Subsation Transformer Ultimate Guide, You Need To Know

Substation transformers play a crucial role in power distribution systems, facilitating the safe and efficient transmission of electricity across varying voltage levels. Here, we delve into their design, function, types, and testing procedures, highlighting their significance in maintaining the stability and reliability of electrical grids worldwide.

What is a Substation Transformer?

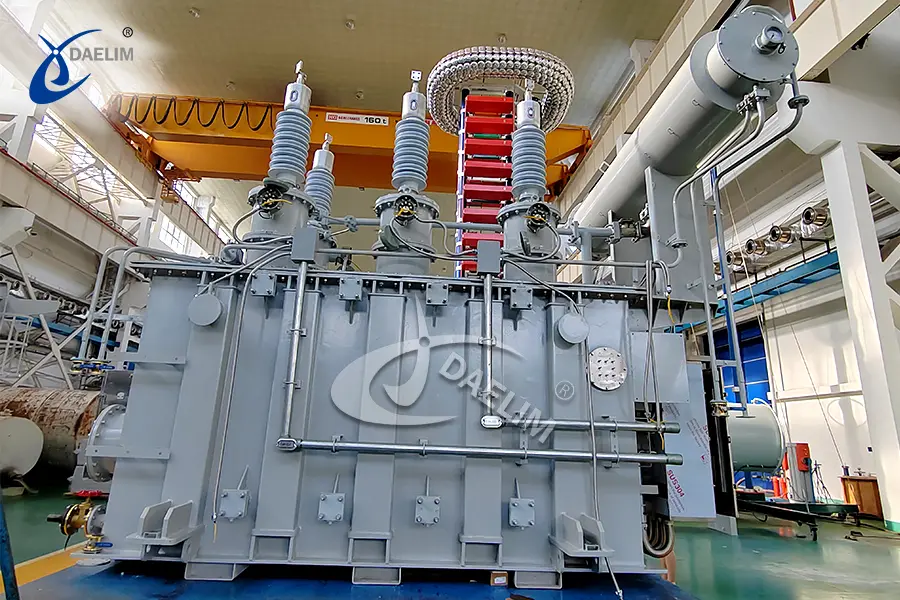

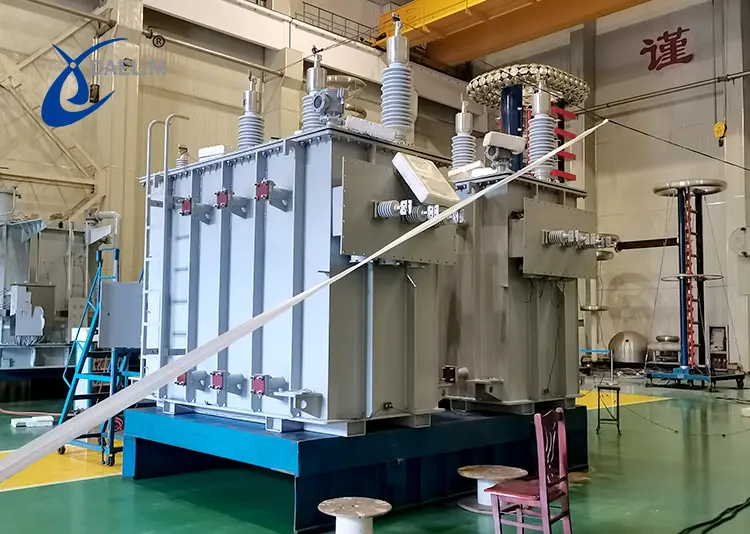

Substation transformers are specialized equipment designed for integration into large or small-scale three-phase transmission and distribution systems. They are typically installed on indoor or outdoor concrete bases, strategically positioned as per project specifications by power engineers during initial planning stages.

These transformers utilize winding coils to adjust voltage levels, ensuring electricity can be safely distributed to end-users through high-voltage or low-voltage cables connected via bushings. They are primarily oil-immersed, using mineral, vegetable, or siliceous transformer oils to enhance insulation and cooling efficiency.

Try for free: Why Substation Transformers Are So Important In Power System?

How Substation Transformers Work

The core function of a substation transformer is to transform electrical energy between different voltage levels. This transformation is achieved through the principle of electromagnetic induction: when alternating current passes through one set of winding coils (primary winding), it creates a magnetic field. This field induces a voltage in the adjacent winding coils (secondary winding), thereby altering the voltage level suitable for transmission or distribution.

By adjusting the ratio of winding turns between the primary and secondary coils, substation transformers enable the efficient management of electricity flow, ensuring the balance, safety, and economic efficiency of power grids.

Types of Substation Transformers

Substation transformers vary in type and application based on voltage levels and specific operational requirements:

Based on Voltage Level

- MediumVoltage Substation Transformers: Handle voltages from 2.4 kV to 46 kV, mainly used to control power distribution systems.

- High Voltage Substation Transformers: Operate within the range of 66 kV to 115 kV, rucial for long-distance power transmission.

Based on Functionality

- Step-Up Transformers: Increase voltage levels for transmission over long distances.

- Step-Down Transformers: Decrease voltage levels for distribution to end-users.

Based on Installation Location

- Grid-Type Substation Transformers: Typically used for high-capacity electricity transmission, installed in outdoor enclosures.

- Urban and Rural Substation Transformers: Found in urban areas (brick-enclosed for protection) and rural regions (mounted on outdoor poles or towers).

10.5MVA-13.8/2.4kV Substation Transformer

Substation Transformer Testing

Ensuring the reliability and safety of substation transformers involves rigorous testing procedures conforming to international standards such as IEC and IEEE. Key tests include:

- Dielectric Test

- Lightning Impulse Test

- Pulse Test

- Pressure Test

- Partial Discharge Measurement

- No-Load and Load Loss Test

- Temperature Rise Test

Learn more about Transformer Test

These tests assess various aspects of transformer performance, insulation, and efficiency, helping manufacturers and engineers validate design specifications and ensure compliance with operational requirements.

Conclusion

Substation transformers are indispensable components of modern power distribution networks, translating high-voltage electricity into levels suitable for industrial, commercial, and residential use. Their design and deployment adhere to stringent international standards, guaranteeing reliability, safety, and efficiency across diverse applications and environments.

For inquiries or questions regarding substation transformers, please feel free to contact Daelim Transformers. They specialize in designing and producing substation transformers with nearly 20 years of export experience, ensuring reliable technology and product quality.

Related Products

Related Article

13.8 kV 10.5 MVA Substation Transformer for Ecuador

A customer from Ecuador contacted Daelim Transformer for a 10.5MVA substation transformer (13.8kV high voltage, 2.4kV low voltage). Daelim Transformer provided a customized solution, conducted virtual factory tours, ensured rigorous quality control via video inspections, and offered post-delivery online training and ongoing support, fostering a successful partnership.

Canadian 69 kV Substation Transformer Project

Today, we are excited to present a case study on a 69 kV substation transformer project by Daelim Transformer. Our Canadian client required a step-down transformer for their substation to connect with the hydroelectric grid in Quebec.

2000 kVA Oil immersed Substation Transformer For Portugal Market

Today, we introduce Daelim Transformer's export of a 2000 kVA oil-immersed substation transformer to Portugal. This transformer represents our commitment to delivering high-quality electrical solutions to global markets. With meticulous design and engineering, this transformer is tailored to meet the specific needs of our customers in Portugal, ensuring reliable performance and efficiency. Daelim Transformer continues to uphold its reputation for excellence, providing innovative solutions that power progress and reliability worldwide.

4500 kVA Substation Transformers for Australian Mining Site

Today, we introduce a project by Daelim Transformer aimed at supplying transformers to a mining site in Australia. This project entails the provision of two units of 4500 kVA substation transformers tailored to fit the narrow confines of mining tunnels. Due to space constraints, the transformers need to be compact in size and mounted on mobile racks for easy maneuverability within the mine shafts. This necessitates meticulous design to meet the strict dimensional requirements set by the client.

230 kV Three Phase Power Transformer For USA Market

In 2023, Daelim Transformer designed and manufactured a cutting-edge 230 kV three-phase power transformer for a client in Nevada, USA. The client recently shared installation and operational photos, showcasing the successful deployment of this remarkable transformer. Let's delve into the specifics of this transformer project!

20MVA Power Transformer for the United States

This project involves the development of a 20 MVA three-phase power transformer tailored for the United States market. The primary voltage is 24.94kV, and the secondary voltage is 4.16kV, indicating it functions as a step-down transformer. The design and production fully comply with IEEE C57.12.00 standards and have passed third-party UL team testing. All accessories also adhere to IEEE standards. FR3 vegetable oil serves as the insulating liquid for the transformers.