How Do You Choose a Transformer Size You Need?

When it comes to choosing the right transformer size does matter. For sure there are standard transformer sizes but there’s no such thing as one size fits all.

Having the right transformer size is crucial in ensuring efficiency and most importantly, the safety of your operation.

For example, an undersized transformer can lead to common issues like overheating which can lead to machine failure.

On the other hand, an oversized transformer is less likely to cause major problems but maintenance and energy consumption would be costly in the long run.

That is why it is important to know how to determine the optimal transformer size that fits your application and define the different factors that can affect the sizing process. Contact Daelim Transformer to help you determine the transformer rating size.

Contact Daelim TransformerIn this article, we will give you a quick step-by-step guide on how to choose the right transformer size. We will also take a look at the things you need to consider and the transformer calculations involved.

How To Choose the Right Transformer Size?

Step-by-Step Guide

-

Decide on the type of transformer based on load distribution.

There are two types of transformers based on load distribution or power supply. These are the single-phase and the three-phase types.

Single-phase types are more suitable for smaller load requirements and are practically used as voltage regulators in power distribution systems in residential areas.

While the three-phase transformer application is more inclined toward large businesses and industrial sectors. Like energizing high-power machinery such as furnaces and commercial HVAC systems.

As much as getting the suitable transformer size it is equally important to choose the appropriate type that is most suitable for your application.

Learn more about Transformer Size

-

Calculate your load requirement and load voltage.

The load requirement means the current rating of the electrical unit that your transformer needs to power or protect.

If you are connecting several electrical units, then you need the current rating of each unit and sum it up to get the total current rating.

Meanwhile, the load voltage refers to the rated voltage of an electrical unit. This typically equates to the power output your unit or system requires.

Current rating is expressed in units of amperes while voltage is expressed in volts.

Where can you find the current and voltage ratings?

The current and voltage ratings are normally found on the nameplate of the electrical device or equipment located at the back or on the sides of the panels.

-

Calculate the Required Transformer kVA Rating of Your System

At this point, you must have all the details needed for the transformer rating calculation. Utilize the formula below according to the transformer type you intend to use.

You can start your computation or better yet, keep reading for we will have a sample computation later.

| Single Phase Transformer | Three-Phase Transformer |

| kVA=(I×V)/1000 | kVA=(I×V×√3)/1000 |

| Where:

| |

-

Get familiar with the standard sizes and consider future expansion

Transformers are designed according to international standards which include standard sizing. Here are some examples of standard transformer sizes in the market according to application.

| Residential | Commercial | Industrial |

| 15kVA | 45 kVA | 500 kVA |

| 20kVA | 75 kVA | 1000 kVA |

| 25kVA | 150 kVA | 1500 kVA |

| 37.5kVA | 225 kVA | 2000 kVA |

| 50kVA | 300 kVA | 2500 kVA |

| 75kVA | 315 kVA | 3000 kVA |

| 100kVA | 450 kVA | 5000 kVA |

| 167kVA | 500 kVA | 10,000 kVA |

Note that these are only a few standard sizes that you can see in the market. Available sizes can also differ for each manufacturer.

You may enjoy: Different Transformer Types and Their Applications

If your requirement is unique or does not fall under any standard size, you might want to contact Daelim for professional advice to ensure that you get the right transformer size for your specialized needs.

Another important consideration would be upscaling. This is when you allocate an allowance for your transformer in case your capacity will increase in the future.

Having a calculated allowance will also protect your system from overloading in times when your load demand goes higher than your normal operating load. Boosting your capacity to 20% more is typically recommended.

Now it’s time to put this guide into application. Let’s have a simple sample calculation for transformer sizing based on its type.

Sample Calculation

Single Phase Transformer

A commercial lighting system running at 220V draws a total of 68 amps of power. Calculate the transformer rating required for this electrical system.

kVA=(I×V)/1000

kVA=(68A×220V)/1000

kVA=146,940VA/1000

kVA=14.96kVA≈15kVA

Based on this calculation, this lighting system requires a single-phase transformer with a 14.96 kVA rating or higher. If you check the standard size, the most suitable size would be 15kVA.

Computation if you want to upscale the capacity to 20%.

kVA= 14.96 kVA×0.2 = 2.99

kVA= 14.96 kVA + 2.99

kVA=17.95 kVA ≈ 20 kVA

Three Phase Transformer

Suppose a smelting company has to power a 120V and 700 amps furnace. Calculate the transformer rating that the furnace requires.

kVA=(I×V×√3)/1000

kVA=(700A×120V×√3)/1000

kVA=145,492VA/1000

kVA=145.49 kVA

To safely operate the furnace, according to this calculation, it requires a three-phase transformer with a 145.49 kVA rating or more. The best fit based on the standard sizing is 150 kVA.

Computation if you want to upscale the capacity to 20%.

kVA=145.49 kVA × 0.2= 29.098

kVA= 145.49 kVA + 29.098

kVA=174.588 kVA ≈ 225 kVA

Additional Factors To Consider

-

Power Factor

The power factor affects the overall performance of your transformer. The higher the power factor the better.

The ideal power factor would be 0.95 to 1. However, in reality, the power factor can go lower. A low power factor can result in poor power utilization and higher energy costs.

The power factor can be calculated using this formula:

| PF=KW/kVA | To get kVA: kVA=KW/PF |

| Where:

| |

Sample Computation

Let’s say you have two 20 KW motors. The first one has a power factor of 0.95 while the other has a lower power factor which is 0.8. Both motors are connected to a 600V supply.

| MOTOR A | MOTOR B |

| kVA=KW/PF=20KW/0.8 kVA= 25 kVA | kVA=KW/PF=20KW/0.95 kVA=21 kVA |

Theoretically, Motor A with a lower power factor requires 25kVA of apparent power while Motor B with a higher power factor only requires 21kVA.

From there, you will clearly see the difference. Both motors can deliver 20 KW of power but Motor A draws more power than Motor B.

In this case, Motor A is not economical as it would result in higher energy costs. It would likewise need larger wirings and a larger transformer.

Apart from that, a lower power factor can also cause additional issues such as voltage drop and excessive heat that can reduce the lifespan of your transformer.

-

Voltage Level

The voltage level is one of the factors that will determine the compatibility of the transformer size and the required voltage levels of your system. To check this you have to be aware of the voltage ratio.

Voltage ratio refers to the ratio of the number of turns of the primary windings to the secondary windings. Wherein the number of turns is directly proportional to the winding voltage.

To calculate the voltage ratio you can use this formula:

| VR=TR VR=Vp/Vs TR=Np/Ns | Thus Vp/Vs=Np/Ns |

| Where:

| |

The primary side is connected to the source while the secondary side is connected to the load which should have your desired voltage output.

Since the voltage ratio is directly proportional to the voltage ratio, as the number of turns on one side increases, the voltage level on that side also increases and vice versa.

Sample Computation

Voltage Ratio Calculations

Calculate the voltage ratio given a transformer with a primary voltage of 13200V and a secondary voltage of 400V.

VR=Vp/Vs

VR=13200V/400V

VR=33

This implies that every 33 Volts on the primary winding is equivalent to 1 Volt on the secondary side. If so, the voltage level is decreased or stepped down.

1000 kVA Power Transformer-13800V Delta Primary-600GrdY/347 Secondary

Turns Ratio Calculations

A transformer has 2500 turns on the primary side and 500 turns on the secondary side. Calculate the turns ratio.

TR=Np/Ns

TR=500/2500

TR=1:5

The results show that every single turn on the primary side corresponds to 5 turns on the secondary side. This means the output or voltage level is increased on the secondary side. Therefore, the voltage is stepped up.

If you are looking for a high-performance transformer then efficiency is one of the key features you need to watch out for.

Highly efficient transformers shall have 96% to 99% efficiency or higher. These types of transformers are expected to have lower maintenance costs, minimal losses, and overall enhance the operations of your system.

Moreover, these are more achievable on larger transformer sizes with more sophisticated designs which are considerably more expensive.

There are several ways to check this. You can calculate it based on the transformers’ input and output power or by calculating the copper and iron losses.

Reading more about Transformer Efficiency

-

Overload Capacity

Fluctuations, short-term, and emergency overloads in any system are unavoidable. The overload capacity defines the ability of the transformer to manage the load when it exceeds its load capacity.

Overloading in the system is the main cause of overheating which can critically damage the transformer's essential parts like the coils and insulation.

This can be mitigated if a transformer is sized and designed to handle the load at its peak per cycle plus an additional tolerance to give room for potential overload.

-

Environmental Conditions

This refers to the operating conditions of the system and the location where you intend to install the transformer. Some of these conditions are the temperature and humidity.

Typically transformers are designed with a rated capacity at an ambient temperature and humidity. However, other transformers have to be installed in locations with harsh environments and special conditions.

For example, for locations with extreme temperatures, you would need a bigger transformer with additional insulation and a robust cooling system.

Final Thoughts

Sizing a transformer requires knowledge on load computation and a bit of electrical background. Do note that this is only a guide and if your system is too complex, it is highly recommended that you consult a professional to compute the load and other necessary transformer calculations.

More importantly, you have to choose the right partner. The best choice would be choosing a reliable transformer manufacturer rather than relying on transformer distributors alone.

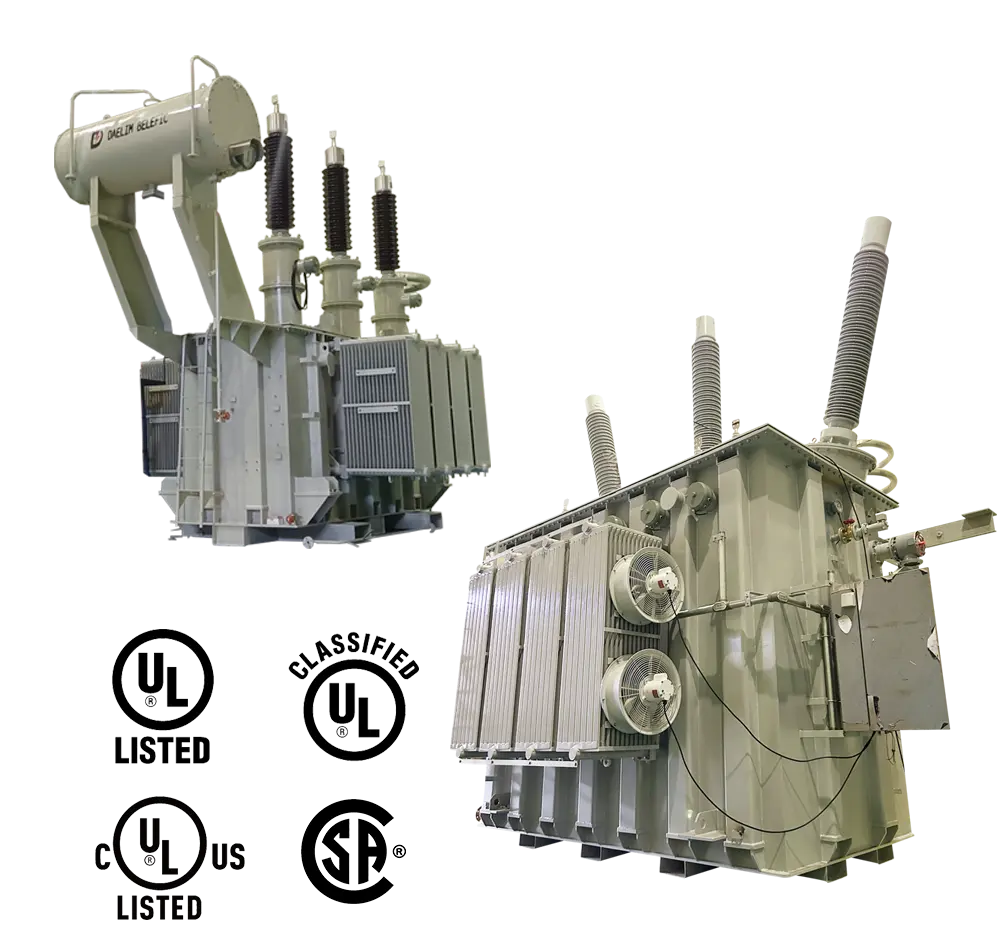

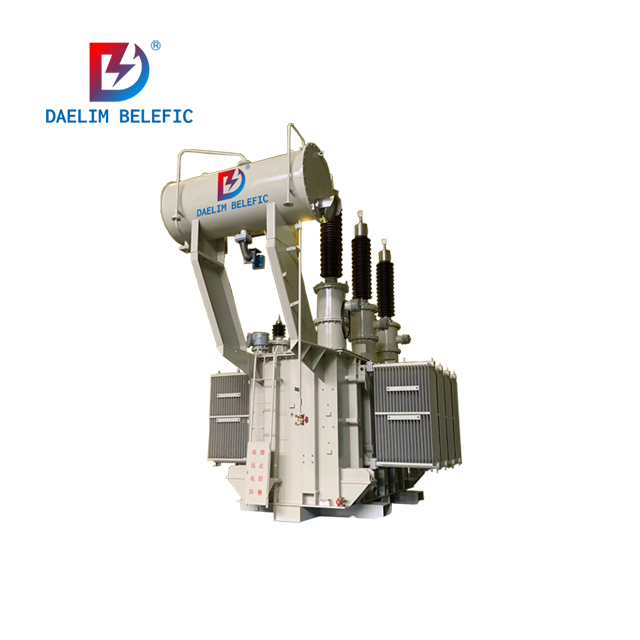

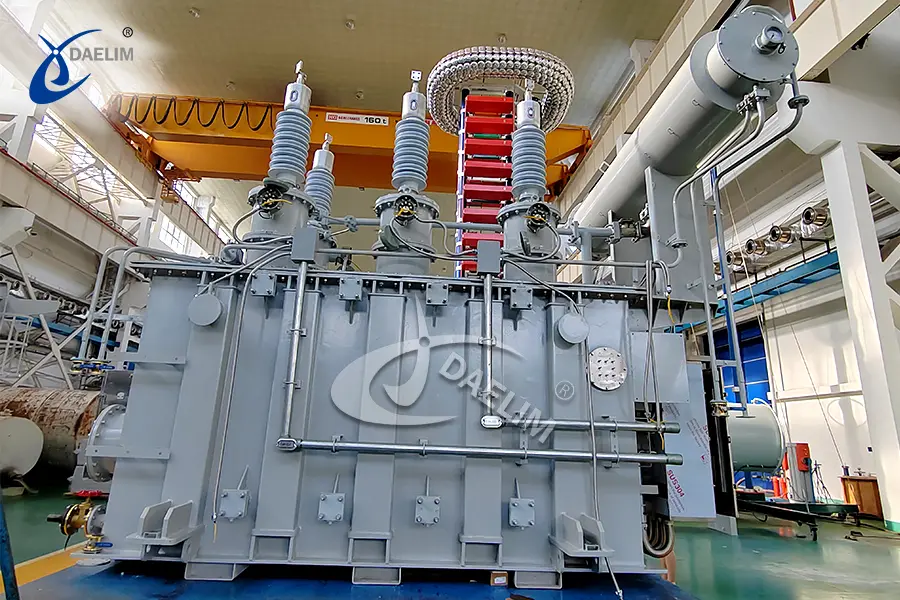

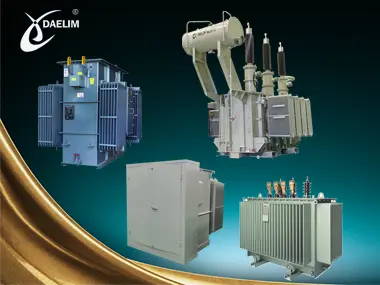

Why Choose Daelim?

Experience

For over 20 years Daelim has been a trusted transformer manufacturer completing various local and international electrical projects.

These projects are done in partnership with diversified industries including large utility companies, renewable energy systems, Bitcoin mining, construction, and many others.

Quality and Capability

At Daelim, quality is a top priority. This is supported by UL/cUL, CE, CSA, ISO,, and other international certifications.

Daelim has multiple manufacturing plants in China offering a wide range of transformers including standard transformer sizes and specialty transformers manufactured with strict compliance with IEEE, ANSI, IEC, EN ... standards according to clients' specifications.

Technical Support and Customer Service

With Daelim, you are assured that you get all the professional guidance that you need especially when you are still in the initial stage of sizing your transformer.

Daelim’s technical service does end after installation. Our technical team is available to offer you if you need any help or after sales service. These are located in several regions including the United States, Canada, Spain, and other countries.

For orders and inquiries, reach out to Transformer Daelim today. Daelim will make sure that you are assisted every step of the way.

Related Products

Related Article

Three Phase Power Transformers for Bitcoin Mining Facility in Texas!

Daelim Transformer thrilled to share details of our project - the supply of 90 units of three-phase power transformers for a large-scale Bitcoin mining operation in Odessa, Texas. Each transformer is rated at 2500(3000)KVA with a primary voltage of 34.5kV Delta and a secondary voltage of 480GrdY/277. With strict UL certification requirements and a focus on high-quality accessories from reputable brands, this project demanded precision, efficiency, and reliability.

2600 kVA Pad Mounted Transformer For Crypto Mine In Kansas

This morning, I received the on-site photos of the pad-mounted transformers from the customer, and I was overwhelmed with excitement and joy. These pad-mounted transformers are installed at a 20MW crypto mining site in Kansas, USA. A total of 5 sets of 2600 kVA pad-mounted transformers, all UL-listed, are being deployed at this site. Currently, 3 sets have already been installed onsite and are scheduled to be powered on imminently.

1500 kVA Transformer for Australian Mining Project

Introduce the 1500 kVA transformer tailored for Australian mining projects. The transformer operates in a three-phase configuration, with a total of four units deployed. Notably, its primary voltage stands at 11kV, while the secondary voltage is 1kV. Characterized by its compact size, emphasis on safety, and unwavering reliability, this transformer is meticulously designed and manufactured to meet the stringent requirements outlined in AS 60076 and AS efficiency value standards.Let's delve into the key features and specifications of this essential solution.

Pad Mounted Transformer for BESS System 4.0 MVA in Riverside County, California

Today, Daelim Transformer is proud to introduce a pad-mounted transformer for a 4.0 MVA Battery Energy Storage System (BESS) project located in Riverside County, California. The transformer is meticulously crafted to comply with the specifications outlined in the California Electrical Code Article 450.

Canadian 69 kV Substation Transformer Project

Today, we are excited to present a case study on a 69 kV substation transformer project by Daelim Transformer. Our Canadian client required a step-down transformer for their substation to connect with the hydroelectric grid in Quebec.

2000 kVA Oil immersed Substation Transformer For Portugal Market

Today, we introduce Daelim Transformer's export of a 2000 kVA oil-immersed substation transformer to Portugal. This transformer represents our commitment to delivering high-quality electrical solutions to global markets. With meticulous design and engineering, this transformer is tailored to meet the specific needs of our customers in Portugal, ensuring reliable performance and efficiency. Daelim Transformer continues to uphold its reputation for excellence, providing innovative solutions that power progress and reliability worldwide.