How To Manage Transformer Inrush Current?

In this article, we will tackle inrush current for transformers including some of the most modern ways how to avoid and effectively handle inrush current. We will also discuss how it affects your electrical system and answer more FAQs surrounding transformer inrush current.

Have you ever wondered why the power suddenly cuts off when you turn on a transformer? That could be an inrush current wreaking havoc on your power system.

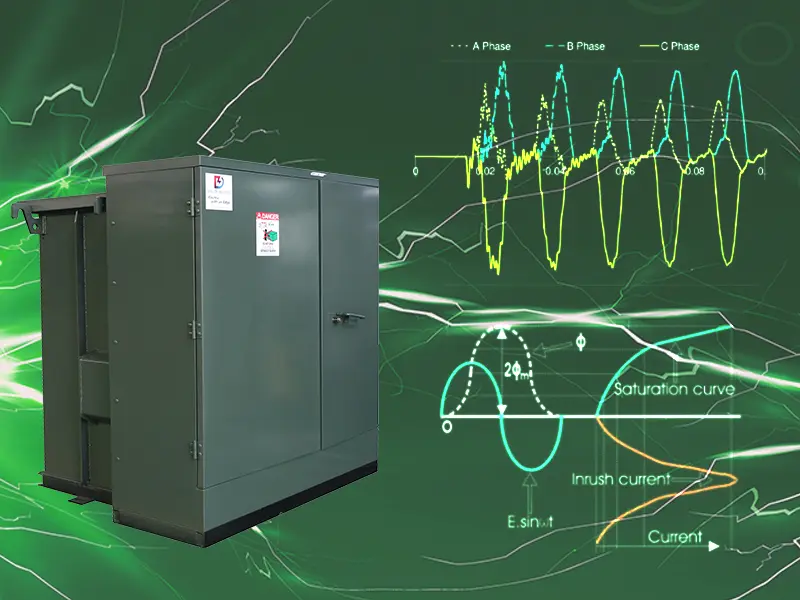

Inrush current is a normal reaction of the transformer upon energization. This is indicated by a brief but sudden spike in the current level.

Although this phenomenon can last for split seconds but could leave your electrical system, especially transformers, with substantial damage depending on how bad the surge is.

However, with careful planning and engineering, you can do something to manage and protect your system from the effects of inrush current.

Ways To Manage Transformer Inrush Current

There are different protective devices you can use to safeguard your electrical systems and transformers from short-lived inrush currents. Some of the options are to install the following protective devices:

- Pre-insertion Resistors

- Inrush Current Protection Circuit

More about Transformer Protection

Pre-insertion Resistors(PIRs)

Adding pre-insertion resistors in the circuit is a highly reliable and tested method in controlling inrush current.

Pre-insertion resistors are typically connected to the core in series upon transformer energization where an inrush current is expected and bypassing it once the electrical flow stabilizes.

This process involves some basic installations ruled by a simple principle of adding more resistance to the system to counter the inrush current.

Moreover, note that this device should match the system voltage and the transformer ratings. It would also require another circuit breaker for its control.

Inrush Current Protection Circuit

Inrush current protection circuits are classified into the NTC(Negative Temperature Coefficient) and PTC (Positive Temperature Coefficient) thermistors.

Inrush current protection circuits are classified into the NTC(Negative Temperature Coefficient) and PTC (Positive Temperature Coefficient) thermistors.

The choice of application depends on the transformer power rating, frequency, short circuit, prevailing temperature, and budget.

NTC and PTC thermistors protect the system from inrush currents by reacting to temperature changes within the system.

The NTC thermistor creates additional resistance when the transformer is switched on. Once current passes through, the temperature of this device increases. When the temperature rises, the resistance is gradually reduced until the current flow reaches the normal level.

NTC thermistors are often considered the first option because of their simplicity and practicality. However, there are cases in which PTC thermistors are more desired. This is when the system:

- Needs frequent resets

- Have to be protected from being short-circuited

- Surrounding temperature goes over or lower than room temperature.

Design Optimization

If you are still in the earlier stage of planning your system, it is better to discuss with your manufacturer to consider how they can incorporate effective safety measures that can handle inrush current impact in the transformer design.

Some of the modern techniques available are focused on the:

- Core Construction

- Winding and Core Placement

- Circuit Breaker

- System Configuration

- Controlled Switching

Reading more about Transformer Design

Core Construction

The material and design of the core can play an important part in suppressing the effects of transformer inrush current.

As much as possible choose a material and design that has low magnetic saturation levels and low residual magnetism.

Solid iron material and silicon steel are some of the few options. Avoid using amorphous or noncrystalline alloys as they can increase inrush current instead.

As for the design, ideally, the core must have more turns, minimal air gaps, and adequate space to avoid saturating the core in case of heavy inrush current.

Try for free: The Ultimate Guide to Core Type Transformers

Winding and Core Placement

Most windings are positioned close to the core to facilitate mutual induction. However, this could easily result in saturation.

Saturation is one thing you need to avoid to prevent inrush current and the possible damage it can cause to the transformer core.

One way to prevent saturation is to position the primary winding on the outmost layer far off the core. This will help slow down the energization process and effectively reduce the amount of inrush current flowing into the system.

Circuit Breaker

Circuit breakers are an essential part of an electrical system which serves as a switch-off mechanism once an overcurrent is detected.

Some circuit breakers like the slow-blow type are temperature sensitive. Its function is to switch off the transformer before it overheats.

However, if the circuit breaker needs to be adequately sized, in the event of an inrush current you may experience unwanted trip offs that could result in frequent resets and delays.

To avoid this scenario and to achieve a well-protected electrical system, the circuit breaker has to be appropriately sized according to the transformer size and specification.

The parameters and calculations should also be guided by the standards established by the National Electrical Code.

System Configuration

Transformers are typically connected depending on your application. However, be aware that how you configure your system can contribute to how your system reacts to transformer inrush current.

Transformers are typically connected depending on your application. However, be aware that how you configure your system can contribute to how your system reacts to transformer inrush current.

For instance, the delta-star connection could be more beneficial in controlling inrush current for transformer since the delta connection on the primary side can manage high current surge upon energization. More about Transformer Connection

On the contrary, some references show that the star-star connection could increase inrush current by up to 50%.

Controlled Switching/Point on Wave Switching

Another innovative way to deal with inrush current is to use controlled switching schemes. This method enhances the function of the circuit breaker using a Point on Wave switching device.

This switching device is available in various types and models which can be used in large transformers. Moreover, the type of switching device to be used is highly dependent on the type of circuit breaker your transformer has.

Most of these switching devices are designed to augment existing set-ups but they can be pre-integrated into the design as well.

FAQs

What Are the Effects of Inrush Current?

Inrush current if not addressed could put your transformer and power system at great risk. This may include two or more of the following:

When the voltage level drops significantly, it will require all parts of the system to work harder than usual which can cause the system to burn out. This can also cause power interruptions and instability in the supply.

Certain levels of inrush current can cause excessive mechanical stress which can detrimentally shorten the lifespan of your transformer, circuitry, and other equipment within the system.

Circuit breakers and other switches may detect the inrush current as an anomaly causing them to trip needlessly.

This results in unwanted interruptions that highly affect the system's overall efficiency. With that, some measures have to be taken such as upsizing the breaker.

If the inrush current is not properly addressed it can result in frequent transformer breakdowns or worse, total system failure which means shortened operations and additional time allocation for maintenance and repair.

The strong surge of inrush current can cause the windings and other parts of the transformer to vibrate. These vibrations can also create noises which is a clear indication that there is something wrong with the system.

Inrush current can go beyond the designed capacity of the transformer. Ultimately, the transformer gets overloaded, overheats, and eventually, breaks down.

More than the time constraints, this may leave damage on the parts of the insulation and other thermal components which eventually lessen the life of your transformer.

What Causes Inrush Current?

Much like warming up, the transformer needs a lot of power to magnetize the core during start-up. The current level could reach its peak in a snap before it stabilizes.

In addition, when the system is fully discharged, impedance is at its lowest. This temporarily allows large amounts of current to flow freely into the system.

What Are the Types of Inrush Currents?

This can take place when you power a transformer in systems where there are two or more transformers actively connected to it.

This is the most commonly observed type of inrush current in most transformers the moment it is switched on after being idle.

This is observed when you restart a transformer subsequently after the voltage flow is momentarily cut off.

Is Inrush Current Quantifyable?

Yes, transformer inrush current can be measured. There are several options you can use to check the level of inrush current in your system.

A multimeter with inrush features such as a clamp meter is one of the safest options. Another option would be using a high frequency oscilloscope and power analyzers.

In large scale set-up, an automatic reading, software aided calculator, or measuring devices are also utilized.

Regardless of the method used, to avoid accidents, this shall be performed by professionals only. Safety electrical standards should also be strictly implemented.

What Are the Things To Consider When Choosing the Suitable Inrush Current Limiter?

Basically, you need to know the specifications like the input voltage and maximum power output of your system.

This also involves the calculation of the minimum resistance, steady state current, and total energy that will help you choose the most suitable inrush current limiter type or model.

Here are some of the useful formulas you can utilize for the inrush transformer calculations:

1. R(Ohms)=1.414VInput(Volts)÷ I( Amperes)

2. Css(Amperes)=[Poutput ÷ VInput(Volts)] × 90% Efficiency

3. ETotal(Joules) = 1/2[C(uF) × V2Peak(Volts)]

Where,

R = Minimum Resistance

VInput = Input Voltage

I = Max Allowable Inrush Current

CSS = Steady State Current

P = Output Power

ETotal = Total Energy

C = Capacitance

VPeak = Peak Voltage

Although calculations can be simple, note that a professional background and proper understanding of these electrical systems are still required for you to get the desired results.

What Are the Factors That May Dictate Inrush Current?

Inrush current in a small transformer is more likely tolerable than those that occur when powering a large transformer.

Large transformers have larger cores, thus they require a large intake of the rushing current to charge the core.

Transformers with residual flux tend to have the highest inrush current as compared to a transformer starting from zero.

This is very relative to the starting point and how much time is left before it reaches the saturation point.

This includes the significant features of the transformer such as the design, the core size, and the number of turns.

The power surge observed upon energization is another factor that determines how bad an inrush current can go.

How Terrible Can a Transformer Inrush Current Be?

Inrush current for transformer severity and duration is determined by various factors. Depending on these factors, the inrush current could reach great levels.

For example, if you have a large transformer plus the presence of residual flux in the core, these amplify the intensity of the inrush current. Expect the inrush current to be ten to forty times higher than the full operating current.

Do You Need Help in Managing Transformer Inrush Current?

Mitigate Transformer Inrush Current With Daelim Transformer

An effective transformer inrush current management does not only mean knowing how to control it but also knowing how to equip your transformer to withstand its effects. With proper design and safety measures in place, you can achieve a solid power system.

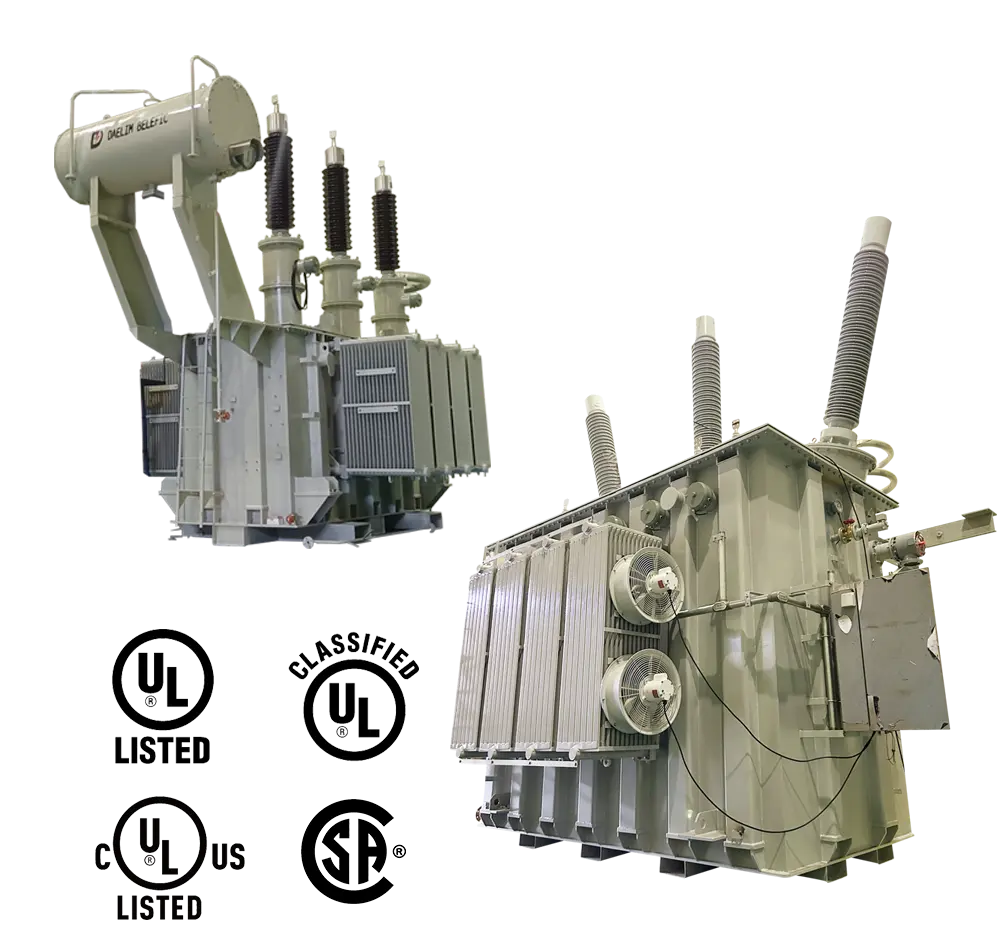

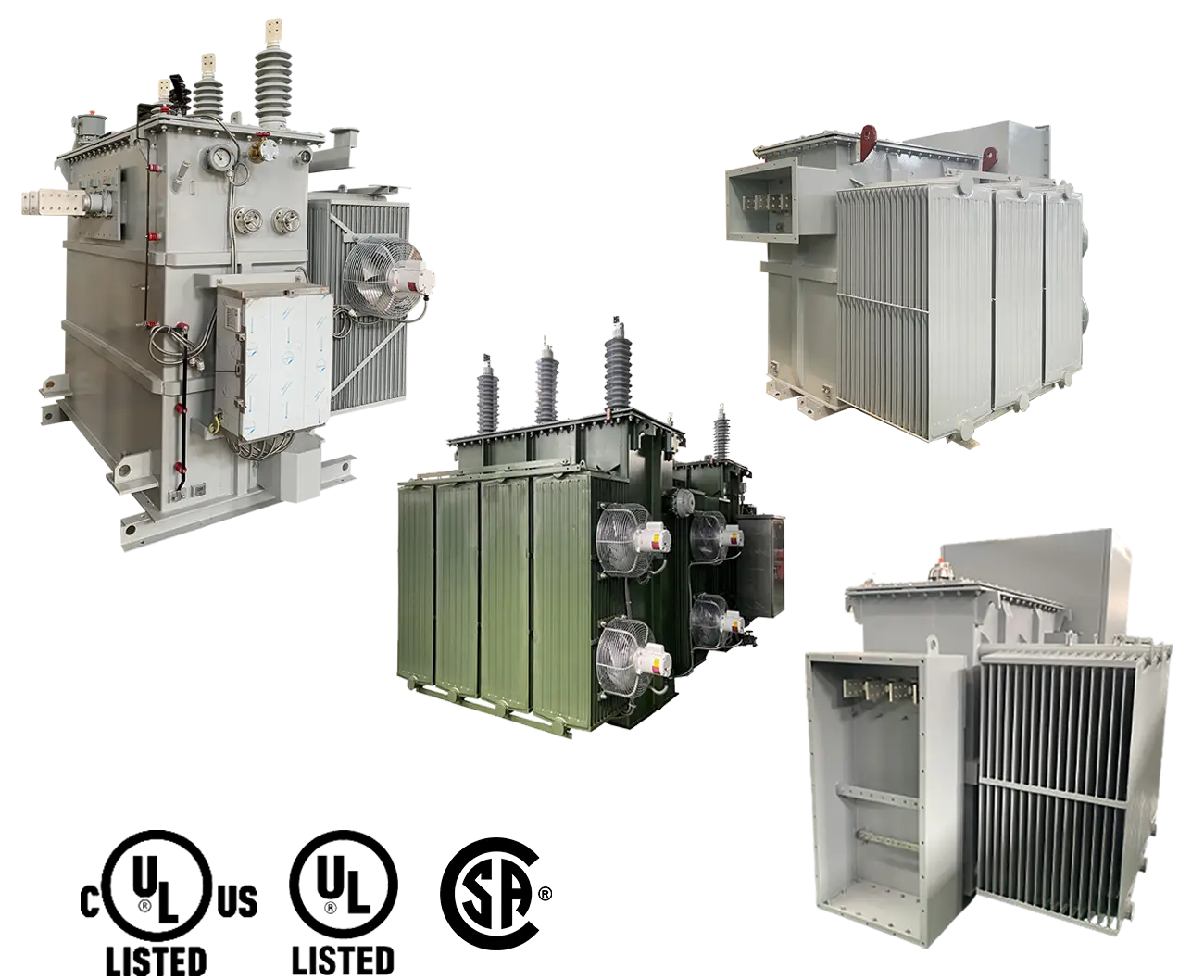

Daelim is a duly certified ISO, CSA, CESI, CNAS, and UL/cUL manufacturer which has been a trusted partner in delivering robust and high quality transformers around the globe with the ultimate goal of ensuring the reliability of transformers in every power system.

At Daelim, transformers are properly equipped with safety protection devices and designed to deliver efficient and optimum performance.

Each unit undergoes rigorous testing such as the impact test which validates the mechanical strength and integrity of the transformer.

With over 20 years of expertise in transformer design, Daelim Transformer can offer diverse strategies and professional guidance on transformer inrush current.

Still worried about transformer inrush current? Daelim Transformer is here to listen. Get in touch with Daelim Transformer to consult with some of our experienced and knowledgeable professionals today.

Related Products

Related Article

Guide To Pad Mounted Transformer Load Break Switch

A load break switch is a power switch specifically designed for pad-mounted transformers. It operates with a spring mechanism and can safely and quickly break and close the load current using a hot rod outside the transformer. It is suitable for 15kV, 25kV, and 35kV ring network and terminal line power distribution systems.

Guide to EV(electric vehicle) Charging Station Transformers

As vital components supplying power to charging stations, transformers play a crucial role in facilitating the swift, efficient, and safe replenishment of electric vehicles. Today's article primarily discusses the types of transformers utilized in charging stations, their design features, how to choose a transformer supplier, and other pertinent issues.

How Do You Choose a Transformer Size You Need?

In this article, we will give you a quick step-by-step guide on how to choose the right transformer size. We will also take a look at the things you need to consider and the transformer calculations involved.