Guide to Transformer Maintenance

Electrical transformers has become critical infrastructure. As such, transformer maintenance has become a vital process when running a transformer.

To help and guide you, we will discuss power transformer maintenance tips, power transformer testing, and maintenance checklists that you can follow.

Why is Transformers Maintenance Important?

Transformers have become a part of powering our society. But like any equipment, transformers can also break down and fail due to various problems.

To prevent this, owners need to perform safety maintenance on transformers. This is critical as it ensures that the transformer components are maintained in good condition to properly and safely work at any time.

Maintenance Checks: Daily, Monthly, and Annual Maintenance Guide and Checklist

When inspecting and maintaining a transformer, there are three maintenance procedures: daily, monthly, and annual maintenance checks.

During these maintenance sessions, read the power transformer maintenance manual and check if your transformer maintenance equipment works properly to avoid the hazards of transformer maintenance.

Power transformer maintenance videos and articles that discuss different high-voltage transformer maintenance procedures can also be helpful. You can also hire third-party transformer maintenance services that help maintain power transformers.

Daily Maintenance

In a daily maintenance check, here are some transformer maintenance tips you can follow:

- Check the oil levels on the MOG (Magnetic Oil Gauge) of the main and conservatory tanks and keep the oil filled up to the desired level. This is important, especially in oil-filled transformer maintenance checks.

- Check the silica gel, replace it only if its colour changes to pink.

- If any leakage is detected, clean the area and seal it using solvents or sealants.

Reading more about Transformer Oil Leaks

Monthly Maintenance

For a monthly maintenance check, here is a transformer maintenance checklist you can follow:

- Much like the daily maintenance check, the oil level must be checked to ensure it doesn’t drop below the save limit.

- Make sure that all silica gel breathers are clean.

- If the maintained and inspected transformer has oil-filling bushing, it is important to keep the oil levels up.

- Do transformer maintenance tests to check for any additional faults.

Annual Maintenance

In an annual maintenance plan, here are some transformer maintenance guides you can follow:

- All bushings must be manually cleaned using a soft cotton cloth.

- Oil conditions and levels should also be checked. To do this, take an oil sample from its drain valve and test for moisture (PPM) and dielectric strength (BDV). If the BDV value is low and the PPM is high, the oil must be changed.

- The marshalling box should also be cleaned inside.

- Space and illumination heaters should be checked.

- Terminal controls and wiring should be tightened once every year.

- Clean all switches, alarms, relays, and circuits using the correct cleaning agent.

- Check the winding temperature indicator and oil temperature indicator for the correct oil levels.

- The Buchholz and Press Release Device relays should also be checked.

- The resistive value of the earth connection should be measured.

- Perform a transformer maintenance and testing procedure to see if everything works smoothly.

Faults and Their Causes You Should Watch Out For

In an inspection and maintenance, it is important to look out for specific faults. These faults can also be detected during a transformer testing and maintenance session.

Here are some examples of them:

- Transformer Oil Leaks: a cooling and insulation element of the transformer, oil leaks occur if there are cracks, holes, or weak seals. This can be seen if the oil levels are lower or if there are visible oil leaks and stains around the unit.

- Winding Failure: Caused by time, wear, and tear, winding failures occur when there is thermal loss and hot areas to be formed.

- Burn marks on or near the unit: Causes may vary, but usually it means wires are exposed, causing sparks.

- Irregular Temperature: Usually these are caused by a loss of oil coolant or winding failure, creating a thermal loss.

- Strange or Loud Noises: Typically, these are caused by vibrations where components are rattling more than usual, indicating loose screws or perhaps even a lack of oil.

- Smoke: Usually, these are caused by exposed wires, which sparks forming smoke.

Learn more about Transformer Faults

Conclusion

Effective transformer maintenance not only extends operational lifespan but also enhances safety and reliability in power distribution systems. By adhering to structured maintenance protocols and promptly addressing detected faults, owners can mitigate risks and ensure continuous, efficient transformer operation.

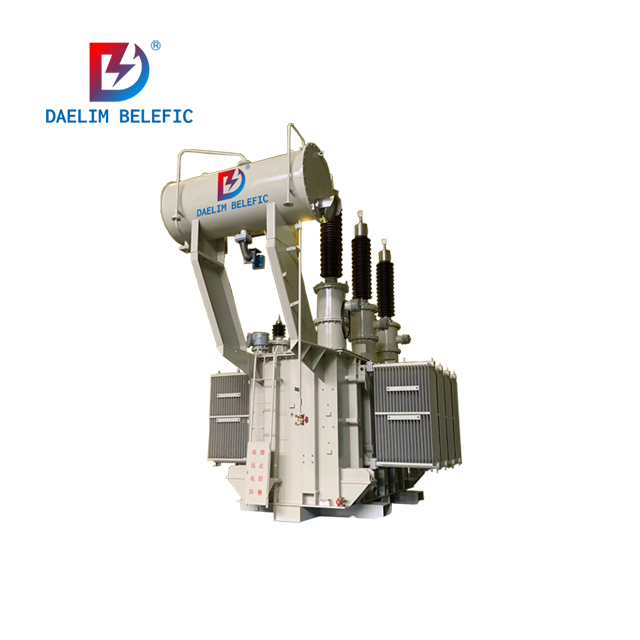

If you have any questions about transformer maintenance, feel free to contact Daelim Transformers.

For your transformer needs, reach out to Daelim Transformers now to receive professional, competitive, and high-quality products along with quotations.

Related Products

Related Article

What are the maintenance points for transformer operation?

To ensure safe transformer operation, monitor allowable temperature, temperature rise, and voltage regulation. Maintain power load at 75-90% of rated capacity. Manage overload conditions carefully. These practices prevent faults, prolonging transformer service life.

Protection and Maintenance Methods for Oil Transformers

Prevent oil transformers from moisture and leakage, regularly monitor oil levels and temperature, ensure proper installation, and timely oil changes and drying. Pay special attention to storage time, sealing, and maintenance to ensure normal operation and insulation performance.

Temperature Protection and Maintenance for Transformers

Transformers require precise temperature protection, monitoring insulation grades, and appropriate oil types. Dry-type transformers trip at 130°C, oil-immersed at 90°C. In cold climates, FR3 fluid is recommended for its effective performance at -50°C.

Comprehensive Guide to Transformer Insulation: Types, Structures, and Maintenance

Transformer insulation is a cornerstone of electrical safety and reliability, crucial for maintaining operational efficiency and preventing catastrophic failures. By understanding the types, structures, methods, and materials involved in transformer insulation, operators can effectively manage and maintain transformers to ensure long-term performance and safety in power distribution networks.

Prevention and Treatment Measures for Transformer Core Grounding Faults

Prevent transformer core grounding faults by ensuring proper insulation, regular current measurements, and chromatographic analysis. Address faults with temporary measures, inspections, and targeted repairs. Emphasize design and manufacturing standards to prevent faults and ensure safe operation.

The Harm of Outlet Short-Circuit Faults to Power Transformers

Outlet short-circuit faults in power transformers cause winding deformation, insulation damage, and overheating, affecting dynamic and thermal stability. Analysis via oil chromatography and electrical testing guides timely repair planning.

Comprehensive Analysis of Large Transformer Faults by Gas Chromatography

Gas chromatography analyzes dissolved gases in transformer oil to diagnose faults, ensuring safe operation. It detects early issues undetectable by standard tests, though it must be combined with electrical tests for comprehensive and accurate fault identification.

Relationship Between Dissolved Gas in Oil and Transformer Faults

Transformer oil serves as insulation and cooling. Faults cause chemical decomposition, producing gases. Analyzing dissolved gases in the oil helps determine fault presence, nature, and severity. Key gases include CH4, C2H6, C2H4, and C2H2, indicating different fault types and temperatures.

Precautions for Analyzing Transformer Faults by Gas Chromatography

Gas chromatography is used to analyze transformer oil for fault diagnosis by identifying dissolved gases. This method, combined with electrical tests, ensures accurate fault detection, preventing transformer damage and ensuring safe, reliable operation.