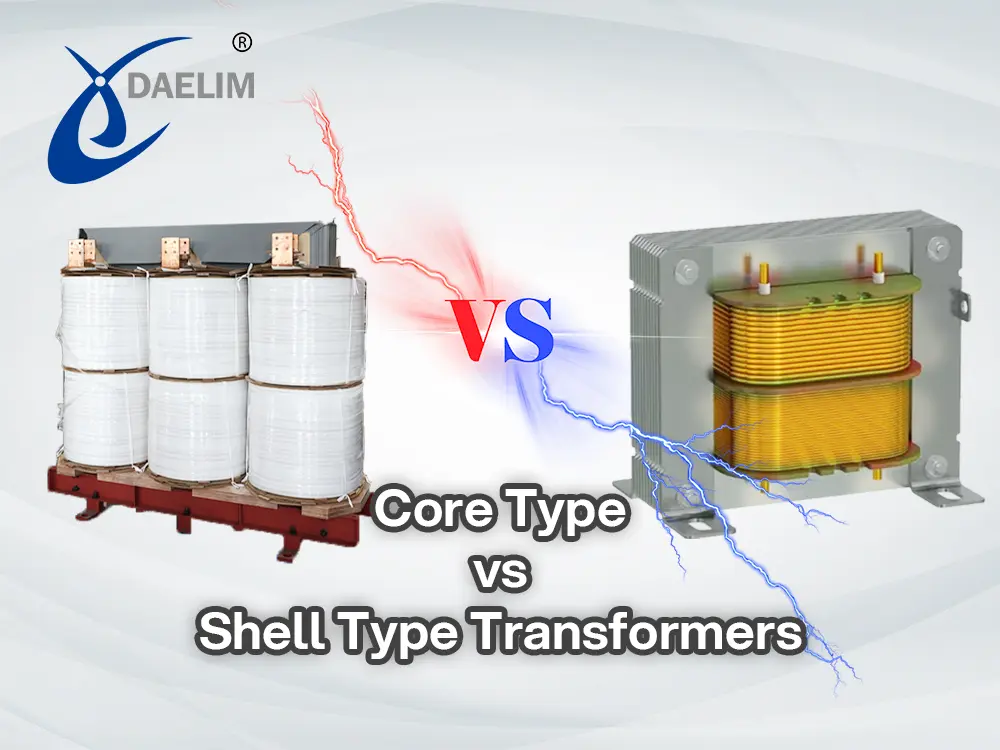

Core Type vs Shell Type Transformers

Have you ever wondered about the difference between core and shell-type transformers?

Whether you're dealing with power systems or electrical equipment, knowing when to use a core type or shell type transformer can make all the difference in performance, and efficiency.

Let’s examine the differences between core and shell-type transformers and understand how they can be applied to diverse power needs.

Contact Daelim TransformerKey Differences Between Core-Type and Shell-Type Transformers

Core type and shell type transformers differ in structure, magnetic paths, and aspects such as construction, flux distribution, cooling, and maintenance. Let’s have a look:

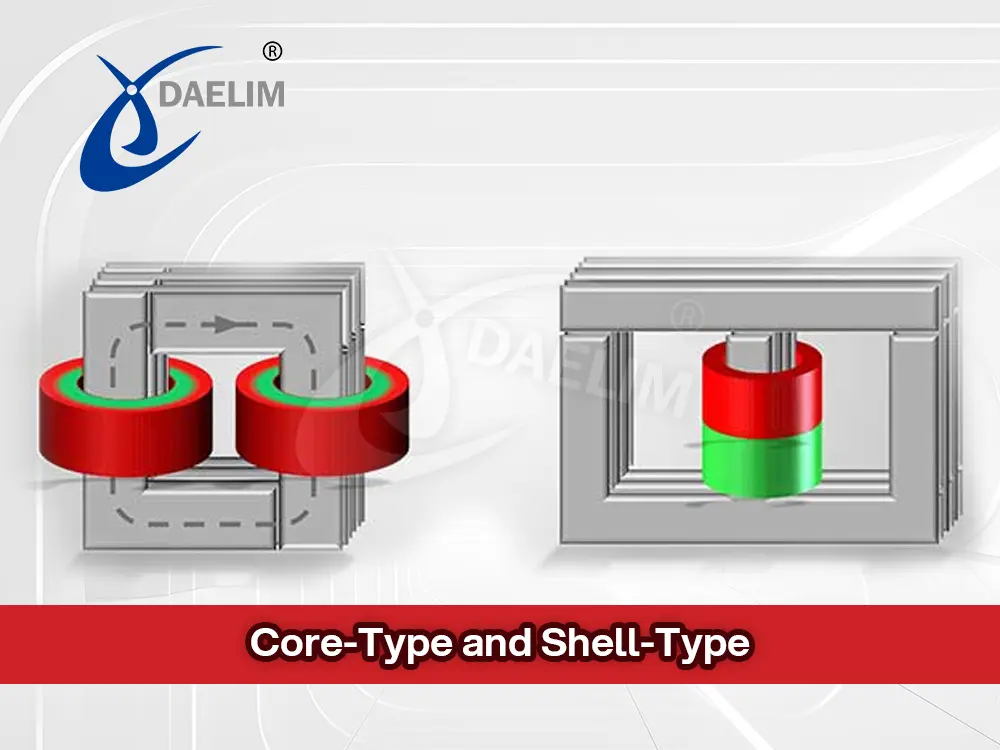

Core Structure

Core-type transformer windings wrap around two vertical limbs of a rectangular core, joined by horizontal yokes, guaranteeing you a reliable performance.

The structure improves insulation, allows for easier cooling, and simplifies maintenance. For shell type transformers, the winding is surrounded by the core.

L-shaped lamination cut is used in core type transformers while both L-shaped and E-shaped cut is incorporated in shell type transformers.

Magnetic Path

Core type transformers have windings that surround the core steel, without forming a closed loop for the magnetic flux around the coils.

The design leads to longer magnetic paths, higher energy losses, and greater material requirements for copper or aluminum windings.

In contrast, shell type transformers have windings placed between two halves of the core, creating a shorter magnetic path.

The design improves efficiency, requiring less magnetizing current and enabling higher power transfer capabilities, making it more energy-efficient.

Conductor Material

More conductor materials are used in core type transformer winding as opposed to shell type transformers. This makes shell type transformers cost-effective for manufacturers.

Average Winding Lenght

Normally, shell type transformers have a longer average winding length than core type transformers, hence more impedance.

It results in a lower percentage of impedance, which improves the overall efficiency of your transformer.

The more direct winding path reduces energy losses, making core-type transformers a more effective choice for certain applications.

The windings are wrapped around the central limb and surrounded by the core, leading to more material being used, thus increasing the impedance.

Cooling and Maintenance

Core-type transformers are easier to maintain because fewer windings need to be removed compared to shell-type transformers. The design reduces downtime and simplifies maintenance.

Shell-type transformers excel in heat management thanks to their core design, which evenly distributes heat generated during operation.

Reading more:What is Transformer Cooling and How is it done?

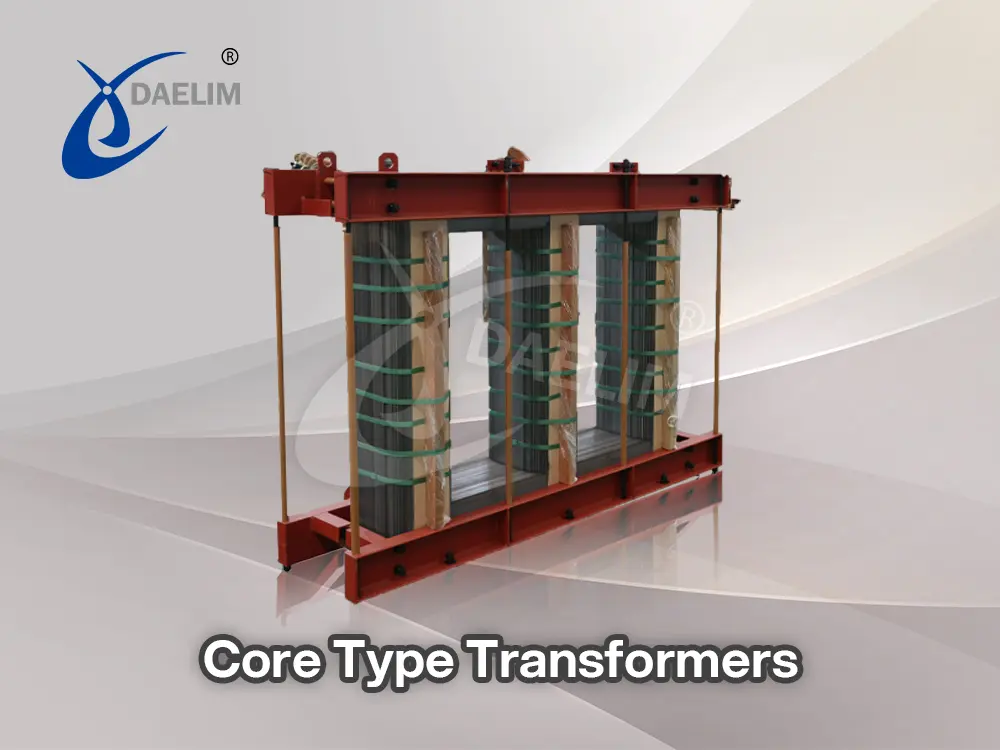

Location of the Winding

For core type transformers, we separate the windings into two limbs. We place the low-voltage winding next to the core and the high-voltage winding next to the low-voltage winding.

In shell type transformers, the winding is located in the central limb affecting the cooling, impedance, and design.

Reading more:The Ultimate Guide To Core Type Transformer

What are the Benefits of Core and Shell Type Transformers?

Core Type Transformers

Core type transformers have laminated cores for reduced energy losses and improved efficiency. They handle strong external forces, making them suitable for heavy-duty use.

The design also helps with better heat dissipation, keeping them cool during operation. On top of that, they are cost-effective for high-power needs, making them suitable for industrial use.

Shell Type Transformers

Shell type transformers stand out for their efficiency, thanks to reduced energy losses. They manage heat effectively, preventing hot spots and ensuring consistent performance over time.

Their compact design makes them ideal for tight spaces, and the added bracing in their construction gives them extra strength and durability, even in tough conditions.

Reading on: Let's know more about the construction of a three-phase transformer

Conclusion: Why Choose Daelim Transformer?

We are a UL/CUL certified and CE-certified transformer manufacturer and supplier, recognized for our swift production capabilities and commitment to quality.

We export over 2,000 units annually to North America and have more than 10,000 units successfully in operation worldwide.

Our dedication to delivering superior transformer solutions ensures every product is built to exceed expectations. Partner with us for trusted expertise and unparalleled value.

Related Products

Related Article

Introduction to Transformer Inspection

Transformer inspection is a vital process to ensure the optimal performance, safety, and longevity of electrical transformers. It involves visual checks, electrical testing, thermal imaging, and oil analysis to detect issues early, reduce downtime, and comply with regulations. Advanced tools like sensors, drones, and digital monitoring enhance inspection efficiency and accuracy.

Power Transformer vs Distribution Transformer

Power transformers regulate high-voltage electricity from power plants to distribution centers, operating at maximum load with high efficiency (95-99%). Distribution transformers step down voltage for residential/industrial use, operating at lower loads and efficiency (50-70%). They differ in size, insulation, cooling methods, and applications, ensuring efficient electricity distribution.

Transformer Selection based on How much energy does AI use

AI's rapid growth significantly increases energy demand, with AI systems, data centers, and cryptocurrencies consuming 460 TWh in 2022, expected to double by 2026. Key factors include model complexity, computational infrastructure, and cooling needs. Transformers are crucial for stable, efficient power supply, requiring careful selection for AI's high and fluctuating energy demands.

Purpose of transformer oil and its Capacity

Transformer oil is essential for cooling, insulation, and isolation in oil-type transformers. Its quantity depends on transformer type, size, power rating, and operating conditions. Proper oil capacity ensures efficient heat dissipation, prevents short circuits, and protects against environmental factors. International standards like IEC, ASTM, and BS EN regulate oil specifications and testing. Accurate oil capacity is critical for transformer performance and longevity.

Can You Convert Single Phase Transformer to Three Phase?

A single transformer cannot convert single-phase to three-phase power, but three single-phase transformers can be configured to create a three-phase system. This upgrade enhances efficiency, handles higher loads, and suits industries like manufacturing and data centers. Daelim Transformer offers reliable solutions for such power needs.

Can a Damaged Transformer Coil Be Repaired, Refurbished, or Replaced?

A damaged transformer coil can often be repaired, refurbished, or replaced, depending on the extent of the damage. Minor issues like insulation wear or loose connections are repairable, while severe damage may require refurbishment or replacement. Consulting experts like Daelim ensures reliable solutions for maintaining power systems.