Losses in Transformer: The Ultimate FAQs Guide

Transformers are used in various applications, from small electronic devices to large power stations. However, all transformers come with inherent losses regardless of their size or intended use. It can be due to several reasons like heating of the windings, hysteresis, and eddy current. This article will answer some of the most frequently asked questions about transformer losses and efficiency.

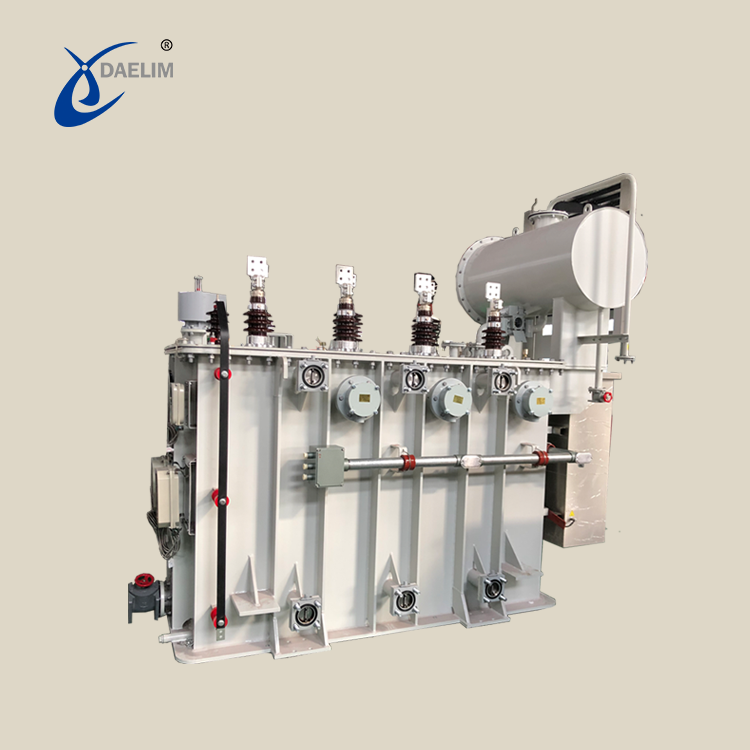

Daelim Transformer is a professional transformer supplier focusing on the North American market. Daelim transformers are meticulously designed to meet and surpass ANSI/IEEE, CSA, and other industry standards. Additionally, they have received UL certification from globally recognized institutions, ensuring exceptional quality and reliability. Our commitment to excellence allows us to deliver transformers with low energy loss, exceptional performance, and utmost safety, providing our customers with unparalleled satisfaction and peace of mind.

Get Transformer PriceHow Many Types of Losses in Transformer?

Despite their size and power, transformers are like other devices—they're not entirely perfect. While the ideal transformer configuration is not to have any losses, the reality is that these devices also have power losses. A transformer's output power will always be less than its input power.

These power losses are then converted to heat that needs to be removed from the transformer to avoid damage. The electricity generated by the coils and the changing magnetic field in the interior generates heat. Load losses refer to the losses that occur with the coils. On the other hand, no-load losses are the ones that happen in the core.

Learn more: The Ultimate FAQs Guide to 25kVA Transformer

The four types of transformer losses are known as resistive, eddy, hysteresis, and flux losses.

Resistive Loss

The resistance of the transformer's windings causes resistive loss (12R), or copper loss, which is a type of electrical breakdown. The current flowing through the resistive material produces heat, which is then dissipated. As a result, the resistive loss is inversely proportional to the current flowing through the transformer.

Eddy Currents

Eddy current losses occur when a transformer's metallic core produces magnetic fields. These magnetic fields induce currents in the core that flow in the opposite direction of the primary current. These eddy currents produce heat that can damage the system if not removed.

Hysteresis

Hysteresis is caused by the magnetism that stays in the material even after removing the source of the magnetic field. In the case of transformers, this magnetism is induced by the alternating current flowing in the primary winding. Therefore, the hysteresis losses are proportional to the square of the magnetizing current.

Magnetic domains possess magnetic properties that move in iron when subjected to a magnetic field. When the magnetic field is removed, a small amount of magnetism remains in the iron. Hysteresis losses are the losses that happen as a result of this phenomenon.

Flux Loss

The last type of transformer loss is flux loss or flux leakage. This type of loss happens when a portion of the flux lines coming from the primary winding doesn't pass through the transformer core and to the secondary winding—resulting in a power loss. There are two reasons why the flux lines can potentially travel through the air instead of through the core:

Saturation in the iron core makes it unable to accept succeeding flux lines. As a result, the flux lines will travel through the air, not the core and secondary winding.

The reluctance ratio of the air and the core in the unsaturated region is 10,000:1. This ratio implies that for every 10,000 lines of flux that go through the core, one goes through the air.

Flux loss is generally minor, especially in a well-designed and well-constructed transformer.

Try for free: Pad Mounted Transformer

What are Iron Losses in Transformers?

Iron loss in a transformer is defined as the loss caused by the alternating flux in the transformer core. Due to this, iron loss is also referred to as core loss. Eddy and hysteresis current losses are examples of core losses.

To further understand how iron losses happen, let's look at iron's magnetic properties. When an alternating current flows in a conductor, it produces a magnetic field. This is the same case with transformer cores made of iron. The current in the primary winding is constantly changing, which in turn creates an alternating magnetic flux in the transformer core.

Read more: The Ultimate FAQs Guide To Dry Transformer

Why Are Iron Losses in Transformers Called Constant Losses?

Iron losses in transformers are called constant losses because, as the name suggests, they remain constant, regardless of the load. They are irrespective of the load condition. No-load or core losses make up a large percentage of the constant losses. That's why iron losses are also called constant losses.

In addition, constant losses also include the losses caused by the resistance of the windings, as well as dielectric and stray losses. Dielectric losses are caused by the insulation heating, while the leakage flux causes stray losses.

What are Copper Losses in a Transformer?

Every material possesses some resistance level, even if it's a very good conductor. When an electric current flows through a material, some of the electrical energy is converted into heat due to the resistance of the material. Copper loss is a term used to describe the loss of conductivity in wire resulting from the use of low-quality copper for winding.

Copper loss is proportional to the square of the load current flowing through the transformer. That means that if we double the load current, the copper loss will increase by a factor of four. At the same time, the voltage will drop by half. Copper losses make up the remaining percentage of constant losses.

What are Stray Losses in a Transformer?

Stray losses refer to the heat losses that occur in all transformer components, except for the copper windings. Stray losses are caused by the leakage flux, which is the portion of the total magnetic flux that escapes from the transformer core. A part of the leakage flux will link with any nearby conductor, resulting in transformer losses.

Stray losses can be divided into two categories: proximity effect and skin effect.

The skin effect is the phenomenon that occurs when the current tends to flow on the surface of a conductor instead of flowing through the entire cross-section. The skin depth is the distance from the conductor's surface to the point where the current has diminished to 1/e (about 37%) of its original value.

The proximity effect is the tendency of an electric current in a conductor to produce an opposing magnetic field, which attracts the current in nearby conductors.

Try for free: The ultimate guide to ONAN transformers

How To Reduce Stray Losses in Transformers?

While losses in transformers are inevitable and frustrating, there are ways to mitigate their effects. In the case of stray losses, you can use two important methods: electromagnetic shielding and eddy current shielding.

Electromagnetic shielding is a conducting barrier that covers an entire device to protect it from environmental electromagnetic interference (EMI). An example of this would be the metal casing around your electrical transformer. It can also prevent emissions from the device itself from disrupting other devices that are in the same environment as the transformer.

On the other hand, Eddy current shielding is a flux rejection technique that is a suitable solution for unconventionally shaped tanks. However, the glaring disadvantage of this method is that eddy currents are transformer losses that occur within the shield, resulting in heating. This heating can potentially cause overheating in other structural parts of the transformer.

Keep reading: The Ultimate FAQs Guide To 1 MVA Transformer

How to Reduce Losses in Transformer?

As owners of a transformer, you would want to keep the losses to a minimum. Unfortunately, this hindrance is unavoidable, so you'll have to work with what you have. Thankfully, there are many ways to reduce the effects of transformer losses to a more manageable degree.

Keep in mind that the methods for reducing losses in a transformer depend on the type of transformer losses. For this discussion, let's focus on iron loss, copper loss, stray loss, and dielectric loss.

Iron Loss

To recap, iron loss (or core loss) results from the alternating influx in the core. The losses can be either hysteresis or eddy current.

The low coercive core material is the most common way to reduce iron losses. This means the core can be easily magnetized and demagnetized, reducing hysteresis losses. Another way to reduce iron losses is using a high resistivity core material.

With a high resistivity, the eddy current losses will be reduced because it would take longer for the electrons to flow through the material. This is due to the fact that the electrons will encounter more collisions with the atoms in the material.

Copper Loss

As for copper losses, the main way to reduce them is by using copper wires with a larger cross-sectional area. This is because a larger cross-sectional area results in a lower resistivity.

With a lower resistivity, the electrons will have an easier time flowing through the material, reducing the losses. Another way to reduce copper losses is by using a larger copper gauge.

Read my article on Types of Transformers

A larger copper gauge means that the wire is thicker, resulting in lower resistivity. However, keep in mind that there is a limit to how thin the wire can be before it becomes too fragile and breaks.

Stray Loss

Stray losses can be reduced in several ways, the most common of which is electromagnetic shielding. As mentioned earlier, this is a conductive barrier that covers the entire device and protects it from environmental electromagnetic interference.

Another way to reduce stray losses is by using eddy current shielding. This is a flux rejection technique that is suitable for unconventionally shaped tanks. However, the disadvantage of this method is that eddy currents are transformer losses that occur within the shield, resulting in heating.

Dielectric Loss

Dielectric losses, also known as insulation losses, are caused by the electrical current flowing through the insulation. The most common way to reduce dielectric losses is using a higher resistivity material.

This is because a material with a higher resistivity will have a lower electrical conductivity. This means that the electrons will have a harder time flowing through the material, which will control and reduce the effects of the losses. Another way to reduce dielectric losses is by using a material with a higher dielectric constant.

This is because a material with a higher dielectric constant can store more electrical energy, lowering the loss effects.

With over 20 years of experience in transformer design, the engineers at Daelim Transformer possess extensive expertise in their field. They are adept at minimizing various types of losses during the design process. If you require assistance with transformer design, our dedicated team is readily available to provide you with the optimal solution promptly. Get in touch with us, and we will swiftly deliver the best possible outcome to meet your specific requirements.

You may enjoy: Step Down Transformer

How To Reduce Iron Losses in Transformer?

To reduce iron losses, you'll need to use a core material that has a low coercivity, which means that it can be easily magnetized and demagnetized and is referred to as "magnetically soft."

Since the hysteresis losses are directly proportional to the material's coercivity, using a magnetically soft material will reduce the hysteresis losses.

Some magnetically soft materials are powdered iron, nanocrystalline cores, and amorphous metal. Another way to reduce iron losses is using a high resistivity core material.

A high resistivity will reduce the amount of eddy current losses because it will take longer for the electrons to flow through the material. As a result, the electrons will experience more collisions within their atoms, ultimately mitigating the losses. Some examples of high resistivity materials are ceramic cores and air cores.

Get it now: The Ultimate FAQs Guide To 20 MVA Transformer

How To Calculate Losses in Transformer?

Calculating transformer losses can be tricky, as many different factors can be considered. The loss in a transformer compares the input (primary power) to the output (secondary power). The input and output voltages, as well as the current rating of both ends, are data that are shown by most transformers.

Calculating transformer losses can be tricky, as many different factors can be considered. The loss in a transformer compares the input (primary power) to the output (secondary power). The input and output voltages, as well as the current rating of both ends, are data that are shown by most transformers.

For example, a step-up transformer raises the voltage but decreases the current. On the other hand, a step-down transformer will decrease voltage but increase current. Therefore, the power rating (in watts) will also differ for each type of transformer.

The Power (P) is the voltage (E) multiplied by the current in amperes (I). Therefore, P = IE.

When calculating the loss of a transformer, you must first calculate both the actual and current-voltage in both the primary and secondary coils. You'll also need to determine the resistance of both coils, as well as the length of the conductor (l).

Once you've obtained these figures, multiply the voltage in volts by the primary winding current in amperes. Next, take the voltage (V) and multiply it by the current (I) of the secondary transformer winding.

Subtract the secondary power from the primary. The resulting number is the power loss of your transformer.

For example, let's say you have a transformer with the following specs:

Primary voltage (V1) = 400 V

Secondary voltage (V2) = 120 V

Primary current (I1) = 10 A

Secondary current (I2) = 2.5 A

Length of conductor (l) = 1 m

Resistance of primary coil (R1) = 2 ohms

Resistance of secondary coil (R2) = 0.5 ohms

To calculate the power losses, you would need to multiply 400 V by 10 A to get the primary power (P1), which would equal 4000 W.

Next, you would like to multiply 120 V by 2.5 A to get the secondary power (P2), which would equal 300 W.

Then, you would subtract 300 W from 4000 W to get the power losses of 3700 W.

Power Losses = P1 - P2

= 4000 W - 300 W

= 3700 W

Conclusion

Transformers inevitably experience various types of losses, including resistive (copper), eddy current, hysteresis, and flux losses. Understanding these losses and implementing strategies to mitigate them is essential for enhancing transformer efficiency and reliability. With proper design and material selection, it is possible to minimize these losses and improve the overall performance of transformer systems.

As a professional transformer manufacturer, Daelim Transformer can provide Low-loss Transformer products that meet or even exceed the efficiency value standards of DOE, CSA, and EU Tier-2. Therefore, if you need a low-loss transformer, contact Daelim Transformer now.

Related Products

Related Article

How to measure the load loss and short-circuit impedance of a transformer?

To measure transformer load loss and short-circuit impedance, apply a rated frequency sinusoidal voltage to one winding, short-circuit the others, and correct load loss to 75°C. Use voltmeters, ammeters, and power analyzers, and calculate impedance using specific formulas. Ensure accuracy by considering instrument placement and correcting measurements as needed.

Guide to Transformer Maintenance

Effective transformer maintenance not only extends operational lifespan but also enhances safety and reliability in power distribution systems. By adhering to structured maintenance protocols and promptly addressing detected faults, owners can mitigate risks and ensure continuous, efficient transformer operation.

Standard Features and Functions of Power Distribution Transformers

This article provides a comprehensive overview of power distribution transformers, covering their components, operational principles, selection criteria, and importance in electrical systems.

2000 kVA Pad Mounted Transformers for Canadian Utility

Daelim Transformer is pleased to announce its contribution to a utility project in Toronto, Canada, involving the supply of two units 2000 kVA pad mounted transformers. These transformers are integral to enhancing the power infrastructure in the region. The project demands adherence to CSA standards, with a stringent delivery deadline of 10 weeks to meet the urgent needs of the client.

4500 kVA Substation Transformers for Australian Mining Site

Today, we introduce a project by Daelim Transformer aimed at supplying transformers to a mining site in Australia. This project entails the provision of two units of 4500 kVA substation transformers tailored to fit the narrow confines of mining tunnels. Due to space constraints, the transformers need to be compact in size and mounted on mobile racks for easy maneuverability within the mine shafts. This necessitates meticulous design to meet the strict dimensional requirements set by the client.

Supply of 37.5 kVA Single Phase Pad Mounted Transformers for Canadian Utility

Today, we are excited to introduce a project undertaken by Daelim Transformer aimed at supplying transformers to a Canadian utility. This project involves the delivery of 80 units of 37.5 kVA single-phase pad mounted transformers, specially designed to meet the utility's requirements. With a high voltage (HV) rating of 24940GRDY/14400 V and a low voltage (LV) rating of 240/120 V, these transformers are vital components in the utility's infrastructure.

500 kVA Distribution Transformer for the Greek Market

Today, we're thrilled to showcase a European transformer project tailored for the Greek market. This project involves the supply of 500 kVA distribution transformers, with an input voltage of 20 kV and an output voltage of 400V. The client has requested adherence to both IEC and TIER-II energy efficiency standards. With a total quantity of 5 units, this project marks another milestone in Daelim Transformer's commitment to delivering high-quality solutions worldwide.

1750 kVA Pad Mounted Transformer for the Dominica Market

Today, we're excited to present a transformer project tailored for the Dominican market. Our 1750 kVA pad mounted transformer is designed to meet the specific requirements of our clients in Dominica. This step-down transformer boasts a primary voltage of 13.8 kV and a secondary voltage of 480Grdy/277V, adhering to the IEEE C57.12.34 standard. With its robust features and reliable performance, this transformer is set to enhance the power distribution infrastructure in Dominica.

Three Phase Power Transformers for Bitcoin Mining Facility in Texas!

Daelim Transformer thrilled to share details of our project - the supply of 90 units of three-phase power transformers for a large-scale Bitcoin mining operation in Odessa, Texas. Each transformer is rated at 2500(3000)KVA with a primary voltage of 34.5kV Delta and a secondary voltage of 480GrdY/277. With strict UL certification requirements and a focus on high-quality accessories from reputable brands, this project demanded precision, efficiency, and reliability.