All You Need To Know About Traction transformer

Every electric train and tram you see moving at very high speed needs an uninterrupted and constant supply of electricity. All these electric trains and trams are so sophisticated that they need a special type of electrical transformer called traction transformer to maintain their performance and efficiency.

These locomotive transformers ensure a smooth operation of electric trains and trams and also of electric buses by regulating the voltage and keeping it to the safe level. This article is for you to know everything about traction transformers and how they work to keep our locomotives safe and efficient.

Contact Daelim TransformerWhat Is a Traction Transformer?

Railway traction transformers are a special type of electrical transformers, designed and developed for locomotive applications like electric trains and trams. These locomotive transformers work to control flow of electric current and the voltage established between the power supply and train traction system. This is where they get their name the “Traction Transformers”.

Each traction transformer you see will be specifically designed to step down the high voltage and increase the current for the electric train and tram traction system. They step down the electricity to the level that is needed and manageable by the train traction system.

You may enjoy: Transformer Design: Step by Step Guide for Safety and Reliable Power Flow

How these railways traction transformers are different from other transformers is how they are designed. These locomotive transformers are designed to handle dynamic loading and work in very harsh operation conditions they might face during their useful life.

These transformers have to provide extremely high current as the train starts to move and then gradually adjust it according to the speed. Same goes with when braking and stopping the train. These transformers make sure that they take on all the variations of load, voltage, and electric current and keep all other electric components of the train safe.

Types of Traction Transformers

There are four main types of traction transformers that are divided into two main classes.

Classification Based on Application

The traction transformers are two basic types based on the major application.

AC Traction Transformer

The AC traction transformers are designed and developed to power your long distance high distance electric trains using AC power supply and powering AC motors. They work as the same step down transformer here.

DC Traction Transformer

These DC traction transformers are designed for direct current and are used in applications like metro trains, trams, and other suburban railways you see all round you. They are efficient and highly reliable for short distance electrically powered locomotives.

Classification Based on Installation Type

Traction transformers can also be classified based on the design that is developed to satisfy specific installation requirements.

Stationary Transformer

Stationary traction transformers are designed and developed for stationary installation at your local substations. These transformers step down the voltage at the substation before supplying it to the moving train through the railway overhead system or using the railway third rail system.

On-board Transformer

These transformers have a compact design and are made very light weight. This is because they are installed on locomotives and they move with those locomotives. They take supply from the railway overhead system or using the railway third rail system, step down the electricity and deliver it to the train or tram electrical system.

Key components and their functions

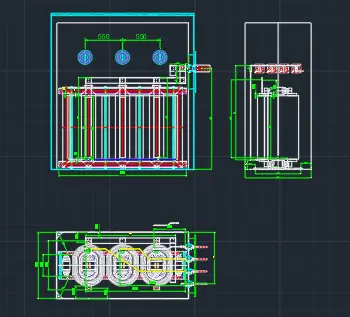

Most of the traction transformers you see will be a dry type transformer as the dry type transformer design best suits the locomotive application. However some of the traction transformers are also oil type transformers. A traction transformer will have all the key transformer parts of a standard transformer with difference lies in the output that each component has to deliver.

Transformer Core

The core of the traction transformer will basically have the same working principle and function as of any other transformer core. It will provide a low reluctance path for electro magnetic flux to pass from one winding to another.

The difference between a normal transformer core and the traction transformer core is that the core of the traction transformer has to be much more efficient as it has to face heavy fluctuating loading conditions as the locomotive moves at different speeds during its journey.

Material has to be stronger and construction of the core has to be rigid to process dynamic loading conditions with efficiency.

Reading more: Differences Between Copper Core and Aluminum Core Transformers

Transformer Winding

Similar to the transformer core, the transformer winding of the traction transformer will work on the same principle of a standard transformer winding but the expectations of traction are different. To enable you to move your electric train or train at different speeds and enable efficiency braking and speeding of your train and tram.

The winding of the traction transformer has to be much more efficiently designed and constructed for rigidity and reliability. Use of high quality material with high standard insulation and isolation material to help handle dynamic loading conditions.

As each traction transformer will be a step down transformer, so the winding of the traction transformer will have step down configuration.

Keep reading: Understanding Types of Transformer Winding and Their Applications

Insulation and Isolation Material

The transformer winding and core assembly needs insulation material for a non contact assembly. Similarly isolation is required to protect winding and core from environmental factors like dust and moisture.

In an oil type traction transformer the insulation and isolation material experience more mechanical vibration, mechanical stresses, and dynamic electrical loading condition than a standard transformer.

So the insulation material and transformer tank containing oil has to be strong enough to resist vibration and hold all the transformer oil without any potential leaks. In dry type traction transformers, the resin used in traction transformers for insulation and isolation of winding and core assembly need to be much stronger and harder than a normal resin used in standard dry type distribution transformers.

One of the most important parts of the traction transformer is its tap charger. Depending on the installation and application of the traction transformer, it can either have an on-load tap changer or an off-load tap charger.

The traction transformer you see installed on the trains or trams have an on-load tap changer as the on-load tap charger allows the voltage adjustment of the transformer while the traction transformer is still energized, connected to the power source and supplying electricity.

The traction transformer you see installed on electric train stations and supply power to the entire system of electric train or tram has an off-load tap charger. The off-load tap changer of the traction transformer needs you to disconnect the transformer you power supply and then change the tap position. This is done when a traction transformer needs to support a train or tram of different load than it was supporting previously.

Learn more: What Is An OLTC Transformer and How Does It Work?

Cooling Mechanism

As traction transformers can be either oil type or dry type transformers, the type of transformer cooling system depends on the type, size, and power rating. A small size traction transformer installed on either metro or tram might not need a forced air cooling system as moving the tram will provide necessary air flow. So it will either have a natural air cooling system in a dry type transformer or oil natural air natural cooling system in oil type transformers.

A medium size transformer installed on an electric train might or might not need a forced convection based cooling system but a large size traction transformer installed on a railway station and providing electricity to electric train or trams will need a dedicated forced convection cooling system.

The on-board cooling system to the traction transformer needs to be robust as it will face high vibrations and mechanical stress due to moving locomotives. These are additional stresses other than the normal temperature stresses a normal transformer cooling mechanism has to face.

Applications of Traction Transformers

Traction transformers are specifically designed for some unique applications. They are not general purpose transformers, so only have limited unique applications.

Railways

All types of high speed trains and their related suburban networks have a traction transformer to support all electrical operations. Similarly the freight rail system utilizes the traction transformer to power the locomotives and other electric multiple units.

Trams and Electric Busses

All trams you see have a traction transformer as their key electrical component. They step down the voltage for tram electric motors and other electrical systems. Similarly all large electrical buses use traction transformers that enable efficient energy conversion.

Industrial Equipments

Traction transformers are also used in various industrial equipment that have variable load and cannot operate on fossil use based power supply. These industrial equipment includes conveyor belts and mining equipment.

More about Transformer Applications

Key Benefits of Traction Transformers

As traction transformers are designed for some specific application. So they are designed to offer some key benefits during operation.

Energy Efficiency

As these traction transformers are designed to power locomotives, they have to be very efficient and offer minimal losses to make the transportation affordable. These transformers have minimal power losses during voltage transformation. This improves overall system performance.

Reading more about Transformer Efficiency

Reliability

Designing stage of these transformers ensures robustness and manufacturing ensures a rigid structure to resist against the harsh operating conditions. This robustness and rigidity ensures consistent, reliability, and long term operation of the traction transformer.

Compactness

As on-board traction transformers are installed on locomotives so they are always designed for compactness. The compact design allows for lightweight and space efficient transformers which is crucial for on-board applications.

Challenges in Traction Transformer Design

As these traction transformers are always designed for some unique requirements. There are always some challenges in traction transformer design that need to be addressed.

High Power Demand

Traction transformers have to deal with huge electrical power especially in case of high speed long distance trains. Designing a transformer that can meet the high power and dynamic loading condition is very difficult.

Thermal Management

Managing high power and dynamic loading conditions produce a lot of thermal stress on the traction transformer winding and cooling mechanism. The cooling mechanism has to be highly efficient to remove all waste heat or else transformer performance will be compromised.

Space Constraints

As most of these traction transformers are installed on-board so there's always space constraints. The traction transformer has to be made for high power demand, thermal management, dynamics loading, lightweight and with space constraints in mind.

Advances in Traction Transformer Technology

To offer the key benefits and to overcome the challenges faced in traction transformer design. There are some advances in the traction transformer technology that offer solutions to challenges and offer key benefits.

Advance Material

Copper is still the best material for traction transformer winding but there are improvements in core materials. The introduction of nanocrystalline alloys and amorphous cores has improved the energy efficiency of the traction transformer core and reduces the core losses significantly.

You may enjoy: What different materials are used in a Transformer?

IoT and Smart Monitoring

As locomotives are getting smarter and more digital, so do their traction transformers for better integration of systems. The use of digital sensors to enable real time monitoring of transformers ensures optimal performance.

High Temperature Superconducting Transformers

Use of good quality high temperature superconducting material enables highly compact, efficient, and reliable traction transformers. This enables locomotives to go faster and travel more distance and still maintain the performance.

Conclusion

Traction transformers are the backbone of our locomotive industry. They are used to power our trains and electrical buses. Transformers work as a bridge between electric power supply and the locomotive electronics and electrical equipment like electric motors. All traction Transformers or step down transformers and they are responsible for reducing the voltage to the level that it is safe for locomotive electronics.

Traction Transformers have compact and rigid design and or specifically design to handle dynamic loading and high mechanical vibrations. Use of advanced materials and digital sensors having steady performance and high efficiency.

Follow Up

Traction transformers are an integrated part of our locomotive electronics and electrical setup. They reduce voltage to manageable levels. At Daelim Transformer we offer traction transformers of all types, sizes, and power capacity. We offer traction transformers that have high efficiency and a very compact design. We follow all international standards during our transformer manufacturing and our products pass all internal safety and reliability tests.

With our manufacturing and distribution network, we offer our reliable services and quality traction transformers in the USA, Europe, Australia, and in other countries around the globe.

If you have any questions regarding Traction Transformers, Contact Us and we will be happy to help you.

Related Products

Related Article

Can You Convert Single Phase Transformer to Three Phase?

A single transformer cannot convert single-phase to three-phase power, but three single-phase transformers can be configured to create a three-phase system. This upgrade enhances efficiency, handles higher loads, and suits industries like manufacturing and data centers. Daelim Transformer offers reliable solutions for such power needs.

Can a Damaged Transformer Coil Be Repaired, Refurbished, or Replaced?

A damaged transformer coil can often be repaired, refurbished, or replaced, depending on the extent of the damage. Minor issues like insulation wear or loose connections are repairable, while severe damage may require refurbishment or replacement. Consulting experts like Daelim ensures reliable solutions for maintaining power systems.

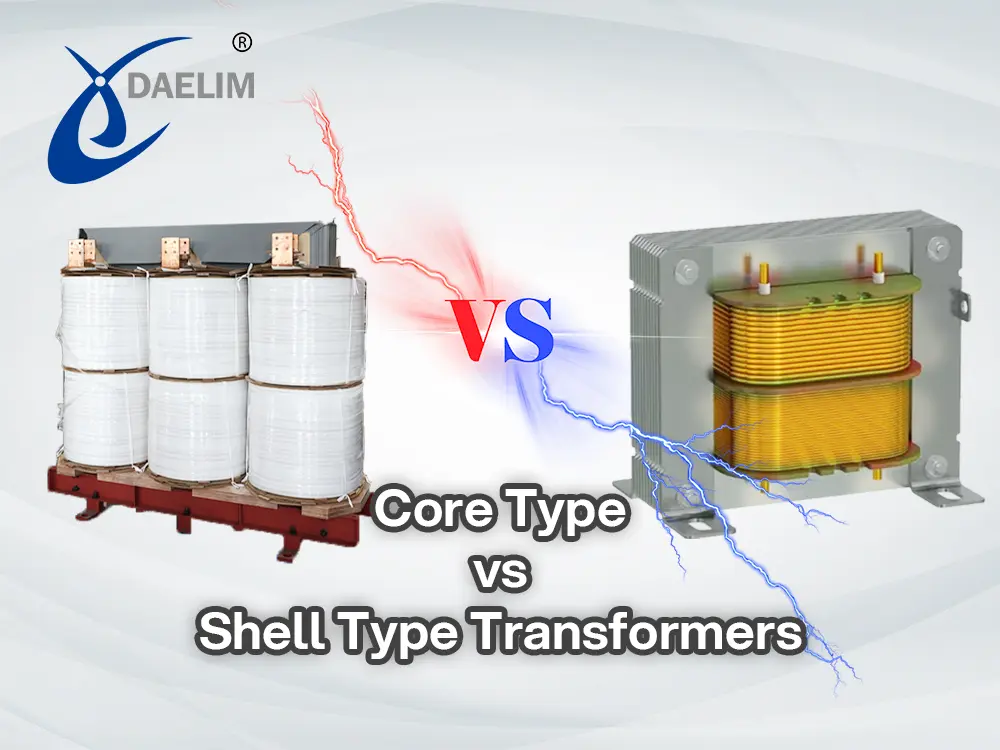

Core Type vs Shell Type Transformers

Core-type and shell-type transformers differ in structure, magnetic path, conductor material, and cooling efficiency. Core-type transformers offer better insulation, easier maintenance, and cost-effectiveness for high-power applications. Shell-type transformers, with a shorter magnetic path and compact design, provide higher efficiency and superior heat management. While core-type transformers excel in industrial use, shell-type transformers are ideal for space-saving and energy-efficient solutions. Choosing the right transformer depends on application needs, cost considerations, and performance efficiency.

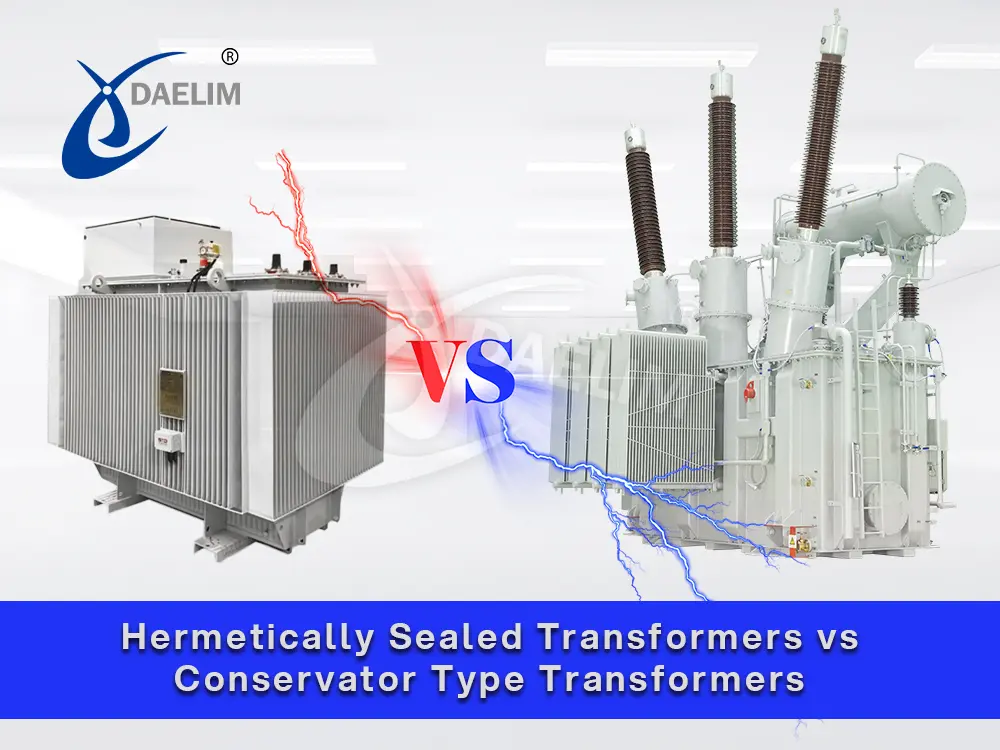

Hermetically Sealed Transformers vs Conservator Type Transformers

Hermetically sealed and conservator-type transformers differ in design, maintenance, and performance. Hermetically sealed transformers are fully enclosed, preventing air exposure and requiring minimal maintenance, making them ideal for harsh environments. Conservator-type transformers use an expansion tank for oil regulation, improving cooling and extending operational life. Each type has distinct advantages depending on application needs, space, and budget. Choosing the right transformer ensures efficiency, reliability, and long-term performance for power systems.

Choosing the Right Transformer Enclosure for Your Project

Selecting the right transformer enclosure ensures safety, durability, and optimal performance. This guide explores different NEMA-rated enclosures, their materials, and protective features against environmental hazards like dust, moisture, and corrosion. Whether for indoor or outdoor applications, choosing the proper enclosure safeguards transformers, extends their lifespan, and reduces maintenance costs. Understand key factors like protection levels, material selection, and environmental conditions to make an informed decision. Contact Daelim Transformer for expert guidance in finding the best enclosure for your needs.

What is electrostatic interference in Transformers

Transformer electrostatic shielding minimizes electrical noise and interference by blocking capacitive coupling between windings. It enhances transformer performance, ensures signal clarity, and protects sensitive electronics. Common shielding materials include copper, aluminum, and conductive coatings, chosen based on performance and cost. Proper placement, grounding, and material selection are crucial for effective shielding. This technique is widely used in medical, aerospace, and defense applications to ensure stable electrical performance and prevent disruptions.