3 Phase Pad Mounted Transformer

- Primary Voltage Ratings: 34.5-19.92/13.8-7.957/13.2-7.62/12.47-7.2,44 kV or others

- Secondary Voltage Ratings: 240/480/480Y-277/600Y-347 or others

- H.V. TAP RANGE: ±2×2.5% or others

- CONNECTION TYPE: Dyn11/Yyn0 or others

- TYPE: Loop feed/Radial feed

- BIL: 30-200 kV

- Standards: IEEE/ANSI, CSA, IEC, DOE, NEMA

- Application: BESS, EV Charging, Ultiliy, Bitcoin Mining, Data Center,Real Estate, Solar photovoltaic power generation

- Power Rating: 75 kVA—10000 kVA

Daelim Transformer is a professional pad mounted transformer manufacturer located in Houston, USA.Specializes in manufacturing 3 phase pad mounted transformers with voltages up to 46 kV and power ratings up to 10 MVA. With over 200 projects completed annually in the Americas, we've installed over 10,000 transformers in the North American market. Our team is well-versed in IEEE, DOE, NEMA, CSA, IEC, and other standards, ensuring compliance and quality. Additionally, our transformers carry UL, cUL, CSA, FM, SGS, and other certifications

Quote Now

Three Phase Pad Mounted Transformer Description

The three phase pad mounted transformer is an oil filled distribution transformer designed for underground distribution loads in commercial settings like shopping centers, schools, and industrial plants. It comes in live front and dead front constructions, suitable for loop feed and radial feed applications, with or without taps. Featuring aluminum or copper windings, it's engineered for efficiency and compactness. Benefits include high voltage, stable neutral point, low loss, small size, cost-effectiveness, safety, environmental friendliness, and an appealing design.

Pad Mounted Transformer Price

The table below provides a price list for 3 phase pad mounted transformers for your reference only. Please note that prices may vary significantly based on different configurations and requirements. Contact us now to get an accurate price for your specific pad mounted transformer.

| Pad Mounted Transformer Price List | |||

| 45 kVA | 6-8K | 1000kVA | 18-36K |

| 75 kVA | 8-10K | 1500 kVA | 20-40K |

| 112.5 kVA | 9-12K | 2000 kVA | 22-45K |

| 150 kVA | 10-15K | 2500 kVA | 25-50K |

| 225 kVA | 12-18K | 3000kVA | 28-56K |

| 300 kVA | 13-20K | 3750 kVA | 30-60K |

| 500 kVA | 14-25K | 5000 kVA | 40-70K |

| 750 kVA | 15-30K | 10 000 kVA | 100-150K |

Pad Mounted Transformer Parts

| Standard Parts | Optional Parts |

| ELSP fuse Bay-O net fuse Oil level gauge Drip tray Drain valve HV bushings LV bushings Carbon steel tank Liquid temperature gauge Pressure vacuum gauge Oil drain valve with sampler Tap changer(5-position/7-positon) Load break switch(4-position or 2-position) | CT IR window ISO link Elbow arresters Kirk key interlock Pressure relief device Sudden pressure relay IFD(fault indicator light) Loadbreak feed-thru insert DV( dual voltage switch) 304/306 stainless steel tank Gauges with alarm/trip contacts NEMA 4 or NEMA 4X rated enclosure Under oil arrester with disconnector |

Live Front Transformer

The live front transformer features both high-voltage and low-voltage terminals exposed and unshielded when the compartment doors are open. Its high-voltage compartment is equipped with spade-type porcelain bushings with exposed conductor connectors on top. Each unit of the live-front transformer has three high-voltage bushings. Cable connections are made using mechanical lugs or clamping plugs. For a GrdY primary configuration, the high-voltage neutral is internally connected to the tank wall at the designated and marked H0 external high-voltage ground terminal.

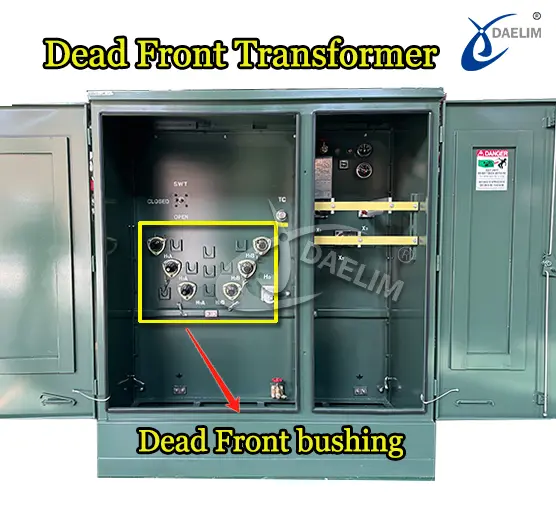

More DetailDead Front Transformer

The dead-front pad-mounted transformer is equipped with three/six high-voltage bushings on the high-voltage side, which are completely enclosed in insulating material for enhanced safety. When the hatch is opened, the high-voltage terminal remains unexposed, ensuring higher safety performance.

Dead-front transformers have two configurations: loop feed and radial feed. In the radial feed configuration, there are three bushings on the high-pressure side, while in the loop feed configuration, there are six bushings on the high-pressure side. In the loop feed setup, three bushings can be connected to cables, and the remaining three bushings can be connected to arresters. Alternatively, all six bushings can be connected to cables.

Send Inquiry Now

Dead Front Transformer

Dead front transformer comes with 200A and 600A separate bushings (bushing well + bushing insert) or a one-piece bushing. In the case of the dead-front transformer with a 200A HV bushing, it can be fully shielded and insulated for the load-break elbow connector connection to the underground cable. For the dead-front transformer with a 600A HV bushing, the current needs to be converted into 200A through the T-body dead-break connector before being connected to the underground cable via the load-break elbow connector. ome BESS projects require 3-phase pad-mounted transformers with 900A dead front bushings, and Daelim Transformer can meet these requirements. We have completed numerous BESS and photovoltaic projects.

Daelim Transformer pad mounted transformer projects

Daelim Transformer pad mounted transformer projects

Learn more about Daelim Transformer Projects

3 Phase Pad Mounted Transformer Sizes

The sizes of 3 phase pad mounted transformers vary based on power ratings, primary and secondary voltages, materials, etc. The table below provides specific dimensions of some pad mounted transformer projects completed by Daelim Transformer for your reference only.

| 3 Phase Pad Mounted Transformer Sizes | ||||||

| kVA | Type | HV | LV | W(mm) | D(mm) | H(mm) |

| 75 | radial | 25000Delta | 480GrdY/277 | 1280 | 1085 | 1085 |

| 150 | loop | 14400v | 600GrdY/347 | 1480 | 1250 | 1750 |

| 225 | radial | 4160Delta | 347GrdY/600V | 1480 | 1295 | 1750 |

| 300 | loop | 345000 | 208GrdY/120 | 1500 | 1730 | 1850 |

| 500 | loop | 1247Grdy/7200V | 600Y/347 | 1447 | 1800 | 1750 |

| 750 | radial | 24940GrdY/14400 | 800GrdY/462 | 1485 | 1730 | 1750 |

| 1,000 | radial | 249400DELTA | 480V | 1730 | 1350 | 1850 |

| 1,250 | loop | 25000V | 416V | 1730 | 1320 | 1920 |

| 1,500 | loop | 4160GRDY/2400 | 600GrdY/347 | 1730 | 1910 | 1965 |

| 1,500 | loop | 34500DELTA | 480GrdY/277 | 2220 | 2069 | 2065 |

| 1,750 | loop | 13800Delta | 480GrdY/277 | 1730 | 2304 | 1900 |

| 2,000 | radial | 4160DELTA | 415GrdY/240 | 1730 | 1950 | 1810 |

| 2,500 | loop | 25000DELTA | 600GrdY/347 | 1730 | 2560 | 1960 |

| 2,550 | loop | 12470DELTA | 415GrdY/240 | 1730 | 2000 | 2200 |

| 2600 | Loop | 34500DELTA | 416GrdY/240 | 1730 | 1695 | 2290 |

| 3000 | Loop | 27,600DELTA | 13,800DELTA | 1830 | 2360 | 2000 |

| 4000 | loop | 27600Delta | 600GrdY/347 | 1900 | 2500 | 2010 |

| 5000 | radial | 13,800DELTA | 4,160GrdY/2,400 | 1900 | 2735 | 2500 |

| 7000 | loop | 27,600DELTA | 13,800DELTA | 2200 | 3030 | 2080 |

| 7500 | loop | 249400DELTA | 4.16kv Wye | 2300 | 3200 | 2100 |

| 10000 | loop | 24900GrdY/14400 | 600V | 2800 | 3500 | 2560 |

Remind

If you need to know the specific size of the transformer you require, please send the transformer specifications to [email protected] or [email protected] to obtain the information.

3 Phase pad mounted transformer grounding

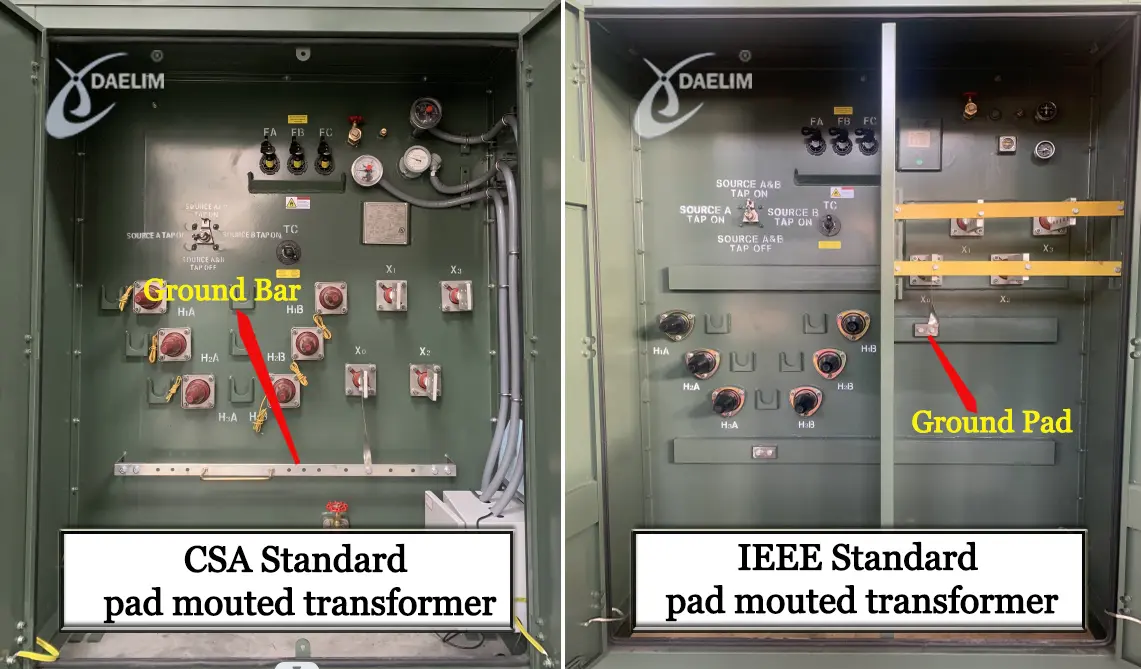

CSA Standard Grounding Provisions

According to CSA standards, grounding provisions for three phase pad mounted transformers include two vertically mounted earth spade terminals welded to the tank wall at a height of at least 150 mm at or above sill level. One terminal is placed on the high-voltage side and one on the low-voltage side. For GrdY transformers, the high-voltage side terminals shall be designated and marked H0. Both terminals shall be unpainted, made of stainless steel, with a width of not less than 40 mm and a thickness of not less than 6 mm. Each terminal is provided with two 14 mm (9/16 inches) holes, spaced 44.5 mm apart.

IEEE Standard Grounding Provisions

For transformers of 500 kVA and below, two steel pads shall be provided, each having a 1/2% inch 13 UNC tapped hole and a minimum thread depth of 11 mm (0.44 in.).

For transformers above 500 kVA, two unpainted copper-faced steel or stainless steel pads measuring 51 x 89 mm (2.0 x 3.5 in) each shall be provided. Each pad has two holes spaced 44 mm (1.75 in) on centers and tapped for a 1/2%-inch 13 UNC thread. The copper finish shall be not less than 0.5 mm (0.02 in.) thick, and the thread depth of the hole shall be not less than 13 mm (0.5 in).

Location

The ground pads should be welded on or near the transformer base, one in each high-voltage compartment and one in each low-voltage compartment. If the transformer tank and compartment are separate, these pads shall be electrically connected.

Pad Mounted Transformer Components

Pad mounted transformers have several key components:

- Transformer Tank: Made of steel, it houses the core and windings.

- Transformer Core: Provides a path for magnetic flux.

- Transformer Windings: Copper or aluminum conductors wrapped around the core.

- Bushings: Insulating devices for electrical connections.

- Tap Changer: Adjusts output voltage as needed.

- Insulating Oil: Provides insulation and cooling.

- Gauges: Measures parameters like oil temperature and pressure

- Lifting Lugs: Used for transportation.

- Grounding Terminals: Ensures electrical safety.

- Nameplate: Displays essential information.

- Loadbreak Switch: Allows for the safe interruption of current flow during maintenance or repairs.

- Fuses: Protects against overcurrent conditions by melting when the current exceeds a certain threshold.

Try for free: Comprehensive Guide to Pad-Mounted Transformers

Daelim Transformer Service

Daelim has a local transformer after-sales service center in North America and South America in the United States, Canada, Mexico, Chile, Ecuador, and other North America. It can be installed, after-sales, maintenance, and other services for transformers locally, and responds 24 hours.

Daelim Transformer's site in Houston has a large number of pad mounted transformers that can be shipped without waiting. Contact us for inventory information

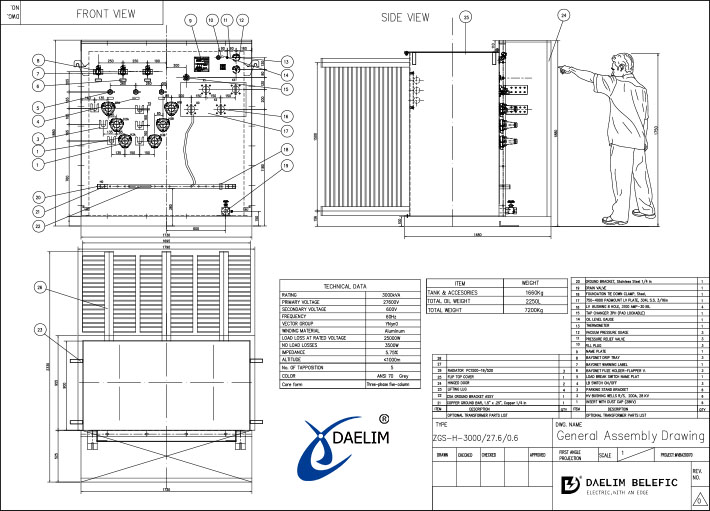

Pad mounted transformer diagram

Daelim Transformer has a professional technical team, which can draw the outline drawing of the transformer for you in a very short time according to your technical parameter requirements.

Learn more about Transformer Diagram

Three phase pad mounted transformer package

Daelim transformer uses the packaging method of wooden boxes and wooden pallets.

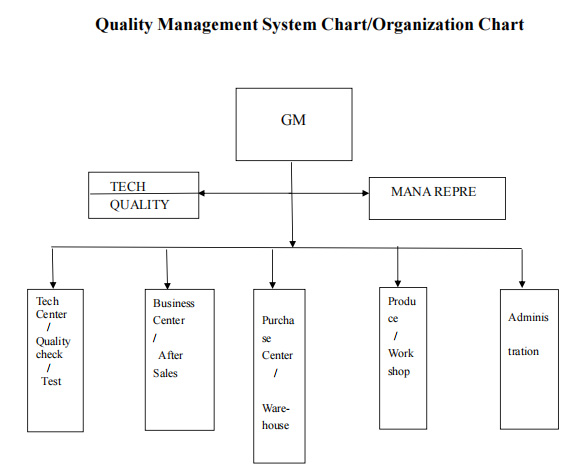

Daelim's pad-mounted transformer quality and tech control

The Daelim Transformer factory has strict technical and quality control to ensure each transformer's reliable, safe, and electrical performance.

Learn more about Pad Mounted Transformer

Daelim Transformer Offers Tailored Transformer Solutions

With a team of highly professional and experienced engineers and marketing service experts, Daelim Transformer can swiftly immerse itself in your project to deliver the optimal transformer solution. Whether your venture falls within industries such as Manufacturing, Utilities, Battery Energy Storage Systems (BESS), Electric Vehicle (EV) Charging, Renewable Energy, Real Estate, Crypto mining, Oil and Gas, or others, Daelim Transformer stands ready to provide you with expert Transformer Solutions.

Pad Mounted Transformer FAQ

The 3 phase pad-mounted transformer is a electrical transformer that integrates bay-o net fuses, backup fuses, tap changers, load break switches (2/4 positions), low voltage distribution devices, and other auxiliary equipment, all based on conventional oil-immersed transformers. It operates at a rated AC frequency of 50Hz/60Hz, with a maximum working voltage up to 35 kV and a capacity ranging from 75kVA to 10000 kVA.

Pad-mounted transformers are widely used due to their high stability and reliability, covering various fields such as power transmission, distribution, industry, transportation, aerospace, communications, and more. Specific applications include:

- General use

- Industrial sites

- Electrical distribution rooms

- Basement distribution

- BESS

- Manufacturing facilities

- Steel mills

- Offshore oil platforms

- Commercial and public places

- Military installations

- Utilities

- Processing plants

Pad mounted transformers are mainly used in regions like North America, South America, and the Middle East, including countries such as the United States, Canada, Mexico, Panama, Honduras, Venezuela, the Dominican Republic, Saudi Arabia, and others.

Pad mounted transformers save energy and offer environmental benefits. Their higher efficiency extends their lifespan and reduces costs for owners through lower energy bills and decreased ownership expenses.

Safe and Reliable: They use efficient insulation protection and heat dissipation equipment, with a well-designed cable cabinet structure ensuring safety and reliability. They have a strong overload capacity, allowing for 2 times overload for 2 hours and 1.6 times overload for 7 hours without affecting their lifespan.

Convenient Connections: The use of elbow plugs makes it easy to connect high-voltage incoming cables, allowing for plug-in and plug-out operations under power.

Strong Defense Capability: They can effectively resist instantaneous voltage peaks, protecting power equipment from damage. They also feature double fuse protection:

Insertion Fuse (BAY-o-NET): A dual-sensitive fuse (temperature and current) protecting against short-circuit faults on the secondary side.

Backup Current Limiting Protection Fuse (ELSP): Protects against faults inside the transformer and the high-voltage side.

Flexible Power Supply: They can be either terminal type or ring network type, allowing one transformer to supply power to another, enhancing power supply distance and reliability.

Energy Saving and Environmental Protection: Designed with energy efficiency and environmental protection in mind.

Related Products

Related Article