DOE Efficiency Standards for Transformers

With the ongoing energy crisis around the world, people continue to seek ways to conserve energy and promote sustainability. Some of the efforts include imposing federal conservation standards for equipment, appliances, and other consumer products including transformers.

Transformers are one the most important parts of every nation's energy system. To ensure that it is manufactured within the minimum energy efficiency requirement the government mandates the manufacturers to abide by the DOE efficiency standards for transformers.

DOE or the Department of Energy in each country may have different rules. Moreover, the US just released the final rule for the amended transformer efficiency standards.

It is very timely that we go through it and see what lies ahead for the consumers as well as for the manufacturers. But before that, let us first answer some basic FAQs and learn a little bit about the background of these standards.

Contact Daelim Transformer

Daelim Transformer's 1 phase pole mounted transformers with high voltages up to 34.5kV and ratings up to 333kVA, meeting global standards like ANSI/IEEE C57, CSA C2.1, IEC 60076, and more. Their products not only comply with DOE and CSA efficiency requirements but exceed them, ensuring reliability, efficiency, and energy conservation.

Daelim is a respected manufacturer providing UL/cUL and CSA listed pad mounted transformers. They offer both single-phase and three-phase options, with 3 phase transformers featuring up to 44kV voltage and ranging from 75kVA to 10,000kVA in power. Single phase pad mounted transformer with high voltage up to 34.5 kV and ratings up to 250kVA.

Daelim Transformer provides substation transformers capable of handling high voltages up to 46kV and ratings up to 50MVA. Their products meet ANSI/IEEE and DOE standards, and are UL listed for up to 44kV and 20MVA. They offer flexible bushing position and arrangement options aligned with IEEE standards, ensuring adaptable solutions for diverse substation requirements.

What do DOE Efficiency Standards for Transformers mean?

The efficiency standards for transformers are regulations established by the Department of Energy that transformer manufacturers and traders must comply with before their products can enter the US market.

The regulation sets the distribution transformer's minimum efficiency according to its type and corresponding kVA ratings.

What Is the Purpose of Establishing DOE Efficiency Standards for Transformers?

The purpose of establishing DOE efficiency standards is to ensure the quality of transformers for their consumers and mainly to support the US government’s program for overall sustainability.

To conserve energy, reduce greenhouse gas, and cut carbon emissions. Apart from that, the efficiency standard also targets lowering the cost of electricity for the consumers and most importantly, strengthening the energy sector and ensuring the stability of the power grid.

What Is the Difference between the IEC Standards and the DOE Transformer Efficiency Standards?

IEC or the International Electrotechnical Commission standards guide manufacturers in testing, commissioning, and manufacturing, including material selection, methods of construction, and design to ensure the safety and reliability of power transformers.

As mentioned, the DOE transformer efficiency standards set the minimum efficiency levels of distribution transformers.

IEC 60076-5:2006: Power transformers are also considered in establishing the standard test procedures in the efficiency rulings.

What Are the Factors Considered in Creating the DOE Efficiency Standards for Transformers?

According to EPCA, DOE shall justify the proposed energy efficiency requirement and its future amendments based on the analysis of the different impacts on the following:

- Economic impact on both product end user and manufacturer.

- The operating cost savings versus the upfront cost and/or the maintenance cost.

- Energy savings

- Performance

- Lowering market competition

- Energy and water conservation

- Other relevant factors determined by the Energy Secretary

When Did the Enforcement of DOE Efficiency Standards for Transformers Start?

The policy started with the Energy Policy and Conservation(EPCA) Act of 1975 which appointed the DOE in early 2007 to establish efficiency standards for certain consumer products and significant industrial equipment such as low-voltage dry-type distribution transformers.

The same year, DOE added efficiency standard provisions for medium-voltage dry-type and liquid-immersed distribution transformers.

Do you ever wonder why DOE proposes new efficiency standards periodically? It is simply because it is required by the law.

According to EPCA, the policy for the energy conservation standards shall be reevaluated within 6 years after the final rule is released, whether the standards still apply or need to be amended.

Reading more about Transformer Efficiency

What Is the Scope of DOE Efficiency Standards for Transformers?

The DOE efficiency standards particularly cover distribution transformers, whether they are dry or liquid-immersed. These two types are further described as follows:

| Distribution Transformer Type | Dry-type | Liquid-immersed |

| Description | The core and coil are immersed and cooled using air or a dry cooling medium. | The core and coil are immersed and cooled using an insulating liquid. |

| Input Voltage | ≦34.5 kV | |

| Output Voltage | ≦600 V | |

| Frequency | 60 hz | |

| Capacity | 15 kVA to 2500 kVA | 10 kVA to 2500 kVA |

| Low Voltage | ≦600 V | - |

| Medium Voltage | 601 V to 34.5 kV | - |

The standards also cover the details of the testing procedures, efficiency determination, and various impact analyses made before they came up with the final rulings.

What are exemptions in the DOE Efficiency Standards for Transformers?

Some transformers are not covered by the efficiency standards. These are transformers that do not fit the description of a distribution transformer defined by the DOE while some transformers are made for different purposes other than power distribution.

The exemption list currently includes 13 transformer types, these are:

- Autotransformer

- Drive or isolation transformer

- Grounding transformer

- Machine-tool (control) transformer

- Non-ventilated transformer

- Rectifier transformer

- Regulating transformer

- Sealed transformer

- Special-impedance transformer

- Testing transformer

- Transformer with tap range of 20% or more

- Uninterruptible power supply transformer

- Welding transformer

How Are the Distribution Transformers Under the DOE Efficiency Standards for Transformers Classified?

The distribution transformers covered by the standards are identified according to 10 equipment classes.

| Equipment Class No. | Transformer Type | No. of Phases | Voltage | kVA Range | Basic Impulse Insulation Level (BIL) |

| 1 | Liquid Immersed | Single | Medium | 10-833 kVA | N/A |

| 2 | Three | 15-2500 kVA. | |||

| 3 | Dry Type | Single | Low | 15-333 kVA | |

| 4 | Three | 15-1000 kVA | |||

| 5 | Single | Medium | 15-833 kVA | 20-45kV | |

| 6 | Three | 15-2500 kVA. | |||

| 7 | Single | 15-833 kVA. | 46-95kV | ||

| 8 | Three | 15-2500 kVA | |||

| 9 | Single | 75-833 kVA. | ≥96kV | ||

| 10 | Three | 225-2500 kVA | |||

| 11 | *Mining Transformers | ||||

*Mining transformers are not required to comply with the DOE efficiency standards.

What Are the Previous Versions of the DOE Efficiency Standards for Transformers? What Are the Changes Compared to the Final Rule?

Before the latest efficiency standards were finalized this year there were older versions pertaining to this legislation.

The standard was first made for compliance in 2007, amended in 2010, and was superseded by the 2016 transformer efficiency standards.

Notice that there are no changes in the DOE 2010 transformer efficiency standards for single-phase dry-type transformers and the 2016 standards.

However, in the final rule, minor increments were noted among all classes. Higher kVA ratings for the three-phase liquid immersed type were also added.

Here is the overview of the most recent and final standards compared to the previous versions.

Low Voltage Dry-type Distribution Transformers Energy Conservation Standards

| Single Phase | ||||

|

Ratings(kVA) | Min. Efficiency(%) | % Increase Since 2010 | ||

| 15 | 97.7% | 97.7% | 98.39% | 0.69% |

| 25 | 98% | 98% | 98.6% | 0.6% |

| 37.5 | 98.2% | 98.2% | 98.74% | 0.54% |

| 50 | 98.3% | 98.3% | 98.81% | 0.51% |

| 75 | 98.5% | 98.5% | 98.95% | 0.45% |

| 100 | 98.7% | 98.7% | 99.02% | 0.69% |

| 250 | 98.8% | 98.8% | 99.09% | 0.32% |

| 333 | 98.9% | 98.9% | 99.23% | 0.33% |

| Three Phase | ||||

|

Ratings(kVA) | Min. Efficiency(%) | % Increase Since 2007 | ||

| 15 | 97.0% | 97.89% | 98.31% | 1.31% |

| 30 | 97.5% | 98.23% | 98.58% | 1.08% |

| 45 | 97.7% | 98.40% | 98.72% | 1.02% |

| 75 | 98.0% | 98.60% | 98.88% | 0.88% |

| 112.5 | 98.2% | 98.74% | 98.99% | 0.79% |

| 150 | 98.3% | 98.83% | 99.06% | 0.76% |

| 225 | 98.5% | 98.94% | 99.15% | 0.65% |

| 300 | 98.6% | 99.02% | 99.22% | 0.62% |

| 500 | 98.7% | 99.14% | 99.31% | 0.61% |

| 750 | 98.8% | 99.23% | 99.38% | 0.58% |

| 1000 | 98.9% | 99.28% | 99.42% | 0.52% |

Note: According to DOE, the values presented are at 35% of the nameplate-rated load

Medium Voltage Dry-type Distribution Transformers Energy Conservation Standards

| Single Phase | ||||

|

Ratings(kVA) | Min. Efficiency(%) | % Increase Since 2010 | ||

| Basic Impulse Insulation Level(BIL) | ||||

| 20-45kV | ||||

| 15 | 98.10% | 98.10% | 98.29% | 0.19% |

| 25 | 98.33% | 98.33% | 98.50% | 0.17% |

| 37.5 | 98.49% | 98.49% | 98.64% | 0.15% |

| 50 | 98.60% | 98.60% | 98.74% | 0.14% |

| 75 | 98.73% | 98.73% | 98.86% | 0.13% |

| 100 | 98.82% | 98.82% | 98.94% | 0.12% |

| 167 | 98.96% | 98.96% | 99.06% | 0.1% |

| 250 | 99.07% | 99.07% | 99.16% | 0.09% |

| 333 | 99.14% | 99.14% | 99.23% | 0.09% |

| 500 | 99.22% | 99.22% | 99.30% | 0.08% |

| 667 | 99.27% | 99.27% | 99.34% | 0.07% |

| 833 | 99.31% | 99.31% | 99.38% | 0.07% |

| Single Phase | ||||

|

Ratings(kVA) | Min. Efficiency(%) | % Increase Since 2010 | ||

| Basic Impulse Insulation Level(BIL) | ||||

| 46-95kV | ||||

| 15 | 97.86% | 97.86% | 98.07% | 0.24% |

| 25 | 98.12% | 98.12% | 98.31% | 0.19% |

| 37.5 | 98.30% | 98.30% | 98.47% | 0.17% |

| 50 | 98.42% | 98.42% | 98.58% | 0.16% |

| 75 | 98.57% | 98.57% | 98.71% | 0.14% |

| 100 | 98.67% | 98.67% | 98.80% | 0.13% |

| 167 | 98.83% | 98.83% | 98.95% | 0.12% |

| 250 | 98.95% | 98.95% | 99.06% | 0.11% |

| 333 | 99.03% | 99.03% | 99.13% | 0.10% |

| 500 | 99.12% | 99.12% | 99.21% | 0.09% |

| 667 | 99.18% | 99.18% | 99.26% | 0.08% |

| 833 | 99.23% | 99.23% | 99.31% | 0.08% |

| Single Phase | ||||

|

Ratings(kVA) | Min. Efficiency(%) | % Increase Since 2010 | ||

| Basic Impulse Insulation Level(BIL) | ||||

| ≥96kV | ||||

| 75 | 98.53% | 98.53% | 98.68% | 0.15% |

| 100 | 98.63% | 98.63% | 98.77% | 0.14% |

| 167 | 98.80% | 98.80% | 98.92% | 0.12% |

| 250 | 98.91% | 98.91% | 99.02% | 0.11% |

| 333 | 98.99% | 98.99% | 99.09% | 0.10% |

| 500 | 99.09% | 99.09% | 99.18% | 0.09% |

| 667 | 99.15% | 99.15% | 99.24% | 0.09% |

| 833 | 99.20% | 99.20% | 99.28% | 0.08% |

Note: According to DOE, the values presented are at 50% of the nameplate-rated load

Liquid Immersed Distribution Transformers Energy Conservation Standards

| Single Phase | ||||

|

Ratings(kVA) | Min. Efficiency(%) | % Increase Since 2010 | ||

| 10 | 98.62% | 98.70% | 98.77% | 0.15% |

| 15 | 98.76% | 98.82% | 98.88% | 0.12% |

| 25 | 98.91% | 98.95% | 99.0% | 0.09% |

| 37.5 | 99.01% | 99.05% | 99.10% | 0.09% |

| 50 | 99.08% | 99.11% | 99.15% | 0.07% |

| 75 | 99.17% | 99.19% | 99.23% | 0.06% |

| 100 | 99.23% | 99.25% | 99.29% | 0.06% |

| 167 | 99.25% | 99.33% | 99.46% | 0.21% |

| 250 | 99.32% | 99.39% | 99.51% | 0.19% |

| 333 | 99.36% | 99.43% | 99.54% | 0.18% |

| 500 | 99.42% | 99.49% | 99.59% | 0.17% |

| 667 | 99.46% | 99.52% | 99.62% | 0.16% |

| 833 | 99.49% | 99.55% | 99.64% | 0.15% |

| Three Phase | ||||

|

Ratings(kVA) | Min. Efficiency(%) | % Increase Since 2007 | ||

| 15 | 98.36% | 98.65% | 98.92% | 0.56% |

| 30 | 98.62% | 98.83% | 99.06% | 0.44% |

| 45 | 98.76% | 98.92% | 99.14% | 0.38% |

| 75 | 98.91% | 99.03% | 99.22% | 0.31% |

| 112.5 | 99.01% | 99.11% | 99.29% | 0.28% |

| 150 | 99.08% | 99.16% | 99.33% | 0.25% |

| 225 | 99.17% | 99.23% | 99.38% | 0.21% |

| 300 | 99.23% | 99.27% | 99.42% | 0.19% |

| 500 | 99.25% | 99.35% | 99.38% | 0.13% |

| 750 | 99.32% | 99.40% | 99.43% | 0.11% |

| 1000 | 99.36% | 99.43% | 99.46% | 0.10% |

| 1500 | 99.42% | 99.48% | 99.51% | 0.09% |

| 2000 | 99.46% | 99.51% | 99.53% | 0.07% |

| 2500 | 99.49% | 99.53% | 99.55% | 0.06% |

| 3750 |

|

| 99.54% | - |

| 5000 |

|

| 99.53% | - |

Note: According to DOE, the values presented are at 50% of the nameplate-rated load

What Is the Proper Way of Calculating the Transformer Efficiency?

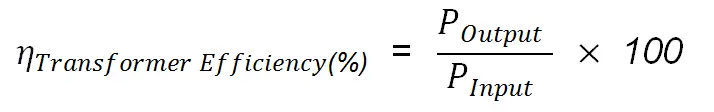

The basic formula normally used in calculating transformer efficiency is:

Where:

η = % transformer efficiency

Pout = transformer output power in watts

Pin = transformer input power in watts

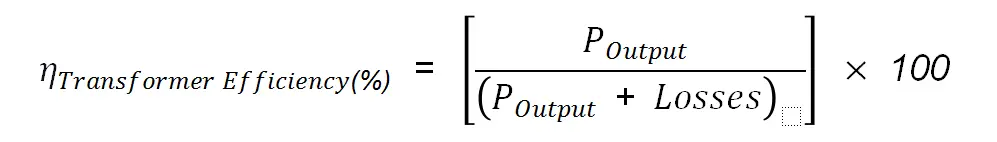

However, this formula does not account for the losses from eddy current and hysteresis. To properly calculate the transformer efficiency you can use this formula instead:

Some online transformer efficiency calculators are also available but one should not rely on this alone.

For more accurate and detailed information regarding the transformer efficiency computation and test procedure, refer to 10 CFR part 431, subpart K.

What Are the Impacts of the DOE Efficiency Standards for Transformers?

Although transformers were quite efficient before these regulations were implemented, having a law makes it official and mandatory.

Raising the bar higher for transformers entails various impacts such as:

- Increase in weight,

- SOP realignment in terms of installation

- Increase cost

Increase in Weight

With the current efficiency target, more material would be needed. It is expected to affect the size and weight of the distribution transformers with the projected increase ranging from 2% to 25% depending on the type and capacity.

| Transformer Type | Capacity | |

| Single-Phase Overhead Transformers | 10-100 kVA | 2% |

| 167 kVA | 21% | |

| 250-833 kVA | 16% | |

| Single-Phase Surface Mounted Transformers | 10-100 kVA | 7% |

| 167-833 kVA | 18% | |

| Three-Phase Surface Mounted Transformers | 30-300 kVA | 4% |

| 500 kVA | 5% | |

| 667-2500 kVA | 2% | |

| 3750- 5000 kVA | 25% |

SOP Realignment in Terms of Installation

With the expected increase in weight, current practices in distribution transformer installation have to be revisited as it may not be suitable when this new ruling is implemented.

For example, an increase in weight would affect the size so the usual pads and mountings may no longer suffice the dimensions and weight of the new transformer, or additional manpower and equipment would be needed for the installation.

Increase Cost

Every increment in the transformer's efficiency equates to additional material and manufacturing costs. Some of these costs are inevitably passed on to the consumers.

However, DOE iterates that the increase in the cost shall be recovered in the form of power savings as highly efficient transformers consume less electricity.

When Will These New DOE Efficiency Standards Take Effect?

This shall take effect on July 8, 2024, while mandatory compliance with the more rigid standards for transformer efficiency stated in the final rule is extended up to April 23, 2029.

What Are the Ways To Meet the DOE Efficiency Standards for Transformers?

DOE understands the challenges that arise along with the new rulings. Moreover, they presented different recommendations to meet the new standards.

The proposition is stressed on the choices of core material technology and design. These were the three options presented:

- Traditional Amorphous Alloy(am)

- High-permeability Amorphous Alloy(hibam)

- High-permeability, Domain-refined Amorphous Alloy(hibam-dr)

Again these are only recommendations and manufacturers still have the final say on what material to use as long as it results in a compliant transformer that suffices the standard efficiency levels.

Transformer manufacturers and DOE agreed that with proper engineering widely used steel such as grain-oriented electrical steel(GOES) can still be utilized to meet the standards.

Furthermore, in terms of engineering and design, DOE suggests that the formula to increase transformers' efficiency should include the combination of the following strategies :

- Using high-grade core material

- Exploring different types of conductors and materials

- Modifying the configuration of the coil and the core

Daelim Standards

Here at Daelim adhering to the DOE efficiency standards and other global standards such as the ANSI, IEC, IEE, CSA, AS, and NEMA is a top priority.

As an experienced transformer manufacturer, Daelim welcomes the challenges that come with the new DOE efficiency standards. This serves as another exciting opportunity to excel in finding innovative solutions to meet these rigorous standards. While aiming towards high efficiency, Daelim also gives high importance to product safety and sustainability.

Daelim promotes eco-friendly and low maintenance design with high short circuit strength, high withstand temperatures, and high overload capacity.

If you are looking for high-efficiency transformers that adhere to the standards, Daelim transformer is your quickest way to go. Contact Daelim and let us help you achieve your transformer efficiency requirement.

Related Products

Related Article

2000 kVA Pad Mounted Transformers for Canadian Utility

Daelim Transformer is pleased to announce its contribution to a utility project in Toronto, Canada, involving the supply of two units 2000 kVA pad mounted transformers. These transformers are integral to enhancing the power infrastructure in the region. The project demands adherence to CSA standards, with a stringent delivery deadline of 10 weeks to meet the urgent needs of the client.

Supply of 37.5 kVA Single Phase Pad Mounted Transformers for Canadian Utility

Today, we are excited to introduce a project undertaken by Daelim Transformer aimed at supplying transformers to a Canadian utility. This project involves the delivery of 80 units of 37.5 kVA single-phase pad mounted transformers, specially designed to meet the utility's requirements. With a high voltage (HV) rating of 24940GRDY/14400 V and a low voltage (LV) rating of 240/120 V, these transformers are vital components in the utility's infrastructure.

500 kVA Distribution Transformer for the Greek Market

Today, we're thrilled to showcase a European transformer project tailored for the Greek market. This project involves the supply of 500 kVA distribution transformers, with an input voltage of 20 kV and an output voltage of 400V. The client has requested adherence to both IEC and TIER-II energy efficiency standards. With a total quantity of 5 units, this project marks another milestone in Daelim Transformer's commitment to delivering high-quality solutions worldwide.

1750 kVA Pad Mounted Transformer for the Dominica Market

Today, we're excited to present a transformer project tailored for the Dominican market. Our 1750 kVA pad mounted transformer is designed to meet the specific requirements of our clients in Dominica. This step-down transformer boasts a primary voltage of 13.8 kV and a secondary voltage of 480Grdy/277V, adhering to the IEEE C57.12.34 standard. With its robust features and reliable performance, this transformer is set to enhance the power distribution infrastructure in Dominica.

Single Phase Pad Mounted Transformer For USA Utility

Introducing a utility transformer project tailored for the USA, located in Virginia. This utility initiative requires 215 units of single-phase pad-mounted transformers, all UL listed, including 175 units of 25 kVA and 40 units of 50 kVA. The end user's project timeline is 90 days. Adherence to IEEE standards is imperative for single-phase transformers. Additionally, the design of transformer components and markings must be customized to meet project specifications.

Three Phase Power Transformers for Block Chain Facility in Texas!

Daelim Transformer thrilled to share details of our project - the supply of 90 units of three-phase power transformers for a large-scale block chain operation in Odessa, Texas. Each transformer is rated at 2500(3000)KVA with a primary voltage of 34.5kV Delta and a secondary voltage of 480GrdY/277. With strict UL certification requirements and a focus on high-quality accessories from reputable brands, this project demanded precision, efficiency, and reliability.