VPI Transformer

VPI (Vacuum Pressure Impregnated) Transformer is a type of transformer or to be more specifically a type of a dry type transformer. In this type of transformer the transformer windings are covered with a special type of resin with the application of vacuum pressure.

The vacuum pressure forces the resin to penetrate into each and every corner and on every wire of the transformer winding. This is done to make sure that the transformer windings are thoroughly insulated and protected from all types of environmental factors like contamination, moisture, and other factors that might change from region to region.

Basic working principle of the VPI transformer is identical to the other transformer as it is used to step up and step down voltage levels for transmission and supply of electricity.

Difference lies in the performance, quality, and reliability of the VPI transformers compared to normal wet/oil type transformers.

Contact Daelim TransformerKey Features of VPI Transformer

High Thermal Endurance

The VPI transformers are designed and developed to deliver high efficiency even in high temperature applications. These transformers can manage thermal stress much more efficiently when compared to the oil type transformers. These transformers remain reliable in all types of environments.

Extended Transformer Winding Life

Due to the VPI process the insulation of the transformer winding is of highest quality. This protects the winding from all types of dust, contamination, and moisture ensuring the winding will not short and thus extending transformer life.

Available in Multiple Power Rating

VPI Transformer are available for wide range application in multiple power ratings. All sizes and power ratings offer the same level of thermal endurance, high performance, and reliability.

Unlike oil type transformers where maintenance, noise and vibrations increase with size and power of the transformer, in VPI transformers these remain the same for all sizes and power ratings.

Minimum Maintenance Requirement

As there is no oil being used in the VPI transformer for insulation and cooling purposes, there is no probability of any type of oil leak or oil related maintenance work.

This also means that all parts that an oil type transformer needs like transformer tank, conservator, and breather are not part of the VPI transformer. Less number of parts means less regular maintenance and less replacement of parts.

Reduced Noise and Vibration Levels

VPI transformers are designed and developed in such a way that they operate very quietly as compared to a regular oil type transformer. Lack of an oil pump and other parts like this also reduce the noise and vibration level. This makes them the perfect transformer for use in noise sensitive areas.

Advantages of VPI Transformer

VPI transformers offer several advantages over conventional oil type transformers.

- VPI transformers are environment friendly as they does not need oil for insulation and heat transfer

- VPI are also consider eco friendly due to use of sustainable and recyclable materials

- Vacuum pressured resin covered windings have lower energy losses due to heat and environmental factors as compared conventional factors.

- High grade insulation of winding under vacuum pressure ensures lower risk of electrical faults and electrical shock.

- VPI transformers have a compact design as it does not need bog oil tanks for cooling and insulation.

- VPI compact design offers space saving options for modern setups.

Applications of VPI Transformer

VPI transformers have quite wide applications and are currently installed in various industries for a number of reasons.

Manufacturing Plants

VPI transformers are used in manufacturing plants to meet the high power consumption demand of heavy machinery, manufacturing process, and automation systems. VPI transformer robust design ensure reliable performance in hard industrial environment

Big Commercial Building

In big commercial buildings that have a huge HVAC system running with all other systems like tubelights, and other electronics needs a dedicated transformer. VPI transformers are widely used in big commercial buildings due to their robustness and reliability.

Renewable Energy System

Step up and Step down VPI transformers are used in renewable energy generation systems ensuring stable power supply through the distribution system. Compact design of VPI transformers with low maintenance make them ideal for small to big renewable energy generation systems.

Critical Infrastructure Installations

VPI transformers due to their low noise level, safety, and reliability are widely used in electrical systems of critical infrastructure like hospitals, data centers and cryptocurrency mining centers. These infrastructures need uninterrupted power supply and VPI are highly recommended for such applications.

Marine Applications

VPI transformers used resin to insulate windings and this also isolated winding from atmospheric factors. Due to this reason, these transformers are used in marine application as their resistance against moisture is the highest when compared to different types of transformers. They are considered ideal for ships, ports, and offshore installations.

Technical Specifications of VPI Transformer

| Specification | Details |

| Power Rating | 10 KVA Up to 25 MVA or as required |

| Voltage Levels | Low Voltage (LV), Medium Voltage (MV), and High Voltage (HV) options Up to 25 kVAC |

| Basic Impulse Levels | 10 to 95 kV |

| Insulation Class | F or H Class (depending on design) |

| Cooling Method | Air-cooled (AN or AF) Customization Available |

| Temperature Rise | Typically 80° C, 100 °C and Up to 150° C |

| Frequency | 50 Hz or 60 Hz |

| Tapping | OCTL, OCTC, OLTC |

| Moisture Resistance | High, due to vacuum pressure impregnation |

| Sound Level | Low noise as per IEC or ANSI standards |

| Efficiency | High efficiency, > 98 % in most cases |

| Environmental Suitability | Designed for harsh and humid conditions |

| Standards Compliance | IEC, ANSI, NEMA, or regional standards |

Customization Options

VPI transformers have such a wide range of applications that one single transformer with fixed specifications cannot be recommended for all applications. So we offer several customizations options for our VPI transformer.

Winding Material

Copper and aluminum are two basic materials being offered for VPI transformer winding. Copper is expensive with excellent conductivity, so used in high end expensive VPI transformers. Aluminum being less expensive with good conductivity is recommended for big transformers basically for transmission purpose.

Cooling Method

Depending on the application, size and power rating of the VPI transformer, it can be designed and developed with three different cooling methods

- Forced air methods. This method is recommended for open space, large size transformers that are mostly installed in outdoor and open space.

- Direct Water Methods. Due to resin isolating the winding, water can be used to cool the winding. This method is recommended for medium size transformers with space constraints.

- Heat Exchanger Method. A complete separate heat exchanger can be designed and utilized to cool VPI transformer winding. This method is Suitable for demanding industrial environments with high thermal requirements.

Enclosure Type

VPI transformers can be delivered in any NEMA ratings including most common NEMA 1, NEMA 3R and NEMA 4 ratings. NEMA 1 is recommended for indoor use with minimal exposure to the environment. NEMA 3R is suitable for outdoor use, protecting against rain and snow.

NEMA 4 rating for VPI transformer enclosure is used for protection against water and dust, ideal for harsh environments. Additional NEMA-rated and specialty enclosure options available based on specific requirements.

Tapping

- OCTL (Off-Circuit Tap Link). Allows manual voltage adjustment when the transformer is not energized.

- OCTC (Off-Circuit Tap Changer). Permits voltage adjustment without full shutdown.

- OLTC (On-Load Tap Changer). Enables voltage regulation during operation for dynamic load conditions.

More resources:

What Is An OLTC Transformer and How Does It Work?

What Is An NLTC Transformer and How Does It Work?

Insulation Class

VPI transformers can be delivered in two different insulation classes depending on the transformer size, voltage rating, power rating, and application. Insulation class F is suitable for standard transformer thermal performance whereas class H is for higher thermal endurance.

Customer Benefits

- Long-term cost savings through reduced maintenance and energy efficiency.

- Reliable performance even under demanding conditions.

- Scalable solutions to meet future energy demands.

- Improved operational safety and compliance.

Certifications & Standards

Daelim offers VPI transformers to customers around the globe. To ensure our transformer meets the expectations, our VPI transformers are designed and manufactured to ensure all international and regional standards.

ISO (International Organization for Standardization)

We follow all ISO standards to ensure that our transformer manufacturing process aligns with the quality management system like ISO 9001, ensuring consistent quality and reliability.

IEEE (Institute of Electrical and Electronics Engineers)

Daelim Transformer follows IEEE standards for all its VPI transformer design. IEEE strict standards ensure reliable electrical equipment design and operational excellence.

More resource: Ultimate Guide To IEEE C57 Standard

IEC (International Electrotechnical Commission)

Following IEC protocols ensures global compatibility and adherence to industry benchmarks for performance, safety, and reliability.

More resource: The Ultimate Guide To IEC 60076 Standard

Certifications

Daelim Transformer has all the required global and local certifications to design, manufacture, deliver, install, and maintain VPI transformers all round the globe including USA, Canada, Australia, Germany, and UK. Some of our certifications include CSA (Canadian Standards Association), UL (Underwriters Laboratories), CE (Conformité Européenne), and RoHS (Restriction of Hazardous Substances).

These certifications and compliance with standards ensure VPI transformers meet the diverse requirements of global markets while maintaining exceptional quality and safety.

Warranty & Support

At Daelim we offer VPI Transformer with the warranty coverage and after sale support which no other transformer manufacturer and supplier can offer.

Standard Warranty

All our VPI transformers are provided with a 3 year standard warranty that covers any manufacturing defect and workmanship.

Extended Warranty

We also offer options for up to 10 years for additional warranty, subject to terms and conditions.

24/7 Helpline Support

At Daelim Transformer we offer all types of customer support 24/7 through our dedicated team of subject matter experts to address operational or trouble shooting concerns.

After Sales Support

At Daelim Transformer we also offer complete after sales support including regular inspection of transformers, on site diagnostics, and preventive maintenance. This is done to ensure optimal performance and longevity of equipment installed. As part of our contract we offer fast access to genuine replacement parts for minimal downtime.

Now you have discovered how good and versatile Daelim VPI transformers are and how they can revolutionize your energy distribution systems. With our VPI transformer unparalleled efficiency, durability, and reliability, we are best in this business.

Contact us today for expert guidance, personalized quotes, or to schedule a consultation with our team of specialists. Let us power your success!

Related Products

Related Article

Empower Your Data Center with Daelim Transformer

Daelim Transformer provides reliable and efficient transformer solutions for data centers, ensuring high power capacity, safety, and energy efficiency. With customized options such as oil-immersed, dry-type, and smart transformers, Daelim addresses critical needs for redundancy, power quality, and load management. Our transformers offer high reliability, scalable designs, and advanced cooling methods, supporting modern data centers with high-density IT equipment. With ongoing maintenance and monitoring services, Daelim ensures continuous, optimal performance for data centers worldwide. Contact Daelim today to power your data center with confidence.

Exploring the Benefits of FR3 Oil vs Mineral Oil Transformer

FR3 oil and mineral oil are two common transformer insulating oils. FR3 oil, made from renewable plant-based esters, is biodegradable, fire-resistant, and performs better in extreme conditions, making it safer and more environmentally friendly. In contrast, mineral oil is cost-effective but non-biodegradable and poses higher fire risks. FR3 oil outperforms mineral oil in safety, sustainability, and performance.

69 kV Power Transformer for Substation in Pennsylvania

Daelim recently completed the design, supply, and installation of a custom 69 kV transformer for a substation in Pennsylvania. This high-efficiency, three-phase transformer is engineered for reliability, scalability, and long-term performance, ensuring a stable power supply to the substation. Key features include low load losses, minimal maintenance, high insulation levels, and flexible cooling options. The solution enhances grid stability, supports future expansion, and minimizes energy consumption, reinforcing Daelim’s commitment to quality and innovation in power systems.

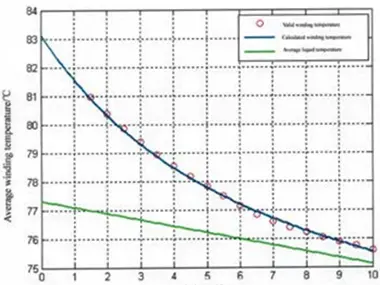

Transformer Temperature Rise: Understand Ratings, Factors, and Impact on Efficiency

Transformer temperature rise refers to the increase in winding temperature above the ambient temperature when a transformer operates at full load. It is influenced by factors like iron loss, copper loss, poor cooling, overloading, and ambient temperature. Transformers are rated with specific temperature rise limits (e.g., 65°C for oil-immersed and 80°C for dry-type), which impact efficiency, reliability, lifespan, and overload capacity. Proper monitoring and high-quality materials ensure safe, efficient operation, preventing overheating and extending transformer life.

The Complete Guide to Transformer Oil Dissolved Gas Analysis

Dissolved Gas Analysis (DGA) is a critical method for monitoring transformer health by detecting gases in the oil. It helps identify issues like oil overheating, insulation damage, air ingress, and partial discharge before they cause major failures. Regular DGA testing enables early detection, extends transformer lifespan, prevents unexpected breakdowns, saves money on repairs, and provides valuable data for maintenance planning.

Signs That You Need to Replace Your Oil-Filled Transformer

This article discusses the key indicators that signal the need for replacing an oil-filled transformer, including persistent oil leaks, abnormal infrared scan results, unusual vibrations or noises, and poor DGA test results. It emphasizes the importance of recognizing these signs early to prevent downtime, efficiency loss, and environmental damage. Additionally, the article highlights the impact of aging transformers and rising energy costs, recommending timely replacement to ensure optimal performance and compliance with modern standards