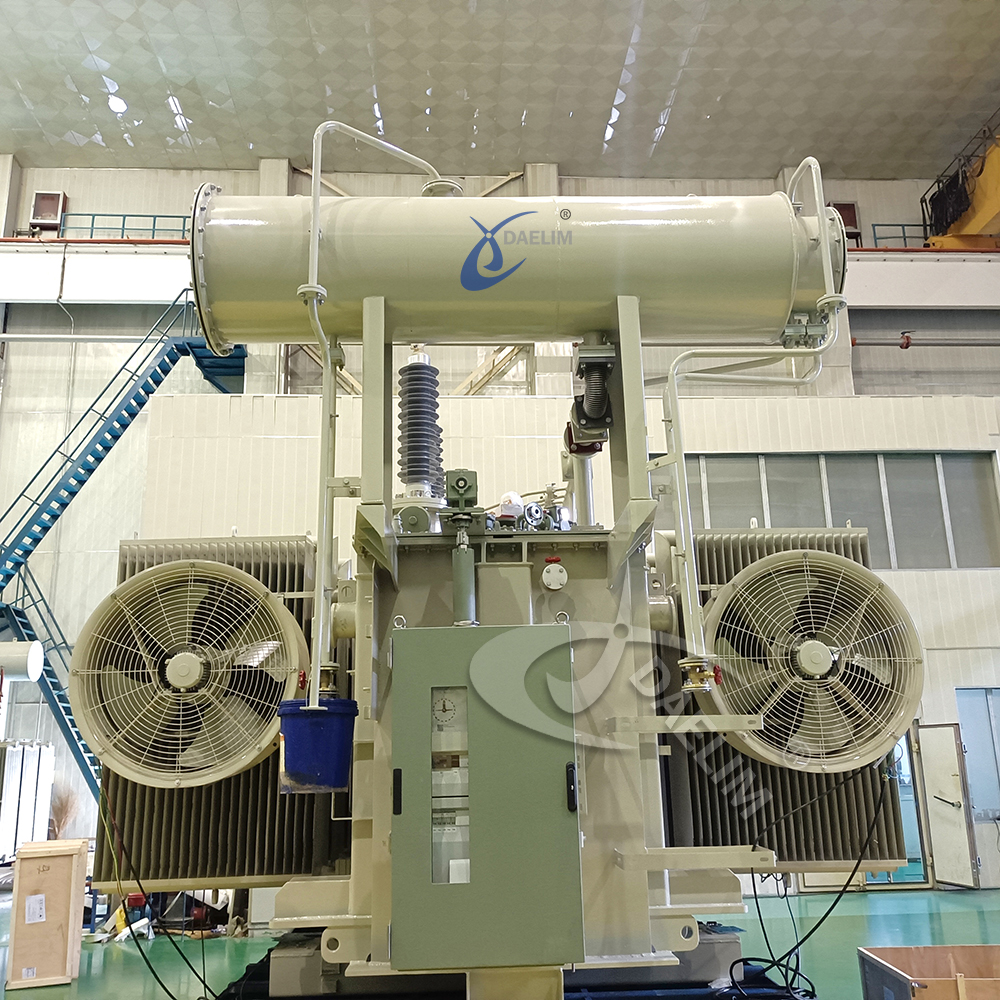

33/44/55 MVA Power Transformer

- Primary Voltage Ratings: 138kV/34.5kV; 69kV/34.5kV

- Secondary Voltage Ratings: 13.8kV

- TYPE: 3-phase,3-winding, oil-immersed construction with a conservator

- BIL: 500/200/125kV; 350/200/125kV

- Standards: IEEE/ANSI/NEMA

- Application: solar power project

- Power Rating: 33MVA, 44MVA, 55MVA

- Cooling Method: ONAN/ONAF1/ONAF2

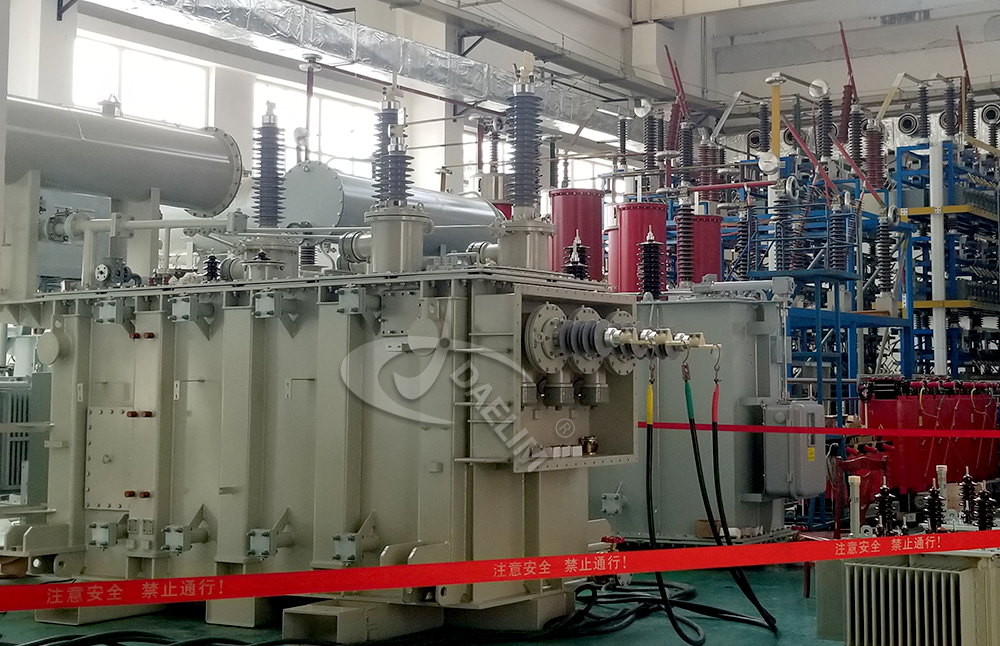

Daelim Transformer provided two 33/44/55 MVA step-up power transformers for a U.S. solar project in 2024. Each transformer features a three-phase, three-winding, oil-immersed design with a conservator. They offer capacities of 33 MVA (self-cooled), 44 MVA (Stage 1 cooling fan), and 55 MVA (Stage 2 cooling fan). Constructed with copper windings and high-quality silicon steel, they use ASTM D3487-compliant mineral oil. Equipped with various accessories and tested per IEEE standards, they come with an 24-month warranty from manufacture .

Quote Now

In 2024, Daelim Transformer provided two 33 MVA / 44 MVA / 55 MVA step-up power transformers for a solar power project in the United States. The design and construction of these transformers comply with IEEE standards and relevant regulations. Both transformers feature a three-phase, three-winding, oil-immersed construction with a conservator.

Transformer Specifications:

-

Transformer 1:

- High Voltage: 138 kV

- Medium Voltage: 34.5 kV

- Low Voltage: 13.8 kV

-

Transformer 2:

- High Voltage: 69 kV

- Medium Voltage: 34.5 kV

- Low Voltage: 13.8 kV

Both transformers are equipped with a two-stage forced air cooling system:

- Self-Cooling Capacity: 33 MVA

- One Fan Operating (ONAF1): 44 MVA

- Two Fans Operating (ONAF2): 55 MVA

Construction Details:

- Windings: Copper

- Core Material: High-quality, low-loss cold-rolled silicon steel

- Insulation Liquid: Mineral oil, compliant with ASTM D3487 standards

- Bushings: Top cover design, porcelain type, ANSI Segment 2 Number, ANSI 70 Gray

- Oil Preservation System: Conservator

Environmental Conditions:

- Location: Harrington, DE

- Site Elevation: 60 ft

- Ambient Temperature Range: Minimum -20°F, Maximum 110°F

- Weather/Load Criteria:

- Radial Ice Buildup: 0.5 in

- Wind Speed: 100 mph

- NESC Loading District: Heavy

- Contamination per IEEE C57.19.100: Heavy

Instrument Transformers:

- High Voltage Bushing CTs

- High Voltage Neutral Bushing CT

- Low Voltage Bushing CTs

- Low Voltage Neutral Bushing CTs

- Tertiary Winding

- ANSI Accuracy Class: C400

Arresters:

- High and low voltage stations class porcelain arresters, ANSI 70 Gray

Accessories:

- Liquid-Level Indicator

- Liquid-Temperature Indicator

- Winding-Temperature Indicator

- Pressure-Relief Device

- Rapid Pressure Rise Relay

- Buchholz Relay

- Pressure-Vacuum Gauge

- Pressure-Vacuum Bleeder

- Pressure Test and Gas Sampling Valve

- Drain and Filter Valves

- Removable Radiators and Isolation Valves

- Transformer Monitoring System

- Dry Air Fill Valve

Testing:

All routine tests as per Table 21, C57.12.00, and accompanying notes, in accordance with methods and procedures outlined in C57.12.90, including:

- Insulation Power Factor Test

- Audible Sound Level Test

- Insulation Resistance Test by Megohmmeter

- Core-Ground Resistance Test

- Temperature Rise Test

- Positive and Zero Sequence Tests

- Short-Circuit Tests

- Seismic Tests

- Sweep Frequency Response Analysis

- Dissolved Gas-in-Oil Analysis

- Front-of-Wave Impulse Tests

- Switching Impulse Tests

- Partial Discharge (PD) and Radio Influence Voltage (RIV)

Preparation for Shipment:

- Radiator cooling units are crated securely for protection, with silica gel bags installed inside each radiator to absorb moisture. Bags must be affixed securely to a ring weld inside blank-off covers.

- Heavy parts are placed on skids for handling, securely boxed, and identified by content.

- Exterior electrical receptacles are covered for protection.

- Hollow external bracings have drain holes.

- Transformers are equipped with a GPS travel recorder to register shocks in three dimensions: travel direction, vertical, and transverse side-sway.

Transformer Shipping:

- Transformers are filled with dry nitrogen.

- The shipping marker indicates pressure and temperature when sealed for shipment.

- A pressure gauge is mounted on the transformer to show tank pressure upon receipt by the buyer.

- Draw leads for HV bushings are tied to suitable clips welded to the underside of shipping covers over bushing openings.

Warranty:

- 24months from the date of manufacture .