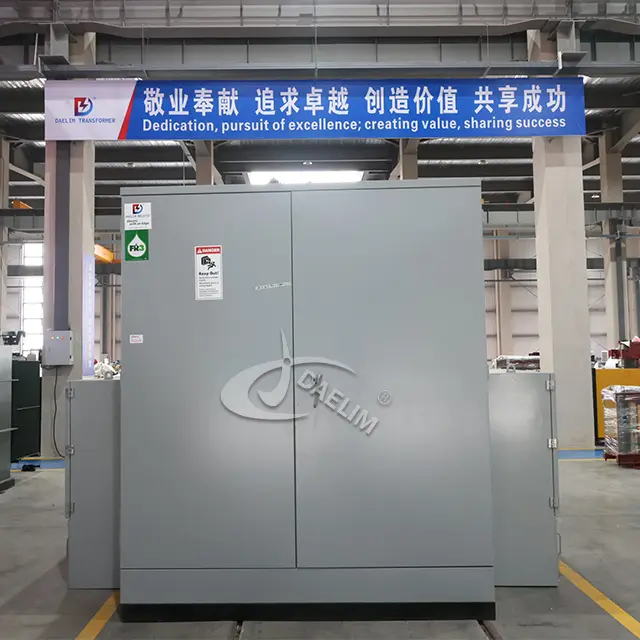

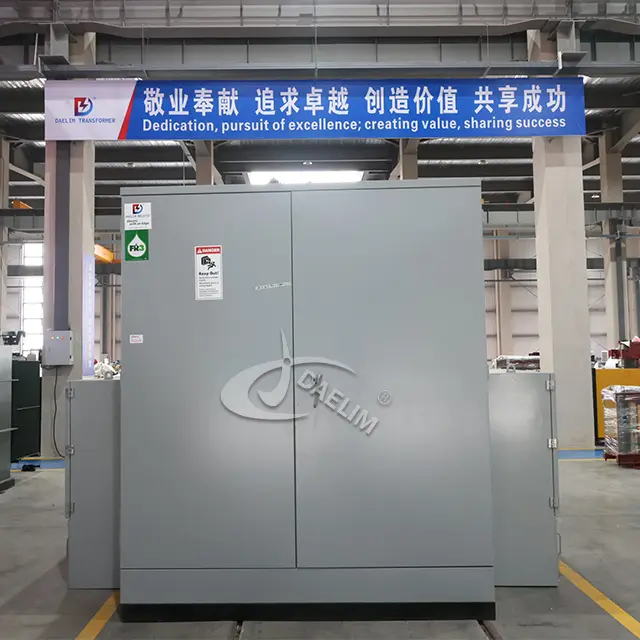

BESS Transformer-13.8kV-0.48-0.48V 5000kVA

- Primary Voltage Ratings: 13800V DELTA

- Secondary Voltage Ratings: 480/277-480/277V

- H.V. TAP RANGE: 13110-14490V

- CONNECTION TYPE: Dyn1yn1

- TYPE: Pad mounted

- BIL: 125/45/45kV

- Standards: IEEE STD C57.12.34

- Application: BESS

- Power Rating: 5000kVA

- Certificate: UL

- Cooling Method: KNAN

Daelim Transformer has just delivered 15 untis BESS transformers for a 75MW solar energy storage project in the United States. These transformers are custom-designed for the unique requirements of the BESS project, with a lifespan of 30 years, taking into account over-voltages, inverter applications, harmonics, saturation, and power factors.

Quote Now

Daelim Transformer possesses extensive project experience and professional technical expertise in the BESS market. We ensure that our transformers are perfectly matched and integrated with various energy storage systems and equipment, enabling the entire energy storage system to operate safely, stably, and efficiently. Contact us today to discuss your BESS Transformer needs.

Technical Features

These pad mounted transformers for the BESS project feature a dual low-voltage split design with a high voltage of 13800V Delta and a low voltage of 480/277V-480/277V, with a capacity of 5000kVA. This dual split design not only perfectly matches the photovoltaic panel circuits but also ensures that if a fault occurs on one low-voltage side, the other side can continue to operate normally.

Get PriceInsulation System

The insulating liquid used in this transformer is FR3 green vegetable oil, which not only offers excellent insulation performance but also features safety, environmental protection, high temperature resistance, effective heat dissipation, anti-oxidation properties, and low catalytic activity. This makes it an ideal choice for photovoltaic energy storage transformers.

Additionally, the insulation of the BESS transformer employs high-quality insulating paper and insulating boards to ensure optimal winding insulation.

Send Inquiry Now

HV Coil & LV Foil Wound Coil

The high voltage winding process is depicted in the image, ensuring the reliability of each transformer under high voltage conditions.

The completed low voltage foil wound coils, shown in the image, utilize efficient winding techniques that ensure stable performance.

Get OfferCore and Coil Assembly

In this video, Daelim Transformer workers are assembling the core and coils of the BESS transformers, ensuring precision and durability in every component.

HV & LV Compartment

The high voltage compartment is equipped with three plug-in bushings, six bay-o-net fuses, a two-position load-break switch, a tap changer, and a ground bar, ensuring safe operation on the high voltage side.

The BESS transformers feature uniquely designed low voltage compartments located on either side of the tank, equipped with four low voltage terminals (X1, X2, X3, and X0) and two ground bars. Each low voltage terminal is equipped with 12 holes for additional support.

Get Price NowValves and Gauges

- 1-inch drain valve with a 3/8-inch sampler.

- 1-inch fill plug for transformer oil replenishment.

- 1-inch upper fill valve with a Schrader valve to prevent moisture and air from entering the insulation oil, helping to lower top oil pressure, moisture, and temperature, protecting the transformer from explosion.

- Pressure relief valve that automatically releases pressure when gas pressure in the tank suddenly increases, and can automatically reset to its initial state.

- Vacuum pressure gauge with two alarms that alert when pressure is too low or too high.

- Oil temperature indicator with an alarm and a trip function, which alarms when the oil temperature exceeds 85°C, and automatically disconnects power if it exceeds 105°C, protecting the equipment and transformer from damage.

- Oil level gauge with two alarms that alert when the oil level is too high or too low.

Packaging and Shipping

The BESS transformers are packaged in wooden crates. To facilitate transportation, the low voltage compartments on either side of the transformer are disassembled and packaged separately. Users can assemble them upon receipt. The transformer body is placed on a wooden pallet, secured with bolts to prevent movement and impact during transport, surrounded by sturdy wooden boards for protection. The crate is reinforced with metal clamps on all sides and corners.

These 15 BESS transformers were shipped using 5 40-foot frame containers and 4 high cube containers.

BESS Transformer SolutionTesting

After production, each of the 15 BESS transformers was tested according to IEEE Std C57. 12.34-2021, ensuring that every unit complies with IEEE standard inspection and testing requirements before shipment.

Contact Now

Related Products

Related Article