Differences Between Dry Transformers and Oil Immersed Transformers

The main differences between dry type transformers and oil immersed transformers are as follows:

Applicable Locations

- Dry Transformers: Commonly used in environments requiring fire and explosion prevention, such as large buildings and high-rise structures.

- Oil Immersed Transformers: Typically used outdoors; some installations feature "accident oil pools" to manage oil spray or leakage in case of a malfunction, reducing fire risk.

Capacities and Voltages

- Dry Transformers: Generally used for power distribution with capacities below 1600 kVA and voltage levels below 15 kV, although some can handle up to 35 kV.

- Oil Immersed Transformers: Capable of handling a wide range of capacities from small to large, with voltage levels reaching up to 1000 kV.

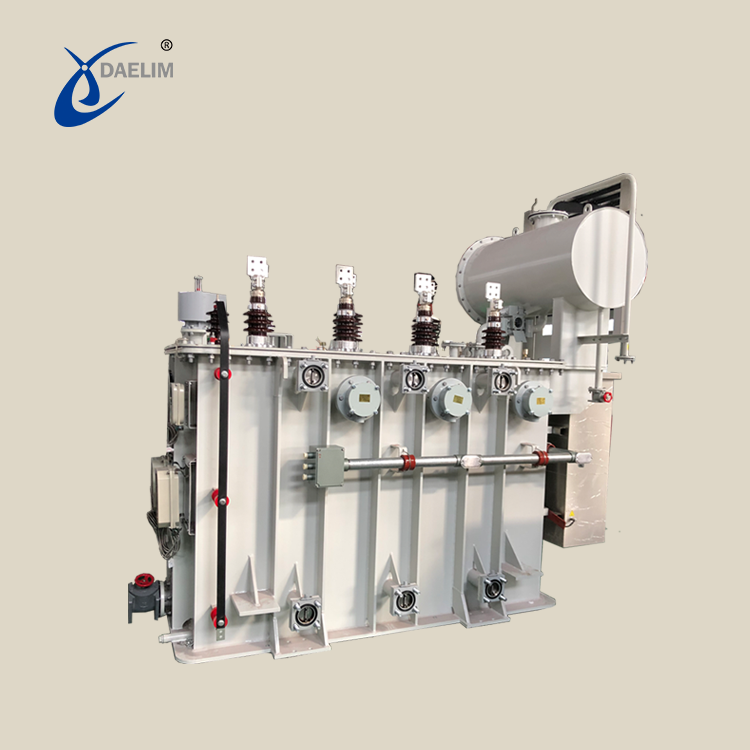

Appearance and Shape

- Dry Type Transformers: The core and coil are visible, as they do not have an outer tank filled with oil.

- Oil Immersed Transformers: Encased within a sealed tank, only the transformer shell is visible.

Lead Wire Form

- Dry Type Transformers: Utilize silicone rubber bushings.

- Oil Immersed Transformers: Use porcelain bushings.

Insulation and Heat Dissipation

- Dry Transformers: Insulated with resin and cooled by natural air. Larger units use fans for additional cooling.

- Oil Immersed Transformers: Insulated with oil. The oil circulates to dissipate heat generated by the coil to the transformer's heat sinks or radiators.

Load Capacity

- Dry Type Transformers: Generally operated at rated capacity.

- Oil Immersed Transformers: Have better overload capacity, allowing them to handle higher loads more effectively.

Costs

- Dry Type Transformers: More expensive to purchase than oil-immersed transformers of the same capacity.

Models of Dry ype Transformers

- Common models include SC (epoxy resin casting), SCR (non-epoxy resin solid insulation), and SG (open type).

Related Products

Related Article

2000 kVA Oil immersed Substation Transformer For Portugal Market

Today, we introduce Daelim Transformer's export of a 2000 kVA oil-immersed substation transformer to Portugal. This transformer represents our commitment to delivering high-quality electrical solutions to global markets. With meticulous design and engineering, this transformer is tailored to meet the specific needs of our customers in Portugal, ensuring reliable performance and efficiency. Daelim Transformer continues to uphold its reputation for excellence, providing innovative solutions that power progress and reliability worldwide.

What is the structure of the oil immersed transformer?

This article mainly introduces the structure of oil-immersed transformers. Important accessories and functions of oil-immersed transformers.Introduction of Daelim transformer factory.

Ultimate Guide To Oil Filled Transformer

Oil filled transformers are a type of electrical transformer that uses oil as both a cooling and insulating medium. They are commonly used in high-voltage power transmission and distribution systems, as well as in industrial and commercial applications.

Relationship Between Dissolved Gas in Oil and Transformer Faults

Transformer oil serves as insulation and cooling. Faults cause chemical decomposition, producing gases. Analyzing dissolved gases in the oil helps determine fault presence, nature, and severity. Key gases include CH4, C2H6, C2H4, and C2H2, indicating different fault types and temperatures.

Precautions for Analyzing Transformer Faults by Gas Chromatography

Gas chromatography is used to analyze transformer oil for fault diagnosis by identifying dissolved gases. This method, combined with electrical tests, ensures accurate fault detection, preventing transformer damage and ensuring safe, reliable operation.

What is the difference between rectifier transformer and power transformer?

Rectifier transformers convert AC to DC for industrial applications like electrolysis and smelting. Power transformers supply AC to power systems. They differ significantly in function, usage, output voltage, and design and manufacturing aspects.