What is a substation transformer?

| What is substation transformer? |

| How does a substation transformer work? |

| What type of substation transformer are there? |

| How much does a substation transformer weight ? |

| Substation transformer testing? |

1.What is substation transformer?

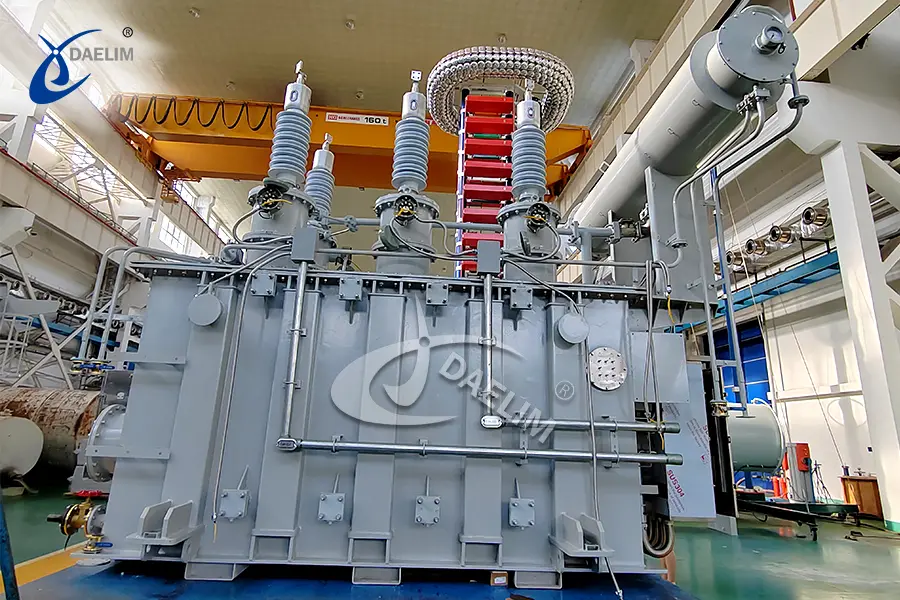

Substation transformers are designed for installation in large or small three-phase transmission and distribution power systems. The installation location is common and must be on the indoor or outdoor concrete base, which needs to be designed by the power engineer in the early stage of project planning.

Substation transformers are designed for installation in large or small three-phase transmission and distribution power systems. The installation location is common and must be on the indoor or outdoor concrete base, which needs to be designed by the power engineer in the early stage of project planning.

At the same time, the cables on the high-voltage side or low-voltage side of the transformer of the substation will be connected through the bushing at the throat type side end or the bushing at the top, so as to directly input the current into the operation room of other substation equipment, such as the control cabinet and other equipment.

In addition, substation transformers are generally oil-immersed. Mineral oil, vegetable oil or siliceous transformer oil. Widely used in various utility or small industrial applications. Construction standards are generally based on IEC, IEEE or other international standards. Let's talk about the voltage class of transformers in substations. The primary voltage of transformers in substations is usually a minimum of 2.4 kV and a maximum of 69 kV, which is based on the IEEE standard. The minimum capacity is 150kVA to the maximum 20MVA, and the secondary voltage can also be a minimum voltage of 0.6KV and a maximum voltage rating of 35kV.

At the same time, substation transformers can be divided into public substation transformers and personal industrial substation transformers in terms of usage scenarios:

* Utility substation transformers:

In this case, it is used by industrial power distribution companies, and then the output voltage is eventually used by private individual consumers. Output both single-phase and three-phase AC current. Some commonly used ones are 120V, 240V, 400V, and so on. Use in urban or rural power distribution equipment. Then input to multiple or single small capacity low voltage power transformers. The transformers of urban substations are usually built with bricks to form a protective wall, and the transformers of rural substations generally appear on the outdoor poles and towers.

You may enjoy: Ultimate Guide to Utility Transformer

*Personal substation transformers

We understand that the substation transformer used by the end user is for the end user's personal use. Generally, it is powered by grids with medium and low voltage levels, and is used in schools, hospitals, restaurants, etc.

*Underground substation transformer

Sometimes due to space limitations, an underground substation transformer is specially designed to meet environmental requirements. It is only the special requirements of the underground that we need to pay attention to:

For installations with limited space, special media, and special oils need to be considered in terms of safety, and in terms of quality, the highest quality must be considered to minimize operational risks and economic benefits of machine operation.

You may enjoy: Pad Mounted Transformer

2.How does a substation transformer work?

The main power source of the transformer in the substation is to rely on the input alternating current in the distribution network to work. A simple understanding of the principle is that the transformer oil in the substation is composed of two adjacent winding coils. A magnetic field occurs when a voltage floats across one of the winding coils. The magnetic field that occurs here couples to the immediately adjacent coil winding, receives a voltage and reacts to it.

The ratio of the induced voltage of the substation transformer to the loop of the winding coil becomes the forward proportional criterion. For example, when 10,000 loops are transmitted, 1,000 loops will be generated in the distribution test, and the voltage generated by the distribution test will be reduced by 10 times. This principle is well understood, so we can pressurize or depressurize according to the needs of using electricity, so that the balance performance of each part of the power grid can be well met, and the safety and economy of each circuit can be ensured.

At the same time, substation transformers also include equipment that controls the entire transmission and distribution network. For example, the circuit breaker transformer is a small transformer, which is mainly used to monitor the safety performance and detect the current and power. In this way, the safe operation of the entire substation equipment can be achieved, complementing the substation transformers. Depending on the transmission and distribution losses, the voltage on the grid can swing outside the acceptable range.

In fact, in many perspectives and aspects, the power system and even the substation transformer is a huge equipment system, which can be related to the life of each of us. Whether it is basic equipment or everyone's daily electricity consumption, electricity will be used, especially reliable and safe electricity. Although the size of the use site, and the voltage level of the power used are different.

Each substation transformer is unique and customized. With the intelligentization of power equipment and the rapid development of various sustainable and environmentally friendly energy generation, it is believed that substation transformers will bring more challenges in our future life. And the possibility of developing more security and reliability.

3.What types of substation transformer are there?

we can divide it into many levels to understand the different types of substation transformers:

we can divide it into many levels to understand the different types of substation transformers:

*To distinguish from the voltage level:

High Voltage Substation Transformer

The voltage range is a minimum of 11 kV to a maximum of 69 kV.

EHV Substation

Voltage ranges from a minimum of 132 kV to a maximum of 440 kV.

There is a step-up from low voltage to high voltage, and a step-down substation transformer from high voltage to low voltage.

* At the same time, there is a substation transformer that does not change the voltage, which refers to a substation transformer that isolates power in a short period of time and plays a role in isolation and safety in the event of a power failure.

*There is also a substation transformer that changes the frequency

Because it changes the frequency, it is called a variable frequency substation transformer, which is less used by individual residents and mainly used in industrial substations.

More directly, there is a substation transformer that changes the AC/DC power supply. Mainly used in electroplating traction.

*There is also a difference based on the distribution location of the power grid: there are two main types

Grid-type substations, which are mainly used to transmit high-voltage large-capacity electricity, can only be used in outdoor buildings and use.

The other is more common around our living environment, that is, urban and rural substation transformers. The main application is to operate at low and medium voltages from 10KV to 33KV.

The above is how to distinguish different substation transformers. We can understand it from a variety of perspectives and contexts.

4.How much does a substation transformer weight?

|

(KVA) Rated Power |

(KV) High Voltage |

(V) Low Voltage | Connection Symbol | (%) Short Circuit Impendence | (W) Loss | Refernence Dimension (W*H*D) mm | Reference Weight kg | |

| (W) No-load Loss | (W) On-load Loss | |||||||

| 800 | 4.16 12.00 12.47 13.2 13.8 14.4 23.0 24.94 34.5 34.8 44 or others | 208/120 415/240 480/277 400 600 12000 12470 13200 13800 or others | Dyn1 Ynyn0 Dyn11 Dd0 Ynd11 or others | 2.7 3.1 4.35 5.75 6.0 | 980 | 9350 | 1060*1500*1780 | 2050 |

| 1000 | 1160 | 11500 | 1085*1570*1800 | 2450 | ||||

| 1250 | 1380 | 13900 | 1160*1610*1890 | 2900 | ||||

| 1600 | 1660 | 16600 | 1190*1630*1950 | 3400 | ||||

| 2000 | 2030 | 18300 | 1260*1700*2090 | 4100 | ||||

| 2500 | 2450 | 19600 | 1150*2150*2250 | 4750 | ||||

| 3000 | 3240 | 26500 | 1900*2600*2150 | 6500 | ||||

| 5000 | 4500 | 27000 | 2500*2210*3180 | 9500 | ||||

| 7500 | 7200 | 32000 | 3660*3100*5100 | 13600 | ||||

| 10000 | 8500 | 35500 | 3830*2640*2216 | 15800 | ||||

* Dimension, weight, and loss are for reference. Will based on actual project, design and standard.

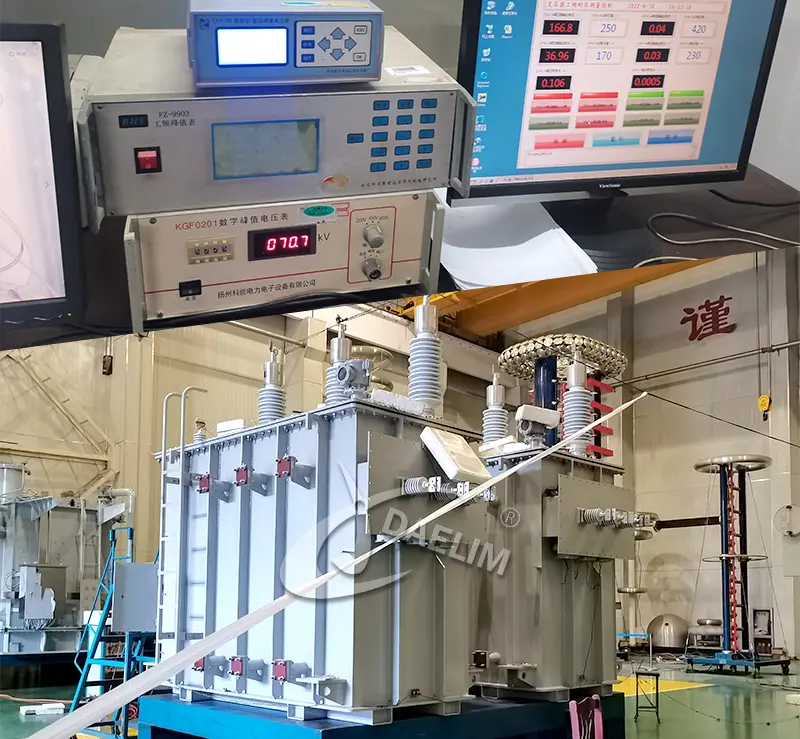

5.Substation transformer testing?

Transformer testing has evolved over a long period of time and has continued to evolve since the transformer's inception. From the beginning of the simple test data is not satisfied to the test data can show the complex data and structure of the transformer from the outside to the inside, which undoubtedly proves that the transformer has played a safe and reliable professional role in the entire power development. We can now discuss the same and different test content under the most widely used IEC and IEEE standards.

Transformer testing has evolved over a long period of time and has continued to evolve since the transformer's inception. From the beginning of the simple test data is not satisfied to the test data can show the complex data and structure of the transformer from the outside to the inside, which undoubtedly proves that the transformer has played a safe and reliable professional role in the entire power development. We can now discuss the same and different test content under the most widely used IEC and IEEE standards.

There are test contents under the IEC standard:

- Dielectric test

- Pulse test

- Lightning impulse test

- Pressure test

- Partial discharge measurement, full discharge test, harmonic discharge test

- Induced AC voltage test,

-No-load loss test, load loss test

-Temperature rise test

These tests can be mandatory or non-mandatory, but can be negotiated according to the manufacturer's actual experimental conditions and customer needs.

Reading more about Transformer Test

Test content under IEEE standards

We should first consider the resistance test, polarity test, phase relationship test, ratio test, no-load loss test, load loss test, and suitability temperature rise test, dielectric test. At the same time, in order to ensure the safety of the test and the damage to the transformer, the voltage part related to the current should be tested first.

In addition, the lightning test is not a mandatory test, especially under the condition of small capacity and voltage, a lightning test may cause catastrophic loss to the transformer, we can consider the sampling test under the conditions.

At the same time, there are low frequency tests, induced voltage tests, etc.

Substation Transformer Manufacturer

Daelim Transformer is your first choice for high-quality substation transformers. As a leading manufacturer and supplier, we offer transformers that meet the latest international standards, including IEEE, ANSI, CSA, IEC, and AS. Our products are certified by UL, cUL, CSA, CE, and FM, ensuring unparalleled reliability and performance.

Daelim Transformer boasts extensive experience in substation transformer projects across North America, Latin America, and Australia. We provide customized solutions tailored to meet your specific technical needs. Our expertise extends beyond manufacturing to include a comprehensive range of services, such as expert installation, ongoing maintenance, and responsive field support, all designed to ensure your operations run smoothly.

With service stations located in the United States, Canada, Spain, and other countries, Daelim Transformer is committed to delivering the best transformer solutions worldwide. Choose Daelim Transformer for your next project and experience the difference that efficiency and expertise can make.

Welcome inquiry and click here to know more!

Related Products

Related Article

13.8 kV 10.5 MVA Substation Transformer for Ecuador

A customer from Ecuador contacted Daelim Transformer for a 10.5MVA substation transformer (13.8kV high voltage, 2.4kV low voltage). Daelim Transformer provided a customized solution, conducted virtual factory tours, ensured rigorous quality control via video inspections, and offered post-delivery online training and ongoing support, fostering a successful partnership.

Canadian 69 kV Substation Transformer Project

Today, we are excited to present a case study on a 69 kV substation transformer project by Daelim Transformer. Our Canadian client required a step-down transformer for their substation to connect with the hydroelectric grid in Quebec.

69KV Series Substation, Latin America

Built in 2016, the 69kv series substation incuding Kaliti-l 69/13.8 mva substation; Cotebie 69/22kv 20mva substation;Kaliti-II 69/13.8kv 24mva substation;

2000 kVA Oil immersed Substation Transformer For Portugal Market

Today, we introduce Daelim Transformer's export of a 2000 kVA oil-immersed substation transformer to Portugal. This transformer represents our commitment to delivering high-quality electrical solutions to global markets. With meticulous design and engineering, this transformer is tailored to meet the specific needs of our customers in Portugal, ensuring reliable performance and efficiency. Daelim Transformer continues to uphold its reputation for excellence, providing innovative solutions that power progress and reliability worldwide.

4500 kVA Substation Transformers for Australian Mining Site

Today, we introduce a project by Daelim Transformer aimed at supplying transformers to a mining site in Australia. This project entails the provision of two units of 4500 kVA substation transformers tailored to fit the narrow confines of mining tunnels. Due to space constraints, the transformers need to be compact in size and mounted on mobile racks for easy maneuverability within the mine shafts. This necessitates meticulous design to meet the strict dimensional requirements set by the client.

GIS Mobile Substation Project , Ecuador

Built in 2015, this GIS was built in a power plant in Ecuador. The high-voltage components are filled with SF6 gas as insulation and arc extinguishing medium. The main function is to protect, measure and dispatch the power system.