Why Is Transformer Oil Change Important?

Changing oil for transformers is important because it is crucial to the transformer's reliable functioning. Here is how transformer oil works for you:

Insulation: Transformer oil is an electrical insulator. The oil prevents short circuits by insulating each winding inside a transformer and parts from each other and also from the tank of the transformer.

Insulation: Transformer oil is an electrical insulator. The oil prevents short circuits by insulating each winding inside a transformer and parts from each other and also from the tank of the transformer.- Cooling: Transformers generate considerable amounts of heat when they are in operation. The oil absorbs the heat generated, then transfers it outwards; therefore the transformer does not heat up and burn up.

- Protection: Air and water can penetrate your transformer due to some corrosion processes, which occur gradually over time, thus causing oxidation and corrosion of internal parts. Oil protects against oxygen and moisture from reaching very crucial parts.

Poor quality, as well as bad maintenance of transformer oil will cause reduced efficiency and reduce the lifespan of transformers. This is dangerous as it might lead to an electrical fire or expensive breakdown.

ECO design transformer(Tier 2) complies with the latest energy efficiency standards of the European Union, and has silicon steel core and amorphous alloy core transformers. Designed and produced according to IEC and BS standards, it is energy-saving, environmentally friendly and highly efficient.

At our facility in Houston, we have hundreds of transformers in stock, including pad-mounted transformers ranging from 300 kVA to 3000 kVA, with voltage levels of 12.47, 13.2, 13.8, 24.94, and 34.5 kV. We also offer single-phase transformers with capacities from 50 to 175 kVA. There's no need to wait—immediate shipment is available!

Daelim Transformer offers a complete line of oil-immersed transformers that meet current applicable standards, including IEC, IEEE, ANSI, CSA, NEMA, AS/NZS, and GOST. Our high-voltage power transformers are available for voltages up to 230 kV and ratings up to 300 MVA. We have successfully supplied hundreds of high-voltage power transformers across America.

When Should You Change Transformer Oil?

It varies with the operating conditions of the transformer, the kind of oil used, and the adopted maintenance practices. Generally, an annual comprehensive oil analysis for transformer oil change frequency is recommended every 12 to 24 months depending on whether the oil condition calls for replacement.

These are some of the signs that transformer oil needs to be replaced soon:

- Oil Analysis Result: The result of regular oil analysis would be the sign that clearly would present the need to have a transformer oil changeover. Indeed, the simple presence of dissolved gasses, high moisture content, or low dielectric strength would be enough to indicate the need to change the oil.

- Visible Degradation: The Quality seems fuzzy, murked, or smoky burned; therefore, the oil is contaminated and needs to be replaced.

- High Temperature: If your transformer is hot, it may be a condition indicating that the oil has lost its cooling capability.

- Gassing: Abnormal oil gassing, which DGA could detect, could be a sign warning that arcing or overheating is happening inside the engine itself and can be corrected with an oil change.

Reading more: How to analysis of gases and check oil level in transformer ?

Steps to Perform a Transformer Oil Change

Transformer oil change is rather dangerous and requires an immense amount of care. The processes involved in such operations need much experience and the correct set of tools. Here is how the whole thing works step by step:

1. Preparation of Apparatus

Before starting off, make sure that you have all your equipment, and protection gear. You will need:

- Vacuum dehydrators or purifiers

- This includes freshly supplied transformer oil from the manufacturer.

- Oil Filtration Systems

- Protective clothing or PPE for workers, including gloves, goggles, and masks.

2. De-energize the Transformer

Since safety is always considered first, the transformer has to be de-energized before the work starts on it. Working on an energized transformer is indeed very dangerous and no safety guideline should ever be compromised.

3. Drain the Old Oil

Withdraw old oil from the transformer into a tank after demagnetizing the transformer and dispose of it. Catch all of it because it is chemicals-contaminated transformer oil which is hazardous waste that needs proper disposal according to local regulations.

4. Inspect the Transformer

This is when the transformer's internal components, in case they are damaged or worn out, are inspected at the proper time when oil drain is done. Oxidation, overheating, or the presence of sludge can hinder the proper functioning of the transformer.

You may enjoy: What inspections are required before the transformer is put into operation?

5. Filter or Replace the Oil

It depends on its state, whether to filter or completely replace the oil. For example, if the oil becomes very saturated with moisture or particles, it should be replaced completely. Its filtering should be accompanied by a vacuum dehydrator to remove the moisture and filtration system to get rid of the particles.

6. Refill the Transformer with Fresh Oil

Replace the new oil in the tank when the old oil is filtered or replaced. Fill it slowly such that no air bubble is allowed to get inside the transformer which later reduces the oil's insulating property.

7. Conduct Oil Testing

After placing new oil, one series of tests should be conducted to ensure that the new oil complies with the specifications. Some tests include dielectric strength, moisture content testing, and dissolved gasses.

8. Re-energize the Transformer

When you are sure that the oil is good and the rest of the components are operating well, you may energize the transformer. Observe keenly when you have replaced the oil so there is no problem.

The Benefits of Regular Transformer Oil Changes

Routine oil replacement for your transformer provides a multitude of benefits, both in terms of longer years of life extension for the equipment and safety.

Here's what you gain by maintaining oil change schedules:

- Enhanced Reliability: Transformers with clean, high-quality oil are less likely to experience electrical faults or failures. This means fewer interruptions to your operations and reduced downtime.

- Longer Equipment Lifespan: Regular oil changes help prevent internal damage caused by moisture, oxidation, and contaminants, significantly extending the life of your transformer.

- Improved Efficiency: Clean, quality oil in a transformer significantly reduces an electrical fault or failure. This means there would be fewer times that your operations would be down.

- Cost Savings: It significantly increases the life cycle of equipment by avoiding damage from inside due to moisture, oxidation, and other contaminants in the transformer.

- Increased Safety: Oil can fracture and induce high temperatures and a potential electrical short circuit, a potential for fire or hazardous conditions that can ignite. Regular oil changes flush away those risks and leave the equipment and human life free from harm.

More resources:

Transformer Efficiency: The Ultimate FAQs Guide

DOE Efficiency Standards for Transformers

Final Thoughts

Maintenance of transformers will ensure no faults happen in your electrical system. Among these, oil change is one significant aspect, which Daelim Transformer provides exceptionally, making the operation even more efficient by boosting its performance and letting it stay longer.

Daelim’s expert team ensures that your transformers remain under optimal conditions, reducing downtime and expensive failures. Need reliable transformer solution? Check out our website or contact us today and ensure your power systems last longer and run at the best!

Related Products

Related Article

What Happens When A Transformer Blows?

Transformers are crucial for our electrical infrastructure, but when they fail, the consequences can be severe. A blown transformer can lead to power outages, fire hazards, and damage to property and electrical devices. Understanding the causes and impacts of transformer failures is essential for ensuring safety and reliability. At Daelim Transformer, we prioritize quality and innovation to minimize these risks.

What Is An OLTC Transformer and How Does It Work?

Are sudden voltage drops affecting your industrial operations? Your aging transformers may struggle to meet energy demands. Fortunately, Daelim's On-Load Tap Changer (OLTC) transformers offer a solution. These advanced devices allow for seamless voltage adjustments without interrupting power, ensuring stability and efficiency. Discover how OLTC transformers can enhance your energy management and protect your equipment in our comprehensive guide.

What Is An NLTC Transformer and How Does It Work?

An NLTC (No Load Tap Changer) transformer efficiently adjusts voltage levels while de-energized, ensuring stable power supply in manufacturing and industrial applications. By manually changing the transformer’s turn ratio, NLTCs maintain optimal voltage without interrupting operations. Their simplicity, reliability, and cost-effectiveness make them ideal for systems with infrequent voltage adjustments. Discover Daelim's NLTC transformers for enhanced energy efficiency.

How to Choose Transformer Supplier

Choosing the right transformer supplier is crucial for ensuring stable power supply and efficient operations. Start by identifying your specific transformer needs, researching potential suppliers, and evaluating their quality and reputation. Consider pricing, customer support, and delivery logistics. Ultimately, trust your instincts and maintain open communication to establish a strong partnership. Discover reliable solutions with Daelim for optimal energy usage.

A Guide to Tier 2 Transformers

This article discusses the EU's Tier 2 Ecodesign Regulations aimed at reducing transformer energy losses. By enhancing design and materials, these regulations lower CO2 emissions and operating costs. DAELIM Transformer is highlighted as a leader in producing compliant, high-efficiency transformers that support sustainability and improved energy performance.

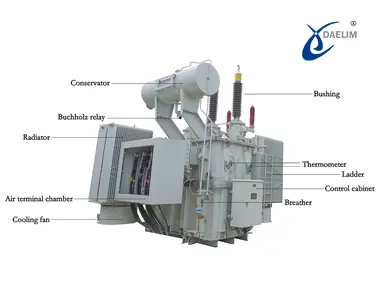

How Transformer Components Function Together to Control & Deliver Electricity

This article provides an overview of the key components of transformers and how they work together. It discusses the functions of transformer windings, cores, insulating materials, and transformer oil, as well as the roles of cooling tubes, tanks, and safety features. Overall, these components ensure effective voltage regulation and safe electricity delivery.