A Guide to Tier 2 Transformers

Did you know that 2.9% of energy generated across the EU27 and the UK is lost due to transformer losses? That equals Denmark's electricity consumption over three years!

Did you know that 2.9% of energy generated across the EU27 and the UK is lost due to transformer losses? That equals Denmark's electricity consumption over three years!

The EU therefore introduced Tier 2 Ecodesign Regulations to achieve transformer loss reduction and lower carbon emissions.

The regulations aim to reduce tier 2 transformer losses and set new manufacturing standards across the EU27 and its markets.

This article will explore how ecodesign transformers reduce losses, their benefits, and DAELIM's role in adhering to them.

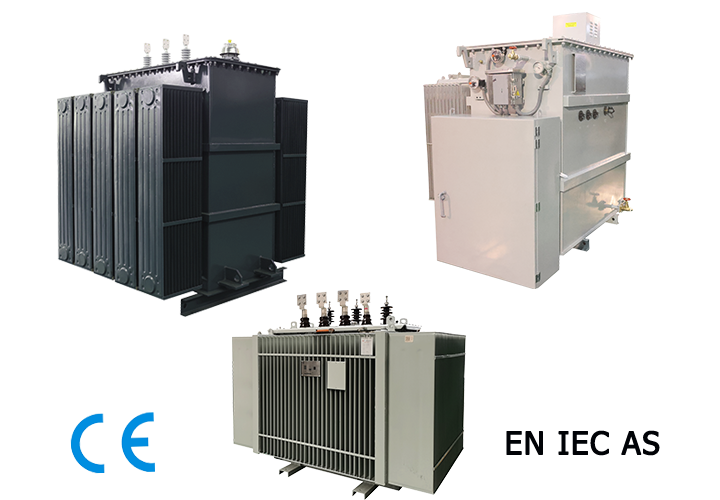

- Standards: BS EN 60076

- Rated Power: 1250kVA

- Rated Frequency: 50 Hz

- Rated High Voltage: 11 kV

- Rated Low Voltage: 415 V

- Cooling Method: ONAN

- Vector Group: Dyn11

- Tier 2 EU 548/2014: Ak Ao -10 %

- Primary Voltage Ratings: 10.5kV

- Secondary Voltage Ratings: 690-690V

- TYPE: Oil immersed type

- BIL: 75kV

- Standards: EN60076

- Application: Energy Storage

- Power Rating: 2500kVA (2.5MVA)

- Certificate: CE

- Primary Voltage Ratings: 10kV, 6kV

- Secondary Voltage Ratings: 400V

- H.V. TAP RANGE: ±2 x 2.5%

- CONNECTION TYPE: DYn11

- Standards: IEC

- Power Rating: 630 kVA

- Certificate: CE

- Cooling Method: ONAN

How Do the Ecodesign Regulations Reduce Transformer Losses?

The Tier 2 standards are a game-changer indeed. They focus on improving transformer energy efficiency, hence a noticeable drop in energy waste and, most importantly, carbon emissions.

But how does it work?

It comes down to optimizing transformer design. By targeting winding and core losses, the standards push for enhanced tier 2 transformers efficiency.

Reducing Winding Losses

In Tier 2 transformers, higher-quality copper and aluminum windings with reduced resistance are used. Such effective change results in less heat generation as the transformer operates. Essentially, the more efficient the winding, the less energy you waste as the load increases.

Minimizing Core Losses

Core losses, which occur through eddy-current and hysteresis effects, can be reduced by using advanced magnetic materials and lamination techniques. Tier 2 standards mandate such improvements for transformers to operate more effectively than ever before.

How Do You Benefit from Tier 2 Transformers?

Wondering what’s in it for you? The benefits of Tier 2 transformers are hard to ignore. Here’s why:

These transformers don’t just reduce energy losses—they dramatically cut down on CO2 emissions, with potential annual savings of up to 16 TWh.

That’s the same as preventing 3.7 million tons of carbon emissions each year, a huge leap towards sustainability.

Even from a financial perspective, the savings are substantial. For instance, a 1000kVA Tier 2 transformer running at 70% load can save you around 13,122kWh annually—enough to lower your energy costs significantly.

Not only that but these transformers are built with advanced materials, which means they last longer and perform better than older models.

Ecodesign Regulations' Impact on Tier 2 Transformer Price

Improving efficiency means using materials with better energetic properties, or increasing the size of key parts like windings and cores. It makes manufacturing more expensive, affecting product pricing.

But here’s the good news: although the initial cost might be higher, the long-term savings more than make up for it. With EU tier 2 transformers, you experience lower energy losses, which translates to reduced operating costs.

DAELIM Transformer’s Compliance with Ecodesign Regulations

At DAELIM Transformer, we’re ahead of the curve. We’ve fully aligned with the ecodesign regulations, producing ecodesign transformers that meet Tier 2 standards.

With over 20 years of research and development experience, we bring cutting-edge technology and innovation to every transformer we build.

Our team of skilled electrical engineers and CAD-certified experts ensures that every design adheres to international standards like IEC, IEEE/ANSI, and CSA.

Final Thoughts

In a nutshell, ecodesign transformers are revolutionizing the industry. They minimize energy losses, reduce costs, and play a pivotal role in lowering carbon emissions.

DAELIM Transformer is proud to be at the forefront of this transformation, producing high-efficiency transformers that not only meet but exceed the EU Eco-Design Regulations 2021.

Thinking about upgrading your transformers? Or simply want to learn more about our eco-friendly designs?

Reach out to DAELIM Transformer today and discuss how we can enhance your energy performance.

FAQs

1. What is the difference between tier 1 and tier 2 transformers?

Tier 2 transformers (2021) create more energy, carbon, and financial savings compared to Tier 1 (2015) or older transformers, thanks to their advanced technical design and the use of high-quality materials that reduce energy losses and improve overall efficiency. .

2. How do energy-efficient transformers contribute to industrial use?

Energy-efficient transformers, such as the ecodesign models, are crucial for industrial applications because they lower energy consumption and operational costs. In industries where power usage is significant, they help reduce load losses and improve overall system performance, resulting in significant energy savings over time.

3. What makes Tier 2 transformers compliant with the Ecodesign Regulations 2021?

Tier 2 transformers meet the energy efficiency standards specified in the Ecodesign Regulations 2021. The regulations require manufacturers to adopt technologies and materials that reduce load losses, no-load losses, and auxiliary losses. Compliance ensures that the transformers are environmentally friendly and cost-efficient over their lifespan.

4. How do Tier 2 transformers reduce energy losses?

Tier 2 transformers use advanced materials such as improved electrical steels and optimized core designs to reduce energy losses. Specifically, they minimize load losses caused by current circulation and no-load losses from magnetic flux circulation, resulting in better overall performance and less wasted energy.

Related Products

Related Article

Pad Mounted Transformer For High Voltage Substation

FWS commissioned Daelim Transformer to design and manufacture a new high voltage substation for the Richardson International Canola Crush facility expansion in Yorkton, SK. The project required two specially designed top-in pad-mounted transformers, one 2 MVA and one 5 MVA. Unable to meet the delivery deadline, local North American suppliers led FWS to choose Daelim Transformer for their capacity and quality. The transformers were successfully produced and delivered within 16 weeks and are now operating safely.

What Happens When A Transformer Blows?

Transformers are crucial for our electrical infrastructure, but when they fail, the consequences can be severe. A blown transformer can lead to power outages, fire hazards, and damage to property and electrical devices. Understanding the causes and impacts of transformer failures is essential for ensuring safety and reliability. At Daelim Transformer, we prioritize quality and innovation to minimize these risks.

What Is An OLTC Transformer and How Does It Work?

Are sudden voltage drops affecting your industrial operations? Your aging transformers may struggle to meet energy demands. Fortunately, Daelim's On-Load Tap Changer (OLTC) transformers offer a solution. These advanced devices allow for seamless voltage adjustments without interrupting power, ensuring stability and efficiency. Discover how OLTC transformers can enhance your energy management and protect your equipment in our comprehensive guide.

What Is An NLTC Transformer and How Does It Work?

An NLTC (No Load Tap Changer) transformer efficiently adjusts voltage levels while de-energized, ensuring stable power supply in manufacturing and industrial applications. By manually changing the transformer’s turn ratio, NLTCs maintain optimal voltage without interrupting operations. Their simplicity, reliability, and cost-effectiveness make them ideal for systems with infrequent voltage adjustments. Discover Daelim's NLTC transformers for enhanced energy efficiency.

How to Choose Transformer Supplier

Choosing the right transformer supplier is crucial for ensuring stable power supply and efficient operations. Start by identifying your specific transformer needs, researching potential suppliers, and evaluating their quality and reputation. Consider pricing, customer support, and delivery logistics. Ultimately, trust your instincts and maintain open communication to establish a strong partnership. Discover reliable solutions with Daelim for optimal energy usage.