Transformer Packaging and Transportation

Transformers are critical components in electrical power systems, requiring careful handling during packaging and transportation to ensure their integrity and functionality upon arrival. This article provides a detailed overview of the best practices for transformer packaging and transportation, drawing from the expertise of professional manufacturers like Daelim Transformer.

Transformer Packaging

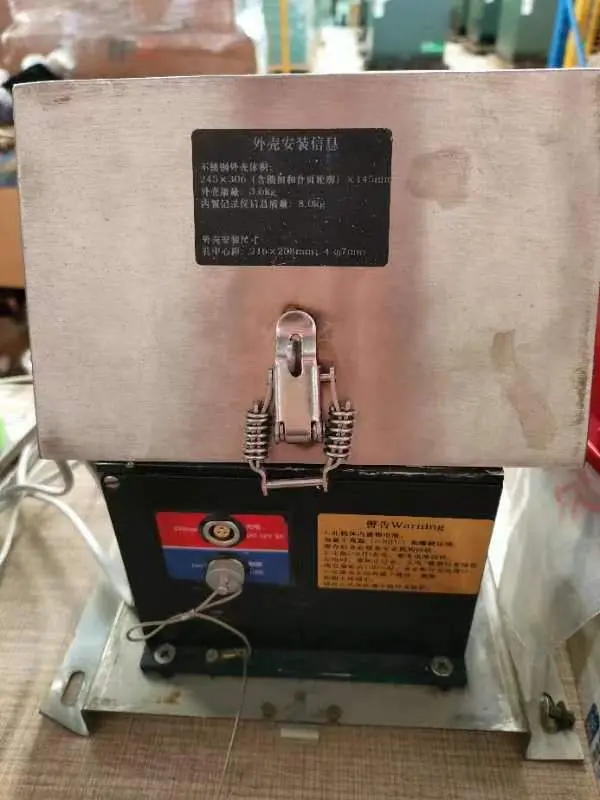

Small and Medium-Sized Transformers

These transformers like pad mount transformers, and substation transformers are generally transported as complete units. However, to protect sensitive components such as bushings, oil level gauges, and radiators from damage, they should be packaged securely:

-

Bushings: High-voltage and low-voltage porcelain bushings are typically transported in wooden or iron boxes. Each bushing should be secured with bolts and drawstrings, and cushioned with rubber or foam to prevent movement. Packages should be marked with "upward" and "shockproof" to ensure proper handling.

Bushings: High-voltage and low-voltage porcelain bushings are typically transported in wooden or iron boxes. Each bushing should be secured with bolts and drawstrings, and cushioned with rubber or foam to prevent movement. Packages should be marked with "upward" and "shockproof" to ensure proper handling. -

Radiators: Fans of radiators must be packed separately to prevent exposure to moisture. Inlet and outlet flanges should be sealed, and radiators should be separated with wooden boards and fixed together to prevent damage during transit.

-

Oil Storage Cabinets: These should be packed separately with all mounting holes sealed. Similarly, bushing-type current transformers and risers need to be sealed with temporary covers and filled with transformer oil.

-

Other Components: Gas relays, desiccants, thermometers, tubular or pointer oil level gauges, and pressure relief valves should be packed with shockproof materials and labeled appropriately. Adsorbents like silica gel should be transported in sealed plastic bags, and transformer oil should be shipped in specialized barrels.

Large and Extra-Large Transformers

Due to their size and weight, large power transformers are often disassembled into parts for transport:

-

Transformer Body: When oil-filled, the oil level should be kept 100-150mm from the top of the box to allow for expansion. If transported with nitrogen filling, only a minimal amount of residual oil is left, and the main tank is filled with dry nitrogen at 0.02-0.03 MPa pressure.

-

Components: Components removed from large transformers must be packaged separately. Temporary covers should be used to seal the transformer body.

Special Considerations

-

Porcelain Bushings: For voltages below 35kV, they can be transported with the transformer body in wooden boxes or iron shields. For voltages of 69kV and above, they are transported individually in wooden boxes.

-

Radiators and Air Coolers: Should be packed separately and secured to prevent deformation and damage. Air coolers need to be packed in waterproof packaging with the fan side facing up.

Transportation

Railway Transportation

-

Selection of Flat Cars: Choose appropriate flat cars based on the transformer’s weight and dimensions.

-

Loading and Securing: Hoist the transformer by its total weight with an angle between the hoisting rope and vertical line of less than 30°. The center of gravity should align with the flat car’s center. The transformer should be fixed with iron or steel wire ropes to prevent movement, with the main body not tilted more than 15°.

-

Nitrogen Filling: Before nitrogen filling, ensure the oil tank is filled with oil. Slowly introduce nitrogen to reach a pressure of 50kPa, then proceed with nitrogen filling, maintaining a pressure of 20-30kPa. The transport vehicle should have a nitrogen replenishing device.

Highway Transportation

-

Road and Vehicle Suitability: Transformers can be transported by car if the route's bridges, culverts, and road conditions permit. Secure the transformer with wire or steel ropes, maintaining a maximum speed of 40 km/h on paved roads and lower speeds on less stable surfaces. The tilt angle should not exceed 15° in the long axis and 10° in the short axis. Avoid transporting in adverse weather conditions.

Water Transportation

-

Types of Water Transport: Ocean and inland river transport are common. Ocean transport is used for exports, while inland transport is suited for nearby towns.

-

Handling and Security: Ensure the transformer is securely fixed during water transport, accounting for potential strong winds and waves. For large transformers, collision recorders are used to monitor vibration, with impact in any direction not exceeding 3g.

Short-Distance Transportation

Upon arrival at the destination, transformers need to be moved to the installation site:

-

Method: Lift the transformer with a jack, place steel plates and rollers underneath, and use a winch or hydraulic jack for movement. The preferred speed is 100m/h, and wire ropes should be used on designated pulling hooks or rings, avoiding main hoists.

Post-Transportation Inspection

After transportation, several checks are necessary:

-

Collision Recorder: Ensure the records are complete and accurate.

-

Appearance: Inspect for any visible damage.

-

Unpacking Inspection: Verify that the contents match the packing list and check for any missing parts.

-

Documentation: Confirm that all factory documents are complete.

Daelim Transformer’s expertise in transformer packaging and transportation ensures that each unit arrives in perfect condition. We are committed to providing high-quality transformers with meticulous attention to detail in every step of the process. For reliable, efficient, and secure transformer solutions, contact Daelim Transformer today. Let us assist you with your transformer needs and deliver excellence right to your doorstep.

Related Products

Related Article

Classification of Gas Generation During Transformer Operation

Gas generation in transformers can stem from various sources and fault types, each indicating specific operational or insulation issues. Understanding these classifications is crucial for effective maintenance and fault diagnosis in transformer systems.

Diagnostic Methods for Power Transformer Insulation

Power transformers rely on robust insulation systems to ensure operational reliability and longevity. Over time, however, various factors can degrade these insulation systems, necessitating effective diagnostic methods to assess their condition. Here, we explore the key techniques employed for diagnosing both oil and solid insulation in transformers.

Parallel Transformer

Parallel transformers connects multiple units to common busbars, enhancing reliability and flexibility. It allows continued power supply if one transformer fails, optimizes load distribution, and reduces initial investment. Ideal operation requires equal rated voltages, matching connection groups, and similar short-circuit impedance. While achieving perfect conditions is challenging, slight deviations are permissible except for connection groups.

13.8 kV 10.5 MVA Substation Transformer for Ecuador

A customer from Ecuador contacted Daelim Transformer for a 10.5MVA substation transformer (13.8kV high voltage, 2.4kV low voltage). Daelim Transformer provided a customized solution, conducted virtual factory tours, ensured rigorous quality control via video inspections, and offered post-delivery online training and ongoing support, fostering a successful partnership.

20MVA Power Transformer for the United States

This project involves the development of a 20 MVA three-phase power transformer tailored for the United States market. The primary voltage is 24.94kV, and the secondary voltage is 4.16kV, indicating it functions as a step-down transformer. The design and production fully comply with IEEE C57.12.00 standards and have passed third-party UL team testing. All accessories also adhere to IEEE standards. FR3 vegetable oil serves as the insulating liquid for the transformers.

2 MVA Pad Mounted Transformer for Utility

Behold the backbone of Canada's utility infrastructure—the 2MVA pad mounted transformer. With a primary voltage of 4160Grdy/2400V and a secondary voltage of 800GrdY/461V, this transformer stands as a testament to efficiency and reliability in power distribution. Crafted in strict accordance with CSA standards and CAN/CSA802.1 energy efficiency guidelines, it embodies the pinnacle of engineering excellence.