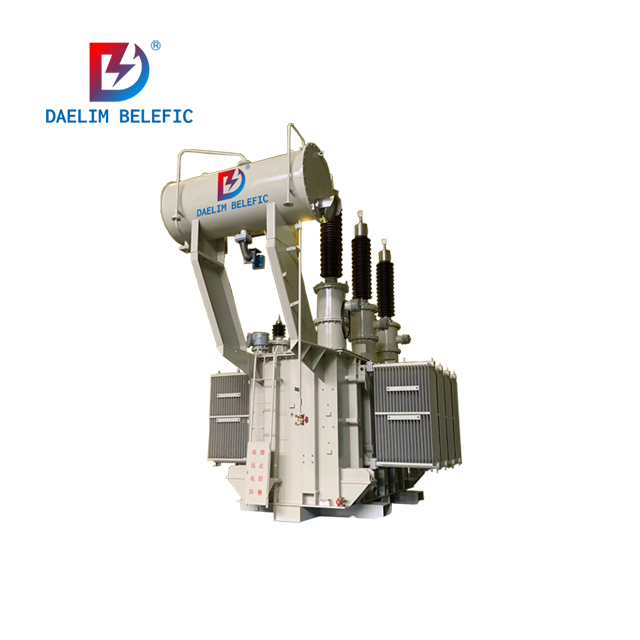

12 MVA Three Phase Power Transformer

- Primary Voltage Ratings: 38 kV

- Secondary Voltage Ratings: 13.2 kV

- CONNECTION TYPE: Dyn1

- TYPE: Oil Type

- BIL: 250/110kV

- Standards: ANSI C57

- Power Rating: 12 16 20MVA & 13.5 18 22.5MVA

- Certificate: UL

- Cooling Method: ONAN/ONAF1/ONAF2

The 12 MVA three-phase power transformer features a sealed tank structure and operates at a high voltage of 38 kV and a low voltage of 13.2 kV. It is meticulously designed and constructed in accordance with the ANSI C57 standard. Employing a two-stage air cooling system, this transformer ensures efficient heat dissipation.With a temperature rise specification of 55℃/65℃, the transformer is capable of achieving a rated capacity of 12 MVA at a 55℃ temperature rise, extendable up to 16 20 MVA. Similarly, at a 65℃ temperature rise, it boasts a rated capacity of 13.5 MVA, with the maximum capacity reaching 22.5 MVA.

Quote Now

12 MVA Power Transformer

The 12 MVA power transformer, meticulously designed and produced by Daelim Transformer, was exported to the United States and used for substations, delivered in the first half of 2024. Undergoing rigorous factory tests and FM tests, each transformer produced by us is subjected to stringent quality control measures, ensuring that every Daelim Transformer embodies the hallmarks of safety, reliability, and efficiency.

The transformer boasts a comprehensive protection design to safeguard against abnormalities during operation, effectively protecting both the transformer and associated load equipment from damage. All transformer gauges are monitored with contacts, triggering alarms in the event of abnormal conditions.

Contact Daelim TransformerProtection

Specifically, when the oil level in the tank deviates from the prescribed range, an alarm is promptly issued. Furthermore, the oil temperature indicator alarm system is activated if the oil temperature surpasses 85℃, with the trip system engaged at 105℃.

In instances where the transformer winding temperature exceeds 60℃, the first-stage fan is automatically initiated to initiate cooling. If the winding temperature exceeds 75℃, the second-stage fan commences operation for further cooling. However, if the winding temperature exceeds 115℃, the winding thermometer trip system is activated, automatically cutting off the power supply.

Moreover, the transformer is equipped with vacuum pressure and pressure relief equipment, capable of autonomously releasing internal pressure during abnormal conditions.

Get Price

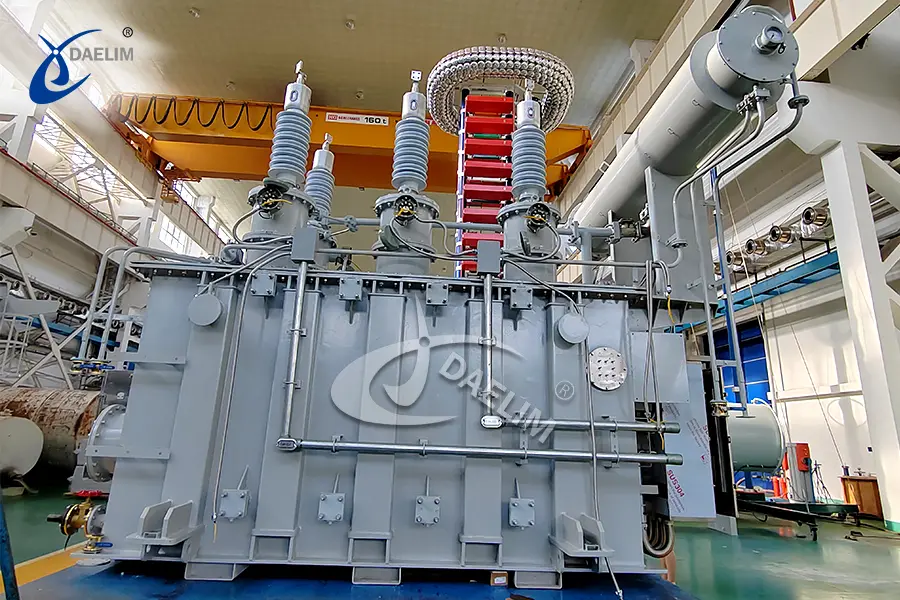

12MVA Power Transformer Picturers

Transformer coil, winding, radiator

Transformer Assembly

Transformer Testing

Testing Procedure

By IEEE Std C57.12.00 standards, the following tests are conducted:

- Appearance check

- Transformer oil test

- Measurement of dissolved gases in transformer oil

- Measurement of voltage ratio and verification of phase displacement

- Measurement of winding resistance

- Measurement of DC insulation resistance between each winding to earth and between windings

- Check of core and frame insulation for liquid-immersed transformers with core or frame insulation

- Measurement of determination and dissipation factor of the insulation system capacitances

- Measurement of no-load loss and current

- No-load current harmonics measurement

- Measurement of short-circuit impedance and load loss

- Lightning impulse test

- Applied voltage test

- Induced voltage withstand test

- Induced voltage test with partial discharge (PD) measurement

- Determination of sound levels

- Temperature rise test

- Measurement of frequency response

- Auxiliary wiring insulation test

- Verification of the ratio and polarity of built-in current transformers

- Leak testing with pressure for liquid-immersed transformers

- Inspection and function test of the control circuit

FAQ

Daelim Transformer offers a comprehensive range of medium and high voltage transformers. Medium voltage transformers are available up to 15 MVA and 46 kV, encompassing pad-mounted transformers, substation transformers, pole-mounted transformers, and Eco-design Tier 2 transformers. High voltage transformers extend up to 345 kV and 500 MVA.

The production timeline for medium voltage transformers typically ranges from 8 to 14 weeks, while high voltage transformers require approximately 24 to 36 weeks for production.

Our services encompass customization, design, production, installation, repair and maintenance, refurbishment, testing, and on-site support. Our professional team is committed to delivering tailored transformer solutions to suit your industry needs.

We offer a warranty period of 2 to 5 years for each transformer.

Our transformers hold certifications including UL, cUL, CE, CESI, CSA, FM, SGS, and ISO, among others.

Daelim Transformer warmly welcomes you or third-party representatives to visit and inspect our factory at any time. Additionally, we provide online video factory inspection services and facilitate test witnessing to ensure transparency and quality assurance.

Related Products

Related Article