The Ultimate FAQ Guide to Wind Transformers-Daelim

Daelim Industrial is the world's leading manufacturer of transformers for wind energy applications. We have supplied units to all major global markets, providing a wide range of options to meet the needs of our customers. Daelim's wind energy transformers include pad-mounted transformers, small substation transformers, and dry transformers. The design and production of these transformers can meet various international standards such as IEEE/ANSI, IEC, DOE, CSA, AS, etc.

If you have any questions about our wind transformers, please check out our FAQs below.

How Much Voltage Does a Wind Turbine Generate?

The average wind turbine produces around 690 volts of electricity. However, the voltage ranges from just a few hundred to over 6,000v. Turbine generator voltage is considered as low-class or below 1,000v. It will also depend on the wind speed.

The stronger the wind current, the more electricity the turbine produces. The voltage produced by the turbine will also depend on its design. For instance, wind turbine wind speeds between 4.86 to 6.41 miles per second generate 7.28 to 11.30 electricity.

Where is the Transformer on a Wind Turbine?

The transformer in a wind turbine is commonly located at the base of the wind turbine. This design minimizes the risk of damage to the transformer in the event of a turbine collapse.

Another important reason for locating the transformer at the turbine's base is to reduce the length of conductor required between the generator and transformer. This can reduce costs and improve reliability.

What are Liquid-Filled Transformers?

A liquid-filled transformer is a type of transformer that uses a liquid to cool and insulate the winding. The most common type of liquid used in liquid-filled transformers is oil. Transformers of this type can also be used in wind power generation.

Liquid-filled transformers are more efficient than dry-type transformers because the liquid can cool the winding more effectively. The liquid also provides better insulation than air, further increasing the transformer's efficiency.

While liquid-filled transformers are more expensive than dry-type transformers, they tend to have a longer lifespan. The main disadvantage of liquid-filled transformers is that they are more susceptible to leaks, which can cause environmental damage if not properly contained.

You may enjoy: 8+FAQ About Pad Mounted Transformers

Can regular transformers be used in wind farms?

Transformers for wind farms need to meet the demands of wind farm turbines. It reduces lost revenue due to downtime and lowers the total cost of ownership compared to conventional distribution transformers. Conventional transformers often fail when used in wind farms because of heat build-up due to rapid and irregular thermal cycling, harsh link conditions, and gas build-up from arcing that occurs when inexpensive tap-changers are used. Therefore, transformers for wind farms require special specialized designs.

Get it now: The Impact of Impedance on Transformer Design

Which Transformer is Used in a Wind Turbine?

The type of transformer used in a wind turbine depends on the turbine's voltage. However, most wind turbines use a generator step-up (GSU) transformer. A step-up transformer increases the voltage of the electricity generated by the turbine. To do this, it will need strong short-circuit resistance to ensure that the electricity is not lost. Without a solid resistance for the transformer, a lot of the electricity produced by the turbine will be wasted. Both liquid-filled transformers and dry-type transformers can be used in wind power systems.

Read more: The Ultimate Guide To Step Down Transformer

As one of the main equipment of wind power plants, transformers have high requirements for energy saving due to the unstable output power of wind power generation, high no-load and load losses of transformers, and high requirements for energy-saving of transformers; the layout of wind power plants is relatively scattered and remote, and transformers need to have a failure rate Low and maintenance-free features.

Liquid filled transformer

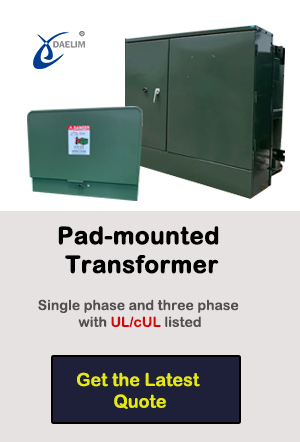

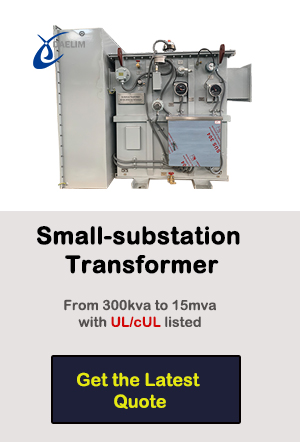

In onshore wind power, wind power step-up transformers are often pad mounted and small substation transformers, and are generally equipped with liquid-filled transformer transformers, because of their compact structure, small size, fully sealed, and fully insulated, easy installation, safe and reliable, and beautiful the environment.

In onshore wind power, wind power step-up transformers are often pad mounted and small substation transformers, and are generally equipped with liquid-filled transformer transformers, because of their compact structure, small size, fully sealed, and fully insulated, easy installation, safe and reliable, and beautiful the environment.

The capacity of the transformer is usually 750kVA, 1000kVA, 1500kVA, 2000kVA, 2500kVA, 3000kVA, and 3750kVA. Higher voltages are usually in the 13.2 kV to 34.5 kV range. On the other hand, the low voltages are between 600v to 800v. The pad mounted and small substation transformer produced by Daelim is specially designed to have much stronger short-circuit resistance than ordinary transformers and can be used in wind power plants.

Read my article on 3 Phase Pad Mounted Transformer-Daelim Belefic

Daelim's professional team of engineers provides customers with the best wind and solar solutions, and many Daelim transformers are used in wind and solar projects in North America.

Daelim wind power solutions:

Adopting pad mounted and small substation transformer technology (12.47kV/13.2kV/25kV/34.5kV), according to the requirements of different power generation schemes, provides a full range of fan side ester oil-immersed transformers that are more environmentally friendly, safer and more reliable solutions; According to the special requirements of the power generation industry for transformer products, a customized special design is given, which reflects the characteristics of small size, lightweight, strong resistance to sudden short circuit, high heat dissipation efficiency, energy saving, and environmental protection, stability and reliability.

Keep reading: Do you want to learn more about a 34.5 kV transformer?

Transformer Customized Design

1. The straight-wound coil structure ensures the anti-sudden short-circuit performance of the transformer

2. Hot air circulation vacuum drying and oil injection process ensure reliable insulation performance of the transformer

3. Corrosion resistance up to C4 level

4. Advanced simulation technology support

5. Environmentally friendly and efficient - using environmentally friendly transformer oil: FR3 and RAPO vegetable oil

6. The low voltage adopts side-mounted bushings, which can be well connected with the switchboard

7. Ensure the effectiveness of heat dissipation

8. Mechanical strength of fuel tank - to ensure the effectiveness of product anti-vibration, anti-internal arc design, etc.

9. Reliable product quality

10. Stable production and quality control process

11. Valid product quality certification (UL/cUL, CESI, CSA, IEEE certificate, SGS, CSA, and other test reports)

12. Transformer test, vibration test, anti-corrosion verification, internal combustion arc test, etc.

You may enjoy: How To Purchase 3000kVA Transformer In USA & Canada

Dry type transformer

Due to the special operating environment (high humidity and high salt density) of offshore wind turbines, the power transformers used for step-up and grid connection can no longer be installed outside the units with oil-immersed transformers like onshore units, but dry-type transformers are usually used. It is installed in the engine room, which not only solves the problem of the whole unit's footprint but also avoids the difficult protection problem caused by installing the transformer in a lower position. At the same time, the transformer is close to the wind turbine, and the transformer directly boosts the 600-800V electricity from the generator to 35kV through the converter, which greatly reduces the use of low-voltage cables, thereby reducing the cost of the entire fan.

Try for free: Ultimate guide of cast resin dry type transformer

Daelim Transformer Design

To adapt to the harsh climate and environmental conditions when operating in the engine room, the dry-type transformer should have the characteristics of strong corrosion resistance. At the same time, the dry-type transformer is installed in the  nacelle of the offshore wind turbine, and the maintenance and repair costs are high. The dry-type transformer should have high reliability. Because the resin cast dry-type transformer is superior in the performance of environmental resistance, weather resistance, and short-circuit resistance, this type of dry-type transformer is preferred.

nacelle of the offshore wind turbine, and the maintenance and repair costs are high. The dry-type transformer should have high reliability. Because the resin cast dry-type transformer is superior in the performance of environmental resistance, weather resistance, and short-circuit resistance, this type of dry-type transformer is preferred.

Design scheme

The core laminations are made of cold-rolled oriented electrical steel strips, with 45° full mitered five-level seams; the high-voltage coils are of segmented cylindrical type, and the vacuum casting process is adopted; The insulating end resin seals and cures.

Due to the limitation of the size of the engine room and the requirements for the load, the external dimension of the dry-type transformer should not be too large, and the weight should not be too heavy. Generally, when copper windings are used, the transformer is small in size and heavy in weight; when aluminum windings are used, the transformer is large in size and light in weight. Therefore, in the electromagnetic calculation stage, it is necessary to repeatedly compare to meet the user's requirements.

Anti-corrosion design

In general transformers, the cooling method is self-cooling or air-cooling. The air inside the transformer shell is circulated with the air in the engine room, and the air with high humidity and high salt mist in the engine room enters the transformer shell, causing serious corrosion of the transformer structural parts. What is more serious is that in this environment, the soluble substances in the dirt on the insulation surface of the transformer gradually dissolve in water, and a conductive film is formed on the surface, which greatly reduces the insulation level of the insulation. The discharge phenomenon, i.e. pollution flashover is one of the main possible causes of fire in wind turbines.

To avoid this problem, the transformer is installed in an enclosure with a protection level greater than IP44, and an internal circulating cooling system is used to exchange heat with the outside world. In this way, the difficulty of the anti-corrosion design of the transformer body is greatly reduced, and the focus of anti-corrosion is transferred to the shell.

Anti-vibration design

During the operation of the wind turbine, the nacelle vibrates all the time, especially during the yaw and windward process of the unit and the braking process. Therefore, the anti-vibration design of the transformer is also very important.

The deformation of the transformer body and the loosening of the fasteners can be reduced by some measures: the transformer coil is cast as a rigid body so that the coil itself has good anti-vibration capability; increasing the number of transformer bottom pads and the number of fixing bolts will not affect the transformer. It plays a very good role in fixing; the long screw is installed on the upper clip of the transformer and is connected with the bracket on the top of the casing so that the transformer and the casing are integrated, and the shaking of the casing is avoided. In addition, all fasteners on the transformer adopt anti-loosening measures to avoid the falling off of transformer parts and tipping of the body.

Ventilation and heat dissipation design

Axial flow fans, air ducts, and heat exchange devices are arranged on the shell; a deflector is arranged on the transformer body, as shown in Figure 2. In this way, during the operation of the transformer, the axial flow fan draws the hot air in the casing into the air duct and performs heat exchange at the heat exchange device. Under the guidance of the air deflector, the transformer coil is cooled through the main air channel of the transformer and the air channel inside the low-voltage coil.

Design for maintainability

Wind turbines are installed in offshore waters, maintenance is difficult and the maintenance cost is very high. Therefore, the design of dry-type transformers should fully consider their maintainability.

The shell adopts a splicing structure, which can be easily disassembled, which is convenient for the replacement of large parts of the transformer such as high-voltage coils; the service life of the axial flow fan of the ventilation and cooling system is generally 40,000 hours. ready form.

The reason why wind turbines hardly use a step-down transformer is that it decreases the voltage, which is not ideal for wind turbines. The voltage of the electricity generated by a typical wind turbine is already too low to be used by the electric grid. That's why a GSU transformer increases the voltage so the grid can use it.

Get it now: The Ultimate Guide to Three Phase Transformer

What is the Efficiency of Wind Power Transformers?

The efficiency of a wind farm transformer is the ratio of the power output of the transformer to the power input. The average efficiency of a wind power transformer is about 90%, which means that the majority of the power generated by the wind turbine is converted into electricity.

However, transformer efficiency can vary depending on the type of transformer and the manufacturer. Some transformers can have efficiencies as high as 99%. The reason for the variation in transformer efficiency is due to the different designs and materials used in manufacturing transformers.

What's the Purpose of the Transformer Being Installed at the Windmill's Base?

The transformer installed at the base of the wind turbine is responsible for converting the low voltage electricity produced by the turbine into high voltage electricity. This conversion is necessary because high voltage electricity is more efficient for long-distance transmission.

Large copper is necessary to transmit electricity over long distances because it has low electrical resistance. To mitigate the cost while maintaining the electrical current, wind farms tend to place both the wind generator and the wind power transformer closer together. That's why the transformer is usually located at the base of the turbine.

Daelim's wind energy transformers feature lower losses, higher efficiency, and strong short-circuit resistance, thereby improving wind power generation efficiency.

Without the transformer, the electricity produced by the turbine would not be able to travel long distances and would be wasted. Therefore, the transformer is an essential component of the turbine; without it, the turbine would not be able to generate sufficient electricity.

Read on: The Ultimate Guide to delta wye transformer

What are the Advantages of Wind Power?

Wind power has three (3) main advantages that set it apart from other forms of energy generation:

Renewable Energy Source

Wind power is a renewable resource, which means that it can never be depleted. The sun will always shine, and the wind will always blow, making wind power a sustainable source of energy.

In addition, wind power does not produce greenhouse gasses or other pollutants. This makes wind power a very attractive option for those who are concerned about the environment.

Low Carbon Footprint

Wind turbines do not require fossil fuels to generate electricity, which means that they have a very low carbon footprint. In fact, wind power has one of the lowest carbon footprints of any form of energy generation.

This is significant because the majority of greenhouse gasses come from the burning of fossil fuels. Therefore, using wind power can significantly reduce our carbon footprint and help mitigate climate change.

Cost-Effective

The wind is a cost-effective energy source. The initial investment may be higher than other forms of energy generation, but the operating costs are very low. In addition, the price of wind turbines has been dropping steadily over the past few years, making wind power even more cost-effective.

Learn more: Transformer Efficiency

What are the Disadvantages of Wind Power?

Wind power also has a few disadvantages that should be considered:

Intermittent Energy Source

The biggest disadvantage of wind power is its intermittent energy source. If wind strength is inconsistent, the turbines will not generate enough electricity.

This is a major problem because it is difficult to store wind energy. Therefore, when the wind is not blowing, there is no way to generate electricity, leading to blackouts.

Needs Backup Power

Because wind power is an intermittent energy source, it needs backup power from another source, such as natural gas or coal. This backup power is typically used when the wind is not blowing.

While backup power is necessary, it defeats the purpose of wind power, which is to generate electricity without using fossil fuels. At the same time, backup power can be expensive, so it is important to consider the cost of backup power when deciding whether or not to invest in wind power.

Creates Low-Level Noise Pollution

Wind turbines generate a low-level noise that can be annoying to some people. In addition, the turbines' blades can create a "flicker" effect that can be disruptive to people who are sensitive to light.

While noise pollution from wind turbines is not a major concern, it is something to consider if you live near a wind farm. In addition, the flicker effect can also be a problem for people with certain medical conditions, such as migraines.

How Does a Wind Turbine Transformer Work?

The wind turbine transformer is a key component of the overall wind turbine. It works by converting low-voltage electricity coming from the turbine generator into high-voltage electricity that the electric grid can use.

The problem with wind energy is that its electricity is very low voltage while it is clean and sustainable. Therefore, for it to be used by the electric grid, this electricity needs to be converted into high voltage using a wind power transformer.

At the same time, it also decreases the amount of power loss that occurs during the transmission of large currents over longer distances via transmission lines. By doing so, the transformer makes the electricity produced by wind turbines more efficient.

Without a wind farm transformer, the electricity harnessed by the wind turbine would not be enough to power even a single light bulb. This is because it needs a boost in voltage to be used by the electric grid, and that's exactly what the transformer does.

Try for free: The Ultimate Guide to Dead Front Transformers

What's the Biggest Challenge to Wind Power?

The biggest power to wind power is that alternating current (AC) electrical energy from the turbine must be converted to direct current (DC) by a power electronic device, such as a diode rectifier, before it can be converted to high-voltage AC by the transformer.

The power electronic device is a big challenge because it uses a lot of energy itself, and it also causes a lot of energy to be lost in heat. So researchers are working on developing more efficient power electronic devices to make wind power more efficient.

What are the Specifications of a Wind Turbine Transformer?

The following are the specifications of a typical wind turbine transformer:

Capacity: 2000kVA, 2500kVA, 2750kVA, 3000kVA, 3750kVA

The high voltage of the wind transformer is usually not too high, and the conventional voltages are:

13.2kV/12.47kV/25kV/34.5kV

Low voltage: 600V/675V/800V

impedance: 6%

No load current: 1.4%

Efficiency: 90%

Temperature rise: 55°C

Insulation class: H

Cooling method: OFWF

Weight: 6 to 8 tons

Connection: Dyn1/YNyn0

Frequency: 50Hz/60Hz

Voltage regulation: ± 0.5%

Phase: Three-phase

Tapping range: ± 2 x -16%

Noise: ≤ 60dB

Read on: Knowing More about A Pad Transformer

What's the Difference Between a Wind Transformer and a Solar Transformer?

Solar and wind transformers have the same basic function, which is to convert low-voltage electricity into high-voltage electricity. However, there are some key differences between the two types of transformers.

For one, solar transformers are typically smaller than wind transformers. This is because solar panels produce less electricity than wind turbines. Solar transformers also have a lower capacity than wind transformers.

Another key difference is that solar transformers are typically located near the solar panels, while wind transformers are located near the wind turbines. This is because it is easier to transmit low-voltage electricity over shorter distances.

Third, solar transformers are typically more efficient than wind transformers. This is because solar panels produce direct current (DC) electricity, while wind turbines produce alternating current (AC) electricity. DC electricity is easier to convert into high-voltage AC electricity than AC electricity.

Finally, solar transformers have DC harmonics, so shielding layers should be prevented between high and low voltages to prevent high and low voltage mutual inductance. Wind power generation generally has obvious seasonality, wind transformers have high requirements for short-circuit resistance, and no-load loss is as low as possible.

Reading on: Solar Transformer - Your ultimate guide

Will a Wind Turbine Provide Power in the Event of a Power Outage?

No, wind turbines will not provide power during a power outage. This is because they are not connected to the electric grid.

For a wind turbine to generate electricity, it must be connected to the electric grid. When the electric grid goes down, so does the wind turbine.

However, some emergency backup generators can be powered by wind turbines. These generators are typically used in hospitals and other critical facilities.

How Much Power Does a Wind Turbine Generate?

The amount of power that a wind turbine generates depends on a few factors, such as the size of the turbine, the wind speed, and the capacity of the transformer.

A typical wind turbine has a capacity of 2 to 3 MW (megawatts). This means that it can generate over six million kilowatt hours (kW) of electricity annually, which is more than enough to sustain the electricity demands of over 1,500 households.

However, the actual amount of electricity that a turbine generates will depend on the wind speed. For example, a turbine with a capacity of 2 MW will only generate about 1 MW of electricity if the wind speed is only 10 miles per hour (mph).

The capacity of the transformer also plays a role in how much power a turbine can generate. For example, a transformer with a capacity of 2 MW can only provide enough electricity to power 1,000 households.

To generate sufficient electricity to power more households, multiple transformers must be used.

Learn more: 5+FAQ About 15kV Transformer

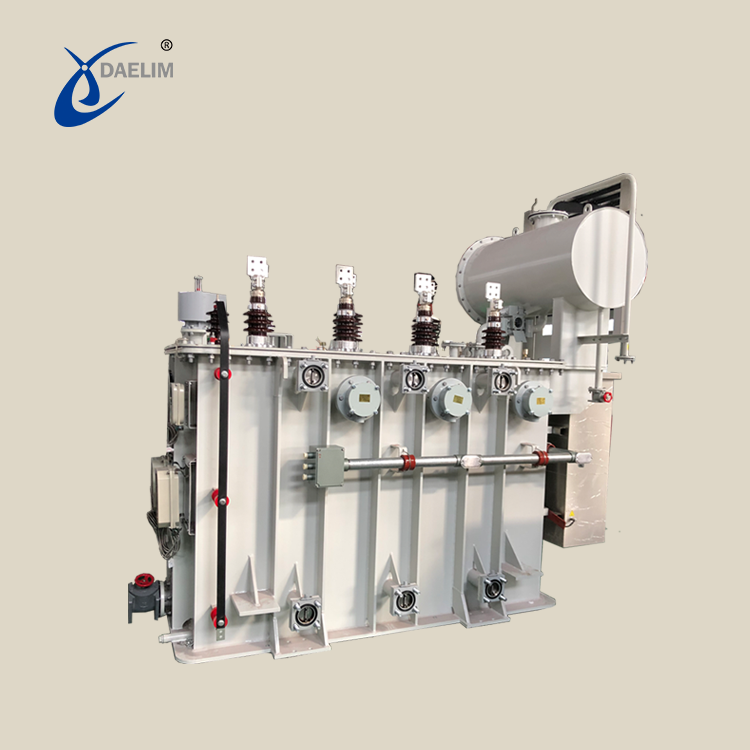

Daelim’s Wind Transfromer

Wind turbine step-up transformers are an important part of wind farm harvesting grids and need to operate efficiently and reliably in the harshest environments. Daelim is the most professional transformer manufacturer in China and one of the most experienced electrical equipment manufacturers in the industry in the international market. Daelim transformers are designed and manufactured for demanding wind and solar farm applications. The design is different for each wind farm project, and the specific design requirements depend on the transformer location, generation capacity, and transmission grid characteristics. Daelim engineers can provide custom-designed wind farm transformers to meet almost any special requirement.

Daelim’s flexible design and manufacturing systems can produce transformers with custom metal enclosures, a wide range of accessories such as low voltage circuit breakers, load break switches, and vacuum fault circuit breakers, and a variety of connections, switching, and protection options. Special size and oil capacity limitations can often be accommodated. Transformer housing colors can be customized to meet any aesthetic requirement.

Daelim has the ability to quickly deliver large orders of wind and solar transformers and is one of the most experienced transformer manufacturers in international projects. Daelim can provide local on-site services to assist developers with their power plant projects. Our engineers and technicians can perform installation supervision, testing, and warranty repairs from any location in the continental United States.

The quality of Daelim transformers you can rely on, Daelim's two-year warranty guarantees that the transformers will provide a long and reliable service life. Higher quality means less hassle, which means lower maintenance costs and higher profits for wind farm operators. Daelim transformer's advanced design, manufacturing, and testing systems ensure consistent quality. Our ISO-9001 registered quality management system connects all aspects of the company's operations, and our products have UL/cUL, CSA, and other certificates, and UL third-party staff will regularly come to the factory to audit each production link and process to ensure that we serve customers. Everything is done with the highest quality transformers.

In today's vigorous advocacy of sustainable development, wind power is still solar power, which is developing rapidly as a renewable energy source. Transformers are also developing rapidly as key equipment in wind and solar power generation systems. Whether it is used for wind or solar power generation, the transformer needs to be specially designed according to the characteristics of the power generation system, so the price is about 15% more expensive than the ordinary transformer. Daelim can produce and design both wind energy transformers and solar energy transformers. If you need, you can contact the Daelim team.

Related Products

Related Article

Pad Mounted Transformer Project Cases

3750kVA Primary 13.8kV, Secondary:0.415kV Loop-feed Pad-mounted Transformer, 12 sets for US market;

Power Transformer-The Ultimate FAQs Guide

Power transformers are one of the most important equipment in the electrical power system. If you have any questions regarding power transformers, you'll find all of the answers you're looking for here.

Solar Transformer, Get The Best Price

Solar energy is the most abundant energy source on earth, and contemporary solar energy can be used to produce other renewable energy sources. We can convert solar energy into electricity. At present, there are two main conversion forms in the world, one is solar photovoltaic power stations, and the other is solar thermal power stations. Whether it is photovoltaic power generation or solar thermal power generation, solar transformers are used.

Pad Mounted Transformer for BESS System 4.0 MVA in Riverside County, California

Today, Daelim Transformer is proud to introduce a pad-mounted transformer for a 4.0 MVA Battery Energy Storage System (BESS) project located in Riverside County, California. The transformer is meticulously crafted to comply with the specifications outlined in the California Electrical Code Article 450.

Solar Photovoltaic System Solution

DB Transformer serves the world's renewable energy field. Here are solutions for some solar projects provided by Daelim for the United States, Canada, and other countries.

MV Skid Compact, Premier Choice for Utility-Scale Solar and Energy Storage

MV Skid Compact represents the pinnacle of cost-effective solutions for Utility Scale Solar and Energy Storage projects. It seamlessly integrates MV transformers, inverters, and medium voltage switches into a single unit, facilitating swift and hassle-free deployment. By consolidating these essential components, MV Skid Compact drastically reduces civil engineering requirements and on-site installation and commissioning times.