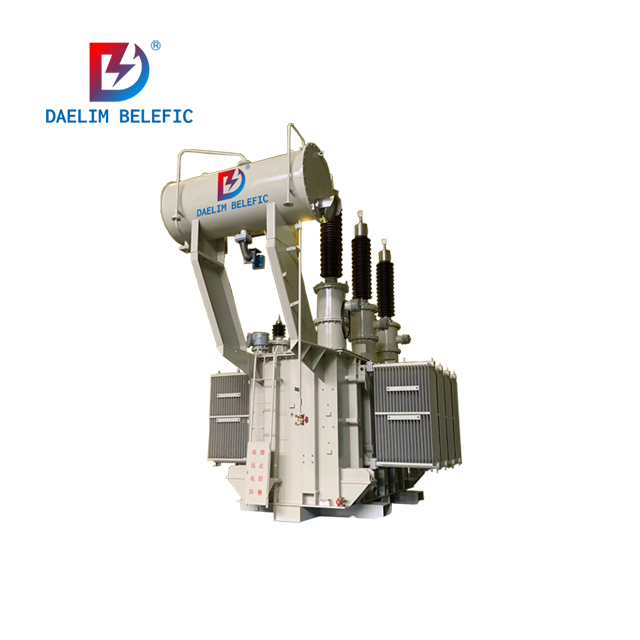

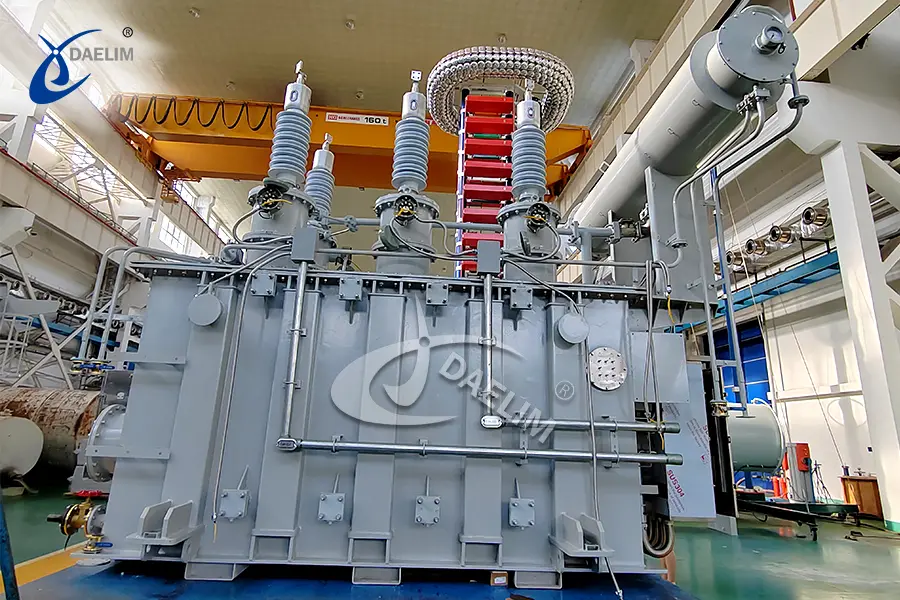

132kV 60 MVA Transformer

- Primary Voltage Ratings: 132 kV

- Secondary Voltage Ratings: 11.5 kV

- H.V. TAP RANGE: 17 STEPS TAPPING WITH EACH STEP 1.5%

- CONNECTION TYPE: DYN11

- TYPE: FREE BREATHING, CONSERVATOR TYPE

- Standards: IEC

- Application: QATAR POWER TRANSMISSION SYSTEM

- Power Rating: 60MVA

- Cooling Method: ONAN

The 132 kV 60 MVA transformer is an outdoor, oil-immersed, three-phase unit with an on-load tap-changer, designed for continuous operation in a 50 Hz transmission system. It has a 50°C temperature rise, 10°C below IEC limits, and is suitable for tropical, corrosive environments. The transformer features IP55 protection, high-quality construction, and accessories for operation and maintenance, including a welded steel conservator and ONAN cooling. It meets latest design standards, suppresses harmonic currents, and is tested per IEC standards.

Quote Now

The 132 kV 60 MVA transformer is an outdoor, oil-immersed, three-phase unit with an on-load tap-changer, adhering to IEC standards. Insulation A class. Designed for continuous operation in a 50 Hz high-voltage transmission system, it features a temperature rise of 50°C, which is 10°C lower than the limits specified by IEC 60076-2 and IEC 60076-7.

Service and Environmental Conditions:

- Max Ambient Temperature: 49°C

- Min Ambient Temperature: -1°C

- Direct Sunlight Temperature: 82°C

- Design Ambient Temperature: 50°C

- Max Relative Humidity: 96% at 49°C

- Altitude: 7.25 meters above sea level

- Environment: Corrosive and humid, tropical

- Degree of Protection (IP): IP55

Additional Accessories:

- Winding Temp Indicator with 2 Contacts

- Liquid Level Indicator with 2 Contacts

- Moving and Jacking Facilities

- Liquid Temperature Indicator with Alarm Contacts

- Pressure Safety Relief Valve with Alarm & Trip Contacts (2 sets)

- Upper Filter Plug or Cap (for units above 2500 kVA)

- DGPT2 Integrated Device

- Lifting Eyes for Cover

- Globe Type Combination Drain and Lower Filter Valve

- Pressure-Vacuum Gauge (Sealed-Tank Construction)

- Sampling Device

- Pressure-Vacuum Bleeder Device (Sealed-Tank Construction)

- Marshalling Panel/Cabinet

- Tap Changer

- Facilities for Lifting Core and Coil Assembly

- Lugs for Lifting the Complete Transformer

- Rating Plate with Winding Diagram

- Stainless Steel Nameplates

- Earthing Lugs (2 sets)

- Breather/Drain for Terminal and Marshalling Boxes

- Ground Pads

- Fault Pressure Relay with Contacts

- Space Heater for Marshalling Kiosk & Terminal Box

- Valve for Radiator (Top & Bottom)

- Padlocking Device for Tap Changer & Terminal Box

Design and Construction:

- Meets the latest development standards in design, construction, and materials.

- Capable of withstanding short-circuit currents and all tapping positions per IEC 60076-5.

- Average surface noise level complies with NEMA TR1.

- Designed to suppress harmonic currents, minimize interference, and prevent leakage flux overheating.

Mechanical Protection:

- All external wiring, control panels, and accessories are shielded for rain protection.

- Accessories, wiring, and components are robust for harsh Qatar weather.

- Control cables are routed through metal conduits for protection.

Magnetic Circuit:

- Core made from high-grade, non-aging, low-loss steel sheets.

- Sheets are insulated with durable, heat-resistant varnish.

- Core is clamped and braced to withstand short-circuit stresses and vibrations.

Windings:

- Made of high-conductivity electrolytic copper with thermally upgraded paper insulation.

- Assembled core and windings are dried in a vacuum to ensure moisture removal.

Tank:

- Welded construction with bolted cover, high tensile strength steel plate.

- Equipped with bolted manholes and hand-holes for maintenance and inspection.

Cooling and Conservator:

- ONAN cooling plant.

- Conservator made of welded steel, designed to withstand a full vacuum and facilitate oil expansion and contraction.

Transformer Oil:

- Highly refined mineral naphthenic oil, free from corrosive sulfur, PCB, DBDS, antioxidants, passivators, and metal deactivators.

Inspection and Testing:

- All tests performed in accordance with IEC 60076, IEC 60060, IEC 60270, and other relevant IEC standards.

60 MVA Transformer Transportation

Related Products