15 MVA Power Transformer

- Primary Voltage Ratings: 34.5kV

- Secondary Voltage Ratings: 12.47kV

- TYPE: Oil immersed seal type

- BIL: 200/110kV

- Standards: IEEE

- Application: Substation

- Power Rating: ONAN 15 MVA & ONAF 20MVA

- Certificate: UL

- Cooling Method: ONAN/ONAF

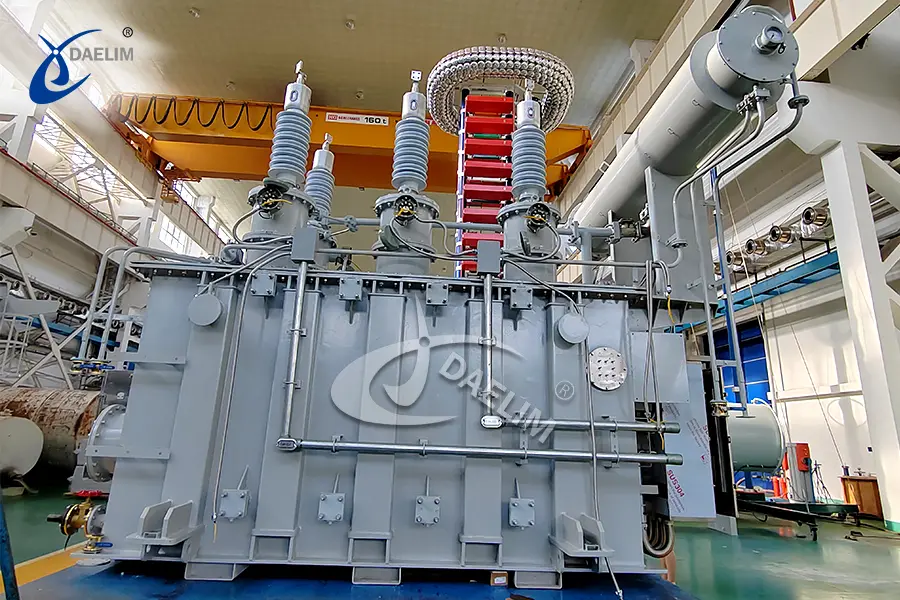

Daelim Transformer’s latest 15 MVA power transformer, boasts advanced features such as an MR load tap changer, 316L stainless steel construction, and robust cooling and temperature management systems. Adhering to rigorous IEEE standards, it ensures reliable performance in harsh environments and has undergone comprehensive testing before shipment.

Quote Now

In August 2024, Daelim Transformer delivered a cutting-edge 15 MVA power transformer to the United States for a substation, underscoring our commitment to excellence in the North American power market. This latest transformer, equipped with advanced technology and designed for harsh environments, highlights Daelim Transformer’s ongoing dedication to quality and innovation.

Advanced Specifications and Design

The 15 MVA power transformer features several notable attributes designed to ensure optimal performance and durability:

- Load Tap Changer: The transformer is fitted with an MR load tap changer (LTC) on the secondary side, enhancing voltage regulation and stability.

- Corrosion-Resistant Construction: Built for outdoor installation in corrosive, salty, and tropical marine environments, the transformer utilizes 316L stainless steel for all tanks, radiators, and fittings. This ensures long-lasting protection against environmental stressors.

- Cooling System: The unit is air-cooled rated 15 MVA with one stage fan-cooled rating of 20MVA , featuring stainless steel radiators and fan motors (240V, single-phase, 60Hz). It is equipped with automatic control equipment and a fan failure alarm system to maintain operational reliability.

- Temperature Management: Designed for operation at a maximum ambient temperature of 40°C, the transformer’s average winding temperature rise is 65°C at full load. The hottest-spot winding temperature rise above ambient is capped at 80°C, ensuring efficient performance even under high-load conditions.

- Dielectric Coolant: The dielectric coolant complies with NEC Section 450-23 standards and is maintained under positive nitrogen pressure. The system includes an alarm to detect any pressure deviations.

- High-Voltage and Low-Voltage Terminals: The high-voltage terminal chamber features four sidewall-mounted bushings with NEMA terminal pads and three polymer station-class surge arrestors. The high voltage bushings located in ANSI Segment 2. The low-voltage terminal chamber includes multi-ratio current transformers and surge arrestors for comprehensive protection.

State-of-the-Art Components

- Core and Windings: The transformer core is constructed from high-grade, grain-oriented silicon steel laminations, while the windings are made of copper, optimizing both performance and efficiency.

- Connection Configuration: It features a Grounded Wye – Grounded Wye connection with separate neutrals and a buried delta-connected stabilizing (tertiary) winding for enhanced operational stability.

- Load Tap Changer Details: The MR load tap changer includes a diverter mechanism housed in a separate oil-filled compartment. This compartment is equipped with a pressure fault relay, an oil level gauge, and a pressure relief device. The LTC control system offers both local and remote control options, automatic control capabilities, and a seven-digit non-resettable operations counter.

Rigorous Testing and Quality Assurance

Before delivery, the transformer undergoes thorough production testing in compliance with IEEE C57.12.90 standards, including Sweep Frequency Response Analysis (SFRA) and Dielectric Frequency Response tests. The customer's engineer visited our facility for final testing and all test results met and exceeded IEEE standards, ensuring the highest quality and performance standards for this 15MVA power transformer.

Shipping and Package

To safeguard against damage during transport, the 15 MVA power transformer’s radiators, bushings, and other components are removed, packaged separately, and wrapped in plastic within wooden boxes. Impact recorders, shielded against damage, are mounted on the transformer to monitor and verify any potential transport impacts upon delivery.

To safeguard against damage during transport, the 15 MVA power transformer’s radiators, bushings, and other components are removed, packaged separately, and wrapped in plastic within wooden boxes. Impact recorders, shielded against damage, are mounted on the transformer to monitor and verify any potential transport impacts upon delivery.

This transformer’s design and specifications highlight Daelim Transformer’s expertise in delivering reliable, high-performance solutions tailored to the demanding needs of the North American power sector. With over 30 large power transformers delivered this year to various industries, including BESS, solar energy, utilities, and commercial sectors, our collaboration with numerous Fortune 500 companies continues to solidify our reputation as a leader in the industry.

Applications

Ideal for various industries including Substation, Battery Energy Storage Systems (BESS), solar energy, utilities, and commercial sectors, the Daelim 15 MVA Power Transformer offers a robust and reliable solution for high-demand power distribution needs.

Contact Us

For more information or to request a quote, please contact Daelim Transformer. Our team is dedicated to providing top-quality service and support to meet your specific requirements.

Related Products

Related Article