Standard Features and Functions of Power Distribution Transformers

Power distribution transformers are critical components in electrical infrastructure, serving to step up or step down voltages for efficient transmission and distribution of electricity. Here, we delve into their standard features, operational principles, and selection criteria.

Components of Power Distribution Transformers

Oil Tank: Houses insulating oil that aids in cooling and insulation.

Airways: Allow for ventilation and heat dissipation.

Oil Level Indicator: Monitors the oil level for maintenance purposes.

Temperature Detector: Ensures the transformer operates within safe temperature limits.

Pressure Relief Mechanism: Prevents excessive pressure buildup inside the transformer.

Temperature Switch: Activates cooling systems based on temperature thresholds.

Radiator: Enhances cooling efficiency by dissipating heat from the oil.

Bushing: Insulated device for conducting current into or out of the transformer.

Reading more: How to choose the best distribution transformer?

Operational Characteristics

- High Voltage Input: Receives high-voltage electricity from transmission lines.

- Low Voltage Output: Provides lower voltage suitable for local distribution.

- Efficiency: Operates optimally at 70%-75% efficiency under normal load conditions.

- Material: Typically utilizes CRGO (Cold Rolled Grain Oriented) steel for its core due to low iron loss.

- Amorphous Substances: Some transformers use amorphous materials for improved efficiency.

Working Principle

Power distribution transformers operate on the principle of electromagnetic induction:

- Core and Windings: The transformer core made of soft magnetic material (often CRGO) enhances magnetic flux linkage between primary and secondary windings.

- Coils: Primary coil connects to the power supply, inducing an alternating magnetic flux.

- Voltage Transformation: Secondary coil outputs a lower voltage, maintaining a proportionate relationship based on the turns ratio of the windings.

Get it free: 500 kVA Distribution Transformer for the Greek Market

Selection and Installation

Choosing the right distribution transformer involves:

- Type: Selecting between substation-type, pole-mounted, or pad-mounted transformers based on application and space availability.

- Specifications: Considering rated capacity (kVA), input/output voltage requirements, and any special needs such as environmental considerations (e.g., oil vs. dry type).

- Supplier Selection: Opting for reputable manufacturers with certifications (e.g., UL, CSA, IEC) and a track record of quality and reliability.

Step-by-Step Guideline On Installing A Transformer

Importance in Electrical Systems

Distribution transformers are indispensable in:

- Power Transmission: Reducing high voltages from substations for safe local distribution.

- Voltage Regulation: Ensuring stable voltage levels suitable for residential, commercial, and industrial applications.

- Efficiency: Minimizing power loss and enhancing energy efficiency across the grid.

More about Transformer Efficiency

Conclusion

Power distribution transformers form the backbone of electrical distribution networks, enabling safe and efficient transmission of electricity from substations to end-users. Understanding their components, operational principles, and selection criteria is crucial for ensuring reliable and effective electrical infrastructure.

For reliable distribution transformers tailored to your needs, consider partnering with trusted manufacturers like Daelim Transformer, known for their commitment to quality and innovation in transformer technology.

Related Products

Related Article

Supply of 37.5 kVA Single Phase Pad Mounted Transformers for Canadian Utility

Today, we are excited to introduce a project undertaken by Daelim Transformer aimed at supplying transformers to a Canadian utility. This project involves the delivery of 80 units of 37.5 kVA single-phase pad mounted transformers, specially designed to meet the utility's requirements. With a high voltage (HV) rating of 24940GRDY/14400 V and a low voltage (LV) rating of 240/120 V, these transformers are vital components in the utility's infrastructure.

500 kVA Distribution Transformer for the Greek Market

Today, we're thrilled to showcase a European transformer project tailored for the Greek market. This project involves the supply of 500 kVA distribution transformers, with an input voltage of 20 kV and an output voltage of 400V. The client has requested adherence to both IEC and TIER-II energy efficiency standards. With a total quantity of 5 units, this project marks another milestone in Daelim Transformer's commitment to delivering high-quality solutions worldwide.

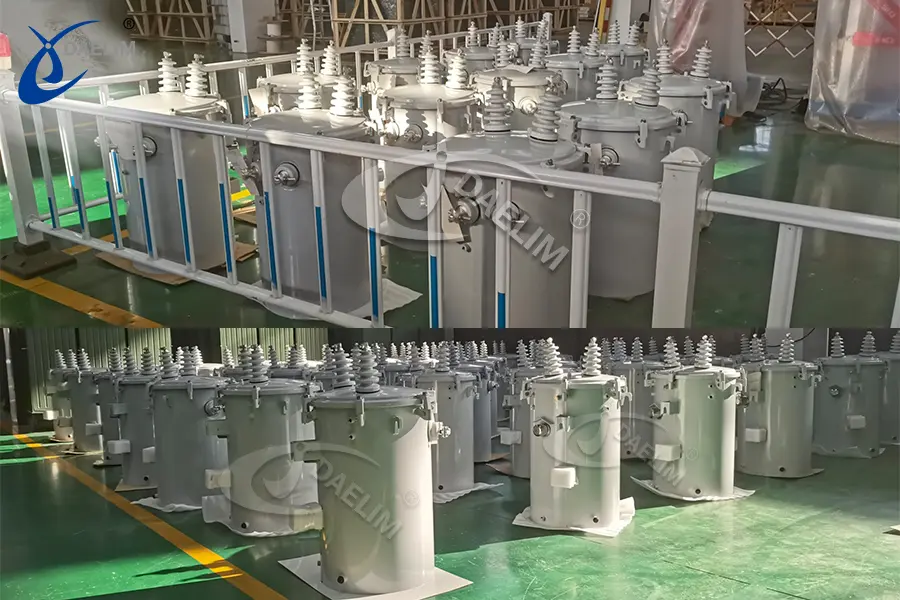

Single Phase Pole Mounted Transformer For Guyana

In August 2023, Daelim Transformer completed production and Factory Acceptance Testing (FAT) for a batch of single-phase pole-mounted transformers. These transformers are destined for a prominent distributor in Guyana. The customized order comprises 44 units transformers, with 32 units of 50 kVA, 6 units of 100 kVA, and 6 units of 167 kVA. All adhere to traditional design principles, featuring dual high-pressure bushings. The standard manufacturing and testing procedures follow IEEE Std C57, with the specified type as Conventional.

Overview of Oil-Immersed Distribution Transformers

This article mainly describes the oil-immersed distribution transformer, including the oil transformer application, characteristics, types, and other issues of the transformer.

What Is Distribution Transformer?

Daelim Transformer, a professional American Standard manufacturer, offers a variety of UL-listed distribution transformers, including pad-mounted, pole-mounted, and small power transformers.

CSA C227.3 For Single Phase Pad Mounted Distribution Transformer

What we have here are the Canadian Standards Association standards. This will include the CSA-C227.3 guidelines for single-phase pad-mounted distribution transformers.