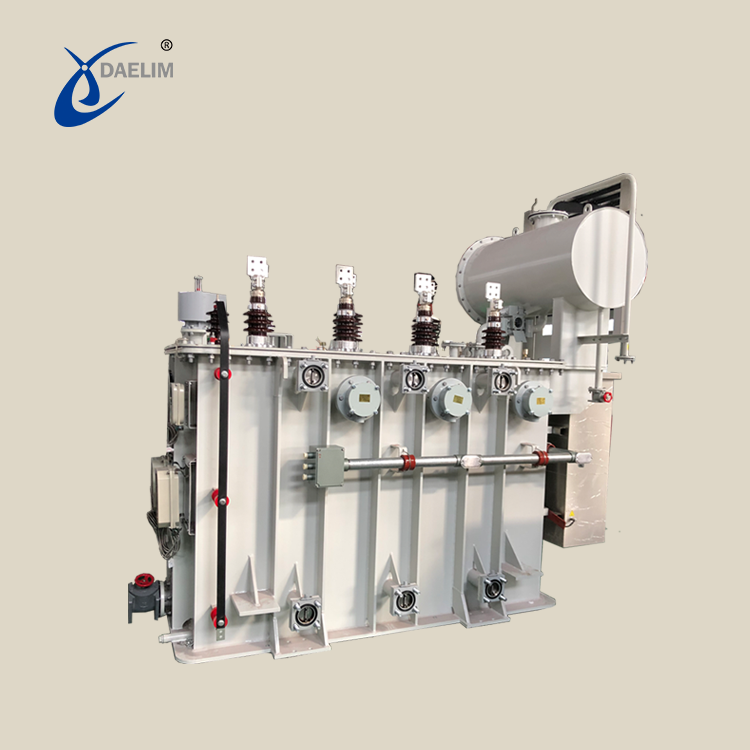

20KV Class Three Phase Oil-Immersed Distribution Transformer

- Primary Voltage Ratings: 20

- Secondary Voltage Ratings: 0.4

- H.V. TAP RANGE: ±2×2.5%

- CONNECTION TYPE: Dyn11

20KV Class Three Phase Oil immersed Distribution Transformer capacity from 100kVA to 3000kVA.

Quote Now

Compared with the 10kV class, the 20kV three phase oil-immersed distribution transformer has some advantages:

Compared with the 10kV class, the 20kV three phase oil-immersed distribution transformer has some advantages:

1. Increase power supply capability

2. Ensure the voltage quality

3. Debase the electric energy loss in the power system, etc.

It can save the construction fee of the power system. It is the developing product of energy conservation in power systems.

20kV Three-phase oil-immersed distribution transformer Specification

| Rating | No Load Loss | On load Loss | Connection | Oil Weight(kg) | Tatal Weight(kg) |

| 100kVA | 200 | 1500 | Dyn11/Yyn0 | 115 | 600 |

| 200kVA | 335 | 2600 | 170 | 980 | |

| 400kVA | 560 | 4300 | 240 | 1525 | |

| 500kVA | 670 | 5100 | 270 | 1780 | |

| 630kVA | 840 | 6200 | 320 | 2050 | |

| 800kVA | 980 | 7500 | 490 | 2800 | |

| 1000kVA | 1190 | 10300 | 570 | 3030 | |

| 1250kVA | 1360 | 12000 | 650 | 3535 | |

| 1600kVA | 1640 | 14500 | 750 | 4350 | |

| 2000kVA | 1980 | 18500 | 950 | 5040 | |

| 2500kVA | 2260 | 22500 | 1250 | 6060 | |

| 3000kVA | 2730 | 27000 | 1800 | 7200 |

Low-voltage windings generally adopt a cylindrical structure made of copper foil except for small-capacity copper wires. High-voltage windings adopt a multi-layer cylindrical structure so that the ampere-turns distribution of the windings is even, the magnetic leakage is small, and the mechanical strength is high. Strong short-circuit resistance.

The iron core and the windings are respectively tightened, and the tightening parts such as the height of the device and the low-voltage lead are equipped with self-locking lock nuts, and the suspension core structure is adopted, which can withstand the bumps of transportation.

The coil and iron core are dried in a vacuum, and the transformer oil adopts the process of vacuum filtering and oil injection to minimize the moisture inside the transformer.

The oil tank adopts a corrugated sheet, which has a "breathing" function to compensate for the volume change of the oil caused by the temperature change,

Since the corrugated sheet replaces the oil conservator, the transformer oil is isolated from the outside world, which effectively prevents the entry of oxygen and moisture, which leads to the decline of the insulation performance.

According to the above five points of performance, it is ensured that the transformer does not need to be changed during normal operation, which greatly reduces the maintenance cost of the transformer and prolongs the service life of the transformer.