Transformer Protection Devices

Transformers play a crucial role in power systems, and ensuring their reliability and safety requires the implementation of various protective devices. These devices not only monitor transformer conditions but also act swiftly to prevent potential faults that could lead to operational disruptions or damage.

Thermometer

Usually, the thermometer installed on the transformer is used for temperature measurement and control of temperature signal collection. There are two types of measurement: local measurement and remote measurement; the control type is to control the start and stop of the cooling equipment and temperature alarm. A few transformers are also equipped with analog winding thermometers, which are based on the transformer load current (measured by bushing current transformer) and the pre-adjusted ratio to indirectly reflect the average temperature or hot spot temperature of the winding. If the hot spot temperature of the winding is measured, the difference between the hot spot temperature rise and the average temperature rise is usually the design calculation value.

There is also a fiber optic thermometer that is rarely used directly on the transformer. It is to bury the fiber optic temperature probe directly at the expected hot spot of the winding to measure the hot spot temperature of the winding. This type of fiber optic thermometer is often only used in experimental research in manufacturers or research departments to test computer programs, etc.

Oil pillow

This device prevents direct contact between insulating oil and air by setting a synthetic rubber chamber on the surface of the internal insulating oil. The rubber chamber is made of nylon with good oil and rain resistance. The air in the rubber chamber is connected to the outside air through a respirator equipped with silica gel, thus preventing the deterioration of the rubber. The device indicating the oil level in the oil pillow is an electromagnetic oil level gauge, and the maximum and minimum displacement of the oil level float position is divided into 10 scales and marked on the dial, rather than dividing the oil volume into uniform scales. When the oil level in the oil pillow drops to 0 due to some reason, the contacts in the oil level gauge close and alarm.

Oil conservator and desiccant

Large and medium-sized transformers are equipped with oil conservators. On the one hand, the oil conservator is used to adjust the volume change of transformer oil caused by temperature changes; on the other hand, it reduces the area of contact between transformer oil and the atmosphere, reduces the degree of moisture (water) and oxygen entering the transformer oil, thereby slowing down the deterioration of the oil. In the event of a fault, the heat will vaporize the transformer oil, triggering the gas relay to send an alarm signal or cut off the power supply. If it is a serious accident, the transformer oil will be vaporized in large quantities, and the oil and gas will break through the sealed glass of the safety airway pipe and rush out of the transformer oil tank to prevent the oil tank from bursting.

The desiccant keeps the atmosphere entering the oil storage cabinet dry when the oil in the transformer changes volume with temperature. If the desiccant uses color-changing silica gel to absorb moisture, the silica gel should be replaced in time or dried to restore it to blue when the color of the silica gel changes from blue to red. The moisture absorption effect of silica gel is related to the dryness of the silica gel, the humidity of the air, the ambient temperature, etc.

Capsule-type and diaphragm-type oil storage cabinets can prevent direct contact between oil and air, and prevent external moisture and oxygen from entering the dry transformer oil. However, in addition to the fact that the rubber diaphragm still has a slight amount of air permeability, the life span is often a concern for people. In order to eliminate air permeability and people's concerns about the life span of the capsule, a corrugated expansion oil storage cabinet made of stainless steel sheet has appeared. The corrugated expansion oil storage cabinet not only solves the problem of capsule life, but also completely eliminates the possibility of external moisture and oxygen entering the transformer oil through the oil storage cabinet during transformer operation.

In order to prevent the capsule or external oil type corrugated expander from storing moisture inside during long-term operation, the air entering these oil storage cabinets should also be dried through a dehumidifier.

Gas relay

Buehholz gas relay is installed on the connecting pipe between the main transformer high-voltage bushing riser and the oil pillow. It is a float type. When the gas generated by the transformer fault gathers on the top of the gas relay and reaches 450±10cc, the float F1 of the gas relay drops to connect the alarm circuit contact; when a large fault occurs in the transformer, due to the large amount of gas generated, the oil flow surges. When the oil flow speed reaches 100cm/s, the float F2 acts to connect the trip circuit. The open cup baffle type gas relay, its main structure is two upper and lower open cups and a balance hammer. When the transformer is operating normally, the upper and lower open cups are immersed in oil. The torque generated by the gravity of the open cup in the oil is less than the torque generated by the balance hammer, so the open cup tilts upward and the relay contact does not act. When a minor fault occurs inside the oil tank, a small amount of gas rises and gradually gathers on the upper part of the relay, forcing the oil level to drop. The upper open cup leaks out of the oil surface. At this time, due to the reduction of the float, the torque generated by the gravity of the open cup plus the weight of the oil in the cup is greater than the torque generated by the balance hammer, so that the contacts of the upper open cup are activated and the light gas protection action signal is sent. When a serious fault occurs inside the transformer oil tank, a large amount of gas and oil flow directly impact the baffle of the lower open cup, causing the lower open cup contacts to operate, thereby tripping the heavy gas protection action.

Pressure relief device

The transformer pressure relief device uses a pressure relief valve, which has high sensitivity and can immediately release the increased pressure in the transformer within 2ms. The device discharges the released insulating oil to the lower oil pool of the transformer through a conduit.

Pressure releaser

The pressure releaser is actually a valve compressed by a spring. The valve has the function of instantaneous amplification of the starting force. It is used to release the instantaneous pressure increase in the transformer oil tank to protect the transformer oil tank and avoid damage to the oil tank. When the internal pressure of the oil tank is released to a value lower than the spring pressure, the pressure of the spring will automatically close the valve to prevent excessive transformer oil from overflowing. When the pressure releaser is activated, an alarm signal will be issued. The signal junction box should be kept dry to avoid false alarm signals when it is wet. At the same time, attention should be paid to the timeliness of the spring, and regular inspections should be carried out if necessary.

The pressure releaser is usually installed on the top of the oil tank to reduce the static pressure during normal operation. In order to prevent hot oil from spraying on equipment and personnel when it is activated, the oil guide pipe can be used to limit the sprayed oil in the pipe and flow to the oil pool at the foundation.

Large transformers with oil volume exceeding a certain amount should be equipped with two pressure releasers.

Online dissolved gas analyzer in oil

There are two main types of online dissolved gas analyzers currently used in power systems. One is to use a gas semipermeable membrane probe to contact the transformer oil and collect the gas in the transformer oil. The detectors are gas-sensitive semiconductors and fuel cells; the other is to use gas or liquid chromatography analysis technology for online dissolved gas analysis in oil.

Products using gas semipermeable membrane probes generally have low analysis accuracy. In particular, when using gas-sensitive semiconductor detectors, usually only hydrogen can be responded to; and when using fuel cells as detectors, in addition to hydrogen, other gases can only be detected in part. For example, the total amount of a mixture of four gases, hydrogen (100%), carbon monoxide (18%), ethylene (1.5%), and acetylene (8%), can usually be detected. In other words, the total amount of gas detected is mainly hydrogen.

For example, if the actual dissolved gas content in the transformer oil is:

H2——300*10-6 CO——500*10-6

C2H4——100*10-6 C2H2——5*10-6

Then: Instrument indication value=(300*1+500*0.18+100*0.015+5*0.08)*10-6

H201R and H201i, which use fuel cells as detectors, are analog and digital. The online dissolved gas analysis instrument using a gas semipermeable membrane probe can be considered as just a "dog" guarding the dissolved gas in the transformer oil. If the dissolved gas in the oil indicated by it is abnormal, samples should be taken in the laboratory for more accurate analysis of the dissolved gas in the oil.

Another type of oil dissolved gas analyzer is a real oil dissolved gas analyzer. It can analyze 6 or 8 types of oil dissolved gases, and its analysis accuracy is usually in. Because it is very expensive, it is rarely used on transformers.

Water leakage monitoring

Each transformer cooler is equipped with a water leakage detector. Since the transformer cooler pipeline is a double-layer pipe, when the inner pipe of the cooler heat exchanger leaks, the device will send out an alarm signal. During the patrol process, you can observe the inspection window on the water leakage detector to observe whether there is any leakage.

Oil pillow and oil level gauge

The oil pillow is mainly responsible for the oil replenishment and oil storage of the transformer. It is installed at the highest position of the transformer oil level. It mainly includes the oil pillow body, rubber airbag, oil level gauge, oil pillow body and rubber airbag through pipelines, etc. The oil pillow body includes oil filling valve, oil drain valve, exhaust valve, sampling valve; when the load increases, the temperature of the transformer rises, the insulating oil expands, and part of the insulating oil in the oil tank flows into the oil pillow. The air occupied by the oil pillow space will be discharged through the air pipe and the respirator. When the load decreases, the temperature of the transformer decreases, the density of the insulating oil increases, and part of the insulating oil in the oil pillow flows into the oil tank for replenishment.

The oil level gauge is a disc-shaped oil level gauge, which mainly reflects the oil level in the oil pillow. When the oil in the oil pillow changes, the float in the oil pillow will move up and down with the change of the oil level. The float linkage will drive the gear to convert the rotation of the oil level gauge rotor outside the oil pillow. The pointer tied to the stator magnet (permanent magnet) rotates the corresponding angle through the rotation of the rotor magnet, and reflects the low oil level alarm through the electrical contact. The oil level gauge has a total of 10 scales to reflect the oil level in the oil pillow. When the oil level pointer indicates 0, a main transformer low oil level alarm signal will be issued.

Conclusion

Transformer protection devices are integral to ensuring uninterrupted power supply and prolonging transformer lifespan. By monitoring temperature, managing oil quality, detecting gas anomalies, and controlling moisture, these devices mitigate risks and enhance operational reliability in diverse industrial and commercial applications.

In conclusion, the effective integration of transformer protection devices not only enhances operational reliability but also reduces maintenance costs and ensures safety in power distribution networks.

Daelim Transformer offers advanced transformer protection solutions designed to ensure your equipment's safe and efficient operation under various conditions. By choosing Daelim Transformer, you can benefit from a comprehensive range of protection features that enhance long-term reliability and optimize equipment performance.

Related Products

Related Article

Differential Protection of UHV Transformer

Differential protection is the primary protection mechanism for transformers. By analyzing the arrangement of current transformers (CTs), the function and protection range of each differential protection in UHV transformers can be determined.

Protection and Maintenance Methods for Oil Transformers

Prevent oil transformers from moisture and leakage, regularly monitor oil levels and temperature, ensure proper installation, and timely oil changes and drying. Pay special attention to storage time, sealing, and maintenance to ensure normal operation and insulation performance.

Temperature Protection and Maintenance for Transformers

Transformers require precise temperature protection, monitoring insulation grades, and appropriate oil types. Dry-type transformers trip at 130°C, oil-immersed at 90°C. In cold climates, FR3 fluid is recommended for its effective performance at -50°C.

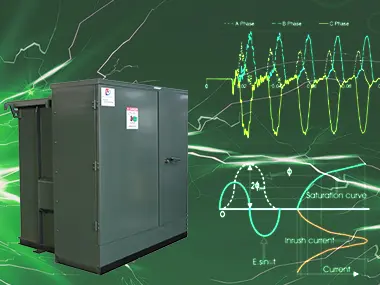

How To Manage Transformer Inrush Current?

In this article, we will tackle inrush current for transformers including some of the most modern ways how to avoid and effectively handle inrush current.We will also discuss how it affects your electrical system and answer more FAQs surrounding transformer inrush current.

MV Skid Compact, Premier Choice for Utility-Scale Solar and Energy Storage

MV Skid Compact represents the pinnacle of cost-effective solutions for Utility Scale Solar and Energy Storage projects. It seamlessly integrates MV transformers, inverters, and medium voltage switches into a single unit, facilitating swift and hassle-free deployment. By consolidating these essential components, MV Skid Compact drastically reduces civil engineering requirements and on-site installation and commissioning times.

Why do PV systems use Double-split step-up transformers?

The double-split transformer offers significant structural advantages. It achieves electrical isolation between two inverters, reducing electromagnetic interference and circulating current between branches. Additionally, it filters the AC output of each inverter separately, resulting in small output current harmonics and improved power quality. In case of a short circuit in one branch, it effectively limits the short-circuit current and maintains voltage at a certain level to ensure uninterrupted user operation.