25 MVA Transformer

- Primary Voltage Ratings: 24.5 kV

- Secondary Voltage Ratings: 14.4 kV

- H.V. TAP RANGE: 23275V, 23887.5V, 24500V, 25112.5V, 25725V

- CONNECTION TYPE: Dyn1

- TYPE: 3 Phase Power Transformer

- BIL: 125/95kV

- Standards: IEEE C57

- Application: Factory

- Power Rating: 25000kVA & 30000kVA

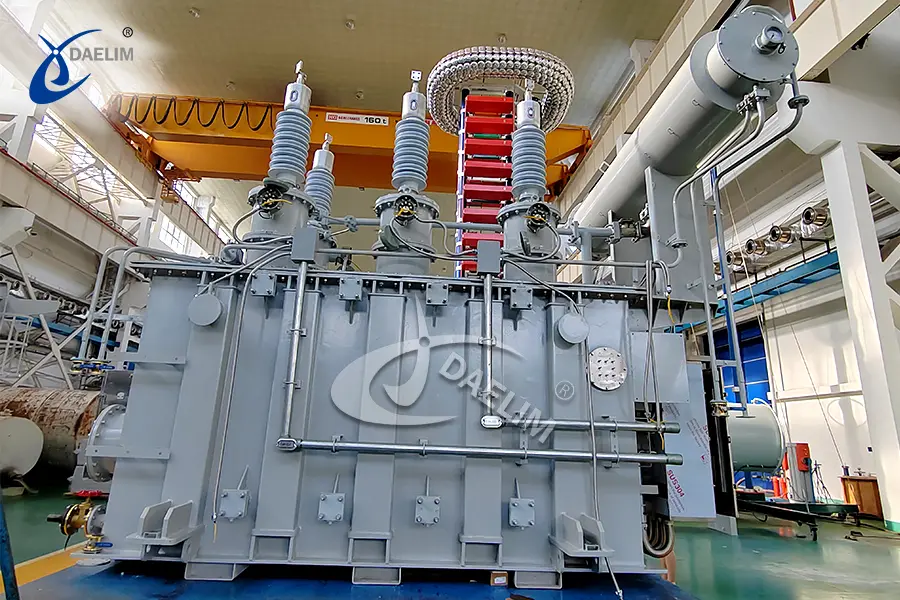

- Cooling Method: ONAN/ONAF

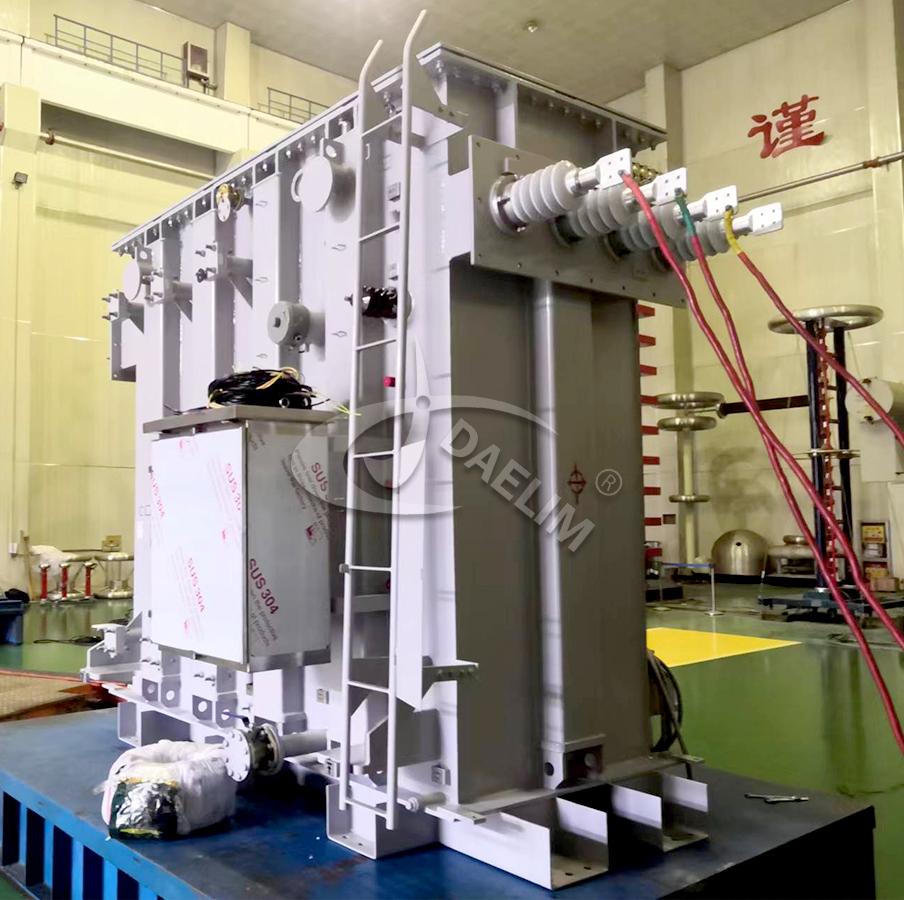

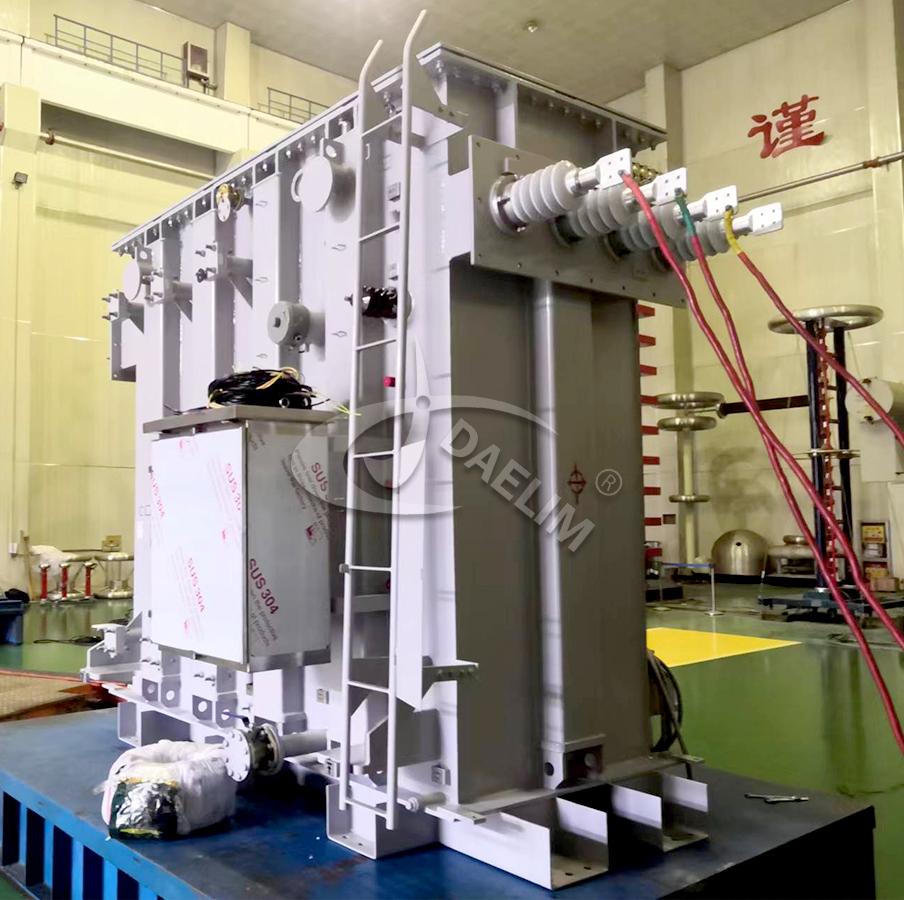

In November 2023, Daelim Transformer delivered a 25 MVA, 24.5 kV power transformer for a relatively large aerospace industry factory in the United States. This oil-immersed, IEEE C57-compliant transformer features copper windings, a Dyn1 connection, and operates at a temperature rise of 65ºC. It can achieve 25 MVA self-cooled and 30 MVA with fan assistance. The transformer includes advanced monitoring and protection features and is shipped disassembled to ensure safe transportation.

Quote Now

In November 2023, Daelim Transformer completed the production and testing of a 24.5 kV, 25 MVA power transformer, which has been ordered by a US customer for use in a relatively large aerospace industry factory in the USA.

In November 2023, Daelim Transformer completed the production and testing of a 24.5 kV, 25 MVA power transformer, which has been ordered by a US customer for use in a relatively large aerospace industry factory in the USA.

The picture below shows the 25MVA Transformer that has been installed and is operating normally.

This 25 MVA power transformer is designed and manufactured in accordance with the IEEE C57 standard. It features an oil-immersed sealed structure. The primary voltage is 24.5 kV with a Delta connection, while the secondary voltage is 14.4 kV with a Wye connection. The connection group is Dyn1. Both the primary and secondary windings are made of copper. The transformer is designed with a temperature rise of 65ºC. It can achieve a power rating of 25 MVA under self-cooling conditions, and up to 30 MVA when the first-stage fan is activated. The high voltage (HV) and low voltage (LV) bushings are porcelain. The transformer uses Mineral Oil Type II for insulation, meeting ASTM D3487 standards.

Specifications:

-

Rated Capacity: 15/20 MVA

-

Temperature Rise: 65°C

-

Cooling: ONAN / ONAF

-

Rated Frequency: 60 Hz

-

Rated Voltage:

-

Primary: 24,500 V, Delta connection, ±2.5%, 5 taps

-

Secondary: 14,400 V, Wye connection

-

-

Connection Group: Dyn1

-

Short Circuit Impedance at Base 25 MVA: 8%

-

BIL:

-

Primary: 125 kV

-

Secondary: 95 kV

-

-

Dimensions: 4550 mm x 2109 mm x 2950 mm

-

Weight: 84,800 lbs

Terminal Chambers:

-

High Voltage Terminal Chamber: Features three sidewall-mounted bushings with 4-hole NEMA terminal pads. Cable entry is from the bottom.

-

Low Voltage Terminal Chamber: Features four sidewall-mounted bushings with 4-hole NEMA terminal pads. Cable entry is from the bottom.

Accessories:

-

Oil Temperature Indicator: Equipped with four contacts—two for controlling fan start/stop and two for alarming/tripping. Alarms are triggered at 95°C, and tripping occurs at 105°C to protect the transformer and its electrical components.

-

Winding Temperature Indicator: Includes four contacts—two for controlling fan start/stop and two for alarming/tripping. Alarms are triggered at 105°C, and tripping occurs at 115°C to protect the transformer and its electrical components.

-

Oil Level Indicator: Includes alarm contacts for high and low oil level conditions.

-

Fans and Blowers: The fan automatically starts when the oil temperature reaches 55°C and stops when it falls below 45°C.

-

Pressure Relief Device

-

Vacuum Pressure Gauge

-

Drain and Oil Sampling Valve

-

Terminal Control Box: Includes alarms, trips, analog signals, CTs, and all necessary equipment for fan control.

Delivery Information

Due to its relatively large size, the transformer must be disassembled for transportation. Components such as the heat sink, fan, and coolant are disassembled and packed in wooden boxes. The main transformer body is transported in a frame cabinet, with impact recorders installed on both sides to monitor any potential damage during shipment. The terminal control box is also enclosed in a wooden box to prevent damage during transit. The transformer body is secured with steel cables and wrapped tightly with thick rainproof cloth to protect against moisture, salt, and other harsh conditions during sea transportation.

DAELIM TRANSFORMER

Daelim Transformer is a leading UL/CUL certified manufacturer in China, renowned in the USA and Canadian markets. We export over 5,000 units annually to North America and Europe, including power transformers, pad-mounted transformers, pole mounted transformers and Ecodesign Transformers. Our factory supports capacities up to 230 kV and 280 MVA. We excel in the Renewable Energy sector (BESS, Solar, Wind), Bitcoin/Utility market, data centers, and the oil and gas industry, partnering with numerous Fortune 500 companies.

In addition to our Chinese facility, we operate a facility in Houston, TX, with over 500 transformers in stock at both locations. For after-sales support, our local team is ready to assist with commissioning, supervision, testing, diagnostics, troubleshooting, spare parts supply, and any necessary repairs. Our sales, engineering, and production teams are committed to providing the best solutions for your projects.

With transformer shortages and high demand, DAELIM offers rapid production times, typically within 20 weeks. We prioritize long-term partnerships over individual orders, focusing on building enduring relationships with our customers.

Related Products