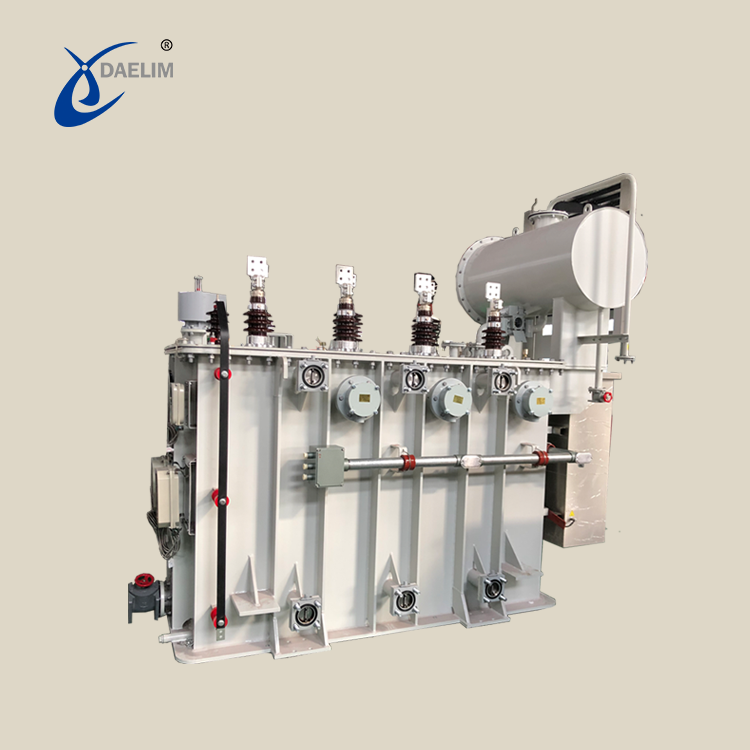

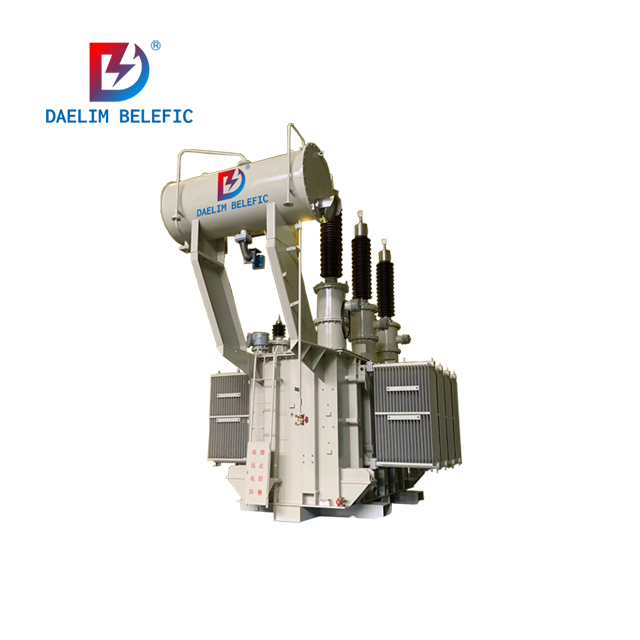

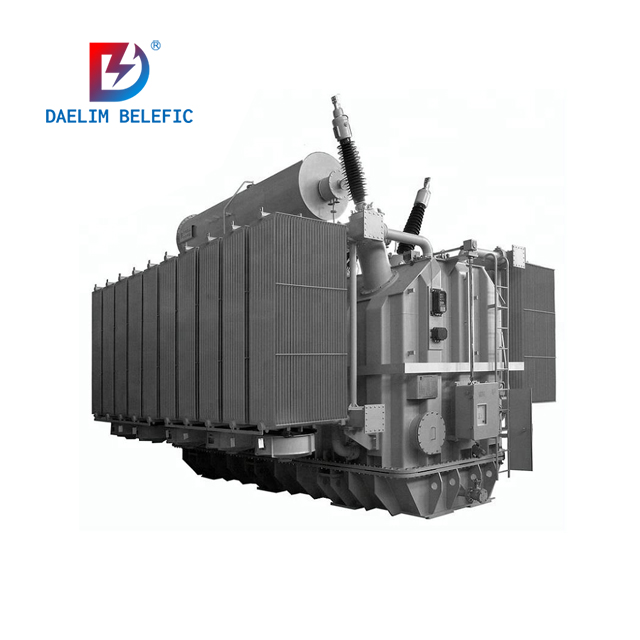

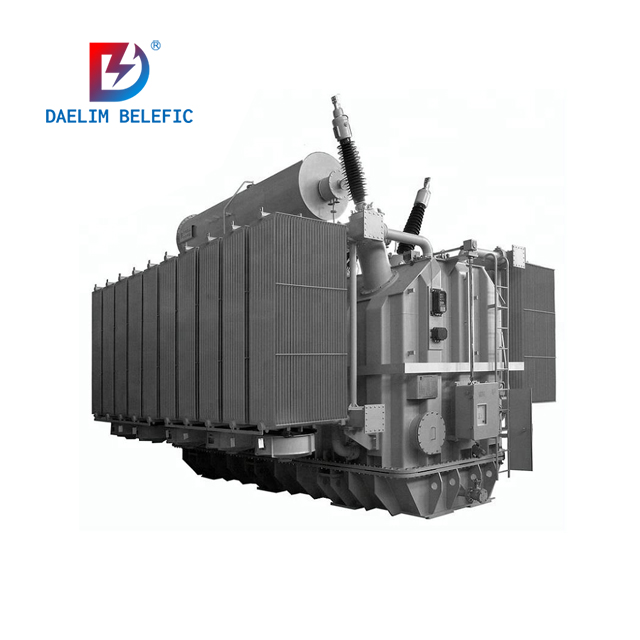

230 kV 220kv Power Transformer

- Primary Voltage Ratings: 220 kV, 230 kV or others

- Secondary Voltage Ratings: 69/35/37/34.5/26.4./11/10.5/6.6/13.2 kV or others

- H.V. TAP RANGE: ±8×1.25% or others

- CONNECTION TYPE: YNd11 or others

- TYPE: Oil immersed

- BIL: up to 900 kV

- Standards: IEEE, CSA, IEC

- Application: Substation, transmison line

- Power Rating: 10MVA, 12.5MVA, 15MVA, 18MVA, 20MVA, 25MVA

Daelim 220kV 230 kV transformers are according to international standard1. GB 6451 Specification and technical requirements for oil-immersed power transformers;2. IEC 60076 Power Transformers;3. AS NZS 60076 Power Transformers;4.CSAC88-16 Power Transformers;5. ANSI/IEEE C57.12.00 IEEE Standard for General Requirements for Liquid-Immersed Distribution, Power, and Regulating Transformers;6. GOST R 52719 Power Transformers - General Specifications; 7. EN60076 Power Transformes8. Local After-Sales Services In North America South America and other regions respond to your needs within 24 hours. etc, the power ratings are up to 270 MVA, and for voltages up to the highest insulation class of 900 kV.

Quote Now

230 kV Transformer

The S-10/12.5/15-230/26.4(13.2) stands as a meticulously crafted HV transformer from Daelim Transformer. It with a primary voltage of 230 kV and a secondary voltage of 26.4/13.2 kV, offering power ratings of 10 MVA, 12.5 MVA, and 15 MVA. This 230 kV power transformer application in Nevada, USA, plays a pivotal role in enhancing power transmission within the region, exemplifying Daelim Transformer's commitment to sustainable power solutions.

Distinguished by its KNAN/KNAF/KNAF cooling system, it relies on environmentally friendly and biodegradable vegetable oil as its insulating liquid. This transformer also employs forced air cooling with two stages, with a one-stage power rating of 12.5 MVA and a two-stage rating of 15 MVA.

It features an ingenious sealed tank design, further complemented by an oil preservation system, ensuring heightened performance and longevity.

More about Power TransformerDaelim Transformer Solutions

An experienced and efficient communication engineer, purchasing and sales team to connect with customers.

- Professional communication

- From transformer design to production, Daelim Transformer's engineers and their partners with customers have repeatedly communicated with each other on the requirements of 230 kV transformer standards, parameters, and accessories to ensure that they meet the requirements of IEEE.

- Customized design as per special requirements

- Based on years of experience in the IEEE/ANSI standard overseas market, Daelim Transformer's power transformer engineer team has improved and optimized their existing oil tanks and paint processes to meet the special technical requirements of customers.

- Business support team assistance

- Daelim Transformer's business support team has closely collaborated with the customer's logistics team. Daelim Transformer always pays attention to every detail of sea and land transportation and monitors the entire transportation process through the installation of impact recorders. Ultimately, the 230 kV transformer is safely transported to the site.

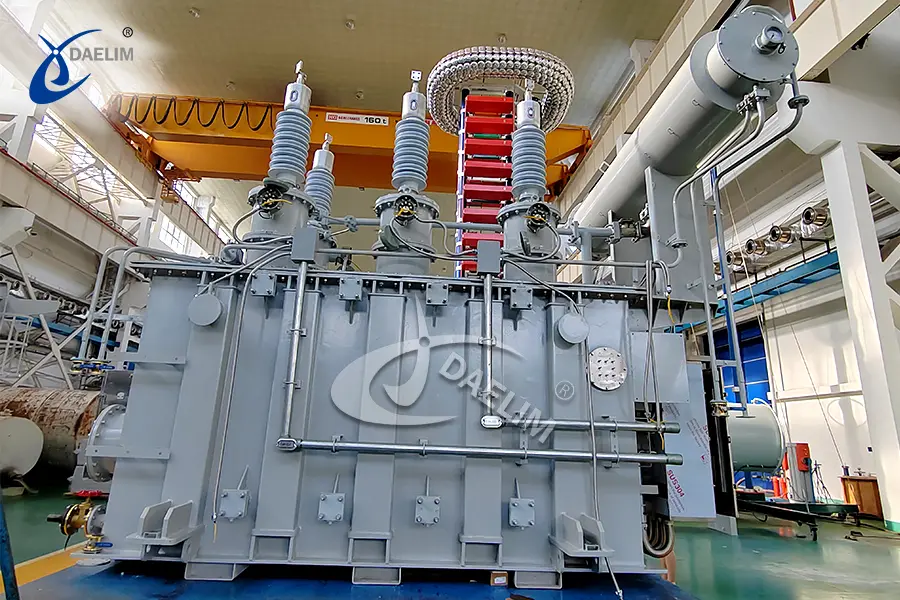

230 kV Transformer Production Process

230 kV Transformer Windings

230 kV Transformer Body

230 kV Silicon Steel Sheet

230 kV Transformer Shipping & Installation

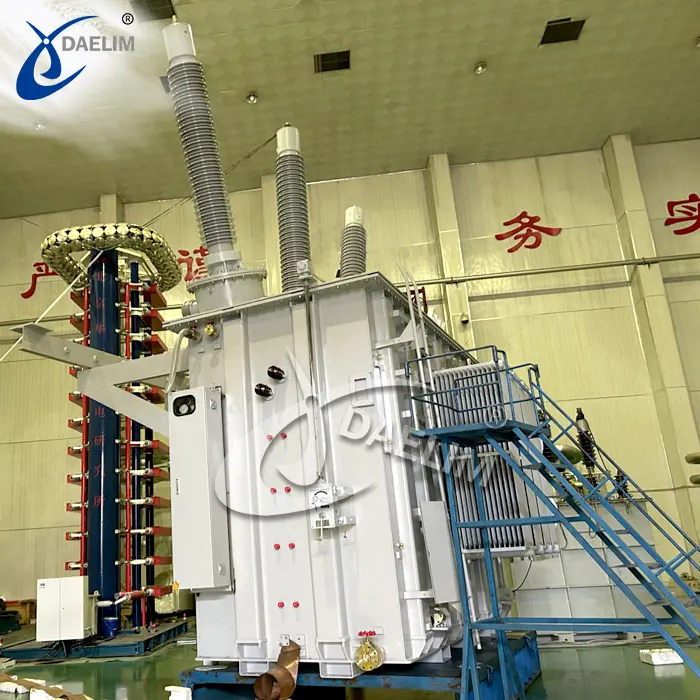

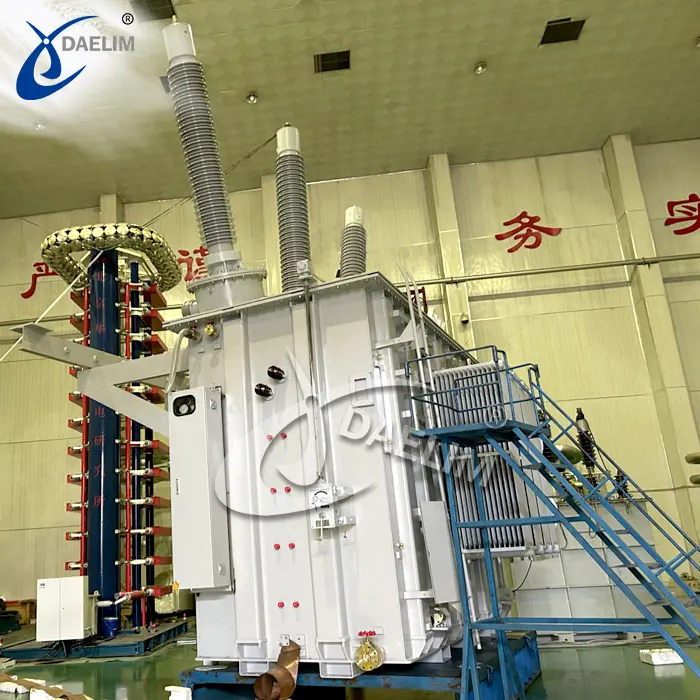

230 kV Transformer Test

This transformer has successfully undergone comprehensive testing in accordance with IEEE C57.12.00 and IEEE C57.12.90 standards, with all tests passed at one time.

- Ratio, Polarity, and Phase Relation Tests: Verified and validated.

- Winding Resistance Measurement Tests: Conducted and confirmed.

- Insulation Power Factor: Checked and met the required specifications.

- Full Wave and Reduced Wave Impulse Test: Completed and found to be within acceptable parameters.

- Applied and Induced Potential Tests: Successfully performed, meeting stipulated criteria.

- No-Load Losses at Rated Current: Tested and found to meet standards.

- Total Losses at Rated Current: Tested and confirmed as per the prescribed guidelines.

- Percent Impedance at Rated Current: Measured and found to be in compliance with requirements.

- Dissolved Gas Analysis (DGA) Test: Conducted and results are satisfactory.

- Leak Test: Performed and validated.

- Control Cabinet Test: Carried out and met the necessary criteria.

This comprehensive series of tests assures the quality and reliability of the transformer.

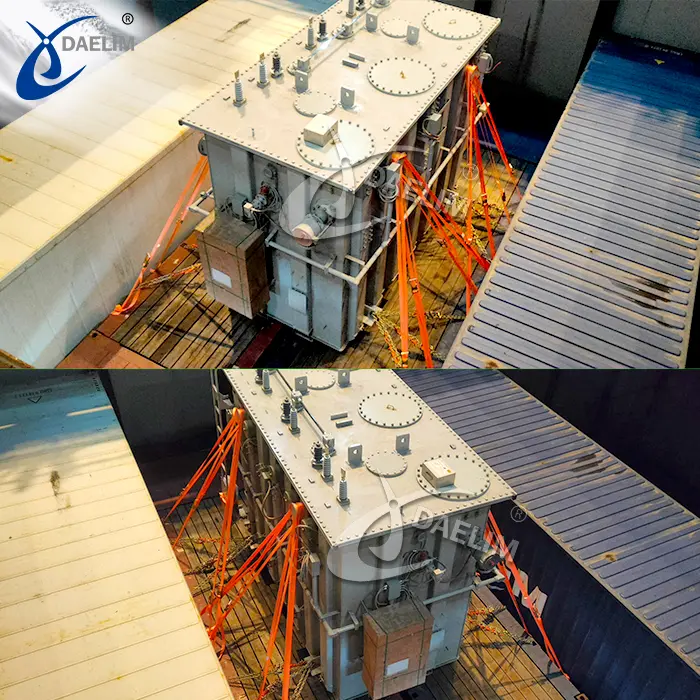

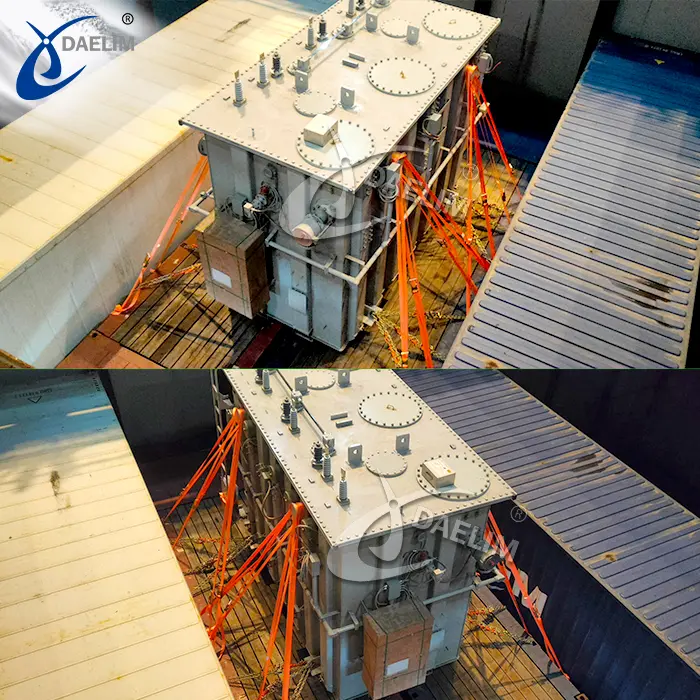

Send Inquiry Now230 kV Transformer Shipping

Daelim Transformer boasts over 20 years of experience in transformer manufacturing and export, making them highly adept in the intricacies of transformer packaging and transportation.

In the case of 230 kV power transformers, with dimensions exceeding three meters in height and a weight surpassing 50 tons, it is common practice to disassemble high-voltage bushings, radiators, fans, and other accessories. Subsequently, the transformer body and these removable components are shipped separately.

Daelim Transformer employs specialized open-top containers to securely house the transformer body, while the detachable accessories are meticulously packed in wooden crates, ensuring their safe transport via a separate container.

Contact Daelim Transformer

Installation and Customer Feedback

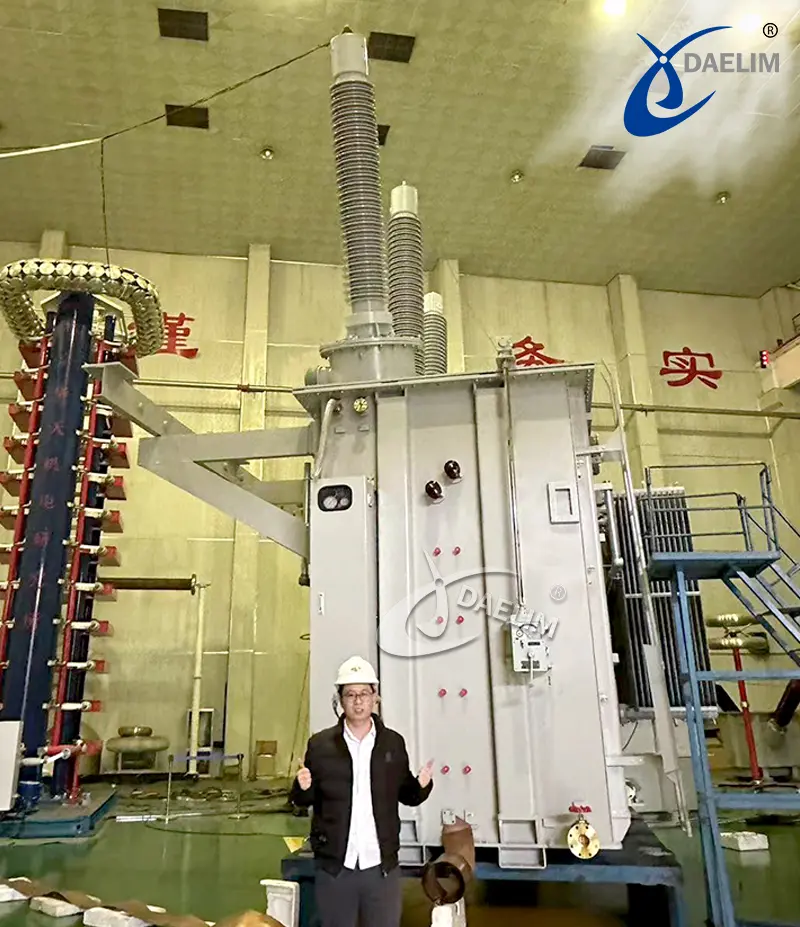

Displayed below is an image of the transformer installation provided by the customer. Upon receiving the transformer, the customer expressed their utmost satisfaction with various aspects. They noted the overall completeness and aesthetics of the transformer's appearance, indicating their contentment.

Furthermore, the transformer underwent performance testing, aligning fully with IEEE standards or, in some aspects, even surpassing the standard requirements, which pleasantly surprised the customer. They also lauded Daelim Transformer's professional team for their technical expertise, business acumen, effective communication, and exceptional after-sales service. Collaborating with Daelim Transformer proved to be a seamless and swift experience for the customer.

The extensive project experience and professional competence of Daelim Transformer significantly enhanced their competitiveness. The customer has expressed their commitment to maintaining a close and enduring partnership with Daelim Transformer.

Get PriceDaelim Transformer

Overseas Project Cases

This 10MVA 230 kV Power transformer is for bitcoin mining in Houston. It was manufactured in our factory in Jiangsu Province and it complies with IEEE standards.

This 20/30MVA 220 kV power transformer was manufactured for a power station in Ecuador.

Daelim 220 kV/230 kV transformer, use Japanese Toshiba analysis software and our company's special calculation and validation procedures for the transformer core, winding, implement body, lead, fuel tanks, etc. Parts of the optimal design and carrying on the Omni-directional validation, ensure product performance. Superior process equipment, elaborate material selection, and efficient manufacturing make the transformer have small volume, lightweight, low loss, low partial discharge, low noise characteristics. The product quality is superior, energy conservation and environmental protection, easy installation and maintenance, reliable operation, and effectively reduced product running costs.

Daelim offers transformer solutions such as high efficiency, environmentally friendly, maximum short-circuit strength, overload capability, high-temperature operation, reliable start-up after a power outage, and low maintenance costs solutions, applied in renewable projects, urban substations, utilities, industrial applications, etc.

Daelim Advantages

• Prompt preparation of bids

• Optimized, consistent end-to-end project management

• Noticeably shorter production and delivery times

• Very high delivery reliability

• Fast, standardized documentation

• Just-in-time delivery

220kV/230kV Transformer Details

Core Assembly

The iron core of the 220kV/230kV power transformer is made of cold rolled, granular-oriented, low-loss, and high magnetic conductive silicon steel sheet, which is of multi-step completely tilted structure to reduce the loss and noise.

Iron core with fixed clamps optimizes the design so as to ensure mechanical strength and reduce leakage losses.

The adoption of PET banding structure ensures the damp force of the core column and lowers the noise.

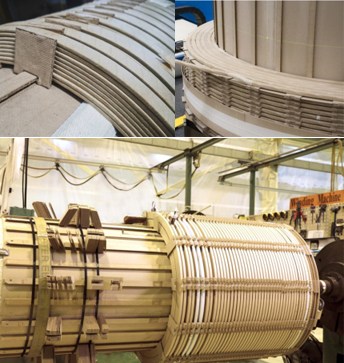

Coil Winding

Daelim 220kV and 230kV transformer HV winding adopt entanglement or inner screened continuous type with phase insulation structure to ensure insulating strength.

MV/LV windings adopt high strength or adhibit-transposition conductors and forced cooling to reduce the temperature rise and enhance the capability of short circuit withstand.

Interleaved, shielded disc, helical, disc, or layer construction (depending on voltage and impulse rating)

Active- parts Assembly

Cold pressing ensures the cleanness of the body's active parts and the reliability of leads.

Daelim 220kV and 230kV transformer uses the entire assembly and insulation material to reduce the assembly time and effectively ensure the size and shape of the insulating structure.

HV lead adopts specially molded insulation parts for protection which effectively guarantees its insulating strength and reduces partial discharge.

Vapor phase

Daelim's modern vapor phase system is the quickest and most effective way to dry transformers.

This process ensures the perfect drying of the 220kV transformer, which brings a longer transformer life. Compared with non-steam, the drying of steam will also be reduced by more than 50 %.

Passing this time savings along the production schedule results in quicker delivery.

Oil Tank

The 220 kV 230 kV transformer fuel tank uses the three-dimensional finite element strength analysis and Pro-E mold, which enhances mechanical strength.

Adopting of welding automatic submerged arc-welding and ultrasonic fluorescence leakage test to guarantee leakage-free.

The surface coating is strictly controlled.

Laboratory Test

220 kV 230 kV transformers testing according to ANSI / IEEE C57.12 I IEC 60076 Standards.

Oil Laboratory

The oil in 220KV 230KV Transformer is based on ASTMD-3487 /2002 / IEC 60296 / IEEE C57.106-2002 / IEC 60422 standards for physical and chemical analysis and chromatography.

220 kV transformer specification

| Three-phase three winding non-field excitation changer self-coupling power transformer | |||||||

| Rating (kVA) | Voltage Combined | Step up Combination | Step Down Combination | ||||

| HV(kV) | MV(kV) | LV(kV) | No Load Loss | Load Loss | No Load Loss | Load Loss | |

| 31500 kVA | 220±2

| 115 121 | 6.6 10.5 11 35 37 38.5 | 25 | 117 | 22 | 99 |

| 40000 kVA | 29 | 144 | 26 | 121 | |||

| 50000 kVA | 34 | 170 | 30 | 144 | |||

| 63000 kVA | 40 | 201 | 36 | 171 | |||

| 90000 kVA | 50 | 276 | 46 | 234 | |||

| 120000 kVA | 10.5 11 13.8 15.75 18 35 37 38.5 | 62 | 340 | 56 | 288 | ||

| 150000 kVA | 73 | 405 | 66 | 342 | |||

| 180000 kVA | 84 | 463 | 76 | 387 | |||

| 240000 kVA | 99 | 595 | 89 | 504 | |||

| Three-phase duplex winding power transformer on load changer | ||||||

| Rating (kVA) | Voltage Combined | No Load Loss | Load Loss | No Load current | Short-circuit impendance | |

| HV(kV) | LV(kV) | |||||

| 31500 kVA | 220±8

230±8

| 6.3 6.6 10.5 11 35 37 38.5 | 38 | 135 | 0.7 | 12-14 |

| 40000 kVA | 45 | 157 | 0.63 | |||

| 50000 kVA | 54 | 189 | 0.56 | |||

| 63000 kVA | 63 | 220 | 0.56 | |||

| 90000 kVA | 80 | 288 | 0.49 | |||

| 120000 kVA | 10.5 11 35 37 38.5 | 99 | 346 | 0.49 | ||

| 150000 kVA | 116 | 405 | 0.42 | |||

| 180000 kVA | 135 | 468 | 0.42 | |||

| 120000 kVA | 66 69 | 102 | 355 | 0.49 | ||

| 150000 kVA | 120 | 415 | 0.42 | |||

| 180000 kVA | 140 | 475 | 0.42 | |||

| Three phase three winding power transformer on load changer | ||||||

| Rating (kVA) | Voltage Combined | No Load Loss | Load Loss | No Load current | ||

| HV(kV) | MV(kV) | LV(kV) | ||||

| 31500 kVA | 220±8

230±8 | 69 115 121 | 6.6 10.5 11 35 37 38.5 | 44 | 162 | 0.77 |

| 40000 kVA | 52 | 189 | 0.7 | |||

| 50000 kVA | 60 | 225 | 0.63 | |||

| 63000 kVA | 70 | 261 | 0.63 | |||

| 90000 kVA | 10.5 11 35 37 38.5 | 92 | 351 | 0.56 | ||

| 120000 kVA | 115 | 432 | 0.56 | |||

| 150000 kVA | 135 | 513 | 0.49 | |||

| 180000 kVA | 156 | 630 | 0.49 | |||

| 240000 kVA | 193 | 780 | 0.45 | |||

220 kV Power Transformer Standard Features

| Capacity range:Through 60 MVA (ONAN), with high-voltage ratings through 230 kV (900 kV BIL) Service Location: Outdoor Core: Regular grain-oriented; mitered cruciform with step-lap construction Coils: Cylindrical construction; all copper windings, custom tempered per design requirements; circular windings with the rectangular or continuously-transposed conductor; helical low-voltage windings; continuous disc medium-voltage windings; shielded disc high-voltage windings Radiators: Detachable panel type with shut-off valves; mild steel Insulating oil: mineral oil typeⅠ& type Ⅱ Tank Cover: Welded, Bolted Manholes: On cover or tank Tank Base: Flat bottom or Skid under the base Tank Material: Mid Steel Frequency: 60 Hertz Winding Tem rise: 55℃ HV Taps: DETC, ETC in tank or out − Above rated volts: 2 x 2-1/2% offload taps of full capacity | Below rated volts: 2 x 2-1/2% offload taps of full capacity Valve: Drain and Filter Valves, w/Sampler Lifting, Moving, and Jacking Facilities Pressure relief valve Magnetic oil-level indicator Dial-type oil temperature indicator Dial-type winding temperature indicator Dial-type sudden pressure relay Vacuum pressure gauge Paint: Exterior polyurethane enamel, ANSI 70 gray color; interior polyurethane enamel, white color HV bushing: IEEE segment 1-4, on the top cover or in Air Terminal Chamber. Porcelain Condenser, Solid Bulk, Solid Dielectric, Quick link LV bushing: IEEE segment 1-4, Cover mounted or in Air Terminal Chamber Porcelain Condenser, Solid Bulk, Solid Dielectric, Quick link Diagrammatic nameplate, engraved stainless steel Transformer lifting lugs Tank grounding pads |

Optional Accessories

Below are optional accessories for Daelim 220kV and 230kV transformers.

| Cooling: ONAN/ONAF, KNAN, KNAN/KNAF Insulating oil: Natural ester( FR3 Enviro Temp, RAPO etc) Frequency: 50 Hertz Average winding rise: 55°C or 55/65°C Future fan wiring and control Automatic pressure relief device Galvanized or stainless-steel radiators Fans Accessories with additional contacts Controls Cabinet: NEMA 3R, 4, 4X Customizable Colors HV lightning arresters: Distribution Class, Intermediate Class, Station Class Harmonic allowances up to k-20 Seismic designs: Zones 1-4 | Rapid Rise Relay Neutral Terminations Other Moving Facilities (Wheels) Nitrogen gas fluid preservation system Gas Test Valve Schrader Valve Junction Box Fiber-optic temperature measurements Line Dissolved Gas Monitor Bushing Mounted Current Transformers Fire Prevention System (SERGI) On-line monitoring system Electrostatic shield Special/low sound level Special environment (i.e: classified areas) Special paint for marine ambient |

Quality & Certification System

DAELIM BELEFIC transformer manufacturing processes are standardized under the norm of ISO 9001:2015 quality, allowing us to have greater control over the production

We offer a full range of testing compliant with ANSI C57.12 and CSA C88-M90 standards, as well as, specialty testing such as lightning impulse, sound, heat run, partial discharge, and SFRA.

| Tests | Transformer Class | |||

| Class I (≤ 69 kV) | Class II (115-765 kV) | |||

| Standard | Optional | Standard | Optional | |

| Winding resistance | • | • | ||

| Winding insulation resistance | • | • | ||

| Core insulation resistance | • | • | ||

| Ratio | • | • | ||

| Polarity and phase relation | • | • | ||

| Insulation power factor | • | • | ||

| Control (auxiliary) cooling losses | • | |||

| Single-phase excitation tests | • | • | ||

| Noload losses and excitation current | • | • | ||

| Impedance voltage and load losses | • | • | ||

| Zero-phase sequence impedance voltage | • | • | ||

| Temperature rise | • | • | ||

| Low-frequency dielectric tests | • | • | ||

| Low-frequency dielectric tests on axiliary devices | • | • | ||

| control, and current transformer circuits | • | • | ||

| Lightning impulse | • | • | ||

| Front of wave impulse | • | • | ||

| Swithing impulse | • | • | ||

| Partial discharge | • | • | ||

| Audible sound level | • | • | ||

| Operational tests (all devices) | • | • | ||

| Dissolved gases in oil | • | • | ||

| Leak test | ||||

Service & Support

DAELIM BELEFIC will work with you to identify your transformer needs and customize the solution. Once we know your exact requirements, our engineers will quickly recommend the right solution based on your specific needs.

Expertise&consulting&: To meet performance requirements we are able to incorporate short circuit strength improvements, kVA upgrades, voltage changes, reduced losses, LTC modernization, sound level reduction, and tank modification. Our engineering team responds fast to answer technical questions from our customers.

- Factory-to-Jobsite logistics support Delivery by ship and truck, the impact recorders measure and store three-axis impact data, identifying any abnormally severe impacts that might have caused damage to the transformer during transportation.

- On-Site Technical Assistance: In Assembly, Oil Treatment, Testing, and Commissioning (Energization) by an Engineer

- Training:by a Factory Specialist, about the operation and maintenance

- Repair: Our technicians replace gaskets, broken bushings, and accessories, purify or replace the oil, sand, prime, and repaint the unit. When complete, the unit is fully tested.

Related Products

Related Article