What Is An OLTC Transformer and How Does It Work?

Does your industrial facility experience sudden drops in power voltage variations or equipment troubles? These could be signs that your old transformers are having a hard time keeping up with your energy needs.

However, you don't have to worry at all since we got you covered—this is where the OLTC Transformer comes in. This smart device also lets you change the voltage without shutting off your power.

Everything stays stable and safe, too. So, what exactly is an On-load Tap Changer Transformer really? In this article, we will discuss an OLTC transformer, how it works, and its importance to the trouble-free operation of electricity.

What is On-Load Tap Changing Transformer (OLTC)?

OLTC lets you control the voltage without turning off the power using a regulation changer. Other transformers require that you switch off power before any change. These are quite the opposite because you can set the voltage at a convenient level without stopping any flow of power.

OLTC lets you control the voltage without turning off the power using a regulation changer. Other transformers require that you switch off power before any change. These are quite the opposite because you can set the voltage at a convenient level without stopping any flow of power.

There are two types of load tap changer: reactance OLTC and resistive OLTC. Although both are used, a tap changer in transformer is utilized with a conservator for most applications, while resistive is hardly used when hermetic transformers are considered.

An OLTC can shift the output voltage by some percentage, typically about ±10% above the rated voltage. In general, big transformers have 16 taps above and below the rated voltage. For every tap above or below the rated value, the voltage will change by 0.625%. This makes fine-tuning feasible until the voltage can go up to 10% over or under the rated voltage.

Example:

For a transformer rated 100kV, a tap moved three positions would cause the total voltage to rise by 1.875%. That adjustment advances the new output voltage to 101,875kV because:

100kV + ((100kV x (0.625% x 3)) = 100kV + 1.875kV = 101.875kV

This is where:

- The Secondary Voltage is equal to 100kV

- The Tap Movement is equal to 0.625 x 3 = 1.875%

Tapping Location

The location on which the tapping is mounted on the transformer is very important. You can connect it at the end of the phase, the middle of the winding, or at a neutral point, and each place has its own merits.

Less insulation is needed to the bushing when tapped at the end of the phase. It requires less insulation between the various parts when tapped in the middle of the winding. This arrangement is very important especially for larger transformers.

So, why is that important? The right tap point allows transformers to operate much more efficiently and safely!

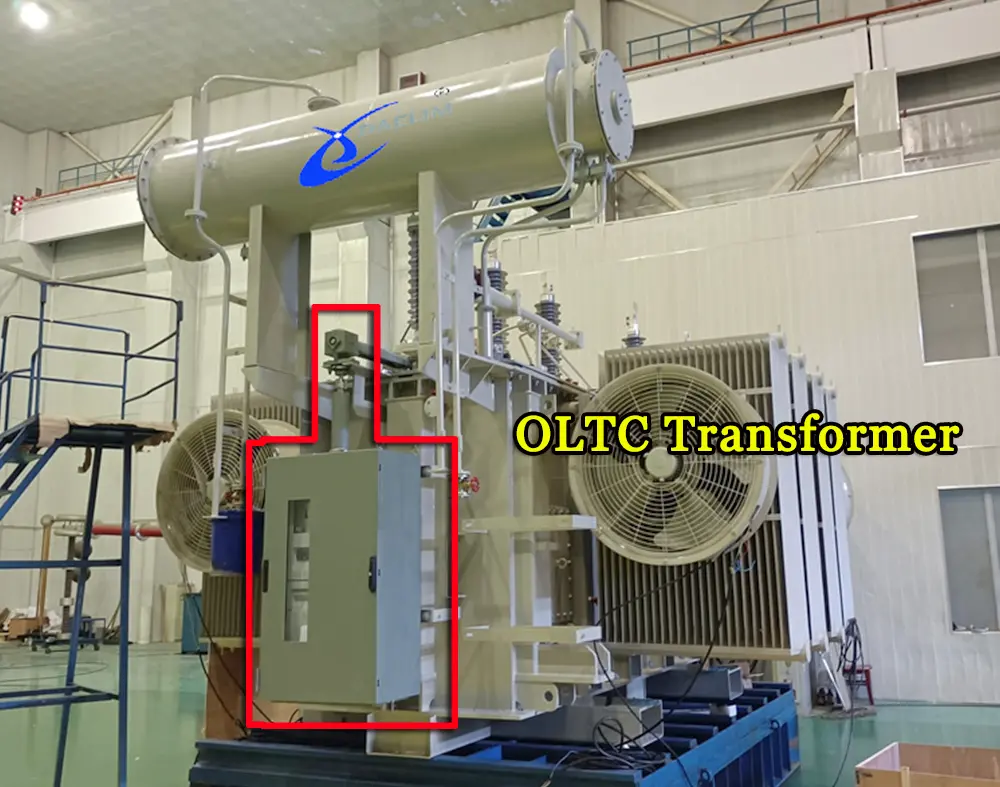

Construction

Try to think of the tap changer as some sort of device which guarantees the safe operation of your transformer. Its heart is called center tap reactor or resistor and may be thought as consisting of high-voltage winding (HV) and low-voltage winding (LV).

There is a diverter switch, which acts like a traffic controller and four selector switches termed S1, S2, S3, and S4 besides four taps that help in voltage regulation: T1, T2, T3, T4. All these taps are kept safely in one independent oil-filled chamber wherein the OLTC is located.

The tap changer can be operated either in the remote mode or hand operated for comfort and safety. For those who feel like operating by hand, a special handle is available.

If the selector switch is faulty, it may create a short circuit and hence endanger the transformer. To prevent this danger from happening, a resistor or reactor is placed in the circuit which delays the electricity flow. This reduces the possibility of a short circuit to a great extent.

In other words, the OLTC keeps everything running smoothly while letting you alter voltage without turning off power.

How Does An OLTC Transformer Works?

An OLTC transformer works by letting you adjust the voltage without turning off the power. This is particularly important to keep your electricity stable, especially under varying demand or fluctuating voltage.

Here’s how it works:

- Taps for voltage adjustment: There are various points termed taps inside the transformer which enable the amount of flowing voltage to be adjusted. The OLTC attaches to these taps and switches in between to increase or decrease the amount of voltage.

- Non-interrupting switching: OLTC switches from one tap to the next without cutting off power since other transformers must be switched off before their voltage can be changed. It uses special switches, such as a diverter switch, to switch through the volts without an electrical break.

- Manual and Remotely Controlled: These transformers can be controlled from a control panel remotely or controlled manually using an associated special handle, thus resulting in flexibility and safety.

- Reducing Short Circuits: To prevent damage to the transformer, OLTCs are typically fitted with resistors or reactors in series. These bring down the rush current caused during switching and ensure that it works out to be a smooth and safer type of switching operation.

Core Functionality of OLTC Transformer

The OLTC plays a critical role in the transformer since it guarantees a constant output voltage irrespective of whether either the input voltage or the load has changed. This is achieved through the adjustment of transformer coils, referred to as turns.

The tap position switch works based on the number of coils in the transformer. This transforms voltage by different switch positions. This means that whatever happens with input, you can always bank upon OLTC to keep the voltage safe and acceptable.

Structure and Operation

An OLTC has three principal parts: the selector switch, the motor drive, and tap connections on the high side of the power transformer. The selector switch will determine a tap position as suitable for the prevailing conditions, and the motor drive moves the tap changer to this selected position.

The motor drive turns the tap changer up or down just before the OLTC switches to a new tap. This results in normal movement of contacts from one tap to another, which yields a new electrical connection.

In short, the OLTC basically keeps your transformer running efficiently by cutting-in or switching voltage levels with no interruption to keep power flow steady!

Importance of OLTC in Power Systems

On-load Tap Changers, or OLTCs, regulate power in power systems where there is use alteration. The transformer will change the voltage in an on-load condition while still in service through the OLTC.

Therefore, OLTCs regulate the voltage by changing the tap position without cutting off the transformer. This prevents any change in voltage while ensuring all persons get a stable power supply.

Advantages of OLTC

- Constant Voltage Control: OLTCs change the voltage instantaneously in order to maintain output stability, either when the load varies under the power supply or input.

- Better Energy Consumption: The OLTC keeps the voltage level at an appropriate point, so energy is not wasted, and the power system runs effectively.

- Long Equipment Life: Since OLTCs ensure stable voltage, machines and equipment come under less stress; therefore, they have a longer life.

- Cost-saving: OLTCs make tap changes occur without the need to lose power, thus saving money in the long run.

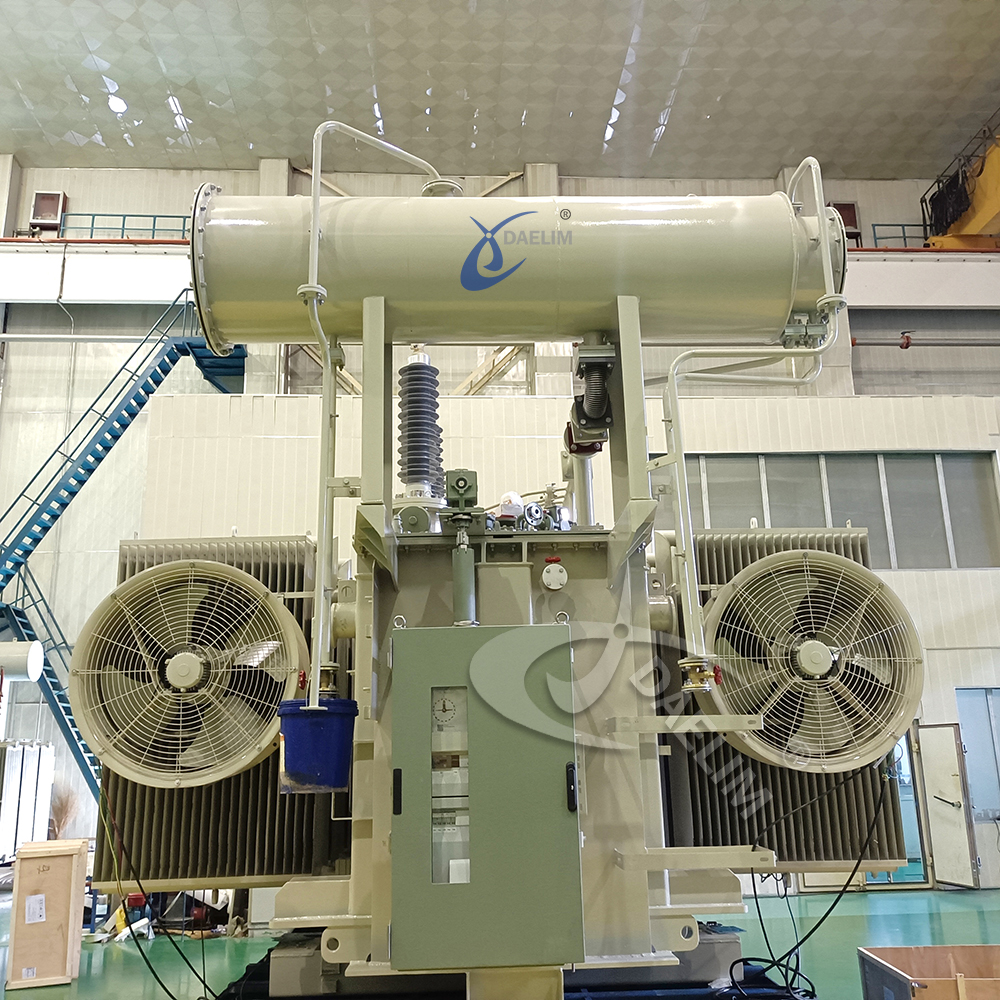

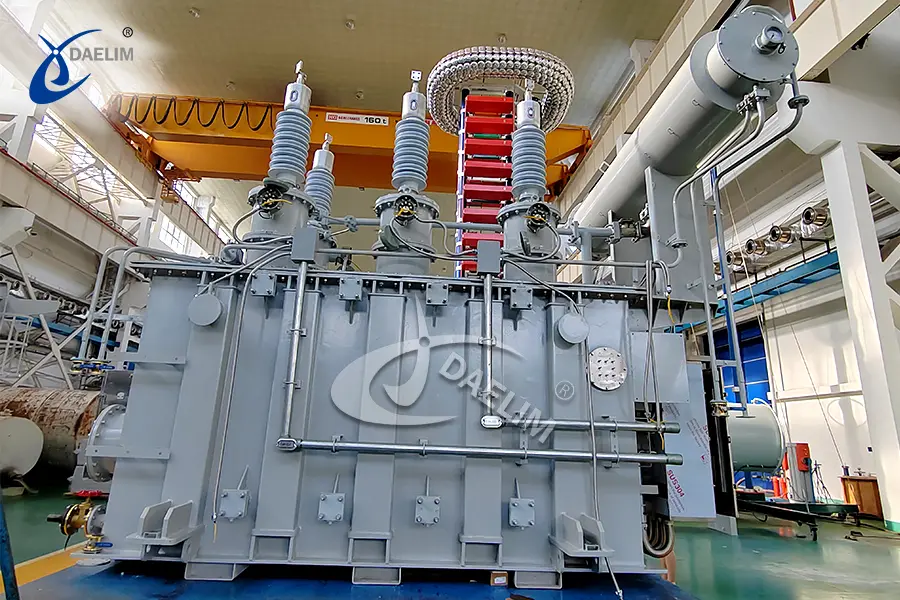

Experience Daelim’s OLTC Transformer

Much of the world relies on electricity power, so an efficient supply system is crucial. Daelim’s On-load Tap Changer fits right here. OLTCs are instrumental for Daelim transformers in the ability to send steady voltage even with a possible change in power demand.

Daelim Transformer with OLTC make it possible to use energy more efficiently and maximize the life of equipment while saving money. These special transformers are designed to always provide power steadily to ensure all your systems work well day after day.

Need a reliable transformer solution? Check out Daelim’s OLTC Transformer and see how it can make your power systems work smoothly. Contact us today!

Related Products

Related Article

20MVA Power Transformer for the United States

This project involves the development of a 20 MVA three-phase power transformer tailored for the United States market. The primary voltage is 24.94kV, and the secondary voltage is 4.16kV, indicating it functions as a step-down transformer. The design and production fully comply with IEEE C57.12.00 standards and have passed third-party UL team testing. All accessories also adhere to IEEE standards. FR3 vegetable oil serves as the insulating liquid for the transformers.

What Is An NLTC Transformer and How Does It Work?

An NLTC (No Load Tap Changer) transformer efficiently adjusts voltage levels while de-energized, ensuring stable power supply in manufacturing and industrial applications. By manually changing the transformer’s turn ratio, NLTCs maintain optimal voltage without interrupting operations. Their simplicity, reliability, and cost-effectiveness make them ideal for systems with infrequent voltage adjustments. Discover Daelim's NLTC transformers for enhanced energy efficiency.

Guide to Tap Changer in Pad Mounted Transformer

Pad mounted transformers play a pivotal role in facilitating efficient energy distribution and management in various applications. Among their key components, the transformer voltage regulating switch, commonly known as the tap changer, stands out as a crucial accessory. In this article, we delve into the significance of tap changer in padmount transformer, their types, functions, and the importance of voltage regulation in ensuring optimal performance and reliability

230 kV Three Phase Power Transformer For USA Market

In 2023, Daelim Transformer designed and manufactured a cutting-edge 230 kV three-phase power transformer for a client in Nevada, USA. The client recently shared installation and operational photos, showcasing the successful deployment of this remarkable transformer. Let's delve into the specifics of this transformer project!

Canadian 69 kV Substation Transformer Project

Today, we are excited to present a case study on a 69 kV substation transformer project by Daelim Transformer. Our Canadian client required a step-down transformer for their substation to connect with the hydroelectric grid in Quebec.

13.8 kV 10.5 MVA Substation Transformer for Ecuador

A customer from Ecuador contacted Daelim Transformer for a 10.5MVA substation transformer (13.8kV high voltage, 2.4kV low voltage). Daelim Transformer provided a customized solution, conducted virtual factory tours, ensured rigorous quality control via video inspections, and offered post-delivery online training and ongoing support, fostering a successful partnership.