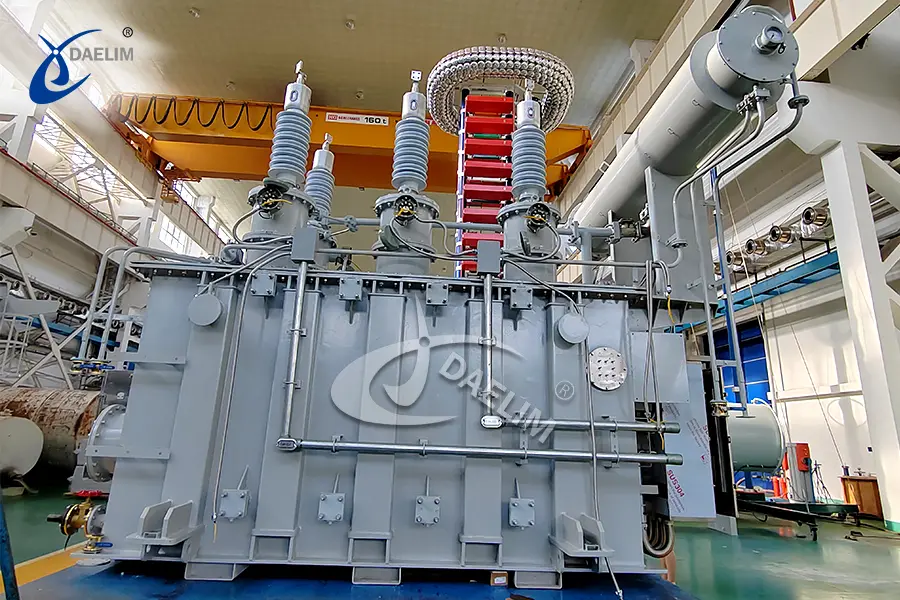

69 kV Power Transformer for Substation in Pennsylvania

Project Overview

Daelim recently completed the design, supply, and installation of a custom transformer solution for a substation in Pennsylvania. This project involved a 69 kV power transformer tailored to meet the specific operational needs of the substation, ensuring that critical electrical systems functioned without interruption. With a focus on efficiency, reliability, and long-term performance, Daelim’s solution has provided the substation with a robust system capable of handling the high demands of the power grid.

Contact Daelim TransformerTransformer Design and Features

The 69 kV transformer was meticulously engineered with the highest standards of efficiency and safety in mind. Key features include:

The 69 kV transformer was meticulously engineered with the highest standards of efficiency and safety in mind. Key features include:

- High Voltage Rating: 69,000V (High Voltage side)

- Low Voltage Rating: 4,160Y/2,400V (Low Voltage side)

- Insulation Levels: 350 kV (High Voltage side), 75 kV (Low Voltage side)

- Phase Configuration: Three-phase transformer

- Cooling Options: ONAN (5,250 kVA) and ONAF (4,200 kVA)

- Impedance: 8.5% at full load (5,250 kVA)

- Losses: Load losses reduced to 30.0 kW, and no-load losses minimized to just 7.5 kW.

Designed with a Dyn1 vector group, the transformer integrates seamlessly with the substation's existing electrical infrastructure, providing stable voltage and reliable power even under fluctuating load conditions.

Key Benefits Delivered

- Reliable Power Supply: The transformer ensures continuous and stable power supply to the substation, critical for maintaining grid stability and uninterrupted service.

- Scalable Design: The system allows for future expansion with minimal infrastructure changes, providing flexibility to meet increasing power demands.

- Energy Efficiency: With its low-loss design, the transformer reduces energy consumption and operational costs, supporting long-term sustainability goals.

- Durability and Low Maintenance: Built to withstand harsh environmental conditions, the transformer is designed for maximum durability with minimal maintenance requirements, ensuring long-term reliability.

- Enhanced Safety: The high insulation levels on both the high and low voltage sides provide industry-leading safety, even under the most demanding conditions.

Project Impact and Real-World Application

This transformer solution exemplifies Daelim’s capability in delivering highly customized, efficient, and reliable power systems. The design and performance of the transformer ensure that the substation can handle high loads and maintain stable power supply, regardless of fluctuations in demand.

Daelim’s commitment to quality and innovation is evident in this project, which meets the complex needs of the Pennsylvania substation while ensuring operational excellence and customer satisfaction. The transformer’s seamless integration into the substation’s infrastructure highlights Daelim’s ability to provide scalable and effective power solutions for critical infrastructure.

Conclusion

Daelim’s work on this project reinforces our reputation for delivering innovative and high-performance solutions that create long-term value for our clients. The success of this project is a testament to our ability to provide customized, efficient, and scalable power solutions that address the complex challenges faced by our customers.

Get in Touch with Daelim for Customized Power Solutions

If you are looking for a reliable and energy-efficient transformer solution for your substation or power system, Daelim is ready to help. Contact us today to learn more about our innovative products and how we can tailor a solution to meet your specific needs.

· Email: sales@daelim-electric.com

· Phone: +1 678-548-5339

· Whatsapp: +86-15801656761

Related Products

Related Article

13.8 kV 10.5 MVA Substation Transformer for Ecuador

A customer from Ecuador contacted Daelim Transformer for a 10.5MVA substation transformer (13.8kV high voltage, 2.4kV low voltage). Daelim Transformer provided a customized solution, conducted virtual factory tours, ensured rigorous quality control via video inspections, and offered post-delivery online training and ongoing support, fostering a successful partnership.

Canadian 69 kV Substation Transformer Project

Today, we are excited to present a case study on a 69 kV substation transformer project by Daelim Transformer. Our Canadian client required a step-down transformer for their substation to connect with the hydroelectric grid in Quebec.

20MVA Power Transformer for the United States

This project involves the development of a 20 MVA three-phase power transformer tailored for the United States market. The primary voltage is 24.94kV, and the secondary voltage is 4.16kV, indicating it functions as a step-down transformer. The design and production fully comply with IEEE C57.12.00 standards and have passed third-party UL team testing. All accessories also adhere to IEEE standards. FR3 vegetable oil serves as the insulating liquid for the transformers.

1500 kVA Transformer for Australian Mining Project

Introduce the 1500 kVA transformer tailored for Australian mining projects. The transformer operates in a three-phase configuration, with a total of four units deployed. Notably, its primary voltage stands at 11kV, while the secondary voltage is 1kV. Characterized by its compact size, emphasis on safety, and unwavering reliability, this transformer is meticulously designed and manufactured to meet the stringent requirements outlined in AS 60076 and AS efficiency value standards.Let's delve into the key features and specifications of this essential solution.

2600 kVA Pad Mounted Transformer For Crypto Mine In Kansas

This morning, I received the on-site photos of the pad-mounted transformers from the customer, and I was overwhelmed with excitement and joy. These pad-mounted transformers are installed at a 20MW crypto mining site in Kansas, USA. A total of 5 sets of 2600 kVA pad-mounted transformers, all UL-listed, are being deployed at this site. Currently, 3 sets have already been installed onsite and are scheduled to be powered on imminently.

Pad Mounted Transformer For High Voltage Substation

FWS commissioned Daelim Transformer to design and manufacture a new high voltage substation for the Richardson International Canola Crush facility expansion in Yorkton, SK. The project required two specially designed top-in pad-mounted transformers, one 2 MVA and one 5 MVA. Unable to meet the delivery deadline, local North American suppliers led FWS to choose Daelim Transformer for their capacity and quality. The transformers were successfully produced and delivered within 16 weeks and are now operating safely.