4800 kVA Pad Mounted Transformer

- Primary Voltage Ratings: 34.5kV

- Secondary Voltage Ratings: 480V/277

- H.V. TAP RANGE: +/- 2@ 2.5% HV taps

- TYPE: Pad mount

- BIL: 150/30kV

- Standards: IEEE, ANSI, NEMA

- Application: BESS

- Power Rating: 4800kVA

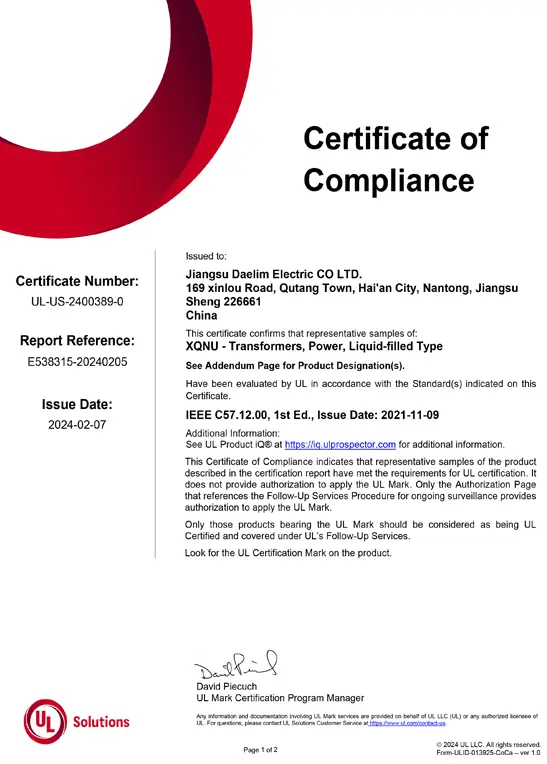

- Certificate: UL

- Cooling Method: KNAN

The 4800 kVA transformer is designed as a dead-front pad-mount unit, specifically tailored for integration into the 4-hour system. It employs a double-split design, where its low-voltage winding is divided into two 2400 kVA branches. Each Battery Pack benefits from a dedicated 2400 kVA capacity on both sides, ensuring efficient energy distribution. This design is exceptionally well-suited for large-scale energy storage projects, facilitating electrical isolation, minimizing electromagnetic interference, and enhancing power output quality. Additionally, in the event of a short circuit in one branch, it effectively limits the short-circuit current while maintaining the other branch at a stable level.

Quote Now

Transformer Factory Acceptance Test

Factory acceptance testing is carried out by IEEE C57.12.90 requirements, including the "Routine" and "Design" listed below

Routine Test

- Resistance measurements of all windings on the rated voltage tap

- Ratio tests on the rated voltage connection as listed on the nameplate

- Polarity and phase relation tests on the rated voltage connection

- Impedance voltage and load loss at rated current and rated frequency on the rated voltage connection, and at the tap extremes of the first unit of a new design

- Dissolved gas in oil analysis

- Winding insulation resistance

- Lightning impulse

- Low frequency

- Oil Leaks

- Turns ratio & phase angle accuracy test.

- Winding resistance test

- Polarity test

- No-load losses and excitation current at 100% of rated voltage and at rated power frequency on the rated voltage tap connections

- Excitation test

Design Test

- Resistance measurements of all windings on the rated voltage tap

- No-load losses and excitation current at 110% of rated voltage and at rated power frequency on the rated voltage tap connections

- Temperature rise at minimum and maximum ratings of the first unit of a new design

- Audible sound level

- Lightning impulse

- Partial discharge test

- Lifting and moving devices

Related Products