Basic Guide for Grounding Transformer

In the three-phase power system, grounding transformer plays the role and function of auxiliary transformer. The function of a grounding transformer is to provide grounding mode for ungrounded delta connect or wye connect. Therefore, a ground transformer is also a very important part of the power grid grounding system.

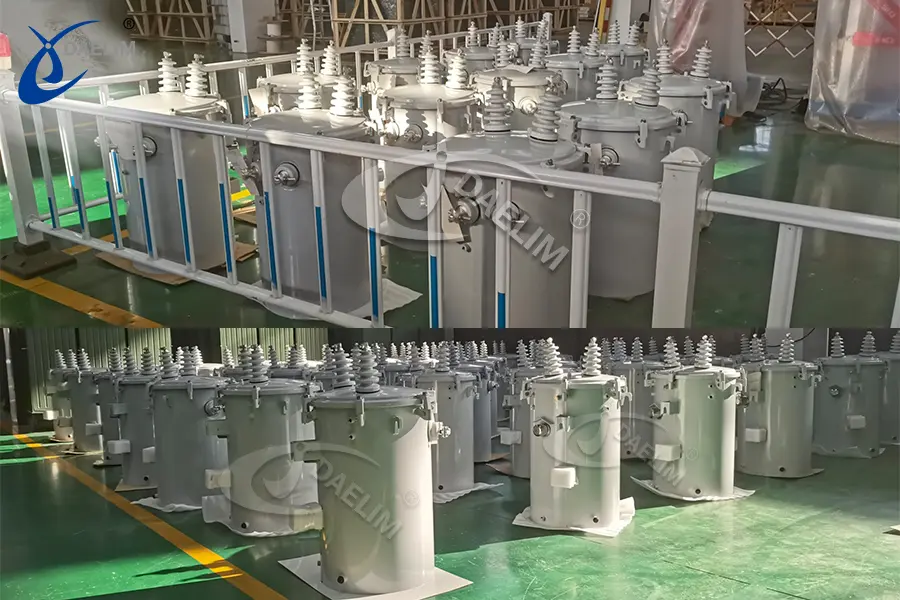

Daelim Transformer is a transformer manufacturer with more than 20 years of experience in transformer production and export. Daelim's main products include Pad-Mounted Transformer, Single Phase Pole Mounted Transformer, Substation Transformer and Power Transformer. DAELIM's transformers produced and sold will undergo strict inspection and testing to ensure the high quality of transformers. Welcome customers who want to buy transformers to come and consult.

What is a grounding transformer

The grounding transformer creates an artificial neutral point for connecting the grounding resistor. In the event of a grounding fault within the system, it presents high impedance to positive and negative sequence currents while offering low impedance to zero sequence currents. This characteristic ensures reliable operation of the grounding protection system.

Read more: 3 Phase Pad Mounted Transformer-Daelim Belefic

Types of grounding transformer

Generally speaking, grounding transformers include two types:

1. a wye (Ynd)-connected winding;

2. a zig-zag (Zn)-connected winding;

Among them, a 2 windings Wye-connected grounding transformer is more widely used and more popular with customers, for several reasons:

1. It is generally believed that the parts of the double-winding transformer are easier to replace or upgrade after being damaged.

2. Designers are more familiar with the design of double-winding transformers, but less familiar with the design of the zig-zag configuration. Therefore, the double-winding transformer will be more popular and common.

3.Wye -connect double-winding transformer can be used for secondary loading and metering, but zigzag design can't.

4. Not all manufacturers will provide zig-zag grounding transformers.

Maybe enjoy: The Ultimate Guide to 2500KVA Transformer

What is the purpose of grounding transformer?

Grounding transformer can provide grounding path for ungrounded system, or can be used when the neutral line of the system fails and is unavailable. The purpose of using grounding transformer or its functions are as follows:

1. When the transformer is grounded, limit the amplitude of transient overvoltage;

2. Provide a relatively low impedance grounding path for the transformer, so as to keep the neutral point of the system at or near the ground potential;

3. Provide current source during line grounding fault;

4. Under special circumstances, connect phase-neutral load.

Get it now:High Voltage Transformer Guide In 2022

Disadvantages of transformer neutral point ungrounded operation

There is a point in the winding of the transformer, which is equal to the absolute value of the voltage between the external terminals, and this point is called the neutral point. The operation mode of neutral point of transformer is divided into neutral point grounding and neutral point ungrounded operation, which has the following disadvantages:

1. Insulation level requirements and high cost

When single-phase grounding occurs, the non-fault voltage increases by √3 times. Therefore, the insulation level of equipment in this power grid is high and the cost is high.

2. There is a danger of arc grounding overvoltage.

When the single-phase grounding current is not large, the arc will be extinguished and the fault will disappear when the current flows through the zero value. When the single-phase grounding current is greater than 30 amperes, a stable arc will be generated, which will form a continuous arc grounding, which will damage the equipment and lead to two-phase or even three-phase short circuit.

3. The selection of grounding relay protection is difficult.

Because it is difficult to realize sensitive and selective protection, especially the power network grounded by arc suppression coil.

4. The disconnection may cause resonance overvoltage.

The breaking of the wire, the switching in different periods and the fusing of the fuse in different periods will cause ferroresonance overvoltage. The resonance overvoltage caused by the disconnection may lead to the explosion of lightning arrester, the reverse phase sequence of load transformer and the insulation flashover of electrical equipment.

5. Resonance overvoltage of electromagnetic voltage transformer

Due to the asymmetry of power grid parameters, neutral point displacement often leads to ferromagnetic resonance overvoltage, which frequently blows the high-voltage fuse of electromagnetic voltage transformer or burns the transformer itself.

Learn more:Basic Guide Of Electrical Transformer

Advantages of transformer neutral point ungrounded operation

1. High reliability of power supply

When a single-phase grounding fault occurs in the power grid, the change of three-phase line voltage and phase current is very small. Because it does not constitute a short circuit, the single-phase grounding current has little influence on the power supply of users. However, the fault must be cleared quickly in a short time (usually 2 hours) to avoid its expansion. Because it won't trip in a short time, the reliability of power supply is high.

2. The interference to communication and signal system is small.

When the three-phase operation is basically symmetrical, the electromagnetic field formed by the power line to the surrounding space is not large, which will not interfere with the communication and signal systems. Similarly, because the single-phase grounding current of the circuit with ungrounded neutral point of the transformer is small, the weak current interference to adjacent communication lines and signal systems is also small. Single-phase grounding arc can be extinguished automatically for small system with ungrounded center point in rural power grid.

Maybe Enjoy: How to choose the best distribution transformer

What is neutral grounding transformer

Neutral grounding of transformer is to firmly connect the terminal connection point of one side winding of transformer with the earth. It is mainly used to prevent overvoltage in power system from damaging transformer winding insulation. Generally refers to the neutral point grounding on the high voltage side. Low-voltage neutral grounding is generally used in distribution network.

Read my article on: Skid mount transformer solution with3 phase pad mounted transformer inside

Characteristics of grounding transformer

1. When the power grid is in normal operation, it is in no-load state for a long time; When the grounding short circuit occurs, it will be overloaded for a short time;

2.The load current flowing through the transformer winding is zero-sequence current, so the zero-sequence impedance of the transformer is more important.

Learn More: How Much You Know For The Different Types Of Transformers?

Harm and treatment measures of oil leakage in grounding transformer

1. Specific hazards of oil leakage of grounding transformer:

(1) The leakage of grounding transformer will first affect the appearance and make the transformer unattractive; Secondly, because the transformer needs to be stopped to eliminate leakage, it causes certain economic losses. Finally, if there are many oil stains on the ground of the grounding transformer, it may become a fire hazard and threaten the life safety of workers.

(2) To some extent, the oil leakage of grounding transformer will interfere with the maintenance personnel's inspection and judgment of the sealing condition in the transformer oil storage tank.

(3) After the oil level decreases due to leakage, if the live connector and switch are operated without being immersed in insulating oil, it may lead to breakdown, short circuit, combustion and even equipment explosion.

(4) After the oil leakage of the grounding transformer, the invasion of external air and moisture will reduce the insulation performance, accelerate the aging and affect the safe and reliable operation of the transformer.

(5) In addition, when there is seal damage at the top of the oil storage tank, such as vent plug and casing conductive head, or there are sand holes at the top of the oil storage tank and its header, even though there may be no oil leakage due to the high position, rain and moisture may enter, resulting in deterioration of insulation performance and even insulation breakdown and winding burning accident.

2. Measures to control oil leakage of grounding transformer

Before dealing with oil leakage, careful analysis must be made to find out the cause of leakage and the exact leakage point. For the existing oil spots, first clean them with detergent, then rinse them with clean water, and finally clean them repeatedly with clean cloth to find the exact location of the leakage point.

When oil leakage is found in the upper part of the oil tank of the grounding transformer, only a small amount of oil needs to be discharged to be welded. When leakage is found in the lower part of the oil tank, welding with oil can be adopted because of the waste of oil draining from the hanging core and the limitation of site conditions. Repair welding with oil should be carried out under the condition that oil leakage is not significant, otherwise, negative pressure should be caused by vacuumizing and oil discharging, and the vacuum degree of negative pressure should not be too high. It is advisable to have equal internal and external pressure to avoid sucking molten iron. When repairing welding, the oil stain on the welding site should be removed, and it is best to rinse with alkaline water and then dry; Pay attention to prevent penetration and fire during welding, and the welding position must be below the oil level; Intermittent and rapid spot welding shall be adopted during welding, and the arc burning time shall be controlled within 10s~20s. Continuous welding for a long time is absolutely not allowed.

When welding pores with serious oil leakage, plug or rivet them with iron wire before welding; When welding near the sealing rubber gasket or other vulnerable parts, cooling and protection measures should be taken.

Read More: What You Need To Know About Substation Transformer In 2022

Daelim Transformer produces grounding transformers with high quality. The transformers produced by Daelim have the advantages of beautiful appearance and excellent quality, and meet many international standards, such as CSA, ANSI/IEEE, IEC, UL, etc. Single Phase Pole Mounted Transformer, Single Phase Pad Mounted Transformer, Three Phase Pad Mounted Transformer and Substation Trasformer are all hot-selling products, which are sold in large quantities to America, Canada, Mexico, and many other American countries and regions.

Related Products

Related Article

69KV Series Substation, Latin America

Built in 2016, the 69kv series substation incuding Kaliti-l 69/13.8 mva substation; Cotebie 69/22kv 20mva substation;Kaliti-II 69/13.8kv 24mva substation;

Pad Mounted Transformer Project Cases

3750kVA Primary 13.8kV, Secondary:0.415kV Loop-feed Pad-mounted Transformer, 12 sets for US market;

Daelim Transformer Custom 1500 kVA Pad Mounted Transformer for Canada

As a professional pad mounted transformer manufacturer & supplier, Daelim Transformer is committed to meeting standards such as ANSI/IEEE, CSA, DOE, and NEMA, offering customized solutions. Here, we present a case of a 1500 kVA pad mounted transformer tailored for the Canadian market.

1000 kVA Pad Mounted Transformers For Jamaica Market

In October 2023, Daelim Transformer successfully manufactured two units of 6 kV 1000 kVA pad mounted transformers, meeting 100% compliance with IEEE C57.12.34 and IEEE 693-2005 standards. These transformers, one step up and the other step down, were tailored for a valued customer in Jamaica. Let's delve into the details of this exceptional project.

Single Phase Pole Mounted Transformer For Guyana

In August 2023, Daelim Transformer completed production and Factory Acceptance Testing (FAT) for a batch of single-phase pole-mounted transformers. These transformers are destined for a prominent distributor in Guyana. The customized order comprises 44 units transformers, with 32 units of 50 kVA, 6 units of 100 kVA, and 6 units of 167 kVA. All adhere to traditional design principles, featuring dual high-pressure bushings. The standard manufacturing and testing procedures follow IEEE Std C57, with the specified type as Conventional.

4000 kVA Three Phase Power Transformer For Canada

A Canadian customer has shared photos with us, showcasing the installation and operation of two 4000kVA transformers designed and produced by Daelim Transformer. The transformers have received highly positive feedback from the customers, who found them to be efficient and expressed satisfaction with the collaborative experience working with the Daelim Transformer team. We look forward to further expanding our cooperation with Daelim Transformer in the future.

Prevention and Treatment Measures for Transformer Core Grounding Faults

Prevent transformer core grounding faults by ensuring proper insulation, regular current measurements, and chromatographic analysis. Address faults with temporary measures, inspections, and targeted repairs. Emphasize design and manufacturing standards to prevent faults and ensure safe operation.

Manifestation Characteristics of Transformer Core Grounding Fault

Transformer core grounding faults cause overheating, gas production, and insulation damage. Symptoms include increased hydrocarbons in oil analysis, high grounding current, and visible core burns or discharge marks. Accurate diagnosis requires comprehensive testing, electrical measurements, and visual inspections.

Requirements for Transformer Core Grounding Points

Transformer cores must have a single grounding point to prevent floating potentials, short-circuit currents, and overheating. Improper grounding can cause insulation damage, increased iron loss, gas generation, and power interruptions, compromising transformer and grid safety.