Different Transformer Types and Their Applications

The transformer is a stationary instrument that is used to manage the voltage and current of an AC electrical supply. They play an important role in power systems and are used in vast applications.

They can be classified into various types according to voltage level, core material, windings, and their usage. In this article, we will provide you with insights about the different transformer types and their applications.

What are the major types of transformers?

The major types of transformers are divided into four categories. These are the voltage level, core material, windings, and their usage.

According to its voltage level

Voltage levels of a transformer are determined by the number of windings on its primary and secondary sections. There are three subcategories under this type. The Step Up, Step Down, and Isolation Transformer.

Step Up Transformer

This type of transformer can convert voltage levels from low input voltage to high output voltage which is made possible by having more turns on the secondary windings.

It is often used in power distribution systems where the voltage level has to be increased prior to distribution and it can also be used to connect generators to the power grid.

Reading more: Step Up Transformer VS Step Down Transformer

Step Down Transformer

This transformer type can receive high voltages in the primary and convert them to lower voltages in the secondary. Its output voltage can range from as low as 5V which is compatible with phone charging and up to 48V.

It is commonly used to step down high voltages from the grid before supplying it to the downstream area such as households and manufacturing plants.

Read more: Step Down Transformer: The Ultimate FAQs Guide - Daelim

Isolation Transformer

This transformer type has uniform windings across the primary and the secondary. Isolation transformers are literally used to isolate specific devices or equipment from the line.

This is primarily done to secure the equipment and the surrounding environment from potential noise and electric shock. It is commonly used in industrial, commercial, and medical applications.

According to its core material

The transmission of energy in the transformer is governed by the core material, structure, and corresponding flux density. There are two subcategories under this type, the Iron Core Transformer, and the Air Core Transformer.

This transformer's core material is composed of several metal plates made of iron. Iron Core type transformer is known to have higher efficiency compared to Air Core type transformer since iron is ferromagnetic which leads to higher flux linkage.

This transformer's core material is composed of several metal plates made of iron. Iron Core type transformer is known to have higher efficiency compared to Air Core type transformer since iron is ferromagnetic which leads to higher flux linkage.

It comes in different constructions or individual laminations which can be E-shape, U-shape, L-shape, and I-shape.

Try for free: The Ultimate Guide to Core Type Transformers

Air Core Transformer

This type of transformer flux linkage across windings is facilitated by air alone. This results in lower mutual inductance, however, there is no magnetization lag and Foucault's current is eradicated.

According to its windings arrangement

Transformers can have different winding arrangements. There are three subcategories under this type.

Three Winding Transformer

This type of transformer is generally relatively high, with three winding compositions, with three voltages: high voltage, medium voltage and low voltage

Two Winding Transformer

Typical transformer set-up where there are two individual windings bounded magnetically. The primary receives power from the source while the secondary is routed to the load.

Auto Transformer

Unlike the typical transformer, these transformer windings are linked in series with a shared common coil. Voltage is changed based on the corresponding position of the center tapping.

According to use

The transformer can be used as power transformer, measurement transformer, and as distribution transformer.

Power Transformer

These are used to transport energy across substations and the grid that supplies power downstream before it goes to the final distribution system. It is mainly used to convert voltages from low to high which is vital in lowering power losses.

It usually comes in huge sizes that can handle ranges from 30kVA up to as high as 100 MVA.

Get it now: How To Choose The Suitable 110KV Power Transformer?

Distribution Transformer

Receives power from power transformers and converts it to lower voltages compatible with utility distribution. They are smaller in size anywhere lower than 200kVA.

This can further be classified according to how it is insulated, it can either be an oil-type or a dry-type transformer.

Reading on: How to choose the best distribution transformer?

What are the 5 applications of transformers?

Transformers application is wide, the five most common applications are the following:

Industrial

Manufacturing industries require different power supplies. In the steel industry, manufacturing plants are able to sustain their daily activities with the help of high-voltage transformers that are specialized to deliver very high currents at varying voltages. It is designed to manage massive mechanical, dielectric, and temperature demands to run a steel furnace.

Transformers do play an important part in the electrochemical industries. Electroplating is carried out smoothly with the aid of rectifier transformers. This transformer type is also essential in other industrial applications like smelting plants and rolling mills.

Transformers Solutions for Industrial and Commercial Buildings

Regulation

One of the fundamental applications of transformers is to regulate the voltage to stabilize power. It can regulate electric current to increase efficiency and protect electrical devices from damage caused by unexpected power surges.

Isolation

Transformers are also used for specific instruments that are required to be isolated for safety or other special requirements.

Modern Application

Transformers are not left behind when it comes to advancing technology. An example of an advanced application of transformers in modern times is charging large batteries used for electric cars.

Other modern applications include data processing, medical, aerospace, military support, communications, and crypto mining.

Power Distribution and Transmission

Transformers are deemed important for the power sector. It basically makes power available for domestic, industrial, and commercial use.

From the power plant, power transmission and distribution are made safe and affordable with the help of transformers. It secures the transmission of high voltages across the lines while another transformer is responsible for converting these high voltages to a level that is usable and safe for electrical devices.

Read my article on Transmission Transformer | At The Power Lines Core

Which type of transformer is most commonly used?

The most commonly used transformers are the power and distribution transformers. You might not recognize it but they are everywhere and anywhere where there is electricity.

From individual homes, small and big businesses, industrial zones, manufacturing and mining sites, to substations and large power grids.

How to choose the correct transformer type?

Choosing the right transformer could be a difficult task but not if you know what to look for. Below we have shortlisted the most important details you must know in a transformer before you can say that it's the right one for you.

Try for free: How To Purchase 3000kVA Transformer In USA & Canada?

Rated Power

This corresponds to the maximum current and voltage a transformer can render. Oversizing may be good but could also cause substantial losses.

On the other hand, cutting edges on the size is even worse. You might not notice it at first, but the windings get exhausted over time, which may implicate declining efficiency and shorter lifespan.

More Resource: Ultimate Guide To Transformer Sizes and Ratings

Primary and Secondary Voltage

The primary voltage refers to your source while the secondary voltage refers to the voltage requirement of your set-up, device, or equipment.

Frequency

This is expressed in hertz. To get the right transformer, it must be able to match the frequency of a particular electrical device or equipment during its operation.

Single Phase or Three Phase

These are other options you must consider, single phase transformers are more economical. They are easier to handle and maintain.

On the other hand, three-phase transformers are more powerful and suited for heavier power requirements.

Keep reading: 3 Phase Pad Mounted Transformer-Daelim Belefic

What type Daelim Transformer offer?

A wide variety of transformers range from small single-phase distribution transformers to HV power transformers. With over 20 years of manufacturing experience, continuously aim to serve every customer's needs.

As Daelim continues to innovate, we bring our service closer. With that, we have strategically installed local after-sales teams around North, South, and Central America so it's easier for you to reach us in case you need any assistance or if you have any inquiries. Here are some of the Daelim Transformers in demand.

Capacity: up to 250 kVA

Primary Voltage: up to 34.5kV

Frequency: 50/60Hz

Cooling method: ONAN, ONAF

Standards: ANSI, IEEE, CSA, DOE, NEMA

Insulation Fluids: Mineral and Vegetable Oil

Applications: Residential,Utilities

Our pad mounted transformers have a full range of UL listed

Capacity: up to 10 MVA

Primary Voltage: 44kV

Frequency: 50/60Hz

Standards: ANSI/IEEE, CSA, DOE, NEMA

Insulation Fluids: Mineral and Vegetable Oil

Application: Industry, commercial, new energy, BESS, EV Charging, utilities, bitcoin mining, etc.

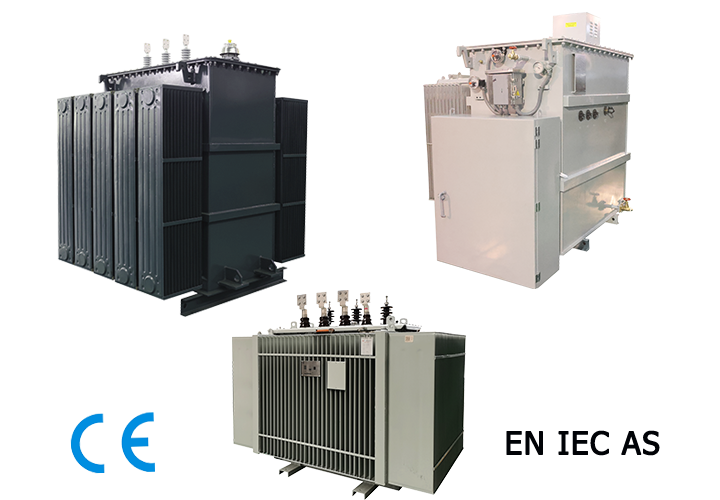

Capacity: 100 kVA to 20000 kVA

Primary Voltage: up to 35kV

Frequency: 50/60Hz

Standards: IEEE, ANSI, CSA, DOE, AS, IEC, NEMA

Certificates: UL, cUL, CSA, CE, FM

HV and LV flange connections

Gauges with contacts

Side-mounted or top-mounted bushings

Insulation Fluids: Mineral insulating oil, Envirotemp FR3 Fluid

Distribution Transformer

Power rating: up to 3150kVA

Voltage: up to 36kV

Standards: 2021 Level 2 EU Directive 548/2014 and BSEN60076

• Modern technology

• Lower energy losses

• Avoided carbon emissions

• Shorter lead time

• Proven quality and reliability

• Long lifecycle with low maintenance

Capacity: up to 500 MVA

Primary Voltage: up to345 kV

Frequency: 50/60Hz

Low partial discharge

Low loss, Low noise

High reliability, Long life

Standards: ANSI, IEEE, CSA, IEC, AS/NZS, BS, NEMA

Insulation Fluids: Mineral Oil Inhibited | Not inhibited | Vegetable Oil

Type: Conventioal and CSP

Capacity: up to 333 kVA

Primary Voltage: up to 34.5kV

Secondary Voltage: 120 to 600 V

Frequency: 50/60Hz

Standards: ANSI/IEEE, CSA, DOE

Certificates: UL, CESI, SGS, ISO

Insulation Fluids: Mineral Oil and Vegetable Oil

Daelim transformers are UL/cUL, CSA, IEEE, and CESI certified. Well-designed and manufactured to attain the highest quality in accordance with international standards for transformers such as ANSI/IEEE, CSA, AS/AZS, DOE, NEMA, IEC, GOST, and or according to customer’s requirement.

Daelim Transformer is a trusted supplier and manufacturer of high-quality transformers. With a wide range of transformer types, capacities, and voltage options, we are committed to meeting your specific needs. Whether you require a customized solution or a standard product, DB Transformer delivers excellence in both product quality and professional services. Trust us to provide you with reliable transformers and exceptional customer support.

Related Products

Related Article

1500 kVA Transformer for Australian Mining Project

Introduce the 1500 kVA transformer tailored for Australian mining projects. The transformer operates in a three-phase configuration, with a total of four units deployed. Notably, its primary voltage stands at 11kV, while the secondary voltage is 1kV. Characterized by its compact size, emphasis on safety, and unwavering reliability, this transformer is meticulously designed and manufactured to meet the stringent requirements outlined in AS 60076 and AS efficiency value standards.Let's delve into the key features and specifications of this essential solution.

20MVA Power Transformer for the United States

This project involves the development of a 20 MVA three-phase power transformer tailored for the United States market. The primary voltage is 24.94kV, and the secondary voltage is 4.16kV, indicating it functions as a step-down transformer. The design and production fully comply with IEEE C57.12.00 standards and have passed third-party UL team testing. All accessories also adhere to IEEE standards. FR3 vegetable oil serves as the insulating liquid for the transformers.

2600 kVA Pad Mounted Transformer For Crypto Mine In Kansas

This morning, I received the on-site photos of the pad-mounted transformers from the customer, and I was overwhelmed with excitement and joy. These pad-mounted transformers are installed at a 20MW crypto mining site in Kansas, USA. A total of 5 sets of 2600 kVA pad-mounted transformers, all UL-listed, are being deployed at this site. Currently, 3 sets have already been installed onsite and are scheduled to be powered on imminently.

Basic Guide for Grounding Transformer

In the three-phase power system, grounding transformer plays the role and function of auxiliary transformer. The function of a grounding transformer is to provide grounding mode for ungrounded delta connect or wye connect. Therefore, a ground transformer is also a very important part of the power grid grounding system.

13.8 kV 10.5 MVA Substation Transformer for Ecuador

A customer from Ecuador contacted Daelim Transformer for a 10.5MVA substation transformer (13.8kV high voltage, 2.4kV low voltage). Daelim Transformer provided a customized solution, conducted virtual factory tours, ensured rigorous quality control via video inspections, and offered post-delivery online training and ongoing support, fostering a successful partnership.

Solar Transformer, Get The Best Price

Solar energy is the most abundant energy source on earth, and contemporary solar energy can be used to produce other renewable energy sources. We can convert solar energy into electricity. At present, there are two main conversion forms in the world, one is solar photovoltaic power stations, and the other is solar thermal power stations. Whether it is photovoltaic power generation or solar thermal power generation, solar transformers are used.