Temperature Protection and Maintenance for Transformers

Transformers, both dry type and oil immersed, require precise temperature protection settings to ensure safe and efficient operation. This article outlines the key aspects of temperature protection, insulation grades, allowable temperature rises, and specific settings for different types of transformers.

Temperature Protection Settings

Dry type transformers generally trip at around 130°C, while oil-immersed transformers trip at around 90°C. The ambient temperature specifications for transformers are a maximum of 40°C, a minimum of -25°C for outdoor transformers, and a minimum of -5°C for indoor transformers.

Insulation Grades and Temperature Rise

The insulation grade of a transformer refers to the heat resistance grade of the insulation material used. It is not a measure of insulation strength but a standard for allowable temperature rise. The insulation grades and their corresponding temperature standards are:

- Grade A: Maximum allowable temperature 105°C, winding temperature rise limit 60°C, performance reference temperature 80°C

- Grade E: Maximum allowable temperature 120°C, winding temperature rise limit 75°C, performance reference temperature 95°C

- Grade B: Maximum allowable temperature 130°C, winding temperature rise limit 80°C, performance reference temperature 100°C

- Grade F: Maximum allowable temperature 155°C, winding temperature rise limit 100°C, performance reference temperature 120°C

- Grade H: Maximum allowable temperature 180°C, winding temperature rise limit 125°C, performance reference temperature 145°C

The difference between the transformer's temperature and the ambient air temperature is known as the temperature rise of the transformer. The "rated temperature rise" on a transformer nameplate indicates the temperature increase due to the heat generated during operation, compared to a "standard environment."

Standard Environment Temperature

In China, the standard environment temperature is set at 40°C. This provides a unified reference standard for using transformers in various locations and seasons.

Temperature Settings for Dry Type Transformers

The start-stop and over-temperature alarm values of a dry-type transformer thermostat should be set according to the transformer's insulation level. The principle is to ensure that the temperature does not exceed the maximum allowable temperature.

For example, for F and H grades:

- Grade F:

- Fan start: 95°C

- Fan stop: 75°C

- Over-temperature alarm: 110°C

- Over-temperature trip: 130°C

- Grade H:

- Fan start: 105°C

- Fan stop: 85°C

- Over-temperature alarm: 130°C

- Over-temperature trip: 150°C

These settings can be adjusted based on actual conditions.

Low Temperature Settings for Oil Immersed Transformers

Oil immersed transformers often use Class A insulation, with a maximum heat-resistant temperature of 105°C. The winding temperature during operation is typically 10-15°C higher than the average temperature of the upper oil. Thus, when the upper oil temperature reaches 85-95°C, the winding temperature is approximately 105°C. Prolonged operation at this extreme temperature can lead to insulation aging and accelerated deterioration of the insulating oil, reducing the transformer's service life.

Recommended settings for oil immersed transformers

- Fan start: 65°C

- Fan stop: 55°C

- Over-temperature alarm: 80°C

- Over-temperature trip: 90°C

Transformer Oil Grades

The grade of transformer oil is determined by its freezing point:

- No. 10: Freezing point not higher than 10°C

- No. 25: Freezing point not higher than -25°C

- No. 45: Freezing point not higher than -45°C

Use of FR3 Fluid in Cold Climates

For regions with very cold climates, vegetable oil-based insulating fluids such as FR3 are recommended. FR3 fluid can maintain its dielectric properties at temperatures as low as -50°C (-58°F), making it suitable for harsh environments where traditional transformer oils may not perform effectively.

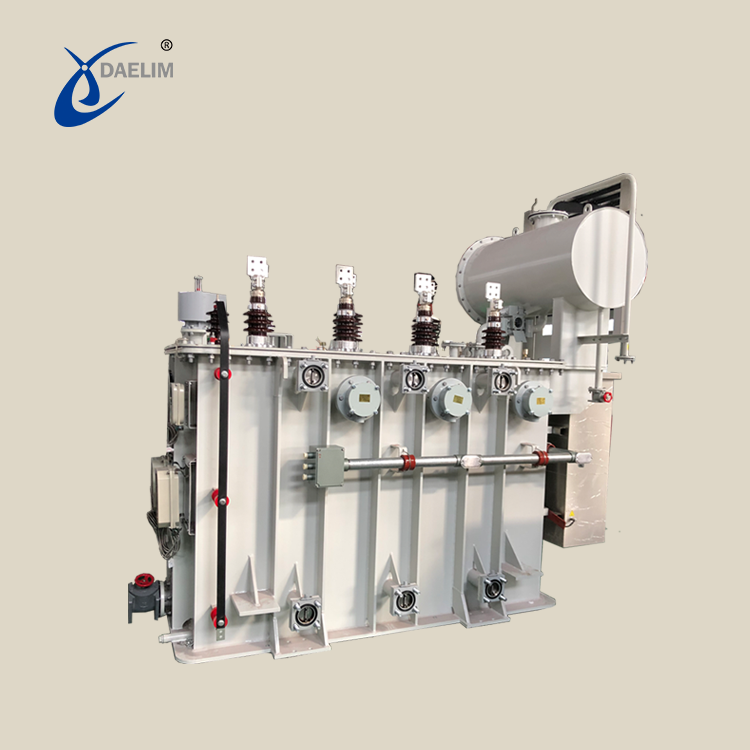

By adhering to these temperature protection settings and maintenance practices, the operational safety and lifespan of transformers can be significantly enhanced. For further information or specific inquiries, please contact Daelim Transformer.

Related Products

Related Article

13.8 kV 10.5 MVA Substation Transformer for Ecuador

A customer from Ecuador contacted Daelim Transformer for a 10.5MVA substation transformer (13.8kV high voltage, 2.4kV low voltage). Daelim Transformer provided a customized solution, conducted virtual factory tours, ensured rigorous quality control via video inspections, and offered post-delivery online training and ongoing support, fostering a successful partnership.

2600 kVA Pad Mounted Transformer for Cryptocurrency Mining

Daelim Transformer successfully provided three customized 2600 kVA pad mounted transformers to power a state-of-the-art cryptocurrency mining facility in Texas, USA. Our transformers were meticulously designed to meet the unique demands of the mining operation, ensuring seamless power distribution with unwavering reliability and efficiency.

20MVA Power Transformer for the United States

This project involves the development of a 20 MVA three-phase power transformer tailored for the United States market. The primary voltage is 24.94kV, and the secondary voltage is 4.16kV, indicating it functions as a step-down transformer. The design and production fully comply with IEEE C57.12.00 standards and have passed third-party UL team testing. All accessories also adhere to IEEE standards. FR3 vegetable oil serves as the insulating liquid for the transformers.

1500 kVA Transformer for Australian Mining Project

Introduce the 1500 kVA transformer tailored for Australian mining projects. The transformer operates in a three-phase configuration, with a total of four units deployed. Notably, its primary voltage stands at 11kV, while the secondary voltage is 1kV. Characterized by its compact size, emphasis on safety, and unwavering reliability, this transformer is meticulously designed and manufactured to meet the stringent requirements outlined in AS 60076 and AS efficiency value standards.Let's delve into the key features and specifications of this essential solution.

2 MVA Pad Mounted Transformer for Utility

Behold the backbone of Canada's utility infrastructure—the 2MVA pad mounted transformer. With a primary voltage of 4160Grdy/2400V and a secondary voltage of 800GrdY/461V, this transformer stands as a testament to efficiency and reliability in power distribution. Crafted in strict accordance with CSA standards and CAN/CSA802.1 energy efficiency guidelines, it embodies the pinnacle of engineering excellence.

2600 kVA Pad Mounted Transformer For Crypto Mine In Kansas

This morning, I received the on-site photos of the pad-mounted transformers from the customer, and I was overwhelmed with excitement and joy. These pad-mounted transformers are installed at a 20MW crypto mining site in Kansas, USA. A total of 5 sets of 2600 kVA pad-mounted transformers, all UL-listed, are being deployed at this site. Currently, 3 sets have already been installed onsite and are scheduled to be powered on imminently.