How to Spot and Repair Transformer Oil Leaks

With today’s society dependent on technology, electrical equipment such as transformers has become relevant and necessary for powering our lives. But, very much like any tool, transformers will also experience failure.

A good example is transformer oil leaks, which can be fixed if you know what to look for. To help you find and fix this problem, we will explore all the facts you should know about how to spot and repair transformer oil leaks.

What are the Causes of a Transformer Oil Leak?

Critical for transformers, transformer oil works as an insulator, cooling liquid, and prevents electrical discharges and arcing. But like any tool, failures such as power transformer leaking oil can occur based on different causes.

And so, here are the different causes of why electrical transformers leak oil and how to fix them:

Poor Weldings

A transformer leaking oil is usually caused by poor or faulty welds, resulting from manufacturing defects or electromagnetic vibrations. Usually, these faults can be fixed by welding and by reinforcing or adding fillers and sealants compatible with water and oil.

Material Defects

Another cause of transformer oil leaks can be sandholes or cracks that occur during manufacturing. This can be solved by making a crack-stop hole to minimize stress and avoid cracks extending.

It is then possible to hammer lead wires based on the cracks made. Then you can start cleaning the leakages and finish the work by sealing them with fillers and sealants compatible with water and oil.

Temperature variation

Usually, transformers operate in places where temperature changes occur. This causes metal components to expand or contract depending on their temperature; with transformers, this can affect the elasticity of gaskets and other seals.

You can replace these gaskets or add fillers and sealants compatible with water and oil to the detected leak points.

Age and Corrosion

Another major cause of an oil leak in transformers is age and corrosion. As time passes, seals will wither or corrode, creating points where a transformer oil leak will occur. This can be fixed by replacing these components with newer and better parts to prevent future oil leak transformer issues.

Weak Radiator Connection

Usually, radiator tubes are composed of welded steel tubes that can bend and warp, causing oil leaking from transformers, due to pressure and tension.

This problem can be solved using steel glues for quick sealing treatments. After the glue has cured, reinforce these repairs with fillers and sealants compatible with water and oil.

How Do You Know If You Have a Transformer Oil Leak?

When inspecting your transformer for oil leaks, there are telltale signs to watch out for.

- Check for visual signs such as oil stains near the transformer, metal discoloration of the transformer casing, or corrosion.

- The smell of transformer oil is also a sign of oil leakage, as transformer oil has a distinct smell.

- Check on the equipment, such as oil gauges, as an unexpected drop in oil levels usually means oil is leaking. You can also check your pressure gauges, as a sudden drop indicates oil leaks.

- Use chemicals like color dye or visualization agents. With color dye, you can highlight the source of the leak using UV light. Visual agents can react to leaked oil by bubbling or changing color if they come in contact with it.

- Connect with professional inspectors to determine if your transformers are working properly or if leaks are still happening after repair.

How Can You Fix a Transformer Oil Leak?

A transformer oil leak repair can be daunting, but to make it easier, here are the steps you should try to follow.

Step #1: Safety

The first step to repairing electrical equipment and handling chemicals is to wear protective gear such as gloves, goggles, masks, and protective clothing. Then, shut off the transformer so you can touch and work on it without being electrocuted.

Step #2: Identify the leak

Try inspecting the transformer; if you smell oil or see oil stains near the transformer, this usually means an electrical transformer leaking oil. You should also check on the gauges and other sensors, such as oil and pressure gauges, to see if they exhibit a sudden drop or are lower than they should be.

Step #3: Clean The Leak and Drain the Oil

To check the source of leaks, it is important to clean the leaked oil around the surface so that you can start your repair and adhesives can be applied. Then drain any oil left within the transformer to avoid an oil filled transformer leak repair.

Step #4: Repairing the Leak

Depending on the damage or cause of the leak, there are different ways to fix it. You can apply epoxies and sealants if the cause is small cracks or holes. Just make sure that you use water- and oil-resistant sealants and epoxies. If the damage is superficial, replace damaged components with newer ones or weld new metal components, which can work as permanent repairs.

Step #5: Refill the Transformer Oil

If you think all the leaks have been repaired, refill your transformer with oil slowly. Check if there is still some oil leaking out in the transformer case or an oil leak inside the transformer.

Step #6: Test The Transformer

After refilling your transformer with new oil, test it to see if it's working. Check your gauges and other parameters to see if they are within the proper range.

You may enjoy: How to test a power transformer?

Step #7: Regular Maintenance

To prevent or spot leaking transformer oil as early as possible, you should do a weekly or monthly check of your transformer’s state. Try to find telltale signs of an oil leak, and also check your gauges to see if they are within the correct range.

Conclusion

In summary, transformer oil leaks can occur due to various factors such as improper seals, defective materials, or corrosion. However, with the knowledge discussed, you now possess the means to identify and rectify these issues.

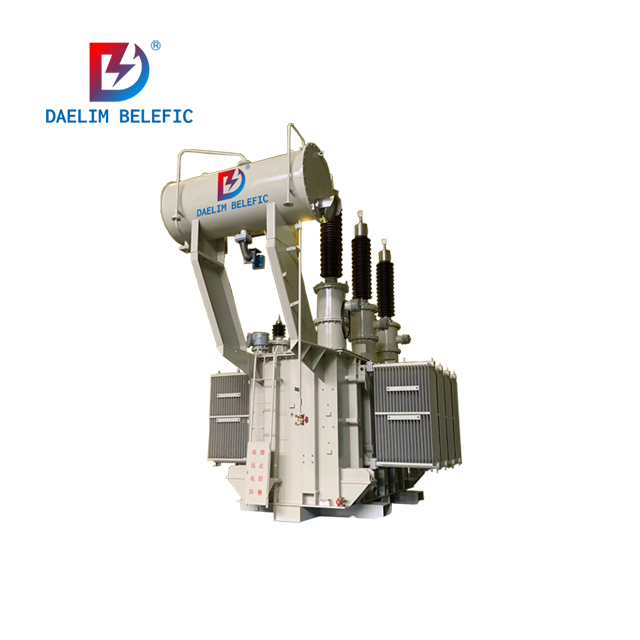

Investing in a reliable brand of transformers is crucial for those looking to prevent such issues altogether. Daelim Transformers exemplifies this reliability as a professional and trusted manufacturer of a wide range of transformer products.

Daelim Transformers stands out for its commitment to safety and quality. They offer diverse transformers including pad mounted transformers, substation transformers, power transformers, eco design transformers, pole mounted transformers, and more.

Daelim Transformers not only offers superior transformer products but also boasts a professional team dedicated to installation, after-sales support, and maintenance. This ensures that any issues, including transformer oil leakage, are promptly addressed with expertise and precision.

Related Products

Related Article

Transformer Oil Aging, Regeneration, and Purification

Effective management of transformer oil ensures prolonged equipment lifespan and reliable performance in electrical applications.

Technical Requirements for Transformer Installation

The article outlines critical technical requirements for transformer installation, covering support, grounding, cable management, safety measures, and fan operation to ensure safe and efficient electrical system performance.

Basic Knowledge of Transformer Transportation

Transformer transportation varies by size. Below 80 tons, use oil with dry air above oil level. Above 80 tons, use dry gas, monitor pressure, and conduct tests. Ensure sealed integrity and monitor regularly during storage.

Comprehensive Guide to Transformer Insulation: Types, Structures, and Maintenance

Transformer insulation is a cornerstone of electrical safety and reliability, crucial for maintaining operational efficiency and preventing catastrophic failures. By understanding the types, structures, methods, and materials involved in transformer insulation, operators can effectively manage and maintain transformers to ensure long-term performance and safety in power distribution networks.

Protection and Maintenance Methods for Oil Transformers

Prevent oil transformers from moisture and leakage, regularly monitor oil levels and temperature, ensure proper installation, and timely oil changes and drying. Pay special attention to storage time, sealing, and maintenance to ensure normal operation and insulation performance.