What Transformers Are Using In power plant?

We all know that a power plant is a very important part of the power transmission and power substation systems. There are many electrical types of equipment in a power plant, and we can say that the most important one is the power transformer.

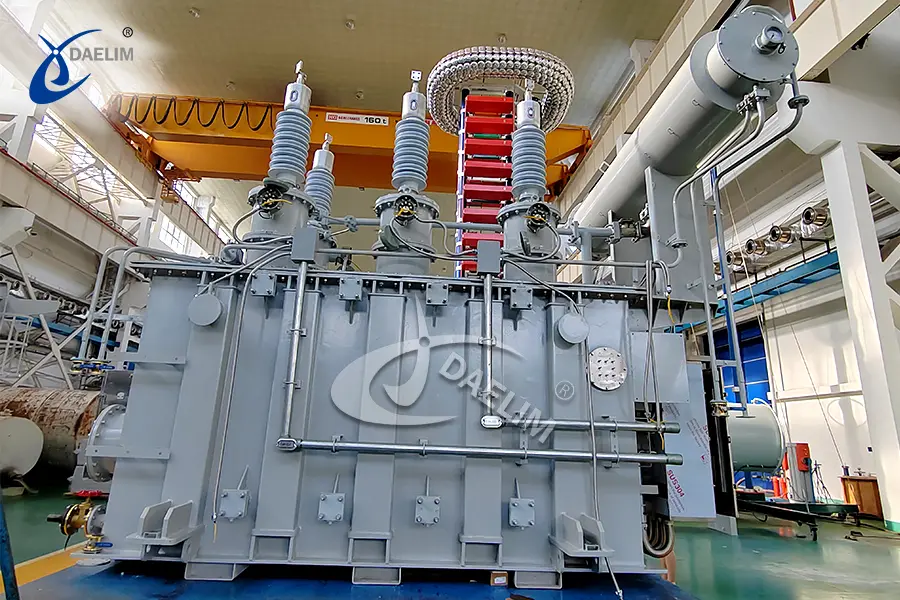

As a professional power transformer manufacturer, Daelim Belecif produces different types of transformers based on different international standards, and with rich experience in different international electrical projects.

So what transformers are used in a power plant? Check out today's article and find out.

How many types of substations are there?

Based on voltage class, there are super high voltage power substations, high voltage power substations, medium voltage power substations, and low voltage power substations. Voltage over 330kV is called super high voltage, between 10kV and 330kV is called high voltage, from 1kV to 10kV is called medium voltage, and less than 1kV is called low voltage.

According to the difference in power supply objects, it can be divided into village and town substations, industrial substations, and agricultural substations.

According to its position and function in the power system, it can be divided into hub substations, intermediate substations, regional (local) substations, enterprise substations, and end (user) substations.

Learn more: Power Transformer In Substation

Hub substation: The hub substation is located at the pivot point of the power system. The voltage level is generally 330kV and above. It is associated with multiple power sources, and there are many loops and large substation capacity. It plays the most important role in the stability and reliability of the power system operation.

Intermediate substation: The intermediate substation is located at the interface of the main ring line of the system or the main trunk line of the system. The voltage level is generally 330 ~ 220kV, and 2 ~ 3 power sources and several lines are converging. After the power outage of the whole station, it will cause the disconnection of the regional power grid.

Regional substation: The regional substation is the main substation in a region and a medium or small city. The voltage level is generally 220kV. After the power failure of the whole station, the power supply in the region or city will be disrupted.

Enterprise substation: The enterprise substation is a special substation for large and medium-sized enterprises, with a voltage level of 35 to 220kV and 1 to 2 incoming lines.

You may enjoy: 230 kV 220kV Power Transformer

Types and functions of power plant transformers

Main transformers for power plants

We know that the voltage emitted by the motor of the power plant is generally below 20kV. At this time, a transformer is required to increase the voltage to the system bus voltage to transmit power to the system to reduce the power in the transmission. Therefore, the main transformer used in the power plant is the power step-up transformer.

High voltage transformers for power plants

The output voltage of the generator is reduced to the bus voltage for high voltage in the power plant, and power is supplied to the high voltage motor and the transformer for low voltage in the power plant.

You may enjoy: High Voltage Transformer Guide

Low voltage transformers for power plants

The high-voltage busbar voltage used in the power plant is reduced to the low-voltage busbar voltage, and power is supplied to low-voltage single-phase and three-phase loads.

Power Plant High Voltage Backup Transformer

As a backup power supply for high-voltage busbars used in power plants.

Power Plant Low Voltage Backup Transformer

As a backup power supply for the low-voltage bus of the power plant.

Isolation transformer

It plays the role of system isolation and safety and is generally used to supply power to remote mortar pumping stations.

There are also some special transformers, such as dust removal transformers, excitation transformers, running light transformers, rectifier transformers, and so on.

Read my article on: 10.5MVA-13.8/2.4kV Substation Transformer

Selection principle of the main transformer for power plant

1. Determination of the number of phases

The power step-up transformer has a single-phase transformer bank and a three-phase transformer. The single-phase transformer bank is composed of three single-phase transformers. Compared with the single-phase transformer group of the same capacity, the three-phase transformer has the advantages of low price, small size, and low loss. Generally, in the power system below 330kV, the three-phase transformer is generally used. Only when limited by the transformer manufacturing and transportation conditions, Only consider single-phase transformer banks.

Generally, the power plant should decide whether to choose a single-phase transformer group or a three-phase transformer according to economic arguments.

2. Determination of the number of power plant transformer windings

According to the number of windings, power transformers can be divided into three-winding, double-winding, self-coupling, and split-winding. When the maximum unit capacity of the power plant is 125kw and below if two elevated voltages are used to supply power to users or connect to the power system, a three-winding transformer is generally used, and the third winding is connected to the generator. However, the power passing through each winding should reach more than 25% of the capacity of the transformer, otherwise, it is not as economical and reasonable as using two double-winding transformers.

When the power plant only raises one level of voltage, a double-winding ordinary transformer can be used. When the maximum capacity of the power plant is more than 200MW, the two-winding transformer unit is generally connected to the system. If the power plant has two boosted voltages, the three-winding transformer (or autotransformer) is often used as the tie transformer. . The low-voltage winding is used as a factory starting power supply or a factory standby power supply, and its main function is to realize the connection of high and medium voltage. Its low-voltage winding is connected in a triangle to cancel the third harmonic component. When the medium voltage is the neutral point and is not directly grounded to the grid, only ordinary three-winding transformers can be used. Transformers with expanded unit wiring, suitable for transformers with low-voltage split windings, can greatly limit the short-circuit current.

Compared with ordinary transformers of the same capacity and voltage level, the economic benefits of autotransformers are very significant. However, since the autotransformer has an electrical connection between the high-voltage grid and the medium-voltage grid, it has the possibility of transferring the overvoltage from the grid of one voltage level to the grid of another voltage level, so its high-voltage side must be high-voltage The pressure side must be the neutral point directly grounded. Therefore, transformers with voltage levels of 220kV and above can choose auto-transformation.

Keep reading: How To Choose The Suitable 110KV Power Transformer?

3. Selection of tap changer

In order to ensure the quality of power generation, the number of turns of the high-voltage winding of the transformer can be changed by switching the transformer split switch, thereby changing its transformation ratio and realizing voltage adjustment. The switching mode is divided into two types: the on-load (excitation) voltage regulation mode with load switching and the no-load (non-excitation) voltage regulation mode without load switching. The no-load adjustment range is generally only within 10% (ie ±2X2.5%), and the on-load voltage adjustment range can reach 30%, but its structure is complex and the price is high. Generally, the no-load voltage regulation mode is adopted when the normal voltage fluctuation can be met. For the main transformer of the power plant whose connection and output voltage vary greatly, and the secondary voltage of the transformer is required to be maintained at a certain level, the on-load voltage regulation method should be adopted. When the generator often runs under a low power factor, an on-load voltage regulating transformer should be selected.

Reading more: Guide to Tap Changer in Pad Mounted Transformer

4. Determination of winding connection method

The connection mode of the transformer windings must be consistent with the system voltage phase, otherwise, the parallel operation is not possible. The transformer windings in the power system are connected in two ways: star and delta. The symbol Y is used to indicate that the high-voltage winding is star-connected, the neutral point is used to indicate YN, and the medium and low voltage windings are represented by y and yn, and the triangle is used.

When connecting, use D to represent the high-pressure side; used to represent the low-pressure side. The transformer with an all-star connection group is used, that is, the high, middle, and low sides of the transformer are all connected in a star shape, which can eliminate the influence of the third harmonic. The zero-sequence group resistance of this wiring is large, which is conducive to limiting the short-circuit current and is also convenient for connecting the arc suppression coil at the neutral point. The disadvantage is that there is no channel for the third harmonic, which distorts the sine wave voltage waveform and interferes with the communication equipment, and also affects the accuracy and sensitivity of the relay protection setting.

Generally, for voltages of 110kV and above, the three-phase windings of the transformer are connected by "Yn"; for transformers from 35kV to 110kV, the "yn" connection is used, so that its neutral point is grounded through the arc suppression coil. Therefore, Yn, d11 wiring is generally used for ordinary double windings; YN, y, d11 or Yn, yn, d11 forms are generally selected for three-winding transformers.

Try for free: What You Need To Know About Substation Transformer

5. Selection of Transformer Impedance

The impedance value of each side of the power plant transformer must be comprehensively considered from the aspects of power system stability, power flow direction, reactive power distribution, relay protection, short-circuit current, voltage regulation methods in the system, and parallel operation. The impedance of the transformer determines the structure of the transformer. The relative position of the transformer winding on the iron core determines the impedance of the transformer.

The three-winding transformer is divided into two types: boost structure and step-down structure. Considering the power system and the quality of the supply voltage and reducing the loss when transmitting power, the higher the transformer impedance is. The smaller the better, but the smaller the group resistance will increase the short-circuit current, making the selection of low-voltage equipment difficult. Therefore, the transformer connected to the generator should choose the step-up type.

Reading more about Transformer Impedance

6. Selection of power plant transformer cooling method

The cooling methods of transformers mainly include natural air cooling, forced air cooling, forced oil circulating water cooling, forced oil circulating air cooling, forced oil circulating guided cooling, etc. It varies with the type and capacity of the transformer. Small-capacity transformers generally choose natural air cooling and forced air cooling; large-capacity transformers use forced oil circulation air cooling; forced guide oil circulation cooling is generally used in large transformers. The main transformers of power plants with sufficient water resources, in order to save land, also adopts forced oil circulation water cooling.

Read on: The ultimate guide to ONAN transformers

7. Selection of voltage on each side of the transformer

If a certain voltage level of the transformer is used as the power supply, in order to ensure the voltage quality of the power supply at the end of the line, that is, to ensure that the voltage at the end of the line is the rated value under the condition of 10% voltage loss, the voltage of this side is selected according to 120% of the rated voltage. If a certain voltage level belongs to the power grid, and the terminal is the load terminal, the voltage of this side should be selected according to the rated voltage of the power grid.

Which transformer is used in the power plant?

Above we have described the main transformer for the power plant in detail. Next, let's talk about the transformers used in other electric field plants. With the development of science, technology, and the economy, the world pays more and more attention to environmental protection and cleanliness. Therefore, solar power generation and wind power generation came into being, which is more environmentally friendly than traditional power generation methods. Pad mounted transformer and dry transformer are often used in solar power plants and wind power plants.

Dry-type transformers are commonly used in solar power plants for safe use as isolation. The dry transformer has no oil immersion in the transformer tank and has the characteristics of flame retardant and explosion-proof, so it has advantages in safe operation. However, according to our project experience, for the safety and personal safety of the transformer, we recommend that the dry-type transformer be installed with a protection cabinet. Protect the transformer from rain, wind, and small animals, and also protect people by keeping a safe distance from dry-type transformers.

Pad-mounted transformers have been widely used in wind turbine solar power plants, especially in the North American market. Pad-mounted transformers are also oil-immersed, but unlike substation transformers, pad-mounted transformers require the cabinet to be connected to the bushing from underground, making pad-mounted transformers safer than substation transformers; the installation of pad-mounted transformers is also much easier than substation transformers, The footprint is also much smaller.

In addition, if the project has high requirements for safe operation, the customer may require a KNAN/KNAF cooling transformer, which is immersed in vegetable oil. Vegetable oils have a higher flash point than mineral oils. Vegetable oil transformers cost more and are safer than mineral oil transformers.

Read more: 1500 kVA Pad Mounted Transformer

In summary, we can understand that high-voltage transformers, pad-mounted transformers, dry transformers, etc. can all be used in power plants.

If your power plant needs transformer and substation projects, please contact the Daelim team. With years of experience in international power projects, our team of engineers can design suitable power transformers according to project needs and customer requirements. Daelim has UL listed for pad-mounted transformers up to 10000kVA,44kV now.

Get it now: Why Substation Transformers Are So Important In Power Systems?

Why power transformer is used in substations & power plants?

We can say that a power transformer is the core of a power substation.

We can distinguish the power transformer to step down transformer & step-up transformer.

Step down transformer is to transfer the electrical power from higher voltage to lower voltage, from the power transmission system to the power distribution system, then transfers to low voltage for the end-user through a step-down distribution transformer.

Step up transformer is the opposite. They transfer the lower voltage to higher voltage, usually used in power plants, and renewable energy projects such as solar farms. The voltage from solar panels is too low for transmission, so will need to step up the power transformer in a substation near the solar farm, to transfer the low voltage to a high voltage, and facilitate the electric power's transmission.

Without power transformer, our factory, farm, and data centers can not just use the high voltage from electric wires directly; Meanwhile, the low voltage electric power can not transfer to us directly by the power transformation system.

How to pick a trusted manufacturer for power transformers?

The power transformer is the most important and expensive equipment in the power substation or power plant. If the transformer got any trouble, the whole power substation must shut down and wait for the repair. So it is very important to pick a trusted manufacturer for power transformers.

1. Brand is important

People always trust famous international brands such as ABB, GE, and Siemens. Those brands are assuredly trusted, no matter of the technical part, experience, or after-sales service.

But compared with those international brands, Daelim Belefic also has its own advantages:

Faster production time: Daelim has moved to our new workshop near Shanghai Port, close to transformer aw materials and accessories’ supply chain. Plus our experienced production team, we can offer a way faster production time.

Competitive price offer: With years of international business experience, the Daelim sales team working with our partners in different markets, we know how to quote a competitive to our clients, and support them to win more and more orders with our transformer solution.

2. Experience & certifications

The different market has different standards & certifications, some manufacturer might do good in their local market, but it wants to sell high-quality power transformers that are suitable for international customers, and that manufacturer must have rich experience in the international electric market, the professional engineer team for designing, protection, and testing.

Daelim Belefic has worked in the US, Canada, Latin America, South America, Australia, Asia, and Africa markets for years. Thanks to our professional engineer team and production department, Daelim’s transformers have already passed the CSA listing test, UL listing test, IEC type test, etc... These certifications and test reports help Daelim and our clients, our partners to win more and more orders in their market.

Also, Daelim has worked with BV, SGS, ASIA IBS, etc.. for third-party inspection work for our customers. With inspection & test reports from them, Daelim is becoming a trusted and popular manufacturer in the international transformer market, especially in USA and Canada.

Try for free: Power transformer specification for tender in Canada

3. Shipping & After-sales

As we all know, the power transformer is big size, high weight, with oil-immersed (oil type transformer), also since it is highly important for the whole project, the shipping, and after-sales service is very important.

Daelim Belefic has an experienced shipping partner for oil or dry type transformer shipping, we can do CIF to any port you need, and DDP/DDU for US & Canada customers.

For after-sales, Daelim offers 2 years warranty, and with the support from our local partner in the North American market, we can easily solve any possible after-sales problems.

If you have any needs for a power transformer, welcome to share with the Daelim team, our offer and solution won't let you down.

Here are some of Daelim's International Transformer Projects, you can check them out!

Related Products

Related Article

13.8 kV 10.5 MVA Substation Transformer for Ecuador

A customer from Ecuador contacted Daelim Transformer for a 10.5MVA substation transformer (13.8kV high voltage, 2.4kV low voltage). Daelim Transformer provided a customized solution, conducted virtual factory tours, ensured rigorous quality control via video inspections, and offered post-delivery online training and ongoing support, fostering a successful partnership.

Canadian 69 kV Substation Transformer Project

Today, we are excited to present a case study on a 69 kV substation transformer project by Daelim Transformer. Our Canadian client required a step-down transformer for their substation to connect with the hydroelectric grid in Quebec.

Why Substation Transformers Are So Important In Power System?

This article highlights the significance of substation transformers in power systems, emphasizing their role, versatility, technological advancements, and economic benefits, while promoting Daelim Transformer as a trusted provider in the field.

What You Need To Know About Substation Transformer?

This article discusses power substations and their key components, focusing on the role, types, purchasing considerations of substation transformers, as well as the importance of safety and testing certification.

What is a substation transformer?

Substation transformers are designed for installation in large or small three-phase transmission and distribution power systems. The installation location is common and must be on the indoor or outdoor concrete base, which needs to be designed by the power engineer in the early stage of project planning.

4500 kVA Substation Transformers for Australian Mining Site

Today, we introduce a project by Daelim Transformer aimed at supplying transformers to a mining site in Australia. This project entails the provision of two units of 4500 kVA substation transformers tailored to fit the narrow confines of mining tunnels. Due to space constraints, the transformers need to be compact in size and mounted on mobile racks for easy maneuverability within the mine shafts. This necessitates meticulous design to meet the strict dimensional requirements set by the client.