Signs That You Need to Replace Your Oil-Filled Transformer

Have you ever noticed a change in the performance of your oil-filled transformer? Time is bound to wear it out, compromising its safety, efficiency and reliability. Hence, it becomes important to know when a replacement is necessary.

Recognizing early signs of trouble can help you save pricey downtime or severe damage. In this article, we will share with you the indicators that warn of transformer replacement, the reasons for this, and why timely action is important.

Contact Daelim TransformerPersistent Oil Leaks

Leakage is a key sign of transformer degradation. Transformer oil acts as insulation and cooling medium. Once leakage begins, the levels start dropping, and the performance of such functions deteriorates.

These can appear as oil marks or spots on the bottom of the transformer, or tracked back to old seals, gaskets, or rusting on the tank. Leakage, if not controlled, can lead to overheating and poor efficiency, and even loss of transformers.

More resources:

How to Spot and Repair Transformer Oil Leaks

Why It’s Critical:

- Lacking suitable oil levels leads to overheating.

- Leak-related oil contamination will damage the inside components.

- Their emissions leak into the soil, hence directly posing environmental hazards.

Abnormal Results from Infrared Scans

Infrared thermography is one of the effective means for detecting thermal anomalies in transformers. Most of the hot spots found by infrared surveys are linked with inner defects like insulation deterioration, loose contacts, or overloading of part components. These thermal deviations might often be a precursor to failure.

Red Flags to Watch For:

- Uneven heating of the cover of the transformer.

- Hot spots are persistent or spreading, even after maintenance.

- Heavily spiked sharply in temperature after months of use.

Unusual Vibrations and Noises

Ideally, a good transformer under normal operation should produce steady low-pitched humming. An unusual vibration or strange noises may show mechanical flaws in a transformer, such as inner corrosion, loose windings, or an unaligned core.

Possible Sources of Noise and Vibration Problems:

- Heats up resulting in burnt windings.

- Mechanical loosening of parts wearing.

- The magnetic core degrades as operating stresses increase.

Concerning Results from DGA (Dissolved Gas Analysis) Testing

DGA testing determines the composition of gases dissolved in transformer oil; it decides whether a transformer is in good status. Generally, hydrogen, methane, and acetylene presence then warns of inner arcing, overheating or insulation breakdown.

Key Indicators to Act On:

- Acetylene at high levels indicates arcing inside the transformer. Higher hydrogen levels correspond to parts overheating. Increasing methane indicates degradation of the insulation.

- Regular DGA Oil filled transformer testing can detect such problems early enough to help decide whether or not to repair or replace the transformer.

External Wear: Flaking or Peeling Paint

The outside condition of a transformer quite often indicates the internal condition. Peeling, flaking or bubbling paint may indicate heat stress, moisture ingress, or corrosion, all of which are external indicators of mechanical or thermal issues.

Why This Matters:

- Corrosion can cause structural damage.

- Paint degradation may lead to moisture penetration, thereby detrimental to internal parts.

- Surface degradation often indicates poor heat dissipation.

Changes in Oil Color and Quality

The transformer insulating oil should be clear or pale yellow. Deepening or discoloration, which often indicates contamination and potential oxidation and chemical breakdown, usually depresses the ability of the oil to cool itself and isolate itself.

Symptoms of Oil Deterioration:

- Cloudy or Murky Appearance.

- Presence of particles or sediments.

- Highly reduced dielectric strength, as reflected in the oil tests.

Electrical Performance Decline

Transformers are designed to provide a steady voltage. Fluctuating voltages, erratic power supply or some other kind of electromagnetic variation could be an indication that the transformer is under capacity for what is being drawn.

Key Signs of Electrical Issues:

- Difficulty maintaining voltage stability.

- Power cuts incidental or periodical.

- More volatile operations for the circuit breaker.

Increased Maintenance Frequency

A transformer at the end of its useful life probably will consume a lot of service. If you are constantly replacing gaskets, topping off the oil, or setting minor electrical balances, then it may be time to turn over and replace the unit outright.

Rising Energy Costs

Inefficient transformers gobble up energy to do what they are supposed to do. If your energy bills are increasing without any corresponding increase in consumption, it can be caused by an old transformer. Modern transformers are more efficient than the old ones, so replacement can be a good long-term investment.

Age of the Transformer

The generally oil filled transformer life expectancy is 20 to 30 years, depending on usage and maintenance. If your transformer is reaching or surpassing this age range, its performance and reliability may already be falling, even when no visual signs are evident.

The generally oil filled transformer life expectancy is 20 to 30 years, depending on usage and maintenance. If your transformer is reaching or surpassing this age range, its performance and reliability may already be falling, even when no visual signs are evident.

Why Age Matters:

- Aging parts are most likely to fail.

- Older models may need to meet the standards of modern-day efficiency or safety.

- Substitution results in compliance with changed regulations.

Discover The Trusted Transformers Replacement and Repairs

Daelim Transformer is your reliable partner with over 20 years of experience in identifying apparent signs that your oil-filled transformer must be replaced. We have been designing and manufacturing a wide range of high-performance transformers for the changing industrial, energy, and infrastructure application needs.

From wear and tear to efficiency concerns, our professional team ensures the safety and reliability of your power systems. Replacement or customized solution—Daelim offers leading technology and superior quality for stable performance even at full loads or arduous conditions.Contact us today for efficient oil transformer solution!

Related Products

Related Article

How Long Does It Take To Repair A Transformer?

The time required to repair a transformer depends on factors such as the extent of damage, part availability, accessibility, and the expertise of the repair team. Minor issues like short circuits or blown fuses can often be fixed within an hour, while more complex repairs, such as replacing bushings or pumps, may take several hours or a day. Major faults, like oil leaks or winding damage, could take several days to weeks to fully repair. Timely repairs are also influenced by the accessibility of the site and the experience of the repair team.

Conservator Transformers and Their Role in Power System Reliability

Conservator transformers play a critical role in enhancing power system reliability by maintaining optimal oil levels, preventing overheating, and protecting against contamination. The conservator tank stores extra oil, allowing for temperature-related expansion and contraction. It also keeps oil clean by shielding it from air, dust, and moisture. Types of conservators include corrugated, capsule, and diaphragm, each offering unique benefits. Daelim’s conservator transformers, designed to meet international standards, ensure long-lasting efficiency, safety, and reduced maintenance in power systems worldwide.

Transformer Solutions for Electricity Generation

Daelim Transformer offers tailored solutions for power generation, supporting efficient electricity transmission globally. With expertise in Europe, America, and Australia, Daelim provides high-performance transformers designed for renewable energy integration, large-scale transmission, and remote off-grid areas. Key solutions include step-up transformers, ecodesign transformers, and auxiliary transformers, ensuring minimal energy loss, sustainability, and reliability. Daelim’s transformers meet global standards, offering scalable and customizable options for diverse power generation needs. With proven expertise and global support, Daelim ensures safe, efficient, and reliable power systems for various energy projects worldwide.

Empower Your Data Center with Daelim Transformer

Daelim Transformer provides reliable and efficient transformer solutions for data centers, ensuring high power capacity, safety, and energy efficiency. With customized options such as oil-immersed, dry-type, and smart transformers, Daelim addresses critical needs for redundancy, power quality, and load management. Our transformers offer high reliability, scalable designs, and advanced cooling methods, supporting modern data centers with high-density IT equipment. With ongoing maintenance and monitoring services, Daelim ensures continuous, optimal performance for data centers worldwide. Contact Daelim today to power your data center with confidence.

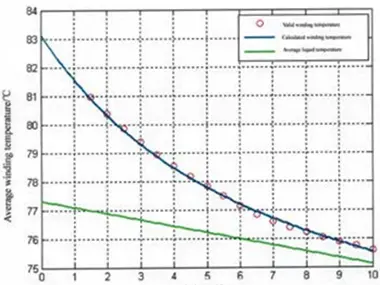

Transformer Temperature Rise: Understand Ratings, Factors, and Impact on Efficiency

Transformer temperature rise refers to the increase in winding temperature above the ambient temperature when a transformer operates at full load. It is influenced by factors like iron loss, copper loss, poor cooling, overloading, and ambient temperature. Transformers are rated with specific temperature rise limits (e.g., 65°C for oil-immersed and 80°C for dry-type), which impact efficiency, reliability, lifespan, and overload capacity. Proper monitoring and high-quality materials ensure safe, efficient operation, preventing overheating and extending transformer life.

69 kV Power Transformer for Substation in Pennsylvania

Daelim recently completed the design, supply, and installation of a custom 69 kV transformer for a substation in Pennsylvania. This high-efficiency, three-phase transformer is engineered for reliability, scalability, and long-term performance, ensuring a stable power supply to the substation. Key features include low load losses, minimal maintenance, high insulation levels, and flexible cooling options. The solution enhances grid stability, supports future expansion, and minimizes energy consumption, reinforcing Daelim’s commitment to quality and innovation in power systems.