Construction and Working of Single Phase Transformer

Electrical transformers are the only electrical device in our entire electricity distribution system that controls and regulates the supply of electrical voltage and current. Among different types of electric Transformers you see, the single phase electrical Transformers are the most common and easily observable type of electric Transformers.

Electrical Transformer you see installed on poles and all around the residential areas are most probably the single phase electrical Transformers. So a transformer that is so widely used all around you, it is important for you to understand the construction and working of these single phase Transformers.

So we have written this article for you to know all the basic parts of a single phase transformer. We will also explain to you about the construction of different parts and how all these parts work to deliver you electricity.

Contact Daelim TransformerWhat is a Single Phase Transformer?

Single phase transformer operates on a single voltage cycle and has only one live wire and one neutral wire. This is unlike three phase Transformers where multiple voltage cycles happen simultaneously and there are three live and one neutral wire.

Transformer output depends on the application for which it is installed. For example in America all standard home appliances operate on 110 volts and this is what most of their single phase domestically installed Transformers delivered as the output.

Different Parts of a Single Phase Transformer

There are 5 main and key parts of a single phase transformer that work together to deliver you single phase alternating current.

Transformer winding

The single phase transformer you see has two windings. Its one winding is called primary and the other winding is called secondary. If you observe closely, you will see that the all single phase transformers receive input at their primary winding. All of these transformers will deliver you output for your homes through their secondary winding.

How much your transformer increases or decreases the electrical voltage for your application depends on your transformer turn ratio.

Learn more about Transformer Winding

Transformer Core

Transformer core is the centre part of any single phase transformer and it is part on which the winding is done. Your single phase transformer core will have its primary and secondary winding at its opposute ends. The core of a single phase transformer is responsible for transferring the electromagnetic wax from primary winding to the secondary warning of the transformer. Core is a simple looking part which can have different shapes and sizes depending on the type and size of the transformer.

Insulation and Isolation

In a single phase transformer the Assembly of the transformer winding and the Transformer cool has to be a non contact assembly. This means that the winding of a single phase transformer does not directly touch the Transformer Core. To develop a noncontact assembly, the contact point between the winding and core of the single phase transformer is insulated using a quality insulating material like epoxy resin or paper press board.

You may enjoy: Why Choose Silicon Steel Sheets for Transformer Cores?

Cooling Mechanism

As most single phase transformers are not big and they only work to regulate electricity that fall within the range of domestic for small industrial appliances. So their size and power ratings are not really that big but they still produce a lot of waste heat. To remove the waste heat, a cooling mechanism is required for every single phase transformer.

Reading on: What is Transformer Cooling and How is it done?

Other Important Parts

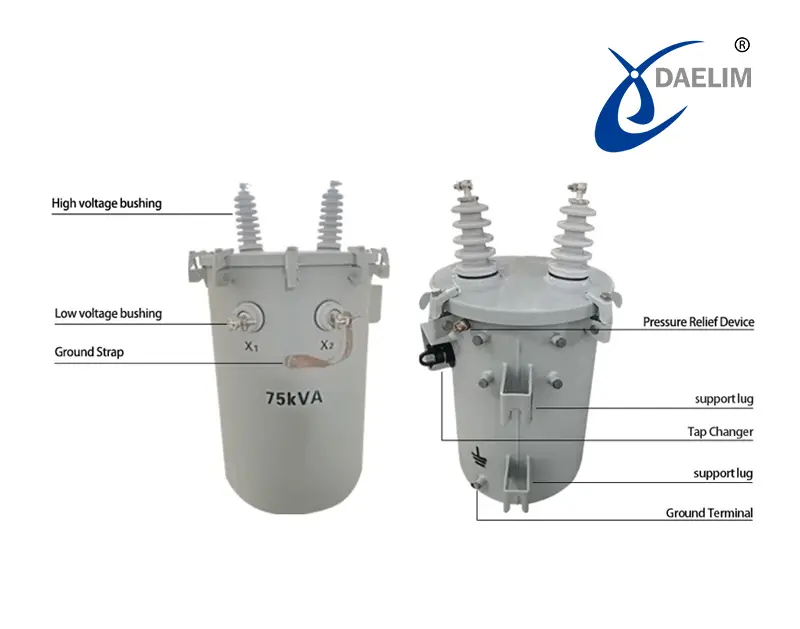

Like any other Transformer a single phase transformer also has all the other standard parts of a transformer. These standard parts include bushing, conservative tank, breather, tab charger, and all others safety tools and sensors.

Construction of a Single Phase Transformer

If you want to truly understand a single phase transformer and want to learn how it works, then understanding its complete structure and how it is constructed is very important.

Here we will try to explain to you about the design of different parts of a single phase transformer, how these parts are assembled together to develop the basic structure and then how all parts are constructed together to give a one single phase transformer.

You may enjoy: Construction of Three Phase Transformers

Core of Single Phase Transformer

Like any transformer you can see installed on the pole, your single phase transformer core, is its most important part. It has a rectangular design with two vertical legs called Limbs and two horizontal bars called Yokes. The limbs and yokes are connected to each other to develop a rectangular frame called the transformer core.

Rectangular frame of the core is really given one of the two basic shapes for single phase Transformers. The construction of the core of your single phase transformer can be done in two ways. You can either have a core type design or a shell type design for your transformer core.

The construction of the quality core is done using high quality laminated silicon steel sheets. A very thin sheet of silicon steel is cut using a precision metal press in either E-I, U-I, or Toroidal Shapes. Number of sheets are then stacked up and a precision machine is used to press and assemble them in a core.

Transformer Winding

You can select either copper or aluminum for your transformer winding. Both of these are the two most commonly used materials for any transformer winding. It depends on the application of the single phase transformer. Transformers developed for general purpose use like those you see installed in residential areas have aluminum wire used in their winding.

The transformer developed for sensitive machinery of any industry has copper wire used in their winding. This is because copper is much better conductor but is expensive and aluminum is lighter, and cheaper but a little less conductor of electricity than copper.

During the construction of a transformer winding high quality and most advanced decision winding machines are used. These machines are automatically and not controlled by a computer system where an operator can provide input about the number of turns. the design and all other technical aspects of Transformer winding. These machines then develop the transformer winding with the exact number of turns.

As the power requirement from a single phase transformer is not huge, the winding is usually constructed in either layer configuration or in disc configuration. Layer configuration Transformer winding is constructed by making multiple layers of copper or aluminium wire with insulation placed within each layer.

In disc configuration, Several discs are constructed using the conductor material wire and then disks are connected with insulation material placed between two discs. Which country creation is usually constructed for high voltage single phase transformers.

Insulation and Isolation

Transformer insulation and isolation is required to develop non contact assembly of winding and core, to avoid short circuit in the winding and core assembly, and to protect winding and core from external environmental factors like moisture, dust and debris.

The insulation and isolation of a transformer is down during the construction depending on the size and type of single phase transformer. If you have to develop a dry type single phase transformer, then the core and winding assembly will be covered in an epoxy resin.

Resin when in its liquid form is put in a tank and core and winding assembly is dipped in the tank. This fills all the gaps and contact regions between the transformer core and winding. The core and winding assembly is then bought out and heated for curing of resin. When cured, resin solidifies to insulate and as well as isolate the core and winding assembly.

If you have to develop a whole type single face transformer, then the contact region of core and warning assembly will be insulated using an insulating press paper board or a special type of insulating tape or cloth. The same insulating material will also be used to insulate the outermost layer of the winding.

Then the entire assembly of the core and transformer winding will be placed inside a tank and field with Transformer oil to complete. It will completely insulate and isolate the core and winding assembly from the outer atmosphere.

Transformer Tank

The Transformer tank is an integrated part of a single phase transformer whether it is a dry type transformer or an oil type transformer. The winding and core assembly of the transformer is placed inside the Transformer tank to protect it from external environmental factors like thunderstorms and from extreme and direct sunlight.

The Transformer tank is an integrated part of a single phase transformer whether it is a dry type transformer or an oil type transformer. The winding and core assembly of the transformer is placed inside the Transformer tank to protect it from external environmental factors like thunderstorms and from extreme and direct sunlight.

The Transformer tank is usually constructed using a high quality stainless steel sheet whose thickness depends on the size and Power capacity of the transformer. The stainless steel sheet when shaped according to the transformer tank design is usually given surface treatment processes to increase its corrosion resistance.

The post process of small single phase transformer tanks is usually a good quality spray paint with multiple layers of paints being done on the Transformer tank whereas in large single phase Transformers this is usually done through different deposition methods like electroplating.

Cooling Mechanism

The electrical Transformers you see installed on poles in your residential areas are dry type single phase Transformers and they usually do not need any dedicated cooling mechanism and a natural air cooling system is enough to remove their waste heat.

As Core and winding assembly of these transformers are covered in a cured reason which is placed securely in the transformer tank, the tank is designed in a way that it enables the air flow over the resin covered winding. The natural flow of air removes the waste from winding using the process called natural convection. This is only suitable for small and domestically using single phase transformers.

The Transformers that you see installed in big residential areas or in small industries are usually oil type single phase transformers. They also most of the time do not need any dedicated transformer cooling mechanism.

To facilitate the heat transfer from Oil to tank and from tank to the environment, the tank is usually designed with several tubes that act as fins going to release surface area exposed to the environment. More area means more heat can be transferred to the environment using the national Convection process

In both dry type and all type transformers, if the natural air system is not enough to remove the waste and electric cooling fan can be installed to remove the waste heat. The electric cooling fan will force air to pass over the either reason covered winding or over the fins of the oil field Transformer tank. This Force air movement over the heated region will remove much more heat using the principle of forced Convection heat transfer.

Working of a Single Phase Transformer

If you take any single phase transformer, it will work on the principle of Faraday law. According to this law when an alternating current is applied on the primary winding of a single phase transformer, it creates a time varying magnetic field in the core of that single phase transformer that in return produces secondary voltage.

How the working of a single phase transformer is a little different from other or a three phase transformer is that there is one single set of primary and secondary transformer winding in a single phase transformer rather than three different sets of primary and secondary windings present in a three phase transformer.

ConclusionSingle phase transformers are the most widely used type of electrical Transformers as most of our domestic and household electrical employees are all operated on single phase alternating current. These electrical transformers are constructed using high quality materials and most of their parts are manufactured using automated and precision machines. Working principle of these single phase Transformers is exactly the same as of any other electrical transformer with the only difference lies in the output which is a single phase electricity.

Follow Us

Your Single Phase Transformers should have reliable construction and efficient working to deliver you safe and constant supply of electricity. We at Daelim Transformer offer single phase transformers that are constructed following the highest international standards of CSA, ANSI, DOE, IEEE, IEC and more. All our electrical transformers offer efficiency of 95% or above as per IEEE standards on efficient electrical devices.

IF you have any questions about transformers, Contact US and we will talk you through the process.

Related Products

Related Article

Can a Damaged Transformer Coil Be Repaired, Refurbished, or Replaced?

A damaged transformer coil can often be repaired, refurbished, or replaced, depending on the extent of the damage. Minor issues like insulation wear or loose connections are repairable, while severe damage may require refurbishment or replacement. Consulting experts like Daelim ensures reliable solutions for maintaining power systems.

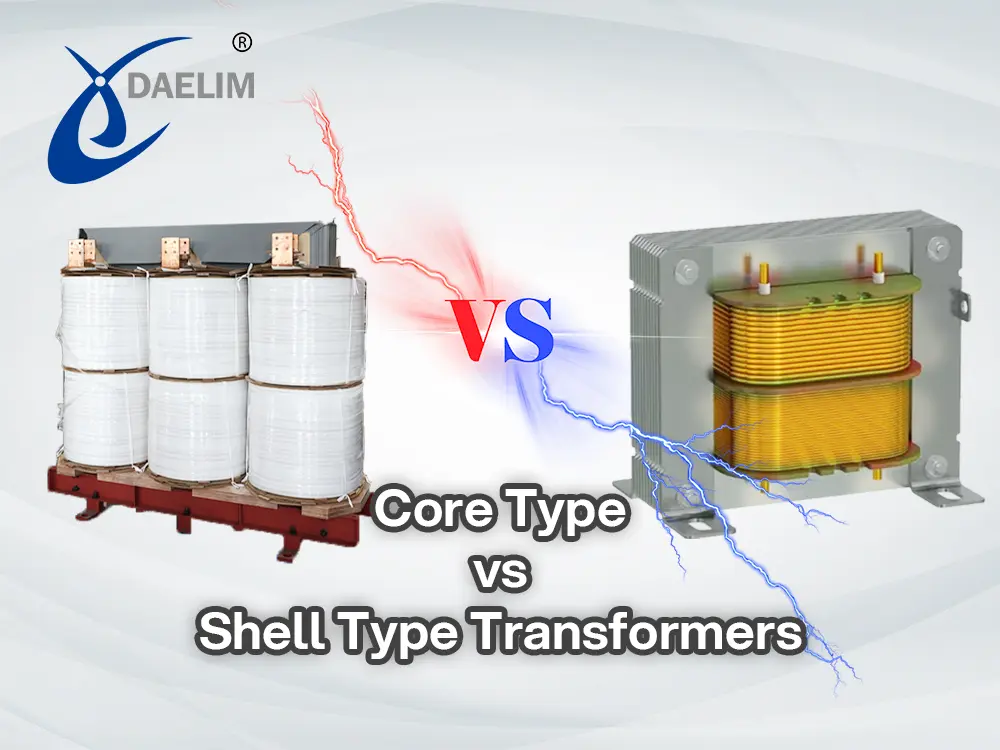

Core Type vs Shell Type Transformers

Core-type and shell-type transformers differ in structure, magnetic path, conductor material, and cooling efficiency. Core-type transformers offer better insulation, easier maintenance, and cost-effectiveness for high-power applications. Shell-type transformers, with a shorter magnetic path and compact design, provide higher efficiency and superior heat management. While core-type transformers excel in industrial use, shell-type transformers are ideal for space-saving and energy-efficient solutions. Choosing the right transformer depends on application needs, cost considerations, and performance efficiency.

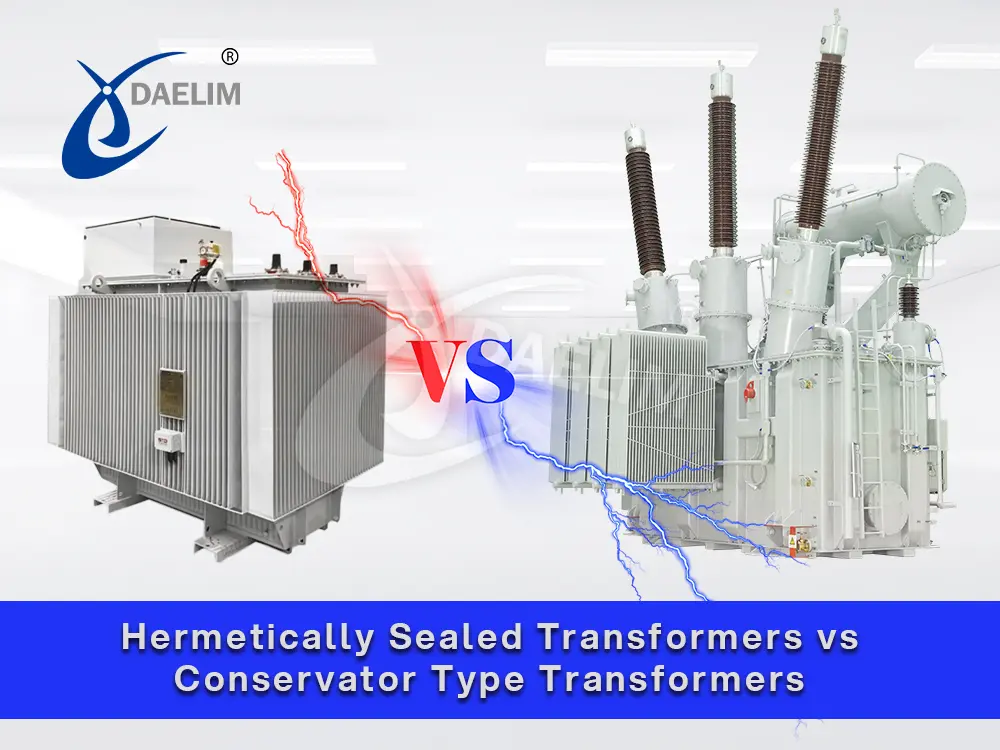

Hermetically Sealed Transformers vs Conservator Type Transformers

Hermetically sealed and conservator-type transformers differ in design, maintenance, and performance. Hermetically sealed transformers are fully enclosed, preventing air exposure and requiring minimal maintenance, making them ideal for harsh environments. Conservator-type transformers use an expansion tank for oil regulation, improving cooling and extending operational life. Each type has distinct advantages depending on application needs, space, and budget. Choosing the right transformer ensures efficiency, reliability, and long-term performance for power systems.

Choosing the Right Transformer Enclosure for Your Project

Selecting the right transformer enclosure ensures safety, durability, and optimal performance. This guide explores different NEMA-rated enclosures, their materials, and protective features against environmental hazards like dust, moisture, and corrosion. Whether for indoor or outdoor applications, choosing the proper enclosure safeguards transformers, extends their lifespan, and reduces maintenance costs. Understand key factors like protection levels, material selection, and environmental conditions to make an informed decision. Contact Daelim Transformer for expert guidance in finding the best enclosure for your needs.

What is electrostatic interference in Transformers

Transformer electrostatic shielding minimizes electrical noise and interference by blocking capacitive coupling between windings. It enhances transformer performance, ensures signal clarity, and protects sensitive electronics. Common shielding materials include copper, aluminum, and conductive coatings, chosen based on performance and cost. Proper placement, grounding, and material selection are crucial for effective shielding. This technique is widely used in medical, aerospace, and defense applications to ensure stable electrical performance and prevent disruptions.

All You Need To Know About Traction transformer

Traction transformers are essential for powering electric trains, trams, and buses by stepping down high voltage to safe levels. Designed for harsh conditions, they offer energy efficiency, reliability, and compactness. Used in railways and industrial systems, they face challenges like thermal stress and space limits. Advanced materials and smart tech enhance their performance and durability.