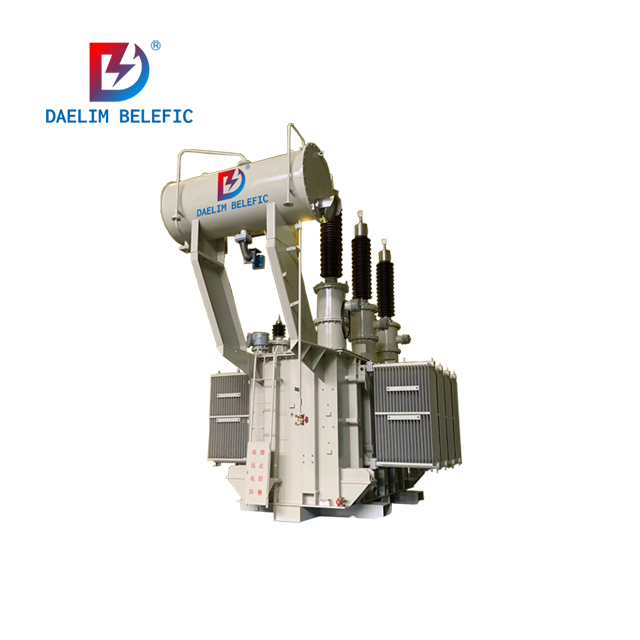

Why are there pebbles under the transformer?

We usually see pebbles under the installed oil-immersed transformer. Why are there pebbles and what is their function?

Various rationales underlie the practice of situating pebbles beneath transformers

Fire Prevention and Oil Containment

Pebbles serve as a deterrent against fire propagation, particularly in instances of insulating oil leakage during high-temperature or fault scenarios, thereby mitigating fire risk.

Drainage and Oil Management

A bed of pebbles beneath the transformer aids in directing leaked oil towards designated collection areas, such as specialized oil pools, facilitating efficient containment and subsequent treatment, thus minimizing environmental impact.

Filtration and Maintenance of Purity

Pebbles act as a filtration barrier, preventing contaminants from infiltrating the oil pool, thereby preserving oil cleanliness and reducing the likelihood of equipment malfunctions.

Thermal Regulation

While not a primary cooling mechanism, pebbles assist in dissipating excess heat generated by the transformer, thereby contributing to optimal operational temperatures.

Insulation and Safety Enhancement

Functioning as a non-conductive medium, pebbles provide an additional layer of insulation between the transformer and the ground, thereby enhancing safety protocols during routine inspections and operation.

Vibration Dampening and Structural Integrity

Pebbles offer shock-absorbing properties, minimizing vibration and providing structural support to safeguard against uneven terrain or minor movements.

Weed Suppression and Maintenance Streamlining

Utilizing pebbles effectively inhibits weed growth in the vicinity of the transformer, reducing the frequency of maintenance tasks and ensuring operational efficiency.

For further inquiries regarding transformers, please feel free to Contact Daelim Transformer for expert guidance

Related Products

Related Article

Differences Between NLTC and OLTC Transformers

OLTC transformers adjust voltage levels under load without power interruptions, ideal for areas with frequent voltage or load instability. NLTC transformers adjust voltage only when de-energized, making them more economical and suitable for stable voltage conditions. Choose OLTC for instability and NLTC for stable conditions.

Differences Between Copper Core and Aluminum Core Transformers

Copper core transformers offer better conductivity, slower temperature rise, and are ideal for high-load applications. Aluminum core transformers are more economical, heat up faster, and are suitable for lower loads. Choose based on your specific load requirements.

Why Does Dry-Type Transformer Make Noise?

Noise in dry-type transformers is mainly caused by poor-quality silicon steel sheets, uneven installation sites, and high grid voltage increasing the core's magnetic density.

What happens if the transformer is overloaded?

Transformer overload results in increased power consumption, causing higher operating temperatures, insulation aging, and shortened lifespan. It can also harm connected electrical equipment. To maintain optimal performance and longevity, load should not exceed 15% of rated capacity in summer and 30% in winter.

Why does the transformer explode?

Transformer explosions are typically caused by factors such as internal short circuits, improper use and maintenance, overload, aging, manufacturing defects, lightning strikes, and load short circuits. Choosing high-quality transformers from reputable suppliers is crucial to minimize these risks.

Why does transformer require a balanced winding?

A balanced winding in transformers minimizes voltage differences between windings, reducing losses, controlling output voltage, and ensuring reliable operation.