How to analysis of gases and check oil level in transformer ?

With the extension of the operating time of the transformer, the transformer may have initial failures, and some flammable gases in the oil are the precursors of internal failures. These flammable gases can reduce the flashpoint of the transformer oil, thereby causing early failures.

Transformer oil and fiber insulation materials are aged and decomposed under the influence of moisture, oxygen, heat, and the catalysis of materials such as copper and iron during operation. Most of the gas produced is dissolved in oil, but the rate of gas production is quite slow. When there is an initial fault inside the transformer or a new fault condition is formed, the gas production rate and gas production volume are very obvious, and most of the initial defects will show early signs. Therefore, a proper analysis of the gas produced by the transformer can detect the fault.

Types of gases in transformer oil

Gas chromatography is the most practical method for the analysis of combustible gases in transformer oil, which includes two processes of degassing and measurement of oil. Mineral oil is composed of about 2,871 liquid hydrocarbons, usually, only hydrogen (H2), oxygen (O2), nitrogen (N2), methane (CH4), carbon monoxide (CO), ethane (C2H6) in insulating oils are identified ), carbon dioxide (CO2), ethylene (C2H4), acetylene (C2H2) 9 kinds of gases, these gases are removed from the oil and analyzed to prove their existence and content, which can reflect the type and severity of the failure of these gases. degree. The gases produced by oil during the normal aging process are mainly carbon monoxide (CO) and carbon dioxide (CO2). CH4). When the fault temperature is not much higher than the normal operating temperature, the gas produced is mainly methane (CH4). As the fault temperature increases, ethylene (C2H2) and ethane (C2H6) gradually become the main physical gas; At ℃ (for example, the arc temperature is above 300℃), the gas generated by oil cracking contains more acetylene (C2H2), and if the fault involves solid insulating materials, more carbon monoxide (CO) and carbon dioxide ( CO2).

How to judge the fault nature of electrical equipment?

Use the three contrast values of five characteristic gases to judge the fault nature of electrical equipment:

(1) C2H2/C2H4≤0.1 0.1<CH4/H2<1

When C2H4/C2H6<1, the transformer has been aging normally.

(2) C2H2/C2H4≤0.1 CH4/H2<0.1

When 0.1<C2H4/C2H6<1, it is a partial discharge with low energy density, which is a discharge in a gas-containing cavity, which is caused by incomplete immersion, gas saturation or high humidity.

(3) 0.1<C2H2/C2H4<1 CH4/H2<0.1

When 0.1<C2H4/C2H6<1, it belongs to the partial discharge of high energy density (except the discharge of air-containing cavity), which leads to the discharge trace of solid insulation.

(4) 1<C2H2/C2H4<3 0.1<CH4/H2<1

When C2H4/C2H6>3, there is power frequency freewheeling discharge, coil, wire cake, arc breakdown of oil between turns or between coil and ground.

(5) C2H2/C2H4≈3 0.1<CH4/H2<1

When C2H4/C2H6≈3, it is a low-energy discharge. With the increase of spark discharge intensity, the ratio of characteristic gas gradually increases to 3. The fault may be the continuous spark discharge of the floating potential body or the breakdown of oil between solid materials.

(6) C2H2/C2H4≤0.1 0.1<CH4/H2<1

When 1<C2H4/C2H6<3, it is a thermal fault below 150°C, and the gas mainly comes from the decomposition of solid insulating materials, usually the wires covered with insulating layers are overheated.

(7) C2H2/C2H4≤0.1 1<CH4/H2<3

When C2H4/C2H6<1, it is a low-temperature thermal fault below 300℃.

(8) C2H2/C2H4≤0.1 1<CH4/H2<3

When 1<C2H4/C2H6<3, it is a medium-temperature thermal fault of 300-700°C.

(9) C2H2/C2H4≤0.1 1<CH4/H2<3

When C2H4/C2H6>3, it is a high-temperature thermal fault higher than 700℃.

The main reason for (7), (8), (9) is the local overheating of the iron core caused by the concentration of magnetic flux. In practice, there is a combination of ratios that are not included, which may be the coexistence of overheating and discharge or the on-load voltage regulating transformer. The diverter switch oil compartment is leaking.

What to do when an internal failure occurs?

(1) Take oil samples and observe, whether there are suspended particles, whether there is aromatic odor and other appearance inspections and chromatographic analysis of dissolved gases in the oil.

(2) Investigate the development trend of the fault, that is, the gas production rate at the fault point (if it exists) is related to the amount of energy consumed by the fault, the fault location, and the temperature of the fault point.

(3) When it is considered that there is a fault inside the transformer, the three-ratio method can be used to judge the type of fault.

(4) In the case of gas inside the gas relay, the analysis results of the gas sample in the relay should be compared with the analysis results of the gas taken out from the oil.

Learn more now: What is the difference between mineral oil, Vegetable oil, and silicon oil?

What are the reasons for abnormal transformer oil levels?

When the oil level of the transformer does not match the oil temperature or the temperature curve, it is judged that the oil level is abnormal. Abnormal oil level mainly manifests as false oil level and low oil level.

1. Oil level indicator failure: Repair the oil level indicator.

2. The respirator is blocked so that the air cannot enter when the oil level drops, and the oil level indication is too high: clear the respirator.

3. The oil chamber of the oil conservator collects gas so that the oil level is higher than the actual oil level: the oil conservator should be filled with oil and exhausted.

4. The oil chamber of the oil conservator is poorly sealed (diaphragm or capsule rupture, bellows crack, etc.), so that the oil level enters the diaphragm or capsule, and the oil level is low: repair the oil conservator.

5. The transformer leaks seriously, causing the oil level to below: deal with the leakage point and refill the oil.

What should we pay attention to when the transformer drains oil?

The interior of the transformer oil chamber is a vacuum environment, so the following items should be paid attention to when draining oil:

1. Open the exhaust hole of the oil conservator or the oil tank to break the vacuum environment.

2. When the oil in the oil conservator does not need to be released, the butterfly valve of the gas pipeline can be closed, and only the oil in the oil tank can be released. (When the following parts of the oil conservator are overhauled, such as bushing replacement work)

3. Calculate the amount of oil discharged according to the maintenance scope. (Replacement of casing, pressure relief valve, vacuum butterfly valve, and overall overhaul of the transformer are different in oil discharge)

4. Pay attention to temperature and humidity when draining oil, and drain oil at a relative humidity of ≤75%.

Note: Be sure to open the vent plug before draining the oil

What should be paid attention to when filling the transformer with oil?

1. The main body should be evacuated before the large area of the transformer is filled with oil, and the connecting pipe should be installed between the tap changer and the main body before vacuuming. (If the gas and oil conservator cannot be evacuated, the butterfly valve of the oil conservator should be closed)

2. Vacuum, the vacuum value should reach 133pa, and keep it for a certain time (110 kV for 4 hours, 220 kV for 8 hours). Vacuuming is strictly prohibited in rainy and foggy weather such as humidity greater than 75%.

3. After the vacuum degree is maintained for a certain period of time, start the oil injection. The oil injection should be injected from the oil inlet valve at the bottom of the main transformer tank. When the injection distance is 200mm-300mm from the top of the tank, stop the oil injection.

What to pay attention to when refilling transformer oil?

1. When the transformer is filled with oil after vacuum filling, it must be injected through the oil filling pipe of the oil conservator, and it is strictly forbidden to inject from the lower oil tank valve.

2. The air vents such as the casing riser and the upper pipe of the radiator should be exhausted several times until they are exhausted.

3. The gas in the oil chamber of the oil conservator should be exhausted to prevent false oil level. For oil conservators of different structures, the exhaust methods are different, but after all, the core inspection principle: oil from the exhaust hole means that the gas is discharged cleanly

1. Personnel working at heights should be qualified for physical examination and obtain a special operation certificate before they can work at heights

2. Personnel working at heights should use seat belts correctly, and it is strictly forbidden to use low hanging and high safety.

3. Special personnel should be set up to supervise work at heights.

4. When oil operations are carried out on-site, corresponding fire-fighting equipment should be equipped.

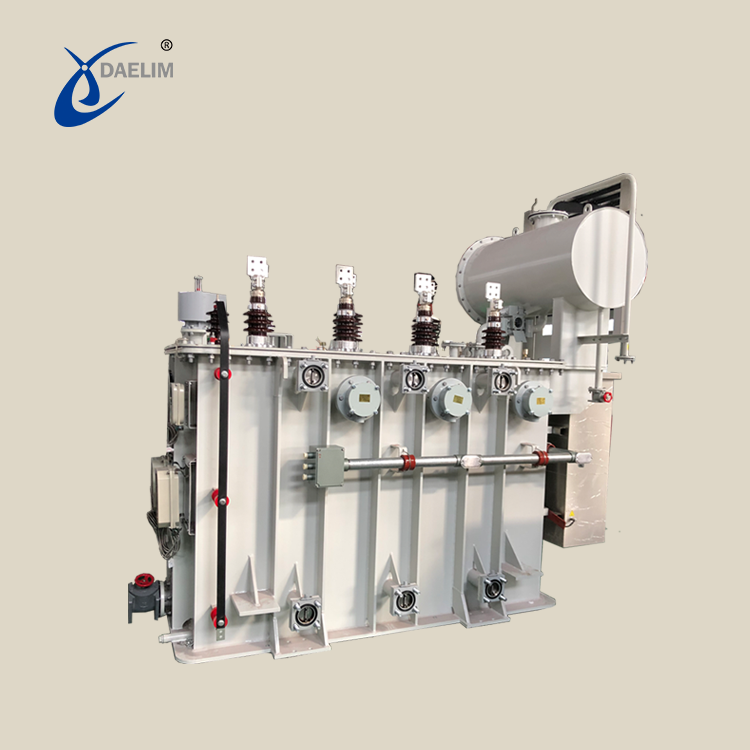

Daelim is a professional transformer manufacturer in China with nearly 20 years of export history. The main products are pad mounted transformers, substation transformers, power transformers, dry transformers and single phase transformers.

The transformers designed and produced fully comply with various international standards, such as IEEE/ANSI/CSA/AS/DOE, etc., and have CSA certification and UL certificate. There are aftermarket installation teams in North and South America. If you have transformer-related needs, please contact Daelim.