are other optional tests such as Resistance test, Temperature rise test, Sound level test and so on.

Send Inquiry NowPole Mounted Transformer Sizes

Single-phase pole-mounted transformers are smaller due to varying power distribution needs and load characteristics compared to three-phase transformers. Size is influenced by capacity and losses, with higher-capacity transformers requiring larger dimensions to accommodate components and cooling mechanisms. Minimizing losses for efficient power transmission affects the physical size. Ultimately, transformer size is determined by phase configuration, power capacity, efficiency requirements, and associated losses. These factors shape the optimal design to ensure reliable power distribution.

Single-phase pole-mounted transformers vary in size based on power capacity, typically ranging from 10 kVA to 333 kVA. The physical dimensions are influenced by factors like insulation type, cooling method, and specific design requirements. For Daelim's conventional single-phase pole-mounted transformers, the standard size can be found in the Pole Mounted Transformer Specifications.

Send Inquiry Now

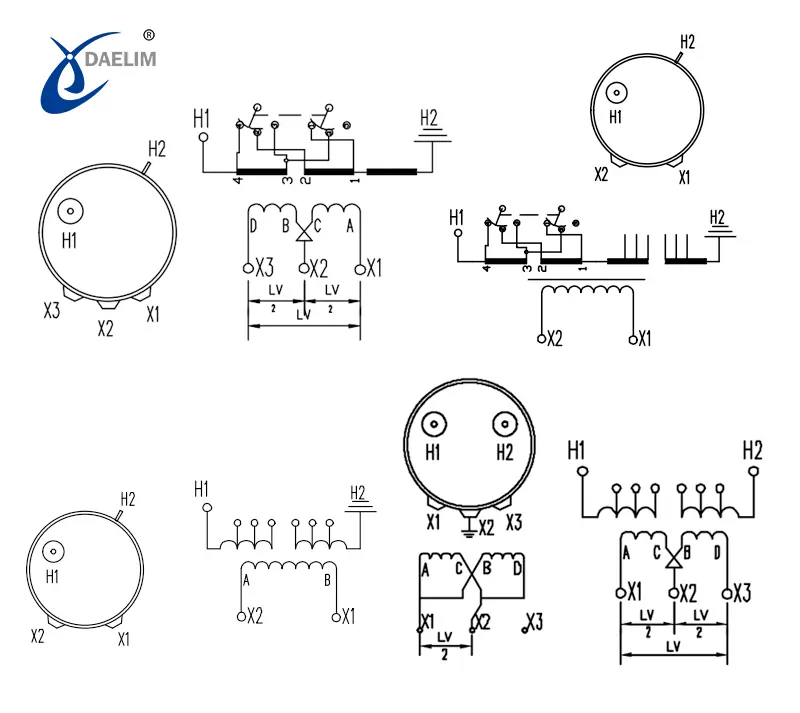

Pole Mounted Transformer Connections

Pole-mounted transformers offer two connection methods: Ii0 and Ii6. The choice of connection method determines the polarity relationship between the primary and secondary windings of the transformer.

Ii0 Connection (Subtractive Polarity)

When a pole-mounted transformer is connected in the Ii0 configuration, the primary and secondary windings are wound in the same direction. Consequently, when subjected to the same magnetic flux, the induced primary and secondary potentials align in the same direction. This configuration is known as subtractive polarity.

Ii6 Connection (Additive Polarity)

In the Ii6 connection method, the primary and secondary windings of the pole-mounted transformer are wound in opposite directions. As a result, the induced potentials in the primary and secondary windings have opposite directions under the influence of the same magnetic flux. This configuration is referred to as additive polarity.

The selection of the Ii0 or Ii6 connection method depends on the specific requirements of the electrical system and the intended application. Each configuration has its advantages and is suitable for different scenarios. When choosing the appropriate connection method for a pole-mounted transformer, factors such as system design, voltage regulation, and load characteristics need to be taken into account.

Pole Mounted Transformer Parts

The following is the introduction of the main parts of the single-phase pole-mounted transformer. The main parts(accessories) on the single phase pole mounted transformer include high voltage bushing, low voltage bushing, oil fill valve, oil drain valve with the sampler, and pressure relief valve.

1. High voltage bushing

The main material of high voltage bushing is porcelain and its main role is to connect high voltage winding and external high voltage lines, insulation protection, protection against external intrusion, heat conduction and heat dissipation, etc., to ensure the normal operation and safety of the transformer.

2. Low voltage bushing

There are two types of low voltage bushing as spade type and clip type. it can be designed according to customer needs.

3. Oil fill valve

The role of the oil filling valve on the single phase pole mounted transformer is to fill the insulation oil into the tank.

4. Oil drain valve with sampler

The oil drain valve and sampler on the single phase pole mounted transformer are used to discharge air and moisture, remove sediment and impurities, ensure the quality and performance of the oil inside the transformer, and ensure the safe and stable operation of the transformer. Meanwhile, we can collect oil samples for analysis and testing.

5. Pressure relief valve

The pressure relief valve on the single phase pole mounted transformer is mainly used to protect the safe operation of the transformer, maintain normal working conditions, and adjust the gas pressure inside the transformer to ensure its stability and reliability.

For the CSP type of single phase pole mounted transformer, there are extra parts(accessories) such as lighting arrester, internal current limiting fusing, and circuit breaker. This CSP type can protect itself from thunder and lightning, short circuits, and protect the transiting and distribution line from current failure because of self-malfunction. All of them three are devices for protection but in the following different ways.

1. Lighting arrester

The lighting arrester keeps the transformer safe from power surges caused by lightning, switching, and other HV sources. It shunts high voltage surges by grounding to avoid the direct impact of the transformer itself.

2. Internal current limiting fusing

The fuse is used to limit the transformer winding from being damaged when there are overload currents.

3. Circuit breaker

One secondary circuit breaker is above the winding inside the tank and here are the operating handle, overload reset, and signal light. It has the function of thermal protection, low oil lever protection, and allowing a percentage of power to go through the breaker to restore service when it trips.

Pole Mounted Transformer Applications

Pole-mounted transformers play a pivotal role in ground-level power distribution systems. Their widespread application is particularly prominent in suburban and rural, where they serve as indispensable components within the power infrastructure of city outskirts and villages. These transformers are commonly anchored to robust cement or wooden poles, ensuring a reliable and secure installation process. Additionally, pole-mounted transformers are extensively utilized in utility networks.

Learn more about Transformer For Utilities

Daelim Pole Mounted Transformer

Pole Mounted Transformer Price

The price of pole-mounted transformers is influenced by several factors, including:

Standards and Regulations: Different regions may have specific standards and regulations that transformers must meet. Compliance with these standards can impact the design, manufacturing process, and overall cost.

Efficiency Values: Transformers with higher efficiency values may require more advanced designs and materials, which can contribute to a higher price.

Materials and Components: The quality and type of materials used in the transformer construction can affect its price. High-quality materials and components often come at a higher cost.

Labor Costs: The cost of labor, including skilled engineers and technicians involved in designing and manufacturing the transformers, can impact the overall price.

Market Demand and Competition: Market dynamics, including demand and competition, can influence transformer prices. Supply and demand fluctuations, as well as competitive pricing strategies, can affect the pricing of pole-mounted transformers.

Customization and Special Features: Transformers with specialized features or customization options may have higher prices due to the additional engineering and manufacturing requirements.

Contact the Daelim Transformer sales engineer to get the exact pole-mounted transformer price.

Pole Mounted Transformer Package & Shipping

Daelim Transformer ensures the safe transportation of their pole-mounted transformers by packing them in wooden pallets and wooden cases. These packaging materials provide sturdy and reliable protection during shipping and handling. By utilizing wooden pallets and cases, Daelim Transformer safeguards their transformers against potential damage that could occur during transportation, ensuring that the products reach their destination in optimal condition.

Daelim Transformer ensures the safe transportation of their pole-mounted transformers by packing them in wooden pallets and wooden cases. These packaging materials provide sturdy and reliable protection during shipping and handling. By utilizing wooden pallets and cases, Daelim Transformer safeguards their transformers against potential damage that could occur during transportation, ensuring that the products reach their destination in optimal condition.

Different capacities and voltage levels of pole-mounted transformers are accompanied by varying heights, weights, and installation capacities within a 40HQ cabinet. The following table provides an overview:

15 kVA & 25 kVA pole-mounted transformer: Approximately 70-80 units can be accommodated.

50 kVA pole mounted transformer: Up to 60 units can be installed.

75 kVA pole mounted transformer: Approximately 32 units can be accommodated.

100 kVA pole mounted transformer: Around 28 units can be installed.

167 kVA pole mounted transformer: Up to 20 sets can be accommodated.

250 kVA pole mounted transformer: Approximately 15 units can be installed.

250 kVA pole mounted transformer: Approximately 15 units can be installed.

333 kVA pole mounted transformer: Approximately 10-12 units can be accommodated.

It's important to note that precise installation capacities may vary based on factors such as specific transformer design, dimensions, and any additional requirements.For accurate and detailed information regarding the installation capacities, dimensions, and specifications of pole-mounted transformers, it is recommended to contact Daelim Transformer.

Pole-mounted transformers are commonly transported by sea due to their size and weight. The estimated shipping durations for different routes are as follows:

Port of Shanghai, China to Vancouver: Approximately 15 days.

Port of Shanghai, China to Houston: Approximately 28 days.

Port of Shanghai, China to Panama: Approximately 30 days.

Port of Shanghai, China to Honduras: Approximately 40 days.

Please note that these are approximate durations and can vary depending on factors such as weather conditions, shipping schedules, customs clearance, and other logistical considerations.

Pole Mounted Transformer Key Craft

1. Magnetic circuit design

The iron core's shape, size, hysteresis, and eddy current loss are important factors to consider. Properly designing the magnetic circuit can lead to efficient energy transmission and reduced loss.

2. Winding design

Factors such as the number of turns, wire material, interlayer insulation, and wiring method should be taken into consideration during the design process. By implementing a well-planned winding design, the transformer can achieve greater load capacity and reliability.

3. Insulation material selection

Choosing the right insulation materials is paramount to ensure safety and longevity. It's essential to opt for insulating materials that offer excellent insulation performance, high-temperature resistance, arc breakdown resistance, and moisture resistance.

4. Vacuum oil filling

Single-phase pole-mounted transformers typically utilize a vacuum oil filling method. This involves treating the transformer chips with a vacuum, injecting insulating oil, eliminating air bubbles, and sealing the transformers. The vacuum oiling process is beneficial as it enhances the insulation performance and thermal stability of the transformer, leading to prolonged service life.

5. Heat treatment

Transformers' mechanical properties and strength can be enhanced through heat treatment. This process alters the material's organizational structure, boosting its hardness and wear resistance while reducing stress and deformation.

Single Phase Pole Mounted Transformer Iron Core & Character

The iron core material of the single-phase transformer is a cylindrical structure formed by winding silicon steel sheets with high silicon content and coil (aluminum wire or copper wire).

The iron core is the main body of the transformer, which consists of two parts: the iron core post and the iron yoke. Among them, the iron core post is used to wind the coil, and the iron yoke closes the magnetic circuit.

The windings generate magnetic flux, and the induced flux generates current. The winding is also called the coil, and it is the carrier of the current.

The iron core, windings and insulated leads, etc. constitute the body, and the body and insulating oil are placed in the oil tank. It forms a single-phase transformer with high and low-voltage bushings and other instruments.

It is characterized by single-phase transformers both primary and secondary. Three single-phase transformers of the same capacity can form a three-phase transformer, but the cost will be higher than that of a three-phase distribution transformer

In terms of volume, it is smaller than a three-phase transformer, so it can save materials when manufacturing, not only can reduce the amount of iron but also reducing the amount of copper.

In terms of weight, single-phase transformers are light in weight and easy to install on utility poles, that is, pole-mounted installations, which are suitable for rural areas with small areas. And because of its simple structure, it can be produced in large quantities, which greatly improves production efficiency.