10.5 MVA Substation Transformer

- Primary Voltage Ratings: 13.8 kV

- Secondary Voltage Ratings: 2.4 kV

- H.V. TAP RANGE: 13.8kV±2×2.5%/

- TYPE: Conservator Type

- Power Rating: 7.5MVA, 9.375MVA, 10.5 MVA

- Cooling Method: ONAF

In 2021, Daelim Transformer designed and produced the 10.5 MVA substation transformer for a customer in Ecuador. This transformer operates with a primary voltage of 13.8 kV and a secondary voltage of 2.4 kV, functioning as a step-down transformer. It complies with IEEE standards and utilizes a two-stage air cooling system. In natural cooling mode, it delivers a capacity of 7.5MVA at rated voltage. Activating the primary cooling system increases capacity to 9.375MVA, and with both primary and secondary air cooling systems active, it achieves the full 10.5MVA capacity.

Quote Now

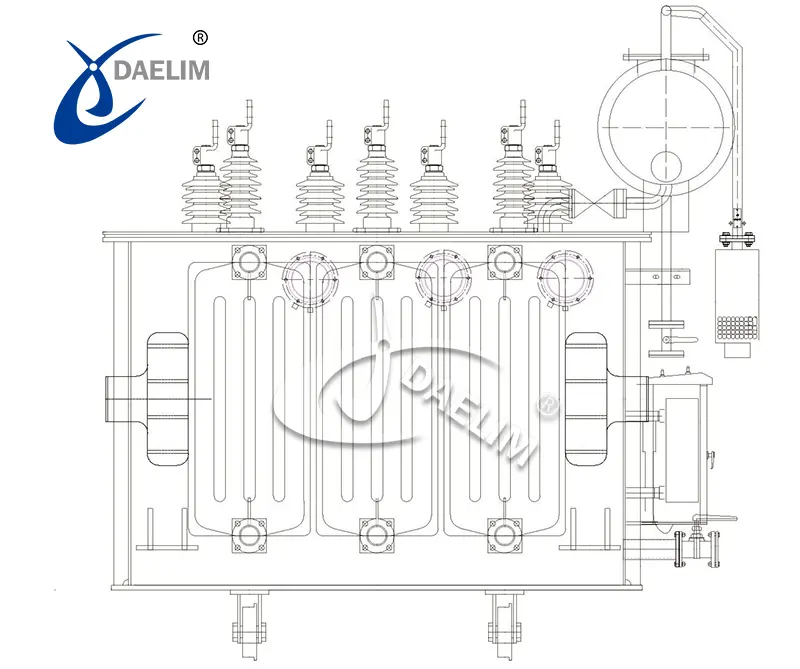

10.5 MVA Transformer Outline Drawing

Within a week of receiving the customer's order, we provided them with the transformer design outline drawing for confirmation. Over the next two weeks, we promptly finalized all the transformer production drawings.

Transformer Production

The transformer undergoes the entire production process at Daelim Transformer's workshop, including winding, body drying, and coil assembly. Customers can monitor the production status and progress through our management system. It took just 12 weeks to complete the production.

Transformer Testing

Stringent factory testing ensures high quality. Amid the pandemic, we offer customers video witness testing, allowing them to observe the entire testing process and results in real-time, facilitating immediate communication and issue resolution.

Transformer Packaging & Shipping

Due to its large size and weight, the 10.5 MVA transformer requires separate shipment of its main body and accessories. Therefore, the oil pillow, fan, and radiator are disassembled and packed in individual wooden crates, while the transformer body is shipped without additional covering.

Additionally, a collision recorder is installed on the transformer to mitigate excessive vibration and impact during transportation.

Transformer installed on site

The picture below shows the 10.5MVA transformer installed and operational, sent to us by our customer in Ecuador.

Related Products

Related Article