The complete guide to Transformer Oil

Transformer oil is a critical component in electrical transformers, serving as both an insulating medium and a coolant. This article explores the types, functions, and distinctions of transformer oils used in various applications, including a comparison between mineral oil and vegetable oil.

What is Transformer Oil?

Transformer oil, also known as insulating oil, is a transparent light yellow liquid essential for insulating and cooling transformers. It consists primarily of alkanes, naphthenic saturated hydrocarbons, and aromatic unsaturated hydrocarbons, with a relative density around 0.895 and a freezing point below -45°C.

Main Functions of Transformer Oil

-

Insulation: Transformer oil offers superior dielectric strength compared to air, ensuring effective insulation and moisture resistance for internal transformer components.

-

Heat Dissipation: With a high specific heat capacity, transformer oil absorbs and dissipates heat generated during operation, maintaining optimal operating temperatures through convection.

-

Arc Extinguishing: It plays a crucial role in extinguishing arcs generated during switching operations within transformers, thanks to its excellent thermal conductivity and ability to handle high temperatures and gas pressure.

Performance Requirements for Transformer Oil

-

Density: Should be minimal to facilitate the precipitation of moisture and impurities.

-

Viscosity: Moderate viscosity ensures efficient heat dissipation without compromising flashpoint.

-

Flash Point: Ideally above 136°C to ensure safe operation under varying conditions.

-

Freezing Point: Lower freezing points are preferred to maintain fluidity in colder environments.

-

Impurity Content: Low levels of impurities (e.g., acid, alkali, sulfur, ash) minimize corrosive effects on transformer materials.

-

Stability and Aging: Optimal balance of oxidation resistance and stability to maintain long-term performance.

Reading more about Transformer Uses and Requirements

Types of Transformer Oil

-

Mineral Oil: Commonly used in traditional transformers, mineral oil variants (#25 and #45) differ based on refining processes and are suitable for different climatic conditions. However, they are limited by high pour points, restricting use in very cold environments.

-

Vegetable Oil (Natural Ester): Derived from renewable sources, natural ester oils offer superior environmental benefits with biodegradability exceeding 97% in 28 days. They provide higher ignition points, fire safety, and extended lifespan compared to mineral oils, making them suitable for environmentally sensitive areas.

-

Silicone oil: Silicone oil has a high ignition point, at least 300 degrees Celsius. It can be used in transformers that require a higher level of fire resistance, such as those used indoors. However, it has the disadvantage of not integrating well with other liquids, and its price is about six times that of mineral oil, which increases the cost of the transformer.

Difference Between Mineral Oil and Vegetable Oil

-

Environmental Impact: Mineral oil is derived from petroleum, a non-renewable resource, and its use raises environmental concerns due to slower biodegradation. In contrast, vegetable oil (natural ester) is made from renewable sources, offering excellent biodegradability and minimal environmental impact.

-

Safety and Fire Resistance: Vegetable oil has a higher ignition point (above 300°C), making it less flammable compared to mineral oil, which enhances fire safety in transformer applications.

-

Longevity and Maintenance: Vegetable oil transformers typically have a longer service life (5-8 times that of mineral oil systems) due to better resistance to aging and degradation, requiring less frequent maintenance.

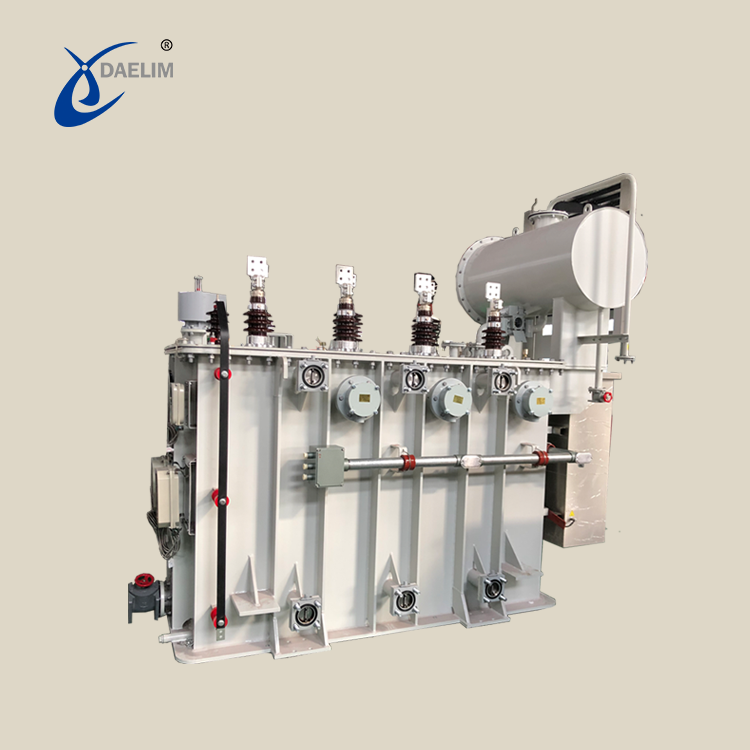

Daelim Transformer

At Daelim Transformer, we prioritize quality and performance in transformer oils. Our transformers can be customized to use mineral oil, vegetable oil (natural ester), or FR3 oil, meeting diverse operational requirements while ensuring reliability and efficiency.

Conclusion

Choosing the right transformer oil involves weighing performance requirements, environmental considerations, and operational conditions. Each type offers unique benefits and limitations, making it crucial to select based on specific application needs and regulatory compliance.

For more information on transformer oils and customized solutions, consult with Daelim Transformer—a trusted partner in delivering advanced transformer technology worldwide.

Related Products

Related Article

Breakthrough Technology Unleashes Transformer Power: Extend Life by 1.5 Times with New Insulating Oil!

The lifespan of transformers using anti-aging ternary hybrid insulating oil exceeds that of traditional mineral oil transformers by more than 1.5 times, significantly extending the transformer's service life. Moreover, in comparison to mineral oil, the biodegradation rate of ternary mixed insulating oil has increased by 25%, making it a more environmentally friendly choice. The anti-aging ternary mixed-insulating oil technology has achieved international leadership status.

How to analysis of gases and check oil level in transformer ?

The gas produced by transformer oil and fiber insulation in operation is mostly dissolved in the oil, but the rate of gas production is quite slow. When there is an initial fault inside the transformer or a new fault condition is formed, the gas production rate and gas production volume are very obvious. Therefore, a proper analysis of the gas produced by the transformer can detect the transformer fault.

Transformers Solution For Oil and Gas Plant

Transformers are crucial for oil and gas plants to maintain a stable and dependable power supply, which is necessary for safe and efficient operations. However, these transformers often face challenges due to harsh operating conditions and high electricity demand, which can result in performance issues and shorter lifespans. At Daelim Transformer Solutions, they offer advanced and innovative transformer solutions that address these challenges.

Transformer Oil Uses and Requirements

Transformer oil is essential for insulation, heat dissipation, arc extinguishing, and the protection of core and coil components.

How to Purify Transformer Oil ?

Oil purification is essential to ensure the quality of both new and in-service oil. It removes water, enhancing the insulation strength of insulating oil and the anti-emulsification properties of turbine oil, thereby reducing the deterioration rate of oil quality. Additionally, oil purification eliminates mechanical impurities and sludge sediments formed after oil deterioration. This helps avoid potential heat dissipation issues caused by oil system blockages and prevents mechanical impurities from damaging the equipment.

How to chose Pad Mounted Transformer for Blockchain Projects

Choosing a blockchain transformer involves assessing input/output voltages (e.g., 208V, 240V/415V, 277V/480V) and calculating required kVA. Daelim Transformer offers customized solutions meeting CSA/IEEE standards, supporting North American mining projects with diverse materials, accessories, and expert support for performance and reliability.