The Ultimate Guide to Oil Cooled Transformers

Oil-cooled transformers are primarily used in industrial applications where space and weight are critical. Consumers and users can generally apply oil cooler transformers in many different kinds of utilization. That includes power and electricity generation, industrial manufacturing processes, heating and ventilation, cooling, and lighting management systems.

Oil-cooled transformers are primarily used in industrial applications where space and weight are critical. Consumers and users can generally apply oil cooler transformers in many different kinds of utilization. That includes power and electricity generation, industrial manufacturing processes, heating and ventilation, cooling, and lighting management systems.

With this guide, we will have an in-depth discussion with oil cooled distribution transformers. These include their purpose, benefits, design, and requirements.

What Is An Oil Cooled Distribution Transformer?

An oil cooled distribution transformer is a type of transformer that uses oil cooling to reduce the transformer's operating temperature.

In a conventional oil-cooled distribution transformer generator, the core is often housed in a tank made of welded steel that is filled with liquid insulation.

This tank contains the normal cooling medium for the transformer.

Learn more about Distribution Transformer

The Fundamentals of Operation Behind an Oil-Cooled Distribution Transformer

These transformers are generally used in distribution channels or for transmission and distribution.

As a result, they are commonly submerged in oil, which conditions the internal components.

Also, these transformers are widely utilized in the electrical industry.

During operation, the coils and cores of these devices are usually covered in oil to remain cool and constructed.

With regard to circulation, oil travels through the internal pipelines of the coil as well as the tubes that cover the core component and the coil itself. Moreover, oil travels via the tubes that cover the core component.

The oil is often cooled by the exterior of the oil tank when the rated value is lower.

However, when the rated value is larger, the oil is then cooled by a radiator that makes use of air-cooling technology.

Oil cooled distribution transformers or air-natural cooling transformers are generally deployed, but other alternatives are available, according mostly to required capacity, for values from 6 and 36 kilovolts.

This approach is frequently applied in order to extract heat from the transformer's core and windings by channeling it into the oil storage reservoir.

The remaining two methods of heat dissipation into the atmosphere are radiation and convection.

Reading more: How much do you know about oil-immersed distribution transformers?

Where Are Oil-Cooled Transformers Used?

Oil-cooled transformers have a wide variety of industrial uses, including power plants, substations, solar and wind power plants, and transportation equipment.

They also cater to metal processing machinery, elevators, and computer numerical control machines.

When the windings and magnetic circuits of a transformer are frequently cooled in oil, the device is effectively insulated and cooled, allowing for optimal equipment performance.

This procedure takes place in a wide range of applications across distribution networks, small-scale industries, and renewable energy generation.

You may enjoy: 3 Phase Pad Mounted Transformer

What Are The Cooling Methods For Oil Cooled Transformers?

Although there are alternatives, oil is primarily responsible for conditioning oil-cooled transformers.

1. Utilizing Natural Air

Distribution transformers that are cooled by oil can keep their temperature stable with the help of the surrounding air as well as the oil.

The base and field winding of most transistors of medium and large capacities are typically cooled and insulated by dielectric oil, which is also pumped through the transformer.

How Do Air Natural Cooling Transformer Work?

The mechanism of airflow, which frequently engages fresh air, removes the heat from the generator.

Cooler air may convect in to replace the hot air if the transformer's heat climbs above that of the ambient atmosphere.

Oil rises due to circulation as it heats and eventually hits the radiators. After the engine oil has heated, it serves to fill up the opening.

It's possible that the transformer oil will continue to flow freely, and that any excess heat will be dissipated into the atmosphere.

This approach is normally applicable if the transformer's MVA rating is much less than 30 MVA.

2. Natural Oil Air Forced

As a result of the heat that is produced by the winds and the core of the transformer, the oil that is contained within the tank is regularly transferred from the tank to the condenser.

Ambient airflow is mainly accountable for conditioning oil in transformers.

3. Air Forced Oil Forced

This has a good association with a heating element that is located at the top of the transformer tank and its primary function is to circulate hot air through the oil.

This cooled oil circulates to the transformer tank.

4. Water Forced with Oil Forced

Water is always poured into the top of the transformer tank, where it is usually tempered by the oil beneath, and then hydraulic fluid serves to discharge the hot oil.

How Does Oil Filled Water Cooling Transformer Operate?

A steady flow of water is essential for this technique as it serves to cool the heat exchangers.

At the same time, oil temperature increases over time as a result of heat produced by a pump.

Once the hot water has been then withdrawn from the system in general, it is regularly cooled in a specialized cooler.

These cooling systems are useful for large oil filled water cooling transformers with a capacity of 101 kV or higher.

Related Article

Ultimate Guide To Oil-Filled Transformer

Why Do Transformers Generally Cool With Oil?

Insulating, conducting heat, and dispersing energy are just some of the many functions that transformer oil accomplishes. To put it another way, it performs the function of a cooling mechanism.

For the most part, it has dual functions.

- Excess heat escapes through the windings' cooling channels and, ultimately, the outside air.

- Performing the function of insulating

Oil cooled transformers benefit from mineral oil as a lubricant due to the substance's excellent dielectric durability and low lipids, moisture, and flammability concentration.

Yet, immersing the windings of some transformers in mineral oil may not be necessary.

Depending on the amount of electricity being usually applied, environmental circumstances, and architectural constraints, additional cooling techniques may be often included.

Instead, you might use water or air to chill it down.

Oil can be generally used for cooling, but it doesn't mean mineral oil is always the best option. It's not uncommon for people to go with a different choice.

Lastly, the transformer's fluid also functions as a heatsink due to its proximity.

Keep reading: Find the Best 250 kVA Transformer Price

Why Does Oil Cooled Transformer Manufacturer Use Oil Inside A Transformer?

Oil is also a crucial component for transformers. Because of this, manufacturers ensure that their transformers function properly only when loaded with the appropriate oil.

It's impressive that it can act both as a dielectric and a heat sink. High temperatures, water, high voltage, and other factors can all degrade transformer oil while it's in use.

Machines are vulnerable to damage from contaminated oil.

Insulation

The dielectric constant and dielectric conductivity of oil make it a significant insulator in a transformer.

Arc Quenching

Oil in the transformer will extinguish any arc caused by mild fault incipients like an inter-turn short circuit.

Cooling

Oil is often used as the primary coolant in transformers, and it circulates via the radiators to dissipate heat.

Thus, an integral part of a transformer's validation is its cooling system's effectiveness.

Damping

Magnetostriction is the term often used to describe the trembling of a transformer's core caused by an intermittent magnetic field. The noise level is drastically lowered by the oil.

Lubrication

Oil helps the only moving part inside the transformer, called the OLTC (On Load Tap Changer), function properly.

Try for free: Power Transformer Manufacturers Around the World

What Are The Advantages and Disadvantages Of Using Oil-Cooled Transformers?

Let's talk about the pros and cons of using this oil in a transformer.

Transformer Oil Benefits

Cooling oil for transformers is cheap, efficient, and has high insulating and thermal conductivity characteristics.

Cooling oil for transformers is cheap, efficient, and has high insulating and thermal conductivity characteristics.- It's effective in isolating high voltages from transformers and dissipating heat from high capacities.

- Oil-immersed transformers can have ratings of 100MVA or higher since oil and a radiator are frequently used as heat dissipation mechanisms. A dry-type transformer cannot achieve the rating.

- When compared to a transformer with a higher rating, it produces significantly less noise while in operation.

- Improved energy efficiency as a baseline.

- Has a lower operational loss.

- Increased potential for lifespan.

- The core coil assembly is recyclable.

Try for free: Pad Mounted Transformer

Transformer Oil Disadvantages

- Regular exposure of cooling oil to flame creates the possibility of explosions or fires.

- An oil-immersed transformer is prone to leakage and can age gracefully.

- When oil leaks at the operating site, it threatens both the integrity of the machinery and the quality of the surrounding environment.

- When submerged in oil, a transformer's sealing performance suffers, yet it ages well.

- It's a major problem when oil leaks at the operating site, endangering both the integrity of the machinery and the surrounding ecosystem.

- Comparatively larger and heavier than dry-type converters

- The added weight necessitates a more robust base and a dedicated oil pit.

- The price of oil cooled transformers is higher.

- Because of the increased potential for fire, a dedicated nitrogen or water-based fire suppression system is typically built. It draws more budget.

- A greater amount of upkeep is necessary compared to the dry variety

What Is The Oil Cooled Transformer Design Requirements?

One of the most important parts of any electrical system is the power transformer. Several transformer layouts are feasible due to the availability of efficient cooling and electrical insulation.

Oil-Cooled Transformer Design, Built and Construction

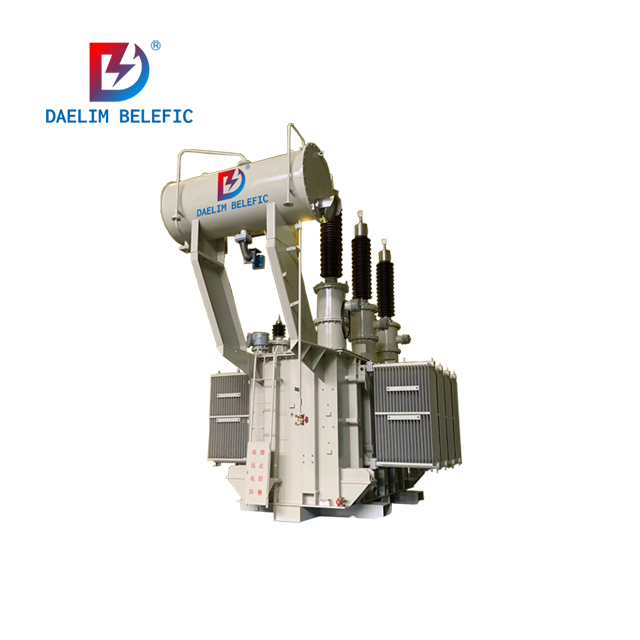

Oil cooled distribution transformers have magnetic cores, windings, and bushings.

Magnetic currents can be traced back to their source via the magnetic core. A conductor coil is constantly wrapped within the windings and shielded by pressboard walls and screens to prevent electromagnetic interference.

The increase in voltage causes an increase in the thickness of the insulation in the windings. Bushings are often used to link a transformer's windings to a power distribution center.

An oil-immersed transformer is identifiable in particular only by an oil reservoir.

Simplifying operations, it monitors oil levels in storage tanks and relays information about the space in that oil needs to expand when heated.

Necessary Oil To Use

These are some of the most standard oil that oil cooled transformers are using:

A. Mineral oil, is one of two main types of petroleum products:

Naptha Oil: Sewage, an oxidative byproduct, absorbs more easily in naphtha oil than in liquid paraffin.

Paraffin Oil: While paraffin oil oxidizes at a lesser speed than naphtha oil, the accompanying filth eventually settles to the bottom of the tank, limiting adequate conditioning of the transformer.

B. Synthetic Oil: These oils are often manufactured in a lab and include Silicon Oil.

Because of their high level of fire resistance, they are only used in high-risk settings.

Low heat conductivity and high moisture absorption. This oil is more expensive than mineral oil.

- Vegetable Oil: These oil is extracted from plants. Not only can it be regenerated, but it can also be 100% degraded, which is more environmentally friendly and ecological, and helps to extend the service life of the transformer.

Daelim can provide the above three oils. Daelim can provide vegetable oil with UL certification, and there are two brands of FR3 and RAPO for you to choose from.

Rating Of Oil-Cooled Transformer

For transformer values under 30 MVA, natural oil, and air technologies have always been generally implemented.

As you can see, the cooling capability of oil-natural and air-forced systems can usually be combined to a maximum of 61 MVA.

The continuous rating for distribution transformers must be either 100kVA, 250kVA, 400kVA, or 630kVA.

The rated power of an oil cooled transformer is always determined by multiplying the line side winding's rated voltage by its rated current.

Get it now: The Impact of Impedance on Transformer Design

Who Can Be Your Reliable Oil Cooled Transformer Manufacturer?

Generally, oil cooled transformers are very effective heat insulators.

Among the many advantages of oil cooled transformers are their low price, great efficiency, and excellent insulating and insulation properties.

DAELIM is a reputable oil-cooled transformer manufacturer, and their equipment always complies with or surpasses the specifications set forth by authorities like the CSA, and ANSI/IEEE. Daelim il cooled transformer type: Three Pad Mounted Transformer, Single Phase Pad Mounted Transformer, Skid Mounted Transformer, HV Power Transformer.

Elements like the cost and ease of use should inform your selection of a transformer.

So, end up coming to Daelim and have them guide you to choose quality products. Their understanding of the electricity transmission market will be essential in selecting a high-quality transformer within your range.

Related Products

Related Article

How to analysis of gases and check oil level in transformer ?

The gas produced by transformer oil and fiber insulation in operation is mostly dissolved in the oil, but the rate of gas production is quite slow. When there is an initial fault inside the transformer or a new fault condition is formed, the gas production rate and gas production volume are very obvious. Therefore, a proper analysis of the gas produced by the transformer can detect the transformer fault.

The Ultimate FAQs Guid To Oil Type Transformer

An oil-type transformer is a kind of transformer that uses oil as a cooling and insulating medium. The core and coils of an oil-type transformer are immersed in oil, which helps to cool the transformer and provides insulation.

Ultimate Guide To Oil Filled Transformer

Oil filled transformers are a type of electrical transformer that uses oil as both a cooling and insulating medium. They are commonly used in high-voltage power transmission and distribution systems, as well as in industrial and commercial applications.