How Long Does It Take To Repair A Transformer?

How long it takes to repair an electric transformer depends on several factors: extent and type of damage, availability of parts, site approach and condition. We will discuss this in detail.

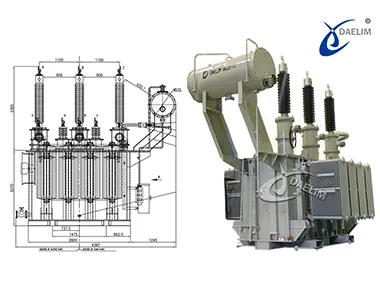

Daelim Transformer has professional service teams across the Americas, Europe, and other regions, offering rapid response within 24 hours for transformer repairs, inspections, installations, and on-site services. Not only do we provide these comprehensive maintenance and testing services for your transformers, but we are also a leading transformer manufacturer, delivering efficient, safe, and environmentally friendly transformers for your various projects. You can rely on us for high-quality, reliable transformer solutions tailored to your needs.

Contact Daelim Transformer

ECO design transformer(Tier 2) complies with the latest energy efficiency standards of the European Union, and has silicon steel core and amorphous alloy core transformers. Designed and produced according to IEC and BS standards, it is energy-saving, environmentally friendly and highly efficient.

Daelim Transformer offers a complete line of oil-immersed transformers that meet current applicable standards, including IEC, IEEE, ANSI, CSA, NEMA, AS/NZS, and GOST. Our high-voltage power transformers are available for voltages up to 230 kV and ratings up to 300 MVA. We have successfully supplied hundreds of high-voltage power transformers across America.

At our facility in Houston, we have hundreds of transformers in stock, including pad-mounted transformers ranging from 300 kVA to 3000 kVA, with voltage levels of 12.47, 13.2, 13.8, 24.94, and 34.5 kV. We also offer single-phase transformers with capacities from 50 to 175 kVA. There's no need to wait—immediate shipment is available!

Minor Issues

Your transformer can be out due to some minor issue like external short circuit or sensor failure. There are several scenarios for each and each will take different time periods for repair.

Short Circuit

In the simplest of transformer electrical connections, there are four wires connected to the transformer. Two wires establish connection between grid station and electrical transformer and two wires make connection between electric transformer and consumer. Any short circuit in these wires will result in transformer blow and power outage till short circuit is removed.

How long it takes to repair an electric transformer short circuit depends on what caused the short circuit and how much other damage has been done. Most of the time, short circuits are due to birds but animals like cats also cause this a lot. It only takes a few minutes to repair a transformer short circuit of this type.

If a short circuit causes any environmental factor like lightning strike or storm, then it will take about an hour or so to repair the transformer short circuit. This is because a storm and lightning strike also damage other transformer parts thus increasing the time of repair.

Sensor Failure

Each transformer has several sensors that are very important for safe and efficient transformer working. These sensors include pressure sensors, temperature sensors, and some safety valves. These sensors are subjected to extreme temperature and pressure during their useful life. Something they get damaged and become useless due external conditions or just lack of maintenance.

If any of these sensors need replacement, then it will take from 30 minutes to a few hours of work to repair the transformer depending on the design and type of sensor. Transformer may or may not continue to work during its repair work. It all depends on the transformer type, size, and design.

Part Failure and Spare Parts Availability

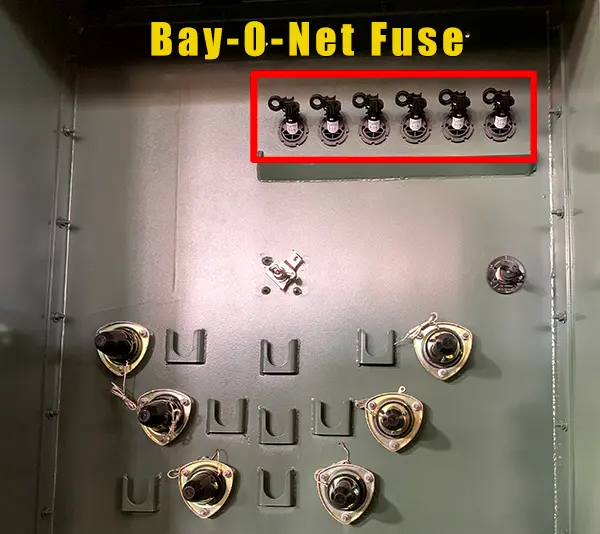

Transformer has several parts that work together to help the transformer work efficiently. The transformer fuse, pump, busing, and breather are the most important of them. Failure of each will result in a blown transformer and each will take a different time period for repair.

Blown Fuse

Any problem with the transformer fuse will immediately affect transformer working and can cause power outages in affected areas. As the matter of fact when our transformer has blown up, most of the time it's the electric transformer fuse that has blown and not the actual transformer.

As blown transformer fuse is a common concept in electrical transformer related issues, it does not take long to repair it. In most cases it takes anything from 30 minutes to an hour to repair the blown transformer fuse. When the transformer repair companies dispatches its team or technician to check the blown transformer report, then it always carries all the equipment and tools to replace the blown fuse.

Pump Failure

Many large size transformers have oil pumps to circulate the oil inside the transformer. This increases the transformer heat dissipation capacity. This pump can get damaged due to environmental factors like corrosion or mechanical factors like wear and tear.

If the transformer pump goes bad, it will take about an hour or more for the technician to reach the site and replace the damaged pump. This work is also done during regular maintenance and it is not necessary that power supply from the transformer is turned off during this replacement.

Busing Failure

Transformer bushings are used to establish a safe connection between external wires and transformer winding. These bushings are made from ceramic material and can get easily damaged due to external factors like a storm or flooding.

If these transformer bushings get damaged, then it can take a few hours of work to repair them as each bushing is made from several small ceramic dish-like pieces assembled together. During the repair work, electricity supply from the transformer is turned off, wires are removed and reattached after all bushing has been replaced successfully.

Breather Failure

Transformer tank is designed in such a way that it holds oil in two different places. One is the main tank and the other is the conservator. Oil when needed moves to and from the conservator into the main transformer tank. This movement of oil needs constant in and out flow of air from and to the atmosphere. In the transformer this happens through a breather that is filled with a gel to absorb moisture.

If the breather stops functioning due to lack of maintenance, then this will affect flow of oil and thus overheating the transformer. If this happens then it will take 15 to 30 minutes for the transformer repair companies to replace the breather and resume the optimal electrical transformer working.

Parts Availability

How long it takes to repair a transformer depends a lot on the availability of transformer parts and machinery needed for the repair.

Small distribution transformers, when needed for repair, do not need big machines and dedicated tools. Most transformer repair companies have good inventory of these transformer parts in their local warehouses. So, when needed, transformers parts can be transported, installed, and made operational in a few hours.

When large size distribution transformers need repair, the transformer repair companies needs to send special machinery like cranes to remove and replace the transformer parts. So, when needed to repair, these large size distribution transformers can be transported and installed in a period of a day or two.

To repair power transformer is a difficult task. Utility companies usually do maintain a small local inventory of these transformer parts. So if we need to repair power transformer, it can take from several days to a few weeks to repair and make the transformer fully functional. This is mainly due to the time of delivery of the transformer parts and need of dedicated equipment for the repair.

Major Fault

Major faults can be oil leak, short circuit in winding, or even damage in the transformer tank. It can take anything from a few hours to a few days to repair the blown transformer parts. If oil leak can be stopped, then refilling can be done in a few hours. If a short circuit is in winding then it is replaced and the transformer needs to be moved to the workshop for repair. This will take days.

Major faults can be oil leak, short circuit in winding, or even damage in the transformer tank. It can take anything from a few hours to a few days to repair the blown transformer parts. If oil leak can be stopped, then refilling can be done in a few hours. If a short circuit is in winding then it is replaced and the transformer needs to be moved to the workshop for repair. This will take days.

In the worst case, the entire transformer can explode damaging multiple parts. It can take anything from a few days to weeks to repair the blown transformer parts. Most of the time it depends on the extent of damage of the installation site and distance the repair team has to cover. With all machinery and equipment at hand, the process of repairing the transformer starts. Removing all connections and the blown transformer parts is the first thing to do. After that, the site is prepared and any structural damage is repaired first.

At the end of the process, all new transformer parts are installed and all the needed electrical connections are made to start the supply of the electricity. This entire process can take from a few hours to a few days depending on the extent of damage.

Affected Area location and Accessibility

Fourth factor that affects the time needed to repair an electric transformer is the ease of reaching the affected location and how easy it is to access the transformer. In all developed countries, transformers are installed in open and easy to assess locations. They have proper roads and infrastructure to help support the transformer repair process. This greatly reduces the repair time.

Opposite to this, there are transformer installation sites that do not have easy access or do not have paved roads for access. This will significantly increase the repairing transformer time as the repair team will need more time to reach the affected area and then face difficulty in assessing the transformer.

Technician Team Expertise

The fifth factor is the expertise of the technical team that any utility team dispatches for the transformer repair process. A team where each member has complete knowledge and experience to perform his task, will complete the repair and maintenance task in a shorter period of time as compared to the team that lacks skills and experience.

Other than this, repairing transformers is a complicated and dangerous task. Any mistake made while repairing work could lead to injury or worker death. So an expert team is necessary for properly repairing transformer.

Conclusion

The time required to repair a transformer depends on various factors, including the type of transformer, the extent and nature of the damage, the accessibility of the installation site, and the expertise of the repair team. Minor issues, such as a blown fuse or a short circuit, can typically be resolved in an hour or less, while more substantial repairs, like replacing bushings or pumps, can take several hours to a day.

About US

Daelim Transformer is a company focused on the power industry, specializing in research and development, manufacturing, maintenance, and services. We not only provide high-quality, safe, and reliable power equipment, but also offer fast delivery and competitive pricing. With a stock of over a thousand transformers on hand, we can ship immediately without delays, ensuring your projects are powered up without waiting. Additionally, we maintain a supply of replacement transformers to keep your operations running smoothly and ensure uninterrupted power during any repair work.

Contact us today to discuss your transformer needs and experience reliable, efficient service for all your power solutions!

Related Products

Related Article

4500 kVA Substation Transformers for Australian Mining Site

Today, we introduce a project by Daelim Transformer aimed at supplying transformers to a mining site in Australia. This project entails the provision of two units of 4500 kVA substation transformers tailored to fit the narrow confines of mining tunnels. Due to space constraints, the transformers need to be compact in size and mounted on mobile racks for easy maneuverability within the mine shafts. This necessitates meticulous design to meet the strict dimensional requirements set by the client.

500 kVA Distribution Transformer for the Greek Market

Today, we're thrilled to showcase a European transformer project tailored for the Greek market. This project involves the supply of 500 kVA distribution transformers, with an input voltage of 20 kV and an output voltage of 400V. The client has requested adherence to both IEC and TIER-II energy efficiency standards. With a total quantity of 5 units, this project marks another milestone in Daelim Transformer's commitment to delivering high-quality solutions worldwide.

Three Phase Power Transformers for Block Chain Facility in Texas!

Daelim Transformer thrilled to share details of our project - the supply of 90 units of three-phase power transformers for a large-scale block chain operation in Odessa, Texas. Each transformer is rated at 2500(3000)KVA with a primary voltage of 34.5kV Delta and a secondary voltage of 480GrdY/277. With strict UL certification requirements and a focus on high-quality accessories from reputable brands, this project demanded precision, efficiency, and reliability.

What different materials are used in a Transformer?

Transformers use a variety of materials to ensure efficient operation and performance. Copper is commonly used for windings due to its excellent conductivity and ductility, while aluminum is a cost-effective alternative. Transformer cores are typically made from silicon steel for high flux density, with materials like amorphous and nanocrystalline alloys offering enhanced efficiency. Transformer oil, such as mineral oil and vegetable (FR3) oils, aids in heat dissipation. Additionally, transformer tanks are often made from low carbon or structural steel, and insulation is typically provided by Kraft paper. These materials work together to enhance transformer efficiency, safety, and longevity.

Everything You Need to Know About Transformer Dimensions

This guide covers the essential dimensions and considerations for selecting, installing, and maintaining transformers. It outlines standard transformer sizes by type and power rating, including medium, high, and ultra-high voltage transformers. Key components like the core, windings, tank, and cooling system are discussed in relation to their dimensions and impact on performance. The article emphasizes the importance of calculating power load, considering location and space, and adhering to industry standards (IEC, ANSI) for safe and efficient transformer operation.

Comprehensive Guide to Unit Substations

Unit substations play a crucial role in safely reducing high voltage from utility lines to levels suitable for use in buildings, factories, and other facilities. They consist of a transformer, primary and secondary distribution equipment, and switchgear. Daelim Transformer provides tailored unit substation solutions, including transformers and switchgear, with extensive experience in the Americas. These substations ensure efficient power distribution, improve safety, and reduce maintenance costs. Contact Daelim Transformer for customized solutions and competitive quotes.