The Top 10 Best Industrial Transformer Manufacturers in The Word

Industrial transformers are the heart and soul of any industrial process. They allow things like power, heat, and motion to be generally converted between different voltages and currents.

In the upcoming sections, we are going to take a look at the best ten industrial transformer manufacturers. Then we will determine their role in the society and market.

We will also discuss the operations of industrial transformers as well as the basics underlying their design. In terms of how much money these products cost and whether or not they're worth it for your business.

| Table of contents |

| 1. What Is Industrial Transformer? 2. Who Are The Top 10 Power Transformer Manufacturers? 3. Purpose 4. Application 5. Design 6. Features 7. Specifications

9. What Is The 2023 Forecast Market Across Electrical Transformer Manufacturers? 10. Contact Daelim As Your Industrial Transformer Manufacturer |

What Is Industrial Transformer?

Industrial transformers are specifically manufactured to order and can endure extreme temperatures and humidity. They are also generally used to withstand massive loads. They are essential in distributing electricity from the source or distributor to several primary circuits.

Industries that rely substantially on electricity, such as steel manufacturing, electrolysis, mining, and offshore oil require industrial transformers to function properly.

In most cases, these devices need to be strongly equipped with sensors that are sending information about their operational state to a safe data storage and analysis platform. With specialized data analytics, operators can increase output while decreasing downtime.

Who Are The Top 10 Power Transformer Manufacturers?

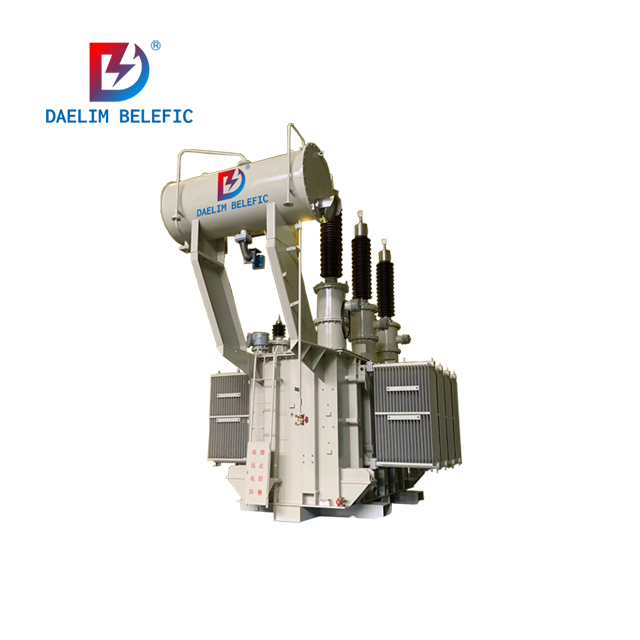

ABB, Eaton, Schneider Electric, and Siemens are generally regarded to be among the top 10 industrial transformer manufacturers. You can also rely on distribution transformer manufacturers such as Daelim Belefic, Mitsubishi Electric Corp., Bharat Heavy Electricals, Toshiba Corporation, Hyosung Power & Industrial, and SPX Transformer Solutions Incorporation. They are all great and leading electrical transformer manufacturers across the globe.

Learn more:Power Transformer Manufacturers Around the World

As you can see, the top 10 power transformer manufacturers have worked hard to build their reputation on reliability and customer satisfaction.

They have been the world's finest distribution transformer manufacturers and high voltage transformer manufacturers so you can acquire the best quality products.

The most important thing when you are looking for a power transformer is to choose one that is reliable and durable.

Several factors affect the reliability of a power transformer, such as how well it was usually manufactured, how long it has been typically used, and whether or not it has been subject to natural wear and tear.

According to the reports, the distribution transformer business is experiencing an increasing degree of focus, with only ten players controlling forty percent of the market.

This list includes the finest distribution transformer manufacturers. as well as high-voltage transformer manufacturers across the globe.

Among the finest and dominant high-voltage transformer manufacturers are:

- Schneider Electric (five percent share)

- GE (six percent share)

- Siemens (seven percent share)

- ABB (eight percent share)

Try for free: Basic Guide To High Voltage Power Transformers

The increasing need for high-quality, energy-efficient distribution transformers is one element driving market consolidation. Other specific segments of the market include the residential, commercial, utility, and industrial spheres.

Leading Companies in the Worldwide Distribution Transformer Manufacturers

Schneider Electric

Hyosung Power & Industrial Sol.

Crompton Greaves

Bharat Heavy Electricals

SPX Transformer Solutions

Siemens

Mitsubishi Electric

Toshiba Corp

ABB

Eaton Corp.

Daelim Belefic

Get it now: How to choose the best distribution transformer?

Purpose

Industrial power transformers are typically utilized to either reduce or increase the voltage of the electricity while maintaining the same level of current.

Keeping the current constant is how this is practically achieved.

Power transformers serve not one but two distinct purposes in electrical systems:

- regulating voltage

- isolating properties

A step-up transformer can be specifically used to increase and decrease the voltage at the load. Both types of transformers are necessary in conjunction with each other.

A transformer can also be usually constructed with an identical number of coils at each terminal. There will be no voltage fluctuations because of this. However, they perform a necessary function in terms of safety.

Electrical transformer manufacturers have come up with a large number of different designs because there are so many different uses for power transformers.

Therefore, high-voltage transformer manufacturers need to be proficient in both design and precision manufacturing to give their customers the best possible performance and cost/energy efficiency.

Reading more: Basic Guide Of Electrical Transformer

Application

By promoting the responsible, safe, and cautious use of electricity, manufacturing facilities will experience fewer power interruptions.

Auto Industry Market

The batteries of several electric vehicles can be simultaneously charged, thanks to modern transformer technology.

By keeping an eye on the current, they can also contribute to cost savings.

They are also used in numerous fields including the following:

- Aerospace

- Medicine

- Information Technology

- Telecommunications

- Manufacturing

You may enjoy: Pad Mounted Transformer

Field of Electrochemistry

In the realm of electrochemical manufacturing, electroplating is a prevalent procedure.

Rectifier transformers serve a crucial part in electrolysis processes involving materials such as copper, zinc, aluminum, chlorine, etc.

Industrial Production of Steel

High-voltage transmission can be also guaranteed by custom-built transformers that can handle the current. The type of industrial transformer commonly used in steelworks is the electric furnace transformer because it can handle relatively high currents.

Furnace transformers are resistant to the dielectric, mechanical, and thermal stresses that occur in a steel crucible.

In 2019, Daelim exported two electric furnace transformers to Mexico, and the customer is a well-known local steelmaking enterprise. One electric furnace transformer with a capacity of 20MVA and one with a capacity of 6MVA are used to replace the old transformers. Currently, these two transformers are operating safely in Mexico, and the customer gave Daelim a high evaluation.

Overall, the construction of industrial transformers is essential for usage in high-temperature environments like those found in steel and ferroalloy furnaces.It is also suggested that industrial transformers undergo factory acceptance testing, which should include both standard quality tests and any additional testing requested by the end user.

Design

An industrial transformer is only going to perform successfully if the input voltage, output power, operating temperature, network design, cyclic load, and current all meet all design specifications.

- Capacity to cool down and heat protection

- Monitoring

- Regulating Voltage

- Saturable reactor

- Technology to protect against strong magnetic fields

- Installing high-power-density systems in small quarters with oil-cooled designs

- On/No Load Tap Changer

- Stable grounding or earthing

- Lead connection designs including magnetic field correction

Learn more about Transformer Design

In general, industrial power transformers are significantly larger than their residential and commercial equivalents.

More strict safety procedures may be necessary to prevent environmental damage when using transformers in more remote applications, such as supplying lighting for oil rigs.

The choice between a liquid coolant and a gaseous coolant for the transformer's cooling depends on the application and features.

The required resistance to heat, radiation, and pressure should also be carefully considered. Thus, it is crucial for high-voltage transformers manufacturers to include all of the standard features found in industrial transformers.

Key Features

- Structured in multiple dimensions

- Vector groupings

- ATEX certification

- On/No Load Tap Changer

- Modular transmission

- Operation in extreme environment

- Filter winding

Technical Features

- Energy ratings up until 200 MVA

- 2nd voltage between 800 V - 36 kV

- Supplemental harmonic filtering

- Merge with frequency converter

Specifications

Here are some of the specifications of an industrial transformer that high-voltage transformer manufacturers should always take into account when producing.

Phase

Single-phase and three-phase systems are both available. The coils are different for each step.

Transformers should generate a 1000-watt AC power source, making it ideal for use with computers and other electronic gadgets.

Kilovolt Ampere Rating

The load that a transformer is usually designed to carry must be more than the kilowatts per square inch (kVA) rating that the transformer carries.

Full-Size Amps Current

The full load current is the maximum current that can flow through a winding. The full-load current can be naturally determined from the following data: voltage, kilowatt-second rating, and the number of phases.

Vector

Similar vector groups are also required for parallel connections of transformers to eliminate the recirculation of current and other potential system disruptions.

Dimensions

The height (H) and width (w) of the window are common units of measurement for electrical power transformers.

The diameter of the border circle (d) and the width (a) of the largest stamping are also critical dimensions.

Weight

Multiplying the transformer's kilovolt ampere (kVA) rating by its basic insulation class yields the transformer's total mass (BIL).

It is possible to determine the core density, winding densities, and insulating oil density.

Terminals

High voltage (H terminal) and low voltage (X terminal) refer to the two ends of a transformer.

These connections are either "primary" or "secondary," meaning they are either directly connected to the power supply or the load.

Serial Number

Transformer serial numbers typically include the country of origin in addition to the year and month of production.

Criteria for Quality

Businesses in the electrical and electronic sectors are generally expected to adhere to global standards developed and proposed by the International Electrochemical Commission (IEC) and ISO Standards.

The standards and government requirements of different countries are also different. For example, the United States requires no more than 2500 kVA distribution transformers. While complying with IEEE standards, they must meet the requirements of DOE 2016 energy efficiency values and must have UL certification.

For Canadian countries, it is required to meet the CSA standard and must have a CSA or CUL certificate.

So here is a reminder for you. When purchasing industrial transformers, be sure to review the qualifications of industrial transformer manufacturers. You can choose only those that meet the requirements, otherwise, it will bring you a lot of trouble and economic losses.

Installation

To set up a transformer effectively, one must be familiar with its function.

Here are the necessary steps you can follow in installing your industrial transformer. Remember that all high-voltage transformer manufacturers has their manual that you can follow and read.

- Make sure all metal fixtures and electrical wiring meet local building codes before beginning the installation process.

- After settling on a solid grounding plan, you may pick the right connectors and cables for your transformer installation.

- It is crucial for the functionality of electronic projects to connect the transformer casing to the chassis ground.

- A ground rod must be basically connected to the case ground terminal of an outdoor power transformer.

- The input/output neutral should also be connected to the ground if possible.

- Make sure the power is off and the right cables and plugs are generally used before connecting the primary input wiring.

- Verify that the input wiring is correct.

- The transformer must be always located and a new fuse or circuit breaker.

- After that, the fuse or circuit breaker that protects the input voltage is connected to the primary wire of the transformer.

- Then check with the secondary windings. As they are often powered by different voltages. These conductors receive their energy from the windings.

- A wiring diagram is necessary so that you know what wires go where. Make sure you use the right-sized and colored wires for easy identification.

- The next step is to attach the cables to the apartment's preexisting electrical infrastructure.

- If you think it's required, add more insulation.

Daelim has local installation and maintenance teams in North America, South America, Australia, and other markets. Offer installation service and guidance for your industrial transformer.

You may enjoy: 3 Phase Pad Mounted Transformer

What Is The 2023 Forecast Market Across Electrical Transformer Manufacturers?

The worldwide distribution transformer market is generally expected to expand and prosper between 2023 and 2027.

The market for distribution transformers is practically expected to expand at a compound yearly growth rate of 4.99% between 2022 and 2027.

This will bring revenue from $210 million in 2023 to $509 million by the end of the forecast period.

By conducting a thorough analysis of various key participants in the distribution transformers market, this study aims to assist clients in strengthening their position within the industry.

This discusses potential future trends and challenges in the distribution transformers industry.

It will put distribution transformer manufacturers in a better position to anticipate and seize future growth possibilities.

- Arkansas Electric Cooperative Corporation

- Lemi Trafo JSC

- Hitachi Energy Limited

- Wilson Transformer Co. Pty Limited

- EL Sewedy Electric Corp

- DB Transformer

- CG Power

- Voltamp Transformers Limited

- ORMAZABAL

- Celme Srl

- Industrial Solutions Limited

- Fuji Electric

- Kirloskar Electric

- Melrose Industries

These factors, among others, are driving the forecasted 4.98% CAGR for this subsegment throughout the forecast horizon.

Currently, there has been a dramatic increase in the use of smart transformers in manufacturing settings as a result of the competitive advantage they bring.

Overall, rising investments in energy generation, industrialization, and urbanization are driving a surge in global demand for transformers.

And in response, market participants are investing in R&D to create more eco-friendly models.

Contact Daelim As Your Industrial Transformer Manufacturer

If you're looking to buy an industrial, electrical, distribution, and high-voltage transformer, then you've come to the right place.

Daelim factory has a complete quality control system, not only does has an ISO9001 certificate but also has UL/cUL, CSA, CE, CESI, and other certifications. Every transformer that leaves the factory will be strictly tested according to international standards to ensure that each unit transformer that reaches the customer is of high quality.

We know how important it is to find the right product that meets your needs, and we're here to help you get there.

At Daelim, we're dedicated to providing our customers with top-ranking transformers at affordable prices. We qualify as one of the best industrial transformer manufacturers in the industry and offer a variety of options for all types of applications.

Whether you need a large power transformer or a small distribution transformer, we have what you need. The Daelim team is ready to help you find the perfect transformer for your needs, so don't hesitate to Call Daelim Today.

Related Products

Related Article

Power Transformer Manufacturers Around the World

In this article, we will tackle the top power transformer manufacturers around the world including snippets of the most powerful transformer and a short guide on how to choose a power transformer manufacturer.

Ultimate Guide To Transformer Sizes and Ratings

Transformers come in a wide range of sizes and ratings, and the specific requirements of the application will determine the appropriate size and rating for a particular transformer. It is important to choose a transformer that is specifically designed and rated for the required voltage, current, power, frequency, and temperature levels.

How To Choose A Transformer Supplier?

Daelim is a professional IEEE/ANISE, CSA, AS/NZS standard transformer supplier. It has all the qualification certificates (UL/cUL, CSA) to enter the North American market. Dalin has a large number of transformers in operation in the United States and Canada, including pad mounted transformers, single-phase transformers, small substation transformers, power transformers, etc.