What is the structure of the oil immersed transformer?

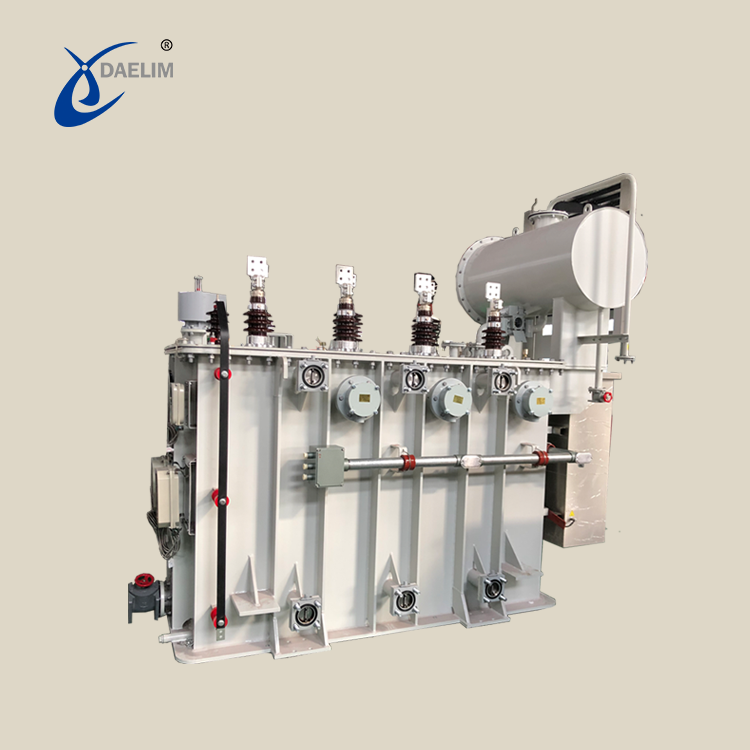

Oil-immersed transformers have the characteristics of good heat dissipation, low loss, large capacity, and low price. At present, most of the power transformers running in the power grid are oil-immersed transformers. This article focuses on analyzing the structure of oil-immersed transformer.

The iron core and winding constitute the important parts of the three-phase oil-immersed transformer. In addition, there are oil tanks, oil conservators, bushings, breathing apparatus, radiators, tap changers, gas relays, thermometers, oil purifiers, etc.

What does the iron core do in a transformer?

The iron core is the main magnetic circuit of the transformer, and its main function is to conduct magnetism. It converts the electrical energy of the primary circuit into magnetic energy, and from the magnetic energy into the electrical energy of the secondary circuit.

The iron core in the transformer is generally made of silicon steel sheets stacked, and the silicon steel sheets are insulated from each other. The silicon steel sheet mainly affects the no-load loss of the transformer.

According to the arrangement of the windings in the iron core: there are two types of iron core type and iron shell type. The three parts of the iron core column, the high and low voltage windings, and the iron yoke constitute the closed magnetic circuit of the transformer.

Daelim's iron core is made of cold-rolled oriented silicon steel sheet, with 80, 85, 90, 100, and 110 grades of silicon steel sheet. The smaller the grade, the lower the no-load loss, the better the transformer performance, and the iron core structure. There are cooling oil passages in the iron core of the large-capacity transformer to achieve a good cooling effect.

The windings constitute the circuit of the transformer and are divided into two types: primary windings and secondary windings. The primary winding is connected to the power supply, and the secondary winding is connected to the load. Daelim transformer windings are made of copper or aluminum wires wrapped with high-strength insulating paper.

The first and second windings of each phase of the three-phase transformer are made into a cylindrical shape and sleeved on the same iron core column. This placement is because it is easier for the low-voltage winding to insulate the core. A sleeve made of insulating material is used to isolate the low-voltage winding and the iron core and between the high-voltage winding and the low-voltage winding to insulate them reliably. In order to facilitate heat dissipation, a certain gap is left between the high and low windings as an oil passage, so that the transformer oil can flow.

1. What is transformer oil tank?

The transformer oil tank is the outer casing of the transformer. The oil tank is filled with transformer oil, and the iron core and windings are installed in it. For transformers with larger capacity, Daelim will be equipped with a radiator outside the transformer oil tank. The transformer tank of Daelim has the characteristics of good sealing and corrosion resistance, and there will be no leakage of the oil tank.

There are two main types of transformer oil used by Daelim: it is mineral oil with good insulating properties. There are two types of mineral oil: No. 25 and No. 45. It has excellent electrical and thermal properties and is cheap;

The other is environmentally friendly vegetable oil, which has the advantages of high flash point, good electrical properties, renewable and biodegradable, etc., but its price is high, 3-4 times that of mineral oil.

You can choose the transformer oil that suits your needs.

Learn more now: What is the difference between mineral oil, Vegetable oil, and silicon oil?

3. What is transformer oil used for?

Transformer oil is insulating. The insulation performance of transformer oil is better than that of air. Immersion of windings in oil can improve insulation performance everywhere, and avoid contact with air to prevent windings from getting wet;

On the other hand, it is the heat dissipation effect, which uses the convection of the oil to dissipate the heat generated by the iron core and the winding to the outside through the transformer tank wall and the heat dissipation pipe.

The transformer oil conservator looks like a cylindrical pillow, so it is also called oil pillow. It is placed horizontally above the oil tank and is connected to the oil tank of the transformer with a pipeline. The volume of the oil conservator is generally about 10% of the volume of the oil tank.

The oil conservators provided by Daelim are Corrugated type, Capsule type, and Diaphragm type. Among them, the corrugated oil conservator will be more expensive, and you can choose according to your needs.

When the transformer oil is heated and expanded, transformer oil flows into the oil conservator from the oil tank; when the transformer oil contracts when cold, the transformer oil is replenished from the oil conservator to the oil tank. The oil conservator has two functions: one is that when the volume of transformer oil expands or shrinks with the change of oil temperature, the oil pillow acts as oil storage and replenishment to ensure that the oil tank is filled with oil so that the iron core and winding are completely It is immersed in oil; second, the transformer oil is only in contact with the air in the oil pillow, which can reduce the contact area between the oil surface and the air, and reduce the chance of the transformer oil being damp and oxidized.

Try for free: Pad Mounted Transformer

The lead wire of the transformer winding is connected to the external circuit through the guide rod. The transformer bushing is an insulator between the guide rod and the box cover, which plays the role of insulating and fixing the guide rod.

There are two types of bushing in the transformer: High voltage bushing(HV bushing) and Low voltage bushing(LV bushing).

The lead wires of the transformer windings must pass through insulating bushings to insulate the live leads when they are led out from the oil tank and out of the tank. The insulating bushings are mainly composed of a central conductive rod and a porcelain bushing. One end of the conductive rod in the oil tank is connected with the winding, and the other end outside is connected with the external circuit. It is a fault-prone part of the transformer. Therefore, transformer bushings require regular maintenance and replacement.

The construction of the insulating bushing mainly depends on the voltage class. For low voltages, simple solid porcelain bushings are generally used. When the voltage is high, in order to strengthen the insulation capacity, an oil-filled layer is left between the porcelain bushing and the conductive rod. This kind of bushing is called oil-filled bushing. When the voltage is above 110kV, the capacitive charging bushing is used, which is referred to as capacitive bushing for short. In addition to filling the inner cavity of the porcelain bushing with oil, the capacitive bushing also has a capacitive insulator between the central conductive rod (hollow copper tube) and the flange to wrap the conductive rod as the main connection between the flange and the conductive rod.

Transformer bushing oil leakage is the most common fault. The reason for the oil leakage of the bushing is the aging of the rubber sealing ring on the upper part of the bushing and the rubber flat gasket at the bottom of the bushing, which requires regular inspection and replacement of the sealing ring and rubber gasket of the bushing.

1. What is a transformer breather?

The transformer breather, also known as a hygroscopic device, usually consists of a tube and glass container with a desiccant (silica gel or activated alumina) inside.

2. Why breather used in transformer?

Clean and dry the sundries and moisture in the air of the oil conservator to maintain the insulation strength of the transformer oil.

When the air in the oil conservator expands or shrinks with the volume of the transformer oil, the exhausted or inhaled air passes through the respirator, and the desiccant in the respirator absorbs the moisture in the air and filters the air to keep the oil clean. Silica gel impregnated with cobalt chloride, its particles are cobalt blue when dry, but as the silica gel absorbs water and is close to saturation, the granular silica gel will turn into powdery white or red, and it can be judged whether the silica gel has failed. The damp silica gel can be regenerated by heating and drying. When the color of the silica gel particles becomes cobalt blue, the regeneration work is completed.

Pressure relief devices play an important role in protecting power transformers. In oil-immersed transformers, if there is an internal fault or short circuit, arcing will instantly vaporize the oil, resulting in a rapid increase in the pressure in the transformer tank. If this pressure is not released within a short period of time, the oil tank could rupture, potentially causing an explosion and fire, causing even more damage, so measures must be taken to prevent this from happening. There are two types of pressure release devices: explosion-proof pipe and pressure releaser. The explosion-proof pipe is used for small transformers, and the pressure releaser is used for large and medium-sized transformers.

Pressure relief devices play an important role in protecting power transformers. In oil-immersed transformers, if there is an internal fault or short circuit, arcing will instantly vaporize the oil, resulting in a rapid increase in the pressure in the transformer tank. If this pressure is not released within a short period of time, the oil tank could rupture, potentially causing an explosion and fire, causing even more damage, so measures must be taken to prevent this from happening. There are two types of pressure release devices: explosion-proof pipe and pressure releaser. The explosion-proof pipe is used for small transformers, and the pressure releaser is used for large and medium-sized transformers.

The form of the transformer radiator is corrugated, fan-shaped, circular, exhaust pipe, etc. The larger the heat dissipation area, the better the heat dissipation effect. When there is a temperature difference between the oil temperature of the upper layer of the transformer and the oil temperature of the lower layer, the convection of the oil is formed through the radiator, and it flows back to the oil tank after cooling by the radiator, which reduces the temperature of the transformer. In order to improve the cooling effect of the transformer, measures such as air cooling, forced oil air cooling, and forced oil-water cooling can be adopted.

Buchholz gas relay is a protective device. Install the gas relay in the direct pipeline between the oil conservator and the transformer oil tank by using the flange. When the internal failure of the transformer produces gas or oil surges, they will first gather in the upper space of the gas relay, so that the contact of the gas relay Action, turn on the designated control loop, and send a signal alarm in time or start the protection element to automatically cut off the transformer

When the oil conservator is used for the on-load voltage regulating transformer, a switch oil conservator without capsules is installed at the bottom of the oil conservator.

2. What are the types of tap changers?

Transformer voltage regulation methods are divided into two types: on-load voltage regulation and no-load voltage regulation.

On-load voltage regulation(on-load tap changer) means that the transformer can adjust its tap position during operation, thereby changing the transformer transformation ratio to achieve the purpose of voltage regulation.

The no-load tap changer is a zero-current transfer switch without arc extinguishing measures, and can only be regulated when the transformer stops running.

3. Where is the tap changer in transformer?

Transformer taps are generally tapped from the high-voltage side, which mainly considers:

(1) The high-voltage winding of the transformer is generally on the outside, and the tap is easy to connect;

(2) The current on the high-voltage side is smaller, the conductor cross-section of the lead wire and the current-carrying part of the split switch is smaller, and the influence of poor contact can be easily solved.

In principle, the tap changer can be on either side, and economic and technical comparisons are required. For example, the tap changer of a 500kV large step-down transformer is drawn from the 220kV side, while the 500kV side is fixed.

When the voltage is too low or too high, and it is necessary to adjust several taps of the on-load tap-changer to meet the requirements, it is necessary to pay attention to the situation:

It should be adjusted one gear at a time, that is, every time the N+1 or N-1 button is pressed, it will pause for 1 minute in the middle, and when a new number appears on the gear indicator, press the button again. Repeat the above process in turn until the final goal is reached. When the electric operation is linked (that is, one operation, more than one tap will be adjusted, commonly known as sliding), the second tap position should appear on the gear indicator of the main transformer control screen, and immediately press the emergency button. Stop the button and change to manual operation.

The oil purifier is a container filled with the adsorbent (silica gel or activated alumina), which is installed on the sidewall of the transformer tank or the lower part of the strong oil cooler. When the transformer is running, due to the temperature difference between the upper and lower oil layers, the transformer oil passes through the oil purifier from top to bottom to form convection. When the oil is in contact with the adsorbent, the moisture, acids, and oxides in it are absorbed, making the oil clean and prolonging its service life of the oil.

Daelim Transformer Manufacturer

Daelim is a professional manufacturer of oil-immersed transformers. The factory is located in Hai'an City, Jiangsu Province. With nearly 20 years of experience in exporting oil-immersed transformers, the main exporting countries are the United States, Canada, Australia, and South American countries. In 2021, the North American market export volume will reach thousands of units.

Daelim's transformers have good mechanical properties and high electrical properties, and their design and production fully comply with international standards IEEE/IEC/CSA/DOE/AS and so on. Daelim's transformer accessories can either come from China or be imported from foreign well-known brands such as ABB/Siemens/Schneider/Qualitrol/MR, etc. The quality of transformers has won unanimous praise from customers. The warranty period of Daelim transformers is at least two years and the service life is more than 30 years. It can be longer depending on your requirements.

Daelim has a team of highly skilled engineers and a rich experienced marketing team in overseas markets. In the past 20 years, Daelim has helped many international clients get power projects. At the same time, it also helps dealers and agents to achieve more profit goals. Daelim's business philosophy is to achieve a win-win and long-term cooperative relationship with customers. If you are also looking for a Chinese transformer supplier, Daelim will be your best choice.

Learn more now: Daelim's International Project

Click here to contact Daelim for transformer technical solutions, transformer drawings, and prices.

Related Products

Related Article

69KV Series Substation, Latin America

Built in 2016, the 69kv series substation incuding Kaliti-l 69/13.8 mva substation; Cotebie 69/22kv 20mva substation;Kaliti-II 69/13.8kv 24mva substation;

Single Phase Pole Mounted Transformer Project, Canada

Used in Saskatoon, Canada, 2019. We provided single phase transformers of 2.4kv, 7.,2kv, 13.8kv and 14.4kv. They are used for remote village net work.

20mVA Furnace Transformer, Mexico

Installation in 2018, is used to supply power to an electric furnace, which lowers the high voltage to the furnace-required lower voltage. It was designed according to client's request.

Pad Mounted Transformer Project Cases

3750kVA Primary 13.8kV, Secondary:0.415kV Loop-feed Pad-mounted Transformer, 12 sets for US market;

Skid Mount Transformer Solution With 3 Phase Pad Mounted Transformer Inside

Daelim Transformer's skid mount solutions with 3-phase pad mounted transformers represent a pinnacle of modern power distribution technology, catering to the stringent demands of various industries including renewable energy, mining, data centers, and transportation sectors. Their innovative design, coupled with robust performance and ease of deployment, makes them indispensable in today's rapidly evolving energy landscape. Whether for large-scale utility projects or specialized applications like electric vehicle charging infrastructure, these solutions exemplify efficiency, reliability, and adaptability in power distribution solutions.

What You Need To Know About Substation Transformer?

This article discusses power substations and their key components, focusing on the role, types, purchasing considerations of substation transformers, as well as the importance of safety and testing certification.

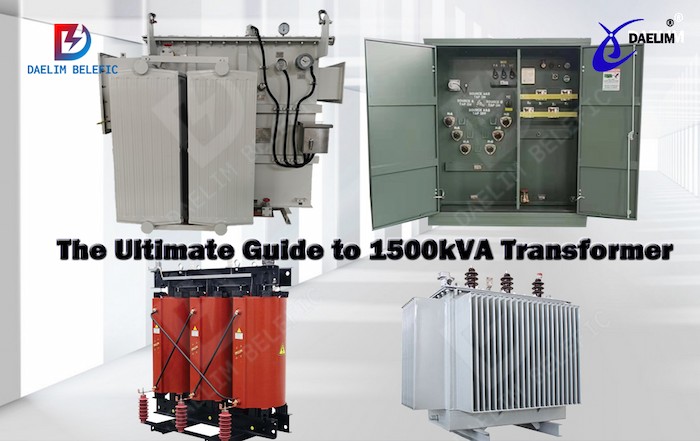

The Ultimate Guide to 1500kVA Transformer

A 1500kVA transformer is crucial for power distribution systems, supplying up to 1200kW of active power. Types include pad-mounted, substation, dry-type, and oil-filled variants, each designed for specific applications like residential, industrial, and commercial settings. Built with advanced materials and methods, these transformers ensure durability, efficiency, and minimal maintenance needs.

High Voltage Transformer:Definition,Principle,Uses and Price

High-voltage transformers are key components in power transmission networks, helping to efficiently transmit electricity over long distances. These transformers are available in voltage levels from 66 kV to over 1000 kV. Key factors that affect their price include voltage capacity, transformer accessories, type of transformer oil used, short-circuit impedance, and special requirements.